Leaderboard

Popular Content

Showing content with the highest reputation on 02/19/20 in all areas

-

12 points

-

Still on daily duties. The datsun club had a meet at Levels in Timaru last weekend and we did a few laps of the track during lunch break. Didnt miss a beat. then on Saturday night I was thinking of excuses to avoid this respray, and essentially had nothing so on Sunday I stripped it and started undrilling the roof. Not too many nasties, really stoked the side rails are mint considering. It has bust out on both front corners, prefect time to slice this out! The new roof skin weighs 8kg. The red one was 15kg. The amount of bog truely is astounding, and I gave it a layer of rhino-liner on the inside to assist in strength.. and a full size piece of dense underlay because I didn’t know if it would drum. Gonna be so good to not have to drag that around! Won’t be running the towbar next time, so minus another 12kg easy. the bootlid is from the old nickM race car, it’s really really fucking tidy. No rust, one small ‘depression’ near the lock, and came with nice bolts and a nicer-than-my-current lock mechanism. Big thanks again to nick for that, the red one had a lot of time, rust repair and bog in it, and wasn’t in nice shape. I have a fair few areas I’m going to re-do but I’m not going to let this drag out. Will be done before the weather cools down again10 points

-

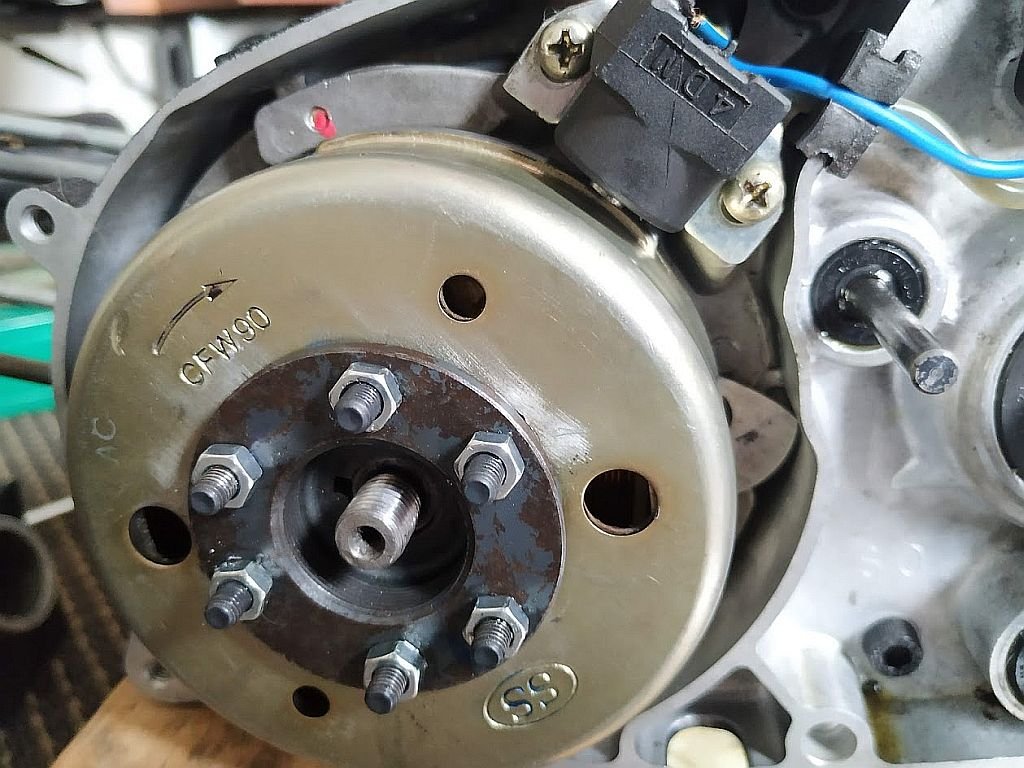

Have gone with the 6 bolts, loctite and hope plan Some "precision engineering" care of my angle grinder got the pick up location sorted Not a huge amount of clearance, but enough! Still loving the blaster Used some copper spray on the head insert and some PC thermal compound between it and the head cover and I think it's pretty much time to do some wiring, sort out the exhaust and give it a nang!8 points

