-

Posts

1,255 -

Joined

-

Last visited

About ProZac

- Birthday 27/04/1983

Profile Information

-

Gender

Male

Converted

-

Local Area

Christchurch

Recent Profile Visitors

ProZac's Achievements

Committed (5/5)

1.6k

Reputation

-

Oh Hey. Because ECU companies don't want to deal with the old systems that have old fucked valves and leaky pipes and cracked tanks... and have people blame the system not working on the ECU, when its 99% of the time a fucked solenoid. Hardware wise and firmware / logic wise the system isn't actually super complicated. Haltech support sequential turbos. You need two PWM capable outputs (for the pre and post switch wastegate controls), and 3 general purpose outputs (charge relief, charge control, and turbo control). https://support.haltech.com/portal/en/kb/articles/sequential-twin-turbo-user-s-guide I bet it would be possible on a Link though, I'm kinda counting on it TBH. But I wont be working on my car for another couple of years. We've kicked into a house renovation project, which is becoming a clusterfuck of epic proportions.

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

That is 100% what its for :-). Although, Lily has extracted promises of her driving it when she's old enough... So maybe I do have some sort of timelime... Still, that's at least 9 years away ;-). I'm insanely jealous of your workshop, it just looks like the most inviting place to tinker for hours on end. We're working on house renovation plans, and pasrt of them includes expansions to my workshop facilities. Nothing major, more a rearrangement, but I'm really really looking forward to turning it into a really nice space. -

