-

Posts

1,527 -

Joined

-

Last visited

-

Days Won

5

dabuzz last won the day on November 5 2024

dabuzz had the most liked content!

Converted

-

Local Area

Auckland

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

dabuzz's Achievements

Committed (5/5)

6.1k

Reputation

-

Legendary push to get it done, and damn she's hot well done man - looks killer

-

huge hustle - no sleeping now! .

-

Thanks, good to meet you too, was such a good day!

-

DABUZZ'z 1971 Mazda Capella RE + New 74 RX4

dabuzz replied to dabuzz's topic in Projects and Build Ups

Sent car to tuner, spent a few hours with him and he had it running far better by the time I left, he's introduced the water meth and intake temps have plummeted which is a great sign, he's done some road tuning since too and is very happy with it. We have found a few issues with the belt drive tensioner, and pulley set up, so currently trying to get that re-engineered asap. All going well it'll hit the dyno next week, and I can get it back to finish off the last bits before MMSB.- 119 replies

-

- 32

-

-

-

DABUZZ'z 1971 Mazda Capella RE + New 74 RX4

dabuzz replied to dabuzz's topic in Projects and Build Ups

- 119 replies

-

- 11

-

-

-

DABUZZ'z 1971 Mazda Capella RE + New 74 RX4

dabuzz replied to dabuzz's topic in Projects and Build Ups

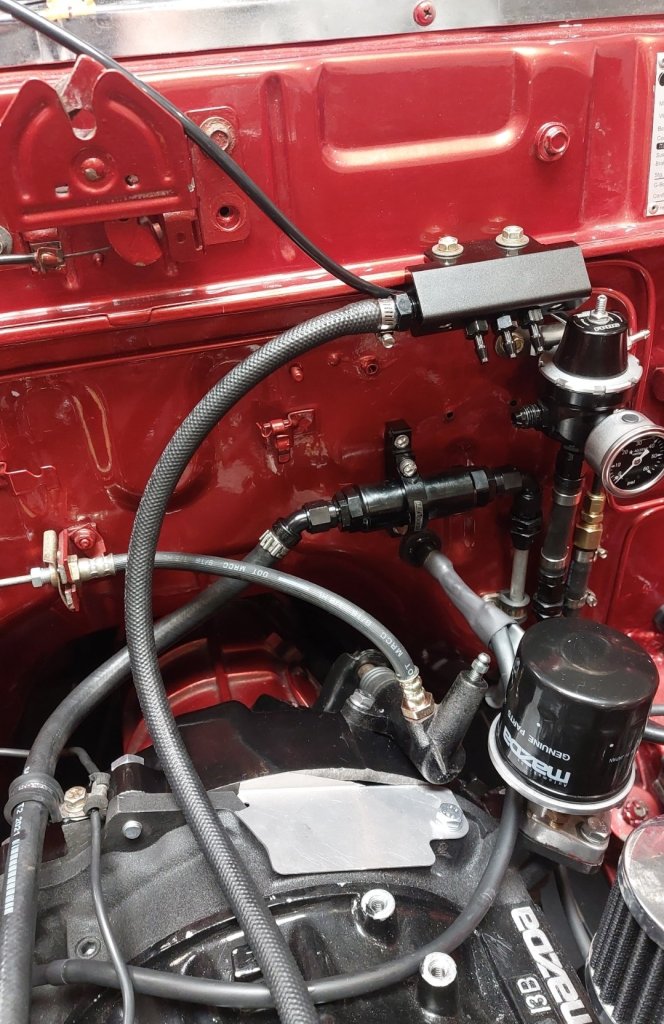

A couple of solid days work and she runs!!!! Mounted fuel tank, plumbed up last of fuel, and water meth systems. wired in pumps, made up throttle cable and mounts, refitted rear brakes and new lines, all fluids done, brakes and clutch bled etc Cranked to get oil pressure up, checked all fuel fittings for leaks then a mate came over with his Microtech handset and punched a few numbers into the computer and I turned the key...... HOLY SHIT - it caught us all unaware!, it literally fired up into a 3000rpm idle on the first 2 second's of cranking, had to scramble to keep it under control. Its angry, I mean real angry!! , once idle came down it just pulsed its head off, instantly we now know I have to solid mount the motor, it was shaking side to side so viciously we had to turn it off to set the idle, couldn't get near it Unfortunately I couldn't take it around the block as we found the new alternator not charging which will just play havoc with the ECU, pretty sure as it doesn't have a dash charge light, we have to wire one in to excite the alternator. It was getting pretty hot too, I had kept the fans wired as per the BP it used to have, but will swap it over from a manual temp sensor to the ECU to be able to set the temp to a lower point so the fans come on earlier, I may look at upgrading them too. Super stoked with only a few things to rectify before tune!- 119 replies