-

so as you know if you have read this topic this year i swapped the original motor out (because it was starting smoke real BAD!!) i put the one that came in the parts car i bought in after swapping all the shit from mine onto it......and all was good with the world...it started ,ran well,and didn't smoke..... this one and then one day on my way home from work it started rattling ....and it didn't go away.....and it started bleeding oil all over everywhere i parked.....(at this point i knew J-W-G was selling his 2.0 out of his mk3) so thought i would try and fix/fuck mine https://youtu.be/BaPxkhkxBoE 2 things happened that night ...1 i didnt fix/fuck it....2 it sounded better and the rattling when a away........................................for 9 hours. so i bought J-W-Gs motor and he kindly dropped it off for me on the Saturday....i didn't do anything with it till the flowing Monday... Drove the old girl to work and it was getting worse so came home and pulled the motor out swapped the flywheel ,p-plate,clutch ,inlet and carb onto the motor(3rd this year) i got from Jesseas i know they worked well on past 2 motors (and against my better judgment not the water pump or thermostat) ....put it all back together and it ran like a dream fried straight up and didn't sound like a diesel...after a couple of days it did pick up a slight knocking sound (that when away when the clutch pedal is even lightly pushed (so wasn't to bothered )..and had a massive hesitation when you put your foot down.(found that to be coil to dizzy HT lead........the hard way......heeeelll of a jolt). then this monday i left to go to work and got a few ks from home and temp was well over half way(normally the fan is just kicking in as i get to work )...it was a hot ass morning tho. got it back home and it was very low on water.....so i bit the bullet and pulled the motor back out ....replaced the water pump and thermostat from mine......i know....i know. found the knocking to be a stone jammed in the sandwich plate ......before you ask ...fuck knows. i also decided to give it a blast and quick paint...and water last the engine bay and put it back together..... and give the old girl a wash......shes happy as now and back to being 100%. cheers all7 points

-

Had some pipe left over (it's also splashed in pigs blood from homekill, so it's a pleasure to weld yum yum) A decent little length, looked about BBQ height, so I scrounged up all the rusty scraps that were too good to throw out, and made this rocket stove. Should have cleaned it up better and not welded outside in the wind. But a tidy up and some Potbelly paint should tart it up. Once I've cranked some temperature in it to burn off the galv as I don't want zinc in my food. lower bit is solely for air intake. Might fandangle something up to control it for simmering. Although fuel is probably the best way to control temp.7 points

-

7 points

-

Bit off topic but this is what narrows down my workspace in the shed, currently used as storage it's my 82 lancer gsl that I've owned since I was 18. It's the car that's waiting for me to get this ute legal so it can have some attention.... Used to have a project thread for it but it's gone these days. Has currently donated some engine parts etc to getting this ute done which is how it has sneaked into this thread5 points

-

I have finally managed to get most of the shaping/repairs done, a few wavy bits and a couple of dings here and there, sorted now. I was also having some problems with leftovers from the old respray reacting with the primer and wrinkling on the roof. I solved the problem by bare metalling the whole roof and starting again, to be sure there was nothing underneath. All good now. So now it's all painted up in filler primer, ready for blocking. It's looking quite good already, pretty crisp and straight. Bonnet and guards not attached properly here, which is why the alignment of the front end is all off. Not bad for a noob effort, I think. There's a tiny bit of fine tuning needed, shapewise, a couple of things which weren't easily visible until it was all light grey. But in general looking pretty good, will block it back and get it as straight as poss, then time for colour, at long last.5 points

-

4 points

-

4 points

-

4 points

-

4 points

-

Ha you are such a cunt. Hows that LTD coming along? Nearly done? I have actually thought about this as it is pretty obviously not great for off road, I am going to make an ally skid guard that will protect that lip and move shit out of the way before it gets wedged up there. Originally I thought i might need to create that duct all the way to the front, but I don't think I will need it now... And anyway i will just need to do some skids in the paddock to muddy it up enough to make it look like I have been off road.3 points

-

That air shroud for the radiator is going to be great for pushing mud up into the radiator when you go four wheel driv.... Oh wait... nevermind Hahaha3 points

-

3 points

-

This sounds pretty similar to what an AW11 does when you don't bleed them properly and get an air lock. Everything seems OK at first, then the temp shoots up and water boils in the head. Sometimes you'd get a hotspot so bad that when the water got there, it would instantly boil and squirt a litre of hot water out of the radiator filler hole.... The solution was usually to force feed water into every cavity (remove rad hoses and squirt water directly into the radiator, same deal with the heater core), then open up all 3 sets of bleeders and run the car for at least an hour until all the air bled out. Once it was burped properly, it was good.2 points

-

While the coolant is out, is it worth poking a snake camera up its passages to look for blockages/forgotten rags etc? I have one if that's any use2 points

-

Also I really appreciate your input team. Im sorry if im coming across as a bit curt or short but I am incredibly fucked off and really angry at not being able to fix this. The radiator guy hasn't has a slot to look at my radiator until now so I'll take that up to him now and hope like fuck that's been the problem. Fuck, I really hope it is because I'm running out of things to try.....2 points

-

Ok so had an issue where the rear wheel always sat to the left when bolted up. Thought this was due to a inner wheel collar not being present. Found one and popped that in but still sitting to the left. Good thing is that I can test the wheel on my other Honda. Did that and it sits bang in the middle so it’s not a lacing rim offset issue. I then placed the wheel in its most straightest position I could measuring off the top shock mounts each end of the tyre Seems like it’s the swing arm itself that’s a bit Swiss cheesed, 95% sure it’s not the frame as it’s inside the swing arm that’s sitting funny. Got a new swing arm on order as I cbf’d pulling the swing arm out of my other one. This Honda has been a basket case hahaha! Fitted the Cafe honda’s rear wheel to check if it sat centre. Fits perfectly in the middle, hella flush on the guards.2 points

