-

Posts

829 -

Joined

-

Last visited

-

Days Won

2

sleeektoy last won the day on December 19 2022

sleeektoy had the most liked content!

About sleeektoy

- Birthday 17/07/1977

Profile Information

-

Gender

Male

Converted

-

Local Area

Auckland

sleeektoy's Achievements

Post Fiend (4/5)

3.6k

Reputation

-

-

As Clint said - there IS a cert system for the heavy vehicles and it seems like that COF place is taking the piss or not following the rules.. I used to be a heavy vehicle certifier up until 2004 and we did many certs for repowers/turbos etc back then. https://www.nzta.govt.nz/assets/resources/heavy-vehicle-specialist-certifiers/heavy-vehicle-specialist-certifiers-list.pdf

-

Yes - The 2-4psi low pressure one for carbs - that is the one i have mounted on my engine block in the factory mechanical pump position. My car has a factory return line. Runs mikuni twin side-draughts no problem

-

Its typically best to mount a pump to something solid close to the tank. however I have replaced my factory pump with a facet steel electric one mounted to the engine block and have had zero issues in 13 years of operation. It only gets a little rowdy when idling at the lights for a long time. I'd steer clear of a plastic pump too - i had one split and it sprayed fuel all over the engine bay - very lucky the car didn't flambe

-

bang on the money, especially with a return line it will shove colder fuel through and hopefully solve this issue

-

-

Watch for cracked valve guides too after a valve bending.. might be ok but possibly worth a once-over too.

-

Sleeektoy's 1977 Racer Celica RA28 (WTF another one!!)

sleeektoy replied to sleeektoy's topic in Projects and Build Ups

Finally bunged it back in the hole. Carbs to have a birthday, extractors to be stripped/coated and driveshaft needs shortening +10,000 other small things- 51 replies

