-

Posts

10,626 -

Joined

-

Last visited

h4nd's Achievements

Committed (5/5)

16.1k

Reputation

-

Oh, 4" CRT for your vector line drawing needs! https://vi.aliexpress.com/item/1005001892618952.html Someone (cough, @Roman) should totally do a period looking ECU display on one of these!

-

Alas, now me also, but only for the shares with passwords. The non-password public dir is a closed book to this crown-jewel of crapitalism.

-

Sooo, I'm now having related fun with my new Win11 install: https://techcommunity.microsoft.com/blog/filecab/accessing-a-third-party-nas-with-smb-in-windows-11-24h2-may-fail/4154300 TLDR: M$ turned off an old sharing thing, and broke many many systems shares. Steps 1 - 5 are: IT'S EVERYONE ELSE'S JOB TO FIX THE THING WE BROKE Steps 6 on are WELL OK, BUT IT'S NO CARE AND NO RESPONSIBILITY Naturally none of steps 5-6, nor 8. to 8.e have fixed it.

-

Installing new ram in new-old PC with tin-snips...

-

Random slightly cool stuff you built but not worth its own thread, thread

h4nd replied to h4nd's topic in Other Projects

Oh, and i farted out an (crude) animation system for that LED. if only I could figure out how to make a 2.5MB video work in this page Indic3x3 test1 crop(1).mp4 -

Random slightly cool stuff you built but not worth its own thread, thread

h4nd replied to h4nd's topic in Other Projects

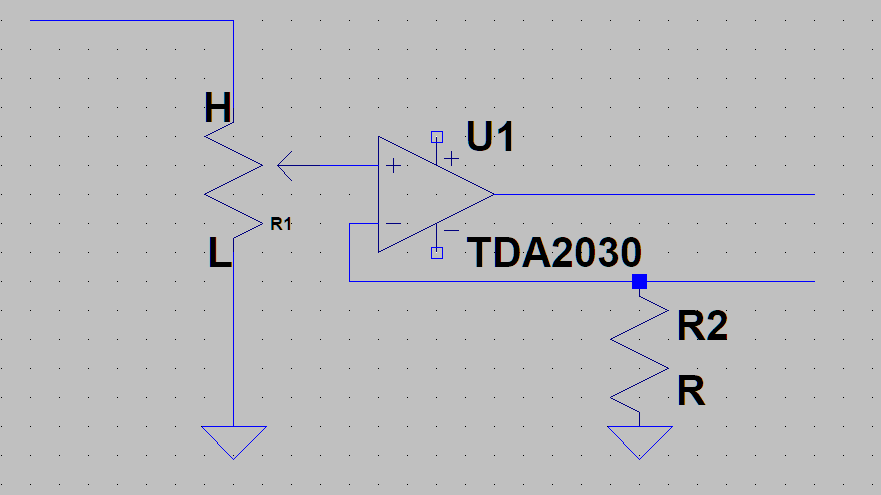

Once upon a time, baby-engineer H4nd was at polytech, and we were making PCBs for flashing LED circuits (Tape and Donuts!). I said, errr: I've been playing with some Audio circuits, Can I make that instead: Add a few scraps from 200A soft starters, and presto: still in service. I refreshed the caps with new cheap low ESR, and it's bumped the bass response a bit, didn't expect that! -

3:50, wide range in EGT

-

Is this the engine noise enablers thread?

-

Gah: there goes my plausible deniability for interfering with his data, should I ever wander past his for a cuppa!

-

I had some code that just wasn't playing well. It was interrupt code running in someone else's environment (Arduino), so that's just about par for the course. I spent all night and failed. Today, I had a fresh look and figured out it was problems interfering with each other that made it intermittent and really hard to diagnose: Arduino Due doesn't use the usual way to assign whatever interrupt # is assigned to a pin, like this: // BUG: BROKEN ISR ALLOCATION STYLE //attachInterrupt(digitalPinToInterrupt(63), ctIsr0, FALLING); nope, you just bang it in there, thusly: attachInterrupt(63, ctIsr1, FALLING); Ok, fine fine, there was random interrupts going off without service routines, no wonder it was jittery and crashing. and an obscure bug: on a Due, if you later on change the pinMode(), any attached interrupt detaches bug report here https://github.com/arduino/Arduino/issues/1693 which got closed and moved to here https://github.com/arduino/ArduinoCore-sam/issues/26 which is still open! Also, I'd had a problem with a Due board and terminal PCB, so I moved to the spare I bought for the job: The SPARE had broken pin 63 (NB above) and another broken pin I happened to be using as an output for testing timing. (!!) then, to add insult to injury, my main scope probe had come loose at the tip, resulting in intermittent connections. (!!!) Yeah, last night was doomed.

-

Another new windows enshittification: Ads on the lock screen, and you have to click one to get to the login text box (which then opens EDGE to that ad as you login). Middy is getting Linux.

-

I needed a 10% random signal at about 100Hz (average count about 10 per second) void setup() { } void loop() { digitalWrite(LED_BUILTIN , !random(9)); delay(10); } Job done.