-

A few people have asked how im going to fuel this..... An aircraft mechanic at work drew me up a sketch on a paper towel and i think its worth a nudge, essentially my fire extinguisher fuel tank is becoming a "rising rate fuel tank" ive got a -8 fitting on my compressor housing which will pressurize the tank and feed the fuel pump at boost pressure. The fuel pump will then add 1.5 -2psi to it keeping fuel from being blown back up the jet in the carb the float bowl will also need to be pressurized as well to make it work. Going to be Braided speedflow lines everywhere but im going for an Extreme! theme on this thing. I get the speed flow lines and fittings from the bin at work no good for the sky anymore but plenty of life in them for this kind of stuff.2 points

-

Managed to get abit more done two days in a row! Just some small things, steam cleaned and painted my brake drums and lower arms. Fitted new balljoints and bushes to lower arms and bolted those pups back in. Tested a different spring, suzuki escudo springs I cut to be captive but they're slightly softer then the original L200 springs. And lastly I put the new swaybar links in! Nothing too spectacular but it's all the little things thatll make it fly through a wof check hopefully2 points

-

Not much Happening since I tucker it in the shed, we've been focusing on the Datto & Nat's 2020 but here's a big Happy Birthday to the Avenger Brand! Which turns 50 today Love 'em or hate 'em there's a cult following around the world : and more on the road here than in the UK! (its not just me)2 points

-

Stayed up way past my bedtime to get some rear brakes sorted. New shoes and cylinders, drums are still mint but will paint them just because.... Also installed the brake lines on diff, realised I'll need a longer rubber hose for chassis to diff being L300 diff in a L200 theres slight difference. And forgot to get a new bleed screw so will sort that asap2 points

-

But first, more important things! As I don't have radio, I've just been plugging my phone into this 222Wattts of retro power! With speakers in the front now, I was keen to get them going, luckily I have two 222Wattts amps. After way to much time trying to somehow fit them both under the back seat, I realize there's heaps of room behind the back seat, I was going to but this behind the back seat. But, without drilling holes in my floor there's nothing to anchor it's considerably weight to. So. Ye ol 6x9th, shall suffice. Tidied up the wiring. Been fiddling with settings, running the low pass on the 6x9, not bad. Had a stupid idea of just mounting the sub like the 6x9s as that rear area is pretty good box. Took the family out for a drive over to Devonport, they weren't that thrilled about not taking mums limo. Well not limo, but a 04 Odyssey is infinitely more comfortable that this tiny smelly noisy little car. Started off great, got on the motorway, had gone about 2kms and the engine stuttered and we're outta gas! Fortunately I always carry spare gas. Are we making memories yet! Had a swim and drove home our wet toggs with an ice cream, i always have to turn the car off a drivethu, cant hear the little man in the box! By the end of the day we all a most excellent day out.2 points

-

Fuck, totally just overheated it.. Was taking it out for a smash after just getting rid of a big flat spot off idle, was just cruising after the fact when I smelt a bit of hot oil. Having just done a skid (and giving it an oil and filter yesterday) didn't think to much of it. Gave it the boot out of a round about and it stumbled a bit.. bit odd. Got home it was really smelling and the tappets were noisy, smoking from the breather and the hoses were soft. Fucken blew a small bypass hose off the water pump, it was only held on with a wire clip and I never thought much of it since its been there for god knows how long.. Anyway put a new clamp on it and slowly dribbled water in while it was idling and the temps came back, noises also stopped.. Hope I haven't warped the head. Its o-ringed for boost so it shouldn't blow gasses, just oil and water.... Typical. Haven't had a lot of time to work on this, but have done a couple of minors.. Like extending the accel cable so it's in a nice wide curve. Don't get the vibration much now except for it'll randomly kind of buzz around 4-5k I think it's where it comes through the firewall and connects to the pedal somehow. Plumbed the fuel pump better, previously was just lots of hoses.. Then it wouldn't run... Ahhh, what now? Whoops.. Forgot about that bit. Bought a k&n filter so I don't suck some small dog in while I'm ironing out the bugs, By the way you can see the offending hose just under the thermostat housing above. Fixed the broken stud on the bonnet, not sure if I trust its strength.. I then trimmed and tapped the thread back on it.. Gonna take it in for a wof this week and if it passes I'll then stick the wideband on it and getting it running at its best. Reason being is I don't want to weld the bung on this exhaust only for it to be failed.. Might just get a no weld bung as eventually I'll bin this exhaust. Was gonna turbo it for nats but I decided without cert insurance is void so I'll do it when I get back.. Good times..2 points