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

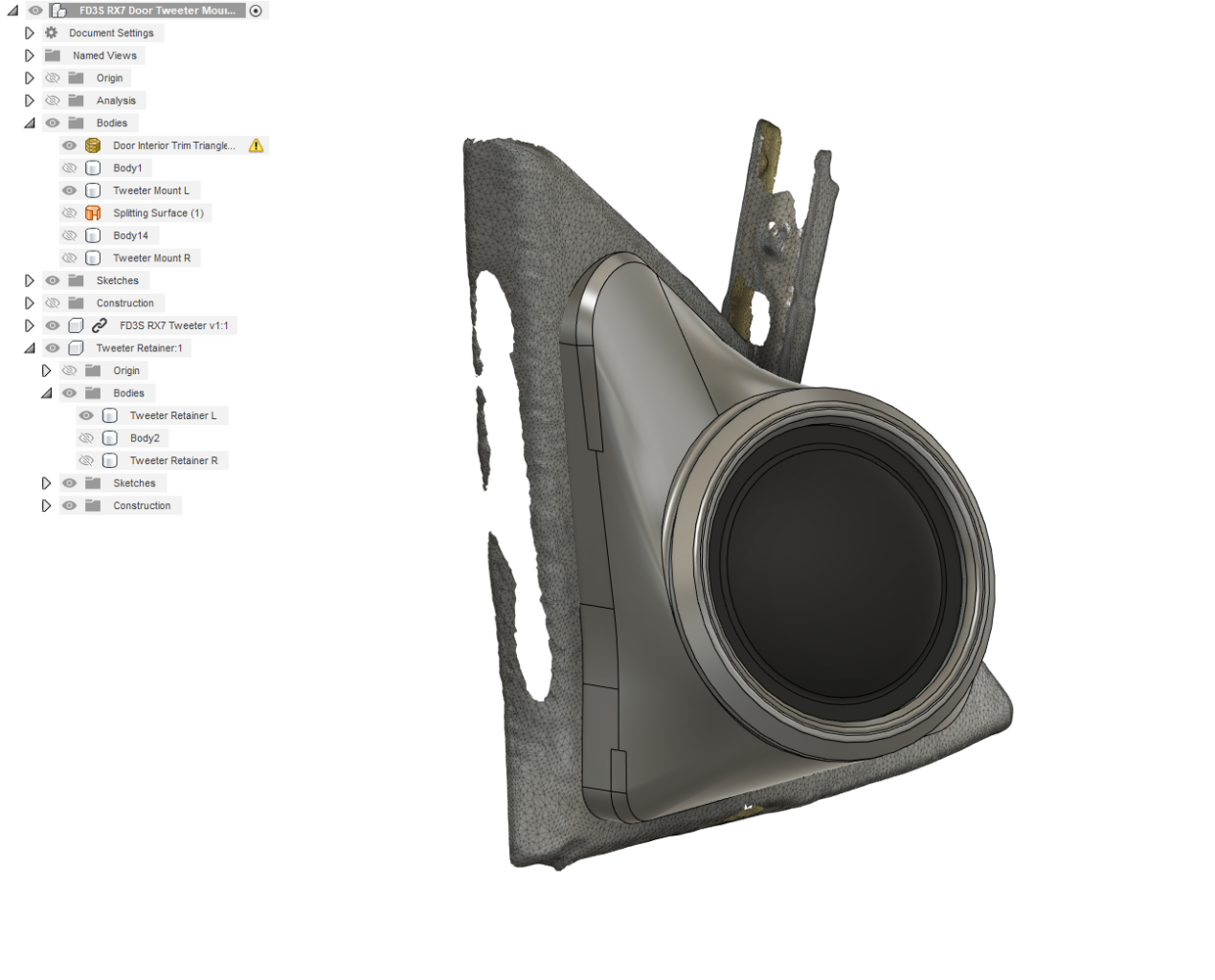

I will absolutely have AC in this car. As its an early one, it was fitted with an R12 system. I luckily managed to get most of an R134a system out of a later car a couple of years back, so gave all that a thorough tickle up. Looks to me like the actual evaporator cores are the same, just the expansion valve and its temperature probe are different. This R134a system is a 'Denso' style one, and has the metric threads on the attachment ports. I did a heap of research when I was playing with it as I'll have to buy fitting and make lines... Most of which I've forgotten now, but I don't remember it being complicated, so I'm sure I'll be able to figure it out again ;-). Have the R134a compressor too. Will roll and aftermarket condenser and dryer. replaced the seals with some 12x9mm adhesive foam tape from para rubber, seems like it'll work well. I tried 12x6mm initially, but it wasn't thick enough. This compressed just a little as I tightened the unit down. All back in place and looking nice and fresh. Smelling much better too :-). Now for some truely barry-spec shit: I'm not some kind of audiophile, but I did work at Repco for 10 years, so I'm good with cars, you know, doof doof? Speakers. The factory ones were shagged, and as I want to get the doors back together SOMETIME they need to be replaced which they're apart. I figured some nice alpine components would be the go, because a: Alpine is an excellent brand, and b: They were on spesh. I figured the little triangle on the front doors at the base of the A-pillar would be a damn fine spot for the tweeters... so went full ham and overcomplicated things. Took a quick and dirty 3d scan of one of the trims, used it as a guide to model the surface (its annoyingly compound in 2 directions). Then played around the in car and figured out how to angle the tweeter.. put it in the model where it needed to be, and generated a mount to keep it there. Used the modelled surface to trim the back side to its a good match, put in some fastening and retaining details, and 3d-printed. This was actually a ball ache, and there were a few iterations... But, this is the shit I love, so I had a good time doing it. Once that was done I figured getting the 6.5" drivers into the stock speaker locations would be a piece of cake, as its a round speaker into a round hole, and there is always a couple of cm of clearance here and there to play with... Nope! I mean, it wasn't *that* bad, but there is less and a mm of clearance at the back to the glass when the window is down, and the grill in the front when the door car is in place.. so still a bit of a ballache. 3d printed some adaptors, the two major circles of which are NOT concentric, because of those clearance issues. This got them nicely in place. The crossover is mounted to the back of the original speaker housing, as well as a DTM 2-pin the tweeter plugs in through, so all the original wiring can be retained, don't need to run anything extra out to the doors. Quite a bit of work for a stereo that will probably never get used for anything except phone calls. And, final little useless detail that I snapped a photo of... I was missing the floor mat retainer, and I didn't really like the original design. So, sheet metal CAD, water jet some 1.5mm stainless, bend, vaporblast, and voila: No, I don't want to cut the little flap of carpet off. Can't see it once the seat is in there :-). Should really finish off that engine bay harness! Yeah. Nah, Maybe. Having fun though :-).- 50 replies