-

- 38

-

-

-

DABUZZ'z 1971 Mazda Capella RE + New 74 RX4

dabuzz replied to dabuzz's topic in Projects and Build Ups

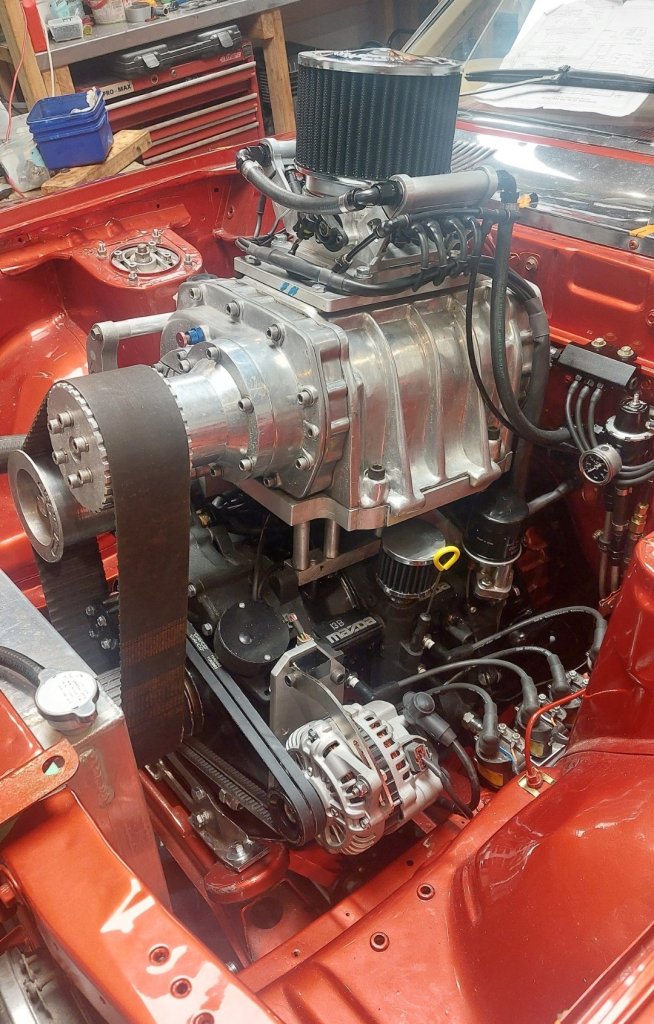

Engine bay 95% done, just need to sort throttle cable, tidy/clamp wiring, fluids and radiator overflow. Decided to run 2x water meth injectors either side of the throttle body, this is to spread the mix right across the vanes to aide in cooling, and also help ensure that both rotors get a dose to help stabilise ignition. One if the injectors is faulty, so also waiting on a warranty replacement for that. Air Filter sorted, although won't pass cert due to height, but I'll sus something come cert day to deal with that.- 119 replies