-

2 points

-

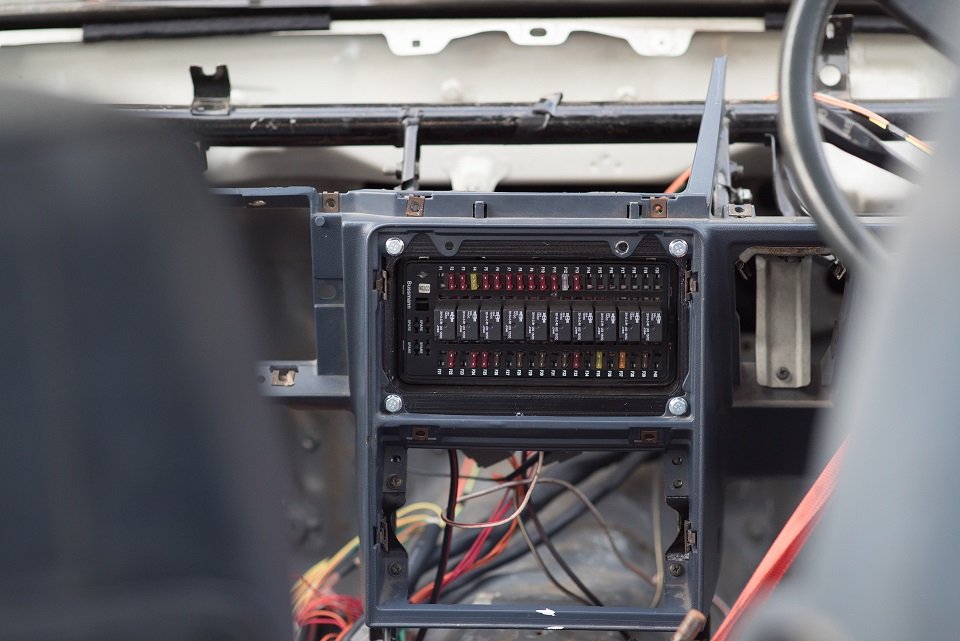

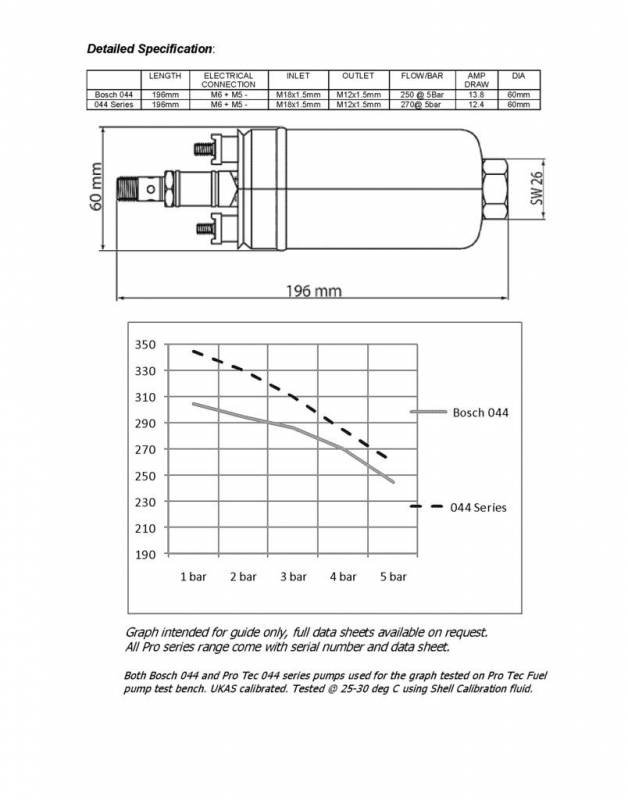

Fusebox all working. But not before I realized I'd wired 9 out of 10 relays backwards. Woops. Lucky was easy to fix. Also, I've always hated the idea of an external FPR, its just so big and shit looking compared to the OEM ones direct on the rail. Since I'm making an effort to keep things tidier though, and this will sneak in behind the cam cover and look discrete. Pinched from the Redtop engine's factory setup. Think I'll give it a hoon. Has the secondary benefit of that I can just run a smaller EFI spec rubber return line hose back to the firewall tucked under the inlet. Rather than a full sized AN-6 line from the rail to the FPR. These FPRs all only regulate to 300kpa (43psi) down from the 60psi I've been using. I havent managed to find a 60psi factory FPR, funnily enough because the only cars that run 60psi or higher are returnless systems. So let me tell you a punishing story about why that is. Traditionally, EFI systems have run at around 43psi. If you're wondering why the weird number, 43.5 psi is 300kpa, and no one in their right mind uses imperial units to design things. Anyway, this pressure range is a good trade off between how hard the pump has to work/reliability, how much fuel it can deliver, and good atomization. As you raise the fuel pressure the l/min rating of the pump decreases. So keeping the base pressure lower effectively gives you a higher flowing pump for same hardware = cheap. Look how much flow rate a Bosch 044 loses when pressure goes up. It also means that as you add boost, and the fuel pressure needs to go up to suit. Spec sheets for electric fuel pumps show that most start to creak and lose heaps of flow after 65psi or so, and with reduced lifespan. With 43psi base pressure and 20 pounds boost only means 63psi required at the pump. Which is considerably better than trying to achieve 80psi. So, why do modern cars run 60psi base fuel pressure instead? When emissions rules are really tight, Fuel vapour emissions are a big problem. When you heat up fuel at the fuel rail and send it back to the tank, it creates heaps of vapour. As well as that when you open the gas cap, this pressurized hot fuel vapour rushes out which is also an issue they need to minimize. A secondary problem here is that fuel isnt just made of 1 thing, it's made of lots of different chemicals which have different boiling points. My understanding is that the additives that turn 95 octane into 98 octane, are the first to flash off into vapour. So minimizing the fuel heating reduces your octane level loss over time. The fix for these problems is to make sure fuel that goes to the rail, never gets back to the tank. Hence returnless. But now the problem is that at 43psi, if it sits long enough in a hot fuel rail it reaches its boiling point. So 60+ psi raises the boiling point above where this is an issue. Which is also why they dont vacuum reference the FPR in the gask tank on returnless, because you never want to drop the fuel pressure below 60psi absolute. And a modern ECU can just deal with a varying differential fuel pressure a lot better than old shitters can. So in my case, going back to 43psi will be fine but with lower pressure the injector duty cycle will need to creep up a bit. As at 60psi Altezza injectors are 450cc/min Injector, at 43psi it's only 370cc. So I'll need 21% more injector opening time. Currently I only get to around 63% duty cycle at lots of RPM so that'll end up around 76% duty cycle instead. No drama. I will just need to be mindful of when