-

- 18

-

-

-

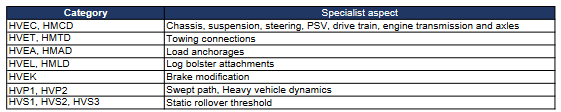

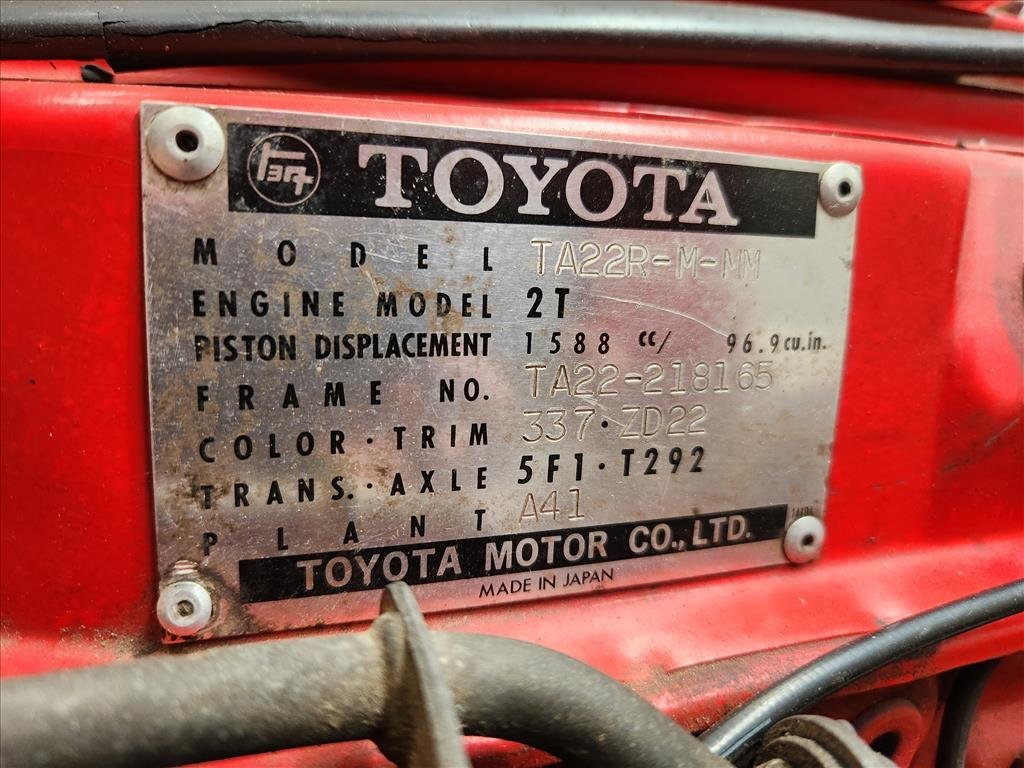

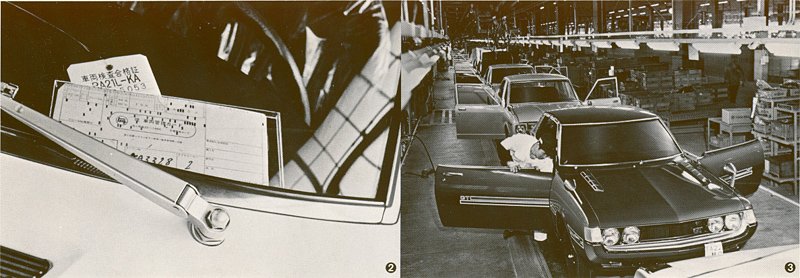

DECODING Frame number should be stamped on the opposite side of the firewall to this tag to confirm the number matches this tag. MODEL - TA22 model - R (right hand drive) - M (5 speed) - MM (LT trim/exterior) 2T - single carb 1600cc 218165 built November 1974 Colour 337 = orangey-brown - TRIM - ZD22 Vinyl/PVC all in black Trans - 5F1 - T50 Gearbox, Axle T292 - T-series 6.7" crown wheel with 4.100 ratio open diff. Plant - A41 - Tsutsumi Plant TMC

-

Chassis fully assembled - with help from my 10 yo nephew who loves hanging out in the shed. Both chassis and body fit with millimetres to spare. onto the bodywork now...

- 32 replies

-

- 21

-

-

Sleeektoy's 1977 Racer Celica RA28 (WTF another one!!)

sleeektoy replied to sleeektoy's topic in Projects and Build Ups

Engine mostly assembled - water pump, alternator, and flywheel/clutch still to sort. Headers might get an acid dip and repaint too. trial of a Kameari 2T-GEU cam chain tensioner in this 18R-GEU head also happening- 51 replies

-

- 18

-

-

-

- 32 replies

-

- 23

-

-

Sleeektoy's 1977 Racer Celica RA28 (WTF another one!!)

sleeektoy replied to sleeektoy's topic in Projects and Build Ups

So... a little yarn at @sheepers place about his motor build and also borrowing a large valve spring compressor from him inspired some work on the motor for this. It has sat a long time and nothing was done - the gear drive became a "too hard basket" and i got put off trying to get it sorted. So it has a chain put back in there for now. There were valve to piston clearance issues with cam timing and some light touching happened. Big end bearings are now replaced, cam lifter buckets replaced and valves checked for bentness found to be ok. So in a "roadkill garage" style fix(found on youtube), an old stainless valve was fashioned into a rough as guts cutter and piston cutout reshaping has been done. Result is a nice reshaping of the cutouts slightly bigger at the same time - the engine has been blinged up to go into the nice clean engine bay- 51 replies

-

- 21

-

-

Chassis all painted in 2K black And reassembly started with the front engine cross member with new hand-cut rubber insert and plated bolts.

- 32 replies

-

- 18

-

-

Overdue update - Body spaced off the chassis then the chassis removed completely then stripped everything off the chassis and epotec primed it Also acid dipped the wheels and straightened them up + painted them and some 155/80 R12 tyres fitted

- 32 replies

-

- 27

-