-

Posts

651 -

Joined

-

Last visited

-

Days Won

1

rivalrx last won the day on September 14 2022

rivalrx had the most liked content!

Converted

-

Local Area

Auckland

rivalrx's Achievements

Post Fiend (4/5)

2.9k

Reputation

-

Thanks to Angus Fogg at Foggys Garage, I now have a template to make a 10mm bracket to mount my Hurst Competition Plus shifter to the Toploader. as usual this site won’t load 99.99999% of my pics so please enjoy this one.

- 93 replies

-

- 5

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

- 93 replies

-

- 4

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

-

Centre caps on the 5 slots did a quick lap around the block and passed an undercover cop coming the other way (reg hold no wof). I hightailed home and closed the garage door as fast as I could. He came past and the evidence was gone. you beauty

- 93 replies

-

- 23

-

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

Engine I bought in bits was measured up by a mate and appears that we are good to go after a hone and a clean. Still looking for the hurst shifter to toploader bracket but other than that, just cobbling the clutch bits I need to get stuck in. Found a gt rep bonnet locally that I may buy and sell my spare. That could save me some cost and time but not if its wavy and unusable. As seen in the thread, I have some OG 5 slots 14x8 riveted rims less the caps. Getting those this week

-

You know I do love my wheels….. 14x8 riveted 5 slots are now in the shed. The tyres suck and need to be binned for some white walls but hey. Simmons will be getting built up soon too

- 93 replies

-

- 12

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

- 93 replies

-

- 10

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

- 93 replies

-

- 2

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

- 93 replies

-

- 2

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

- 93 replies

-

- 8

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

this car bangs - cheers for the hiss up the road Kelly. What a mean build

-

- 93 replies

-

- 6

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

- 93 replies

-

- 5

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

- 93 replies

-

- 4

-

-

- xy falcon

- xy fairmont

- (and 7 more)

-

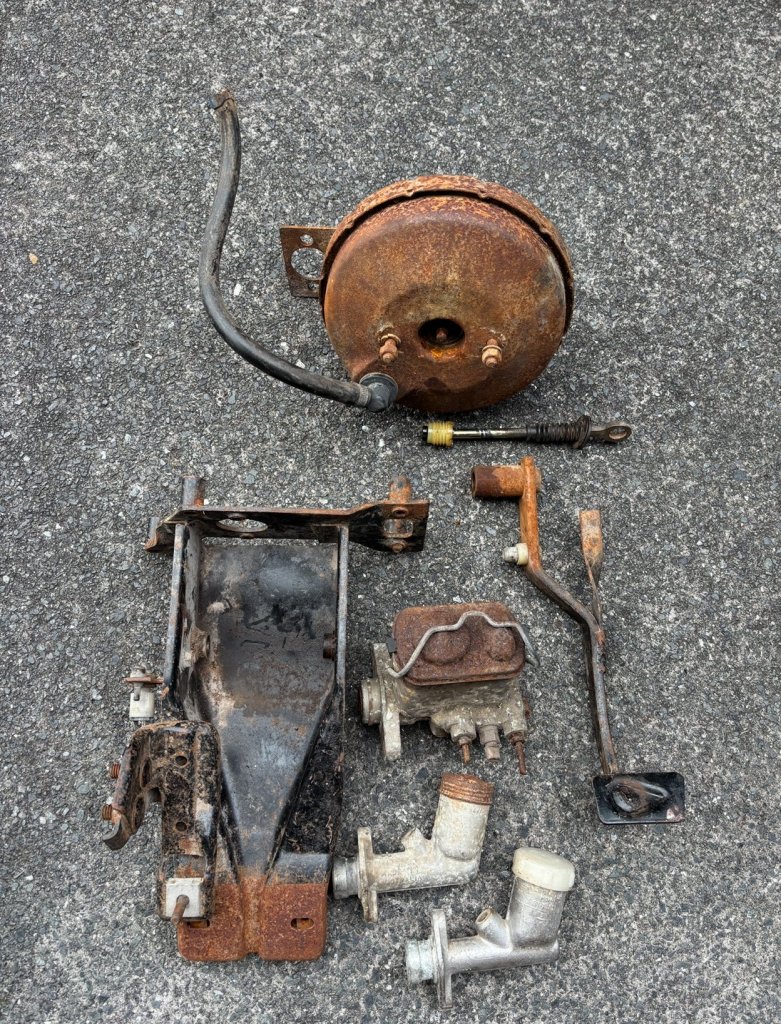

Got this lot for the clutch/brake pedal and shaft. selling this all now less those $100 is anyone is keen.

- 93 replies

-

- xy falcon

- xy fairmont

- (and 7 more)

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)