controlling the fuel pump with PWM, that I'm not setting the flow rate too low that it'll have time to boil the fuel. Although these engines have a fairly well insulated fuel rail compared to some other engines where they are stuck in a valley or whatever. The other problem is that my fuel pressure sensor now has nowhere to go, as previously went into the FPR. I managed to find an AN fitting that has a pressure port on the side, so I'll mount this with the sensor whacked in somewhere after the fuel filter on the inlet hose when it turns up. I got the Bosch E-throttle all working nicely, it's very snappy testing via ECU. It looks like I'll need to ramp down the PID settings a bit compared to Altezza one. Will take some 100hz logs and try fine tune it. Speaking of which, this PID tuning explanation is bloody amazing So now I've gotta sort an E-throttle pedal. I've got two options so far to try, but isnt looking as easy as I'd hoped. First is RX-8 pedal, on the left. Convenient option but it doesnt really fit nicely in the available space. The other issue is that the APS sensors are built into the entire pedal assembly. So if it shits itself, you have to rebuy the whole thing which seems stupid. The other option I've been looking at is a 350Z APS sensor, which looks like a normal TPS but has a little bar on it to be moved by a pedal somehow. This doesnt particularly look like it wants to cooperate with the factory pedal, so need to figure out something else there as well. However it does make it a lot easier to keep a spare and replace if it packs up. But I like the idea of keeping the factory pedal, so if I end up using a cable again to test something I've still got the option. Although I guess I could just refit the factory pedal anyway in that case haha.2 points

-

1. Got all the air burps out of the cooling system? 2. Someone told me a yarn about 1uz heater circuits years ago. If you have the heater outlet looped at the back of the engine it needs a restriction in the loop otherwise the water can hoon around the engine getting hotter and not going through the radiator 3. Radiator hoses the right way around? Probably doesnt matter with a cross flow rad but I had a customer with an uppy downy rad where the hoses were the wrong way round at the engine and it got hot 4. Put a bloody 302 in it like it's meant to have, you bloody wanker2 points

-

well i havnt build the new motor yet .....because i have other shit to play with.....but the old pinhoe has been getting worse......blows shit loads of smoke and sounds like a diesel... the mk3 parts car i bought had a mighty pinthoe in it... so i pulled it out pulled the clutch ,flywheel,pressure plate,inlet and carb , thermostat and water pump of mine and slapped it on to the other one.... reason being mine ran and i had done them last year. some new plugs and oil.....and man it starts first pop.....no smoke.....and so quiet . old pinthoe other old pinthoe blooody good2 points

-

2 points

-

1 point

-

You've changed rods / pistons from 10.5 to 9 CR, yeah? What does that do to the combustion? Maybe the flame front is slower, so it all needs more advance? As Cletus mentions above, over-retarded ignition can cause overheating? (I'm pretty sure I've seen that on -cough- smaller engines). I'm also reading reports on other engines over-heating when too retarded. 1st graph here has some clues miiiight be helpful. https://www.sciencedirect.com/topics/engineering/compression-ratio To my eyes it looks like the r8.6 peak pressure is lower, but also takes longer to come up.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

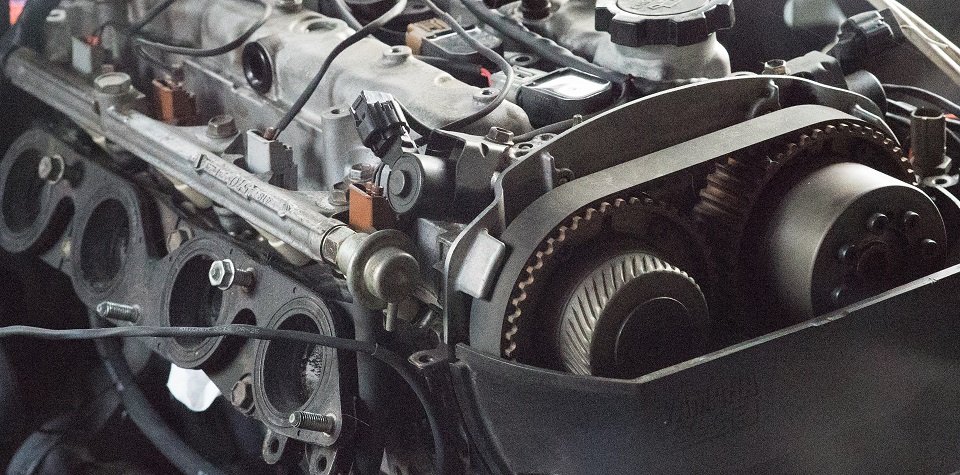

Work and real life have been pretty busy recently, so haven't found much time out in the garage. Students are back next week too, so work is likely to be a bit hectic for a bit. I did manage to get the ignition leads built this afternoon. It's really starting to take shape. SOOOO many nickle and dime jobs to do though. Still need to machine that trigger wheel. I've tapped the fuel rail for M18x1.5 fittings that I'll seal in with bonded washers... But the M18x1.5 -> AN6 adaptors are coming from China, and everything out of there is on the go-slow due to the virus. Not that I'm complaining (much), its got to be pretty horrific. Once those fittings are here though, and I can permanently fit the fuel lines, I can sort the front thermostat housing. Really really procrastinating about that... :-/. Also, I really need to build a garden shed and get all the gardening gear out of the garage.1 point

-

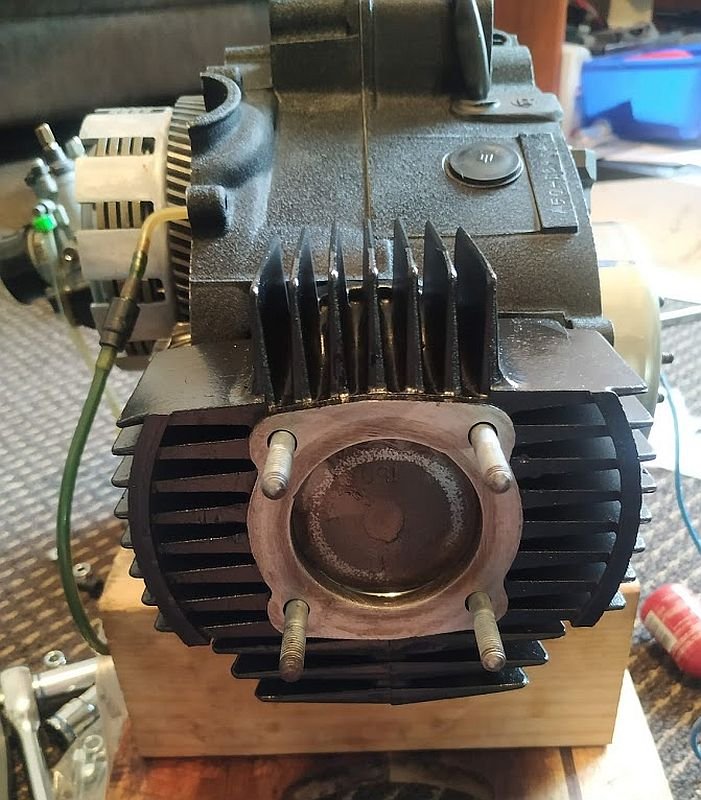

Another goped build. Needs tuning to run right, but I lack the space to get it up into powerband where it wants to run. Its showing real potential though with a newly found ability to drift it. It's going to end badly, probably with another broken arm like last year when I taught myself how to do goped wheelies until failing epically...but yolo✌ Specs: Model - Goped Sport Engine - 23cc Zenoah G23LH (rebuilt with new bearings, seals, cylinder, plug, gaskets, piston and rings) Carburetor - Walbro high performance 167A Exhaust - Dominator expansion chamber Spindle - ADA 0.75" (way to big off my small driveway). Other - velocity stack, air filter, aluminum tank mounts, upgraded engine bolts etc... Nothing over the top, but given room to work the powerband it will be a weapon!1 point

-

Send some bits away to get chromed and bright zinc plated. Fresh chrome looks amazing, points cover and the suspension fork bolts are now perfect. Wasn’t cheap but those parts aren’t available new anymore. To be fair they were pitted badly and most of the time was probably spent tidying up the parts before chroming. The bright zinc was super cheap to get plated, like $20. However no prep is done. If I’d known I’d have polished out the pitting marks more but for 20 bucks it look a million times better than it did.1 point

-

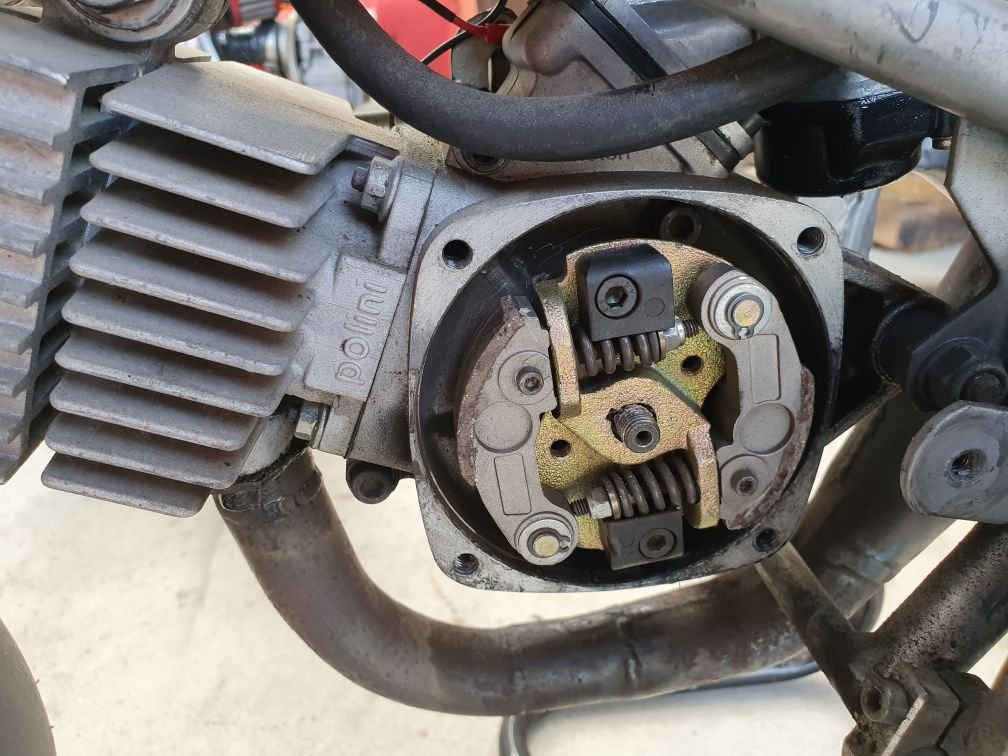

Okay, it's no secret I'm into some pretty niche things. Gopeds, drift trikes, lowrider bikes, skateboarding, gokarts, tallbikes, etc...etc... none of them are popular in NZ by any stretch of the imagination. Now this is about as niche as it gets. 39cc of polini awesomeness! It puts out 6.5hp and sounds like an angry beehive!!! Pops wheelies when the powerband kicks in...its mental. I picked it up a few years ago, with the goal of cutting it up and putting the motor on a goped. As it turns out, its basically the grandfather to the pocket bike craze and is highly collectible in Europe, some selling for over €2500. So needless to say, I won't be cutting it up anytime soon. The clutch fucked out, so I brought this "high performance" clutch. Well if the goal is to add excess weight to the rotating assembly, shift the engagement rpm down low where it's not making power and decrease speed, fun, your will to live as much as possible...then yes, this clutch excels in all those areas. I had other goals, like simply returning it to being awesome like it once was. So, I brought a Chinese clutch for a 49cc kids motorbike, that didn't fit either, then modified it to fit the polini by adapting the new clutch arms to fit the polini hub center. I cut the arms down in the lathe, to fit the polini bolts. Drilling to lighten the arms, this raises engagement rpm. Shortening the springs to put more tension on the arms, this further raises the rpm. Drilling the arm spring pockets to remove the shit casting marks to allow smoother operation, and allow the much fatter polini springs to fit. Back in and running like a dream! I know its ridiculous...I know. However its definitely one of those things that fits the saying "don't knock it until you try it". Not in the way someone may say having sex with men feels awesome "don't knock it until you try it"... no, nothing like that. This is more in the have you ever driven a rotary category... it's only purpose is to make you smile.1 point

-

Due to it not running well last outing, I whipped the carbs off, and they were full of sand. Turns out the drain/vent tubes on the carbs must be able to suck? I assume on the motorbike they went to the air box? I think I'll put some pneumatic spec air filter/exhaust/silencer things on there, just to keep shit out. Like this, After cleaning the carbs it was running tumeke again. We took it up to some paddocks in the whops and had a hoon. At the end of the day I drove it back out to the main road (about a 10 min drive at 90kmh) to see what it's like as a daily. Its doing about 7g rpms at 90, which is quite loud, and also my whole left leg went numb/dead, and I couldn't feel the clutch pedal, so not great as a daily. The only issue we had was bashing a bit of a hole in the exhaust (lowest point) which will be an easy fix. Usual shitty vid:1 point

-

1 point

-

Finally got the wheel tubs spotted in place and sealed against the quarters. I was told by a number of people don’t weld them completely to the quarters as they need to have a bit of flex to them. i haven’t spot welded them to the frame just yet as I need to lift the body one more time so will do that once it’s on for the last time.1 point

-

Decided to remove cab from the chassis as chassis needed some love, made it easy for rust repairs on the cab too Please note this was my first ever attempt at rust repairs too so go easy on the judgement With the chassis I wire brushed it back, covered in crc rust converter, and brush painted smooth black hammerite on it. Why? Because the quote I got from the sandblaster was way out of my budget... Also got my leaf springs reset almost flat, got 3" tapered blocks, new bushes too Also took a L300 van diff, these are wider and 5 stud, cut the mounts and shifted them to suit L200, put a later model L200 lsd in it too Here's a photo dump....1 point

-

Probably first thing I did was convert front end to 5 stud using L300 van hubs, why? Because I had a sweet collection of 5 stud wheels..... Also managed to swap the flat deck tray for a decent condition welside tray, which I was stoked on Also found my mate had an L200 laying in his padock so went and raided any decent parts I could And started stripping things back for rust repairs..... yay!1 point

-

I like that you have a 30yr old machete that is used often enough to wear through three handles, and a tube full of arrows by your back door1 point

-

Was wanting to get a grinder for home, getting into a bit of knife making. Workmate who also does knife making said he had drawn up a 2x72 one. So we got a couple water cut out. Grabbed a motor and a VSD off some equipment at work that was getting thrown out. Few more things to do, get wheels, make a base, turn up an adaptor for my motor, make a housing for the VSD but getting there slowly on our lunch breaks. It also tilts so can use it horizontal which is cool.1 point

-

I needed to replace the speakers in a musical keyboard, so I thought I'd scavenge the factory rear speakers out of the Jag for this purpose and put some new ones in their place. Sounds straightforward. To take out the interior trim panels which hold the rear speakers, you have to take out the rear seat base, rear seat back and front seat belts. The lap section of the belt attaches to a rail which is bolted to the floor of the car, and the lower threads of its mounting bolt protrude below the car where they get all corroded. When you remove these bolts, they get destroyed and their nuts (welded to reinforced sections of the floor) get damaged. Then you're left with no seat belts. So then you have to drive around with no seat belt to visit speciality stores during business hours and buy some stupid imperial 7/16 UNF bolts and a stupid 7/16 UNF thread tap that you will never use again. Aaanyway, here is one of the factory rear speakers: They're mounted to an actual piece of plywood, rather than to flimsy door card like the front speakers. As with the fronts, though, the speakers are mounted on the rear of the panels via threaded rods which are welded to the speaker grilles. I measured the plywood panel dimensions and got the biggest suitable speakers which could be mounted from the rear without modifying the panel (most speakers weren't suitable for rear mounting as they don't provide a standoff ring to stop the edges of the cone contacting the panel). Here is a new speaker, a factory speaker and the factory grille: Then I recessed the mounting nuts for the speaker grilles and cut down their threaded rods as short as I could. This allowed me to slap the new speakers onto the back of the panel while keeping the factory speaker grilles in place. Result: It looks factory (good), and sounds factory (not so good) except a bit clearer. There's still not much bass and the sound starts to distort when the head unit is still quite far from its maximum volume. I probably won't try to improve things further though, because there's no ideal spot for amps / subs in an XJ-S. While I had those interior panels out of the car, I got a look at Jaguar's superb rust traps. Behind the rear speakers / below the rear side windows, there's a join where the bodywork meets the sill. Rather than installing drain holes in case water gets in, Jaguar just fitted lots of foam to absorb the water: This seems like it would promote rust, and indeed it does. My car's not too bad for rust just yet, which is why I was not prepared for this rust under the sound deadening below the rear seat base! Water must have been getting in and pooling at this join, helped by the foam stuff. I took a few handfuls of rust out, revealing some holes. However, the holes revealed that this seat framing is not the floor of the car - there's heat insulation below here to stop the passengers getting toasty bums from the inboard brakes and exhaust. I just hit it with rust killer / corrosion primer / fish oil and hid it away for another day, since it's very easy to access. Before putting the rear seats back in, I noticed they were made by the notorious Jack the Stapler:1 point

-

So I did the upper ball joints as well.. ..but it wasn't those. The push/pull play at 6 and 12 o'clock was still there. So I looked at how to adjust the wheel bearings.. I was expecting it to be horrible but it was easy, and now the play is gone. Should have done that first. Alas, the vibration is still not quite gone. It's probably just something I have to live with in a British car which has made it all the way to..... 200,000kms. So I got a new obsession instead. The engine doesn't run all that well - it has a random half-stumble at idle and low rpm.. You can see the misfires by watching the shaking of the motor, and although it appears to smooth out if you raise the rpm sufficiently, the higher engine speeds could possibly be disguising the problem. The car has also never really started that well from cold. I checked the spark plugs and they looked amazing to someone who has never owned fuel injection before. I looked for bad connections and vacuum leaks, since the ECU directly reads manifold vacuum (in V12 cars, the ECU is in the boot and its vacuum line has to run the whole length of the car, because why not... ). Nothing stood out though. Several tanks of fuel system cleaning pills didn't help either. Today I took off the airflow meter and cleaned it, and this did make an improvement. The raise in engine speed on startup is more pronounced, and the idle speed seems to have raised slightly which makes the car coast better / makes it not decelerate as aggressively when you lift off the accelerator. But just like my reduced 80kph vibration, the shaky running issue's still detectable. I'll try a compression test and then randomly change every ignition system part, idle valve, fuel pressure regulator and injector before giving up in 6 months from now. The Jag let me know what it thinks of my diagnostic skills:1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.384ff72c8d2b0ee0d34a7bdedb55bdcf.jpeg)