-

- 18

-

-

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

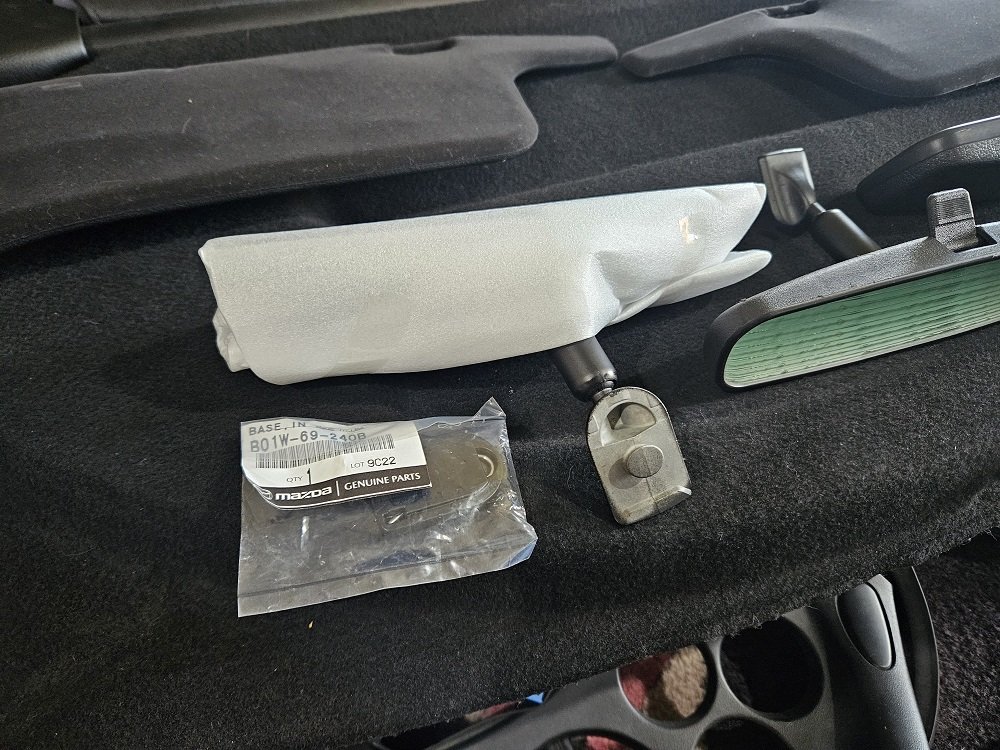

Its been a... year. And I mean that it is both surprising that a whole year has passed, but also not, because it passed in the blink of an eye, because it was a _year_. Lots of things non car-related happened, less things car related happened. I still tinkered in the garage though, as it was excellent therapy time :-). No, it still doesn't run. No its not any closer. Yes, I worked on things that get it no closer to running and driving. Yes, I enjoyed it. No, I don't have a timeframe, not what its about :-). Some highlights: I took the boot lid off because I couldn't get up in there to clean with it on. Overspray all over the wiring boots, grimy, all caked up with the clearcoat, some surface rust here and there, nothing that some scotchbright and etch primer wouldn't fix. Back to back I think the contrast is quite satisfying... Yes, I painted the jam. Removed the rubber boots / washer hose and vaporblasted all the overspray off them, they look brand new now :-). Have cut some rubber gaskets to go around the hatch hinge studs to do the job of the seam sealer that was used from factory. It's not like I'll be driving the thing in the rain much. Process photos: Cleaned the jam thoroughly, then roughed up with grey scotchbright. Sprayed etch primer on the parts that were missing paint up under the top of the hatch. Ordered some 2k paint from a place in NZ. They pre-mix a slow hardener in, put it in a spray can and courier it. Has about a week of pot-life apparently. Worked excellently, no reactions, good coverage. Did 3 coats, then sprayed some into the lid to go around and do touch-ups on various chips and stuff. I'll end up doing all the jams, and probably the bay like this myself, then one day It'll get a door shut respray by someone a little more into body work than I. Made it look a heap tidier in the mean time. Back into the interior, the rear-view mirror was all delaminating / corroding around the edge like they do. As this is a super early car it has the early style mirror... I didn't realise there were different types when I bought a new replacement mirror from Mazda.... Well... I figured I should swap to the newer style, as if I ever need a replacement windscreen they are way, way more common. This meant I had to remove the mirror mount that was glued to the screen... This puppy: I popped a couple of screws in there to give me something to grab, but it was on there solid (which is a good thing). I read about removing them, and it seems that heat is the key. I went gently gently with the heatgun... heating from the outside.... This was wrong and got me nowhere. After turning my heatgun from 'kitten breath' to 'dragon flame' (the only two settings is has), I heated the ever loving crap out of it from the inside... I mean got it properly hot... I gave it a tweak with the pliers and it fell right off, into the wet rag I had right below it... where it sizzled and steamed. I read horror stories of people dropping them, where they then melted the dash and carpet.... No thanks. I got most of the residue glue off with solvents and careful scraping. Its some sort of bonded on ceramic pad on the windscreen I'm pretty sure, I was scared I'd scratch it and you'd be able to see the scratch from the outside. No chance of that, the black portion is very, very hard. Have got the later style button and the correct Loctite adhesive to bond it on, but haven't done it yet as I need to come up with a plan to get it perfectly in the right place, or it'll drive me nuts every time I look at it. During my experiments with powering up the electronics in the car, I played with the HVAC system a bit. It all seemed to work as it should, but it was kind of noisy, and the blower motor sounded terrible.. I'm sure you can see where this is going.. Rejuvenation time! Turns out you can remove the A/C evaporator and blower motor without pulling the dash, its not even that hard... but the distribution / mixer / heatercore box is right in the middle... So I pulled the dash. I was expecting a headache, but genuinely the easiest dash I've pulled out of any car, was pleasantly surprised! I'm super lucky that the dash in this car is in very good condition (see the original interior photo, its the only part that IS), so its stored safely inside on the spare bed :-). Will need one repair to a plastic mount where the glovebox screws in, but basically all FD dashes are broken there. Will glue the cracked bit up, and come up with some sort of 3d-printed reinforcement I reckon, to stop it happening again. Pulled this completely apart.. The DC motors that drive the blowers are pretty grunty.. The original one from the car was particularly nasty too. Brushes still looked okay, but the casing was a bit corroded, and it was packed full of leaves, dust, feathers, grime, your mothers underwear, shells, nuts... everything. I had a spare blower motor, so yanked the motor from that as it was a much cleaner unit. Still pulled it apart, tickled up the commutator and brushes, re-lubed everything... the usual. The plastic impeller and casings all got a low pressure vaporblast to bring them back to new. Took the recirculation door actuator apart, cleaned tested and re-lubed as well, tested the relay... all the things. Should be good to go :-). Gave the distribution box the same treatment. Although I cleaned this one in the sink, as the foam was actually still in really good condition so I didn't want to blast it off. The heater core pipes were in a really sorry state though. So pitted. Removed all the corrosion, made sure they were still nice and strong, blasted and had them plated. Reinstalled with new o-rings. Hope like hell they don't leak at the interface to the core, as that's a dash-out job to fix, but I reckon they'll be alright :-). Dummy fitted this with the pipes loose so I could adjust them to be right in the middle of the holes in the firewall, have new pass through grommets on the way from Amayama. -

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

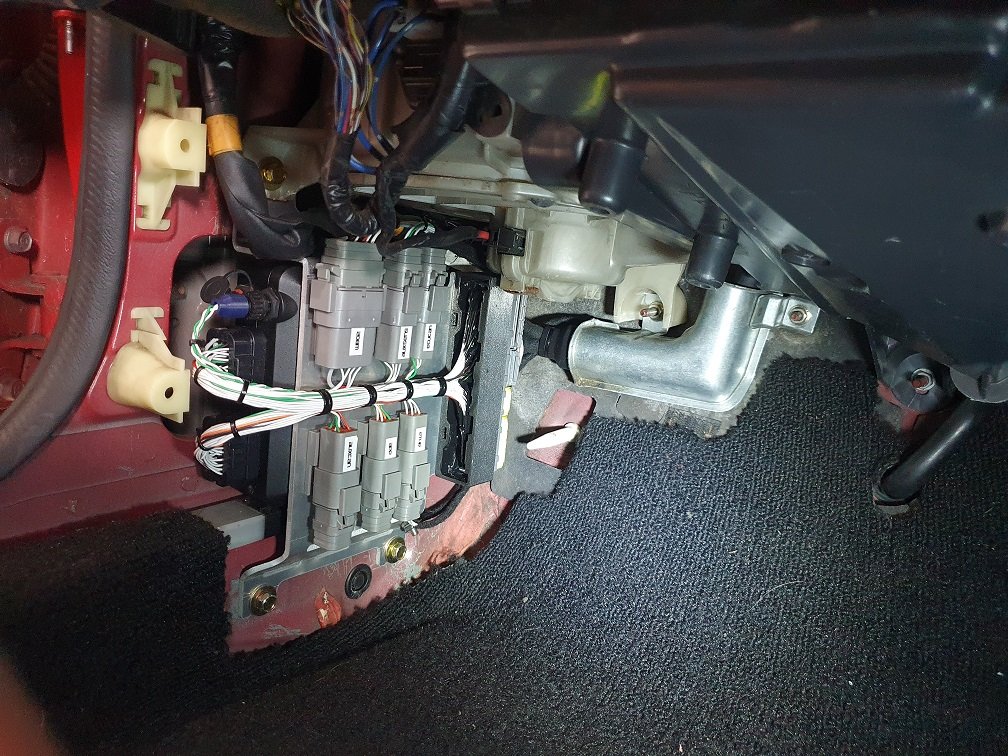

Months go past, and alas little work done on this thing... Lots of family visiting, really busy with work, usual life stuff, you know the drill I'm sure. I have been tinkering away a little though. I've built the starting and charging harness, the two times I've ordered the correct pins for larger contacts in the two grey connectors by the strut tower they haven't shown up, so I gave up and have swapped them to a DTM12 and DTP4. I moved some stuff around a bit so the connectors for the aircon clutch, power steering pressure sensor and oil level switch are now in the main engine harness, so the starting and charging harness interfaces with this by a single DTM6, keeps things a bit cleaner. Now, the main engine harness... I've done a heap of work on this, but there is still a bit to go. It's designed to work with a factory ECU, a power FC, or the link fury I have. Its future proofed for modifications like another turbo control system and e-throttle. Its made out of the good stuff, M22759/32 wire, twisted, DR25 sheathed, etc. I don't want to have to build another one! After some basic measuring and figuring of branch point locations, I put the core together, this is the shielded wiring for the engine position sensors, knock sensor, gearbox output speed sensor and O2 sensor, aswell as a couple of unshielded twisted pair runs for CAN. Many hours of work later, and another three layers of 22AWG: This is the run from the interior breakout by the ECU, through the firewall, to a branch just by the oil filter pedestal, where the UIM interface connector will be, the gearbox wiring, oil pressure and water temp gauge wiring, as well as an aftermarket combined oil pressure and temp sensor. After sheathing this section in DR25, I fabric tap wrapped the breakouts at the ECU end. Fabric tape is awesome in interior sections, as it stops rattles :-). I printed a mid-shell to house the splices and wire turn-arounds, keeping them protected, and making the transition between the DR25 and the fabric wrapped breakouts nice and tidy. No need to boot and pot this interior stuff. Can see the Link ECU mount all finished and wired up there too. There was a bit of test fitting along the way, but got it fully plugged in with the OEM trim and cable protector this morning for the first time. Hmmm, satisfying. And then hide it all away! I still have all the engine bay side to do, organising the other three branch points, sheathing the main runs, putting the boots in place, sheathing the branches terming and then potting it all up... You know, not much work at all! Total overkill for a mildly modified street car, but its work I'm familiar with and enjoy, and I've never actually built a ham-spec harness for one of my own projects before, so it'll be nice to have one. Most of the materials are left-over from projects over the last few years, so its not been a massive financial burden... time wise though? yikes. For the aftermarket oil pressure and temp sensor, I drilled and tapped the banjo bolt that connects the oil coolers to the filter pedestal. This should work well, and means I don't need to buy an aftermarket pedestal or anything, but it does put the connector for the sensor annoyingly close to the heater pip in that area. Clears, but not by as much as I'd like. Tapped it to 1/8NPT, and used a M10x1 adaptor with the correct seat for the sensor. About as compact as I could get it. Even did it on a lathe so its nice and straight :-). When building the starting and charging harness I made up some ignition leads as well They're tight to the oil filler neck, but everything clears and they're a bit tidier than then OEM ones. Separators are printed in PETG, will see how they hold up. Might have it running by Christmas? Yeah, nah, probably not, but no rush eh? :-).- 50 replies

-

- 28

-

-

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

Hah, haaaard pass on an old actual flare, can see a smoky ending there! But, a USB re-chargable torch that doubled as a powerbank, in flare formfactor.... that would be the tits. -

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

Oooooof, very cool. Looks like a bit too big of a diameter on the shaft though (lol), really stressing that plastic? -

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

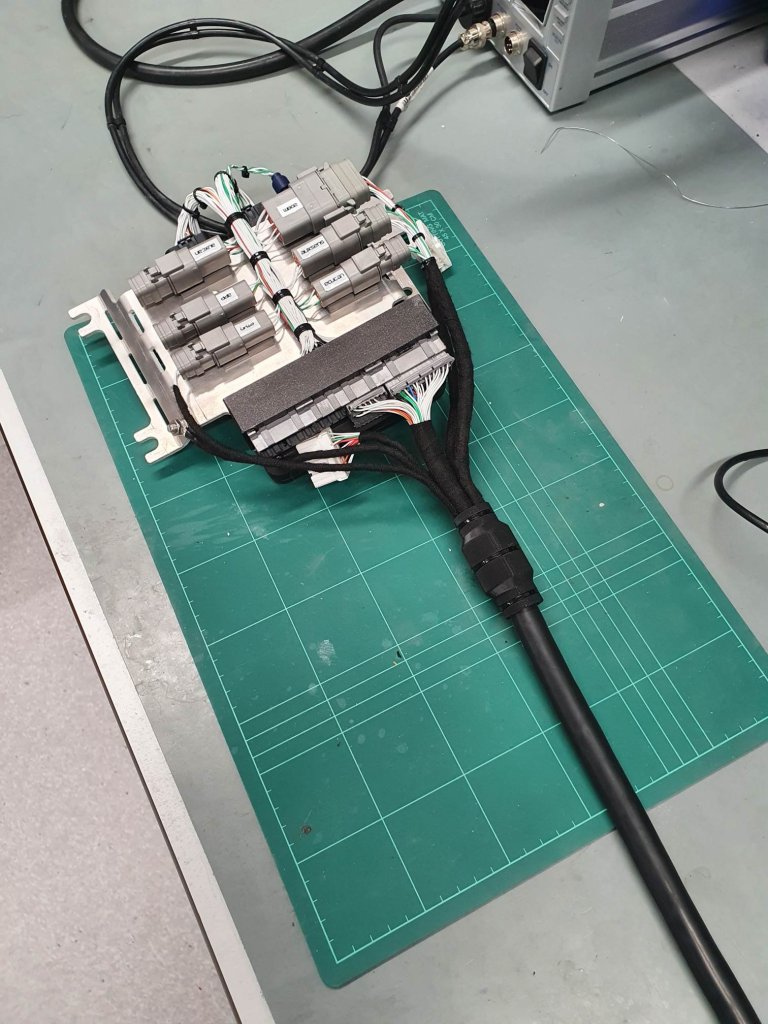

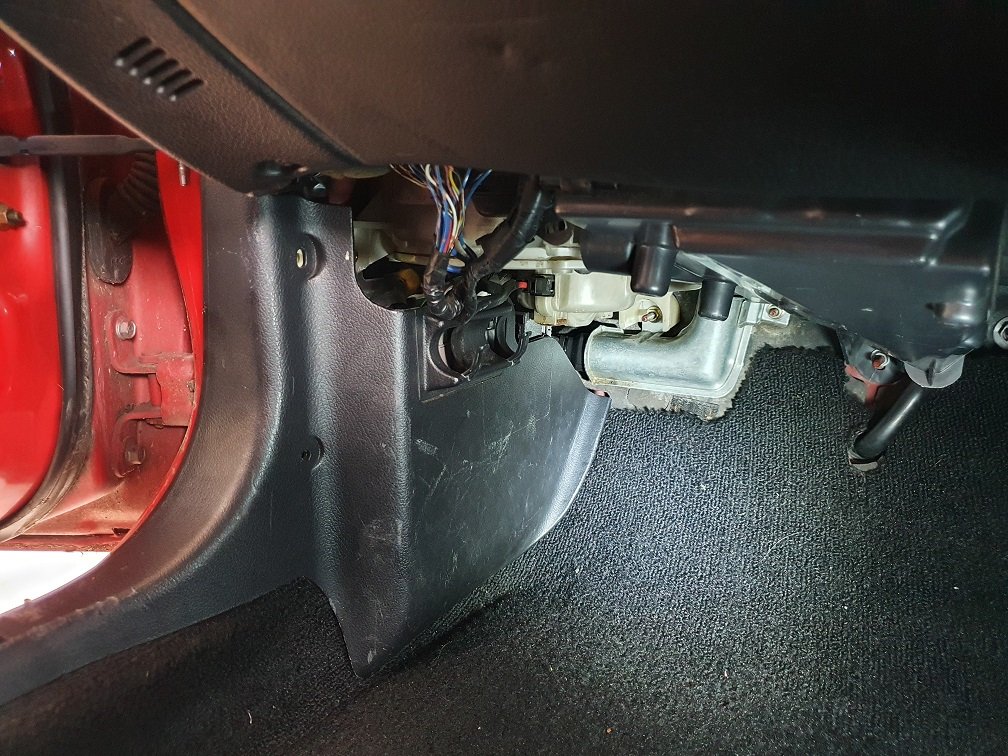