-

- 36

-

-

DABUZZ'z 1971 Mazda Capella RE + New 74 RX4

dabuzz replied to dabuzz's topic in Projects and Build Ups

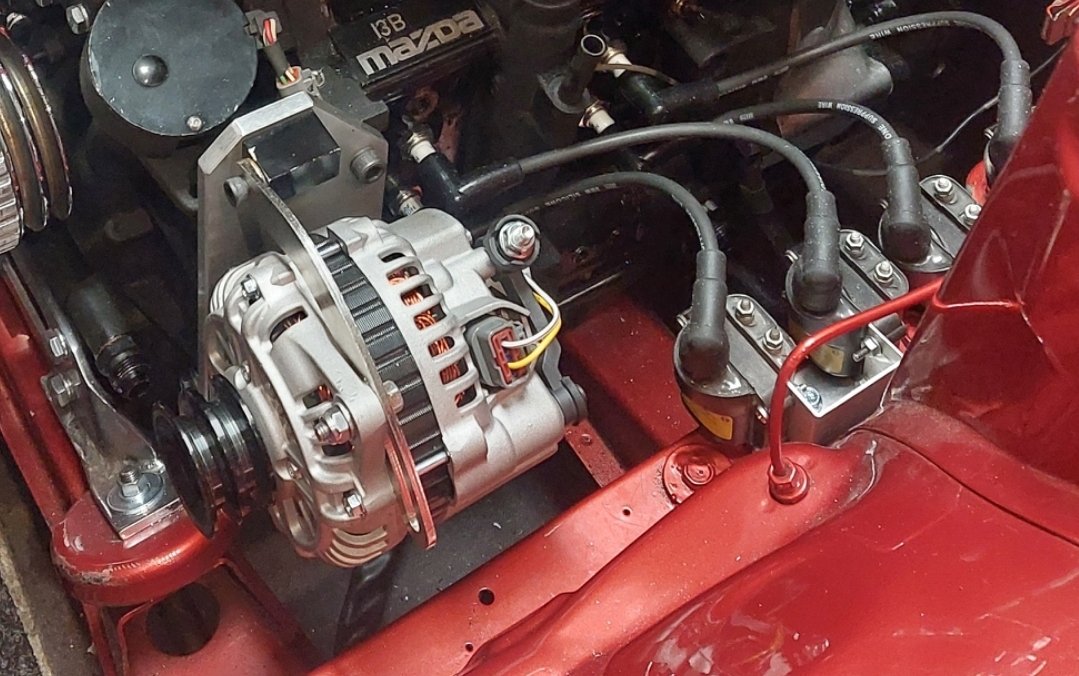

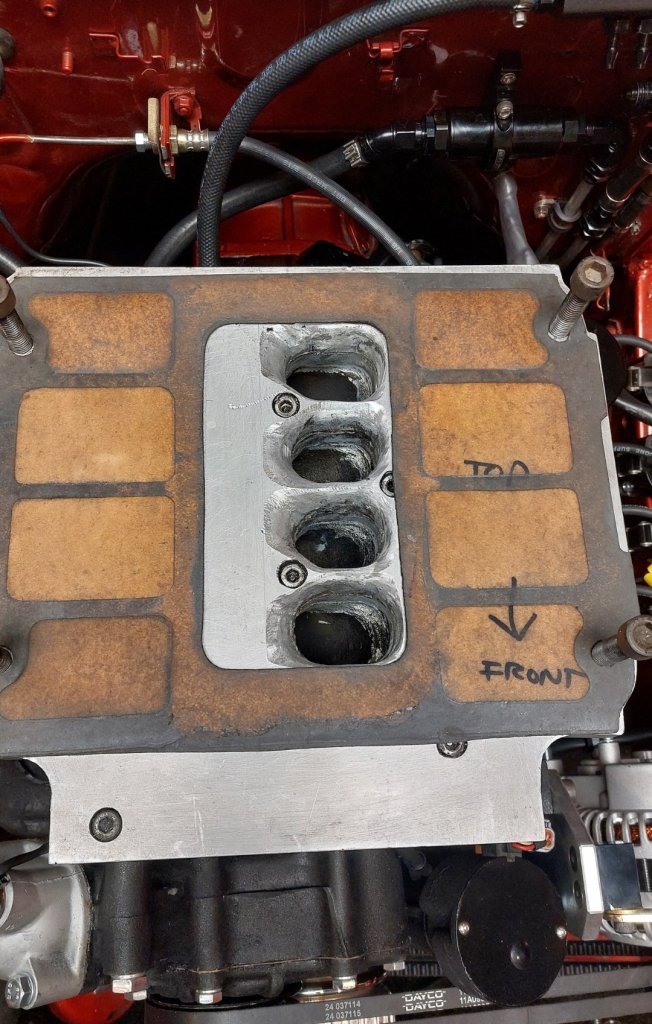

Stupid alternator side mount kit remade (after spending $300) to actually fit the car, turns out unless you have an rx7 they don't fit earlier chassis. Also coil brackets made, and fuel filter and vacuum block mounted. Lastly, have opened up the small intake holes and flowed as best as possible into the manifold- looks shit in the images, but go's hard as G.- 119 replies

-

- 16

-

-

I'm sure I've said this before but - Brown with these stripes

-

you've already got it - then slam it on- The brown will look mean I reckon

-

Michael14's 1959 Dodge Kingsway Discussion

dabuzz replied to michael14's topic in Project Discussion

rock auto is probably your first stop for motor parts. cool looking front - need many more pics!! -

Who is repair certifier? I struggled to find anyone out west who would even show up, and when I did they were mostly dicks, the guy I eventually used has retired now.

-

Agreed possibly the dumbest car to want to steal. such a shame it happened though.

-

That will work, also relocate the oil fitting to a sandwich plate under the oil filter, far better position for it

-

Have you just tried running a (non AN) standard rubber hose without the npt fitting inline? By your pics it looks like it would go, the aftermarket hose is less pliable, so needs more radius. It doesn't look to far off a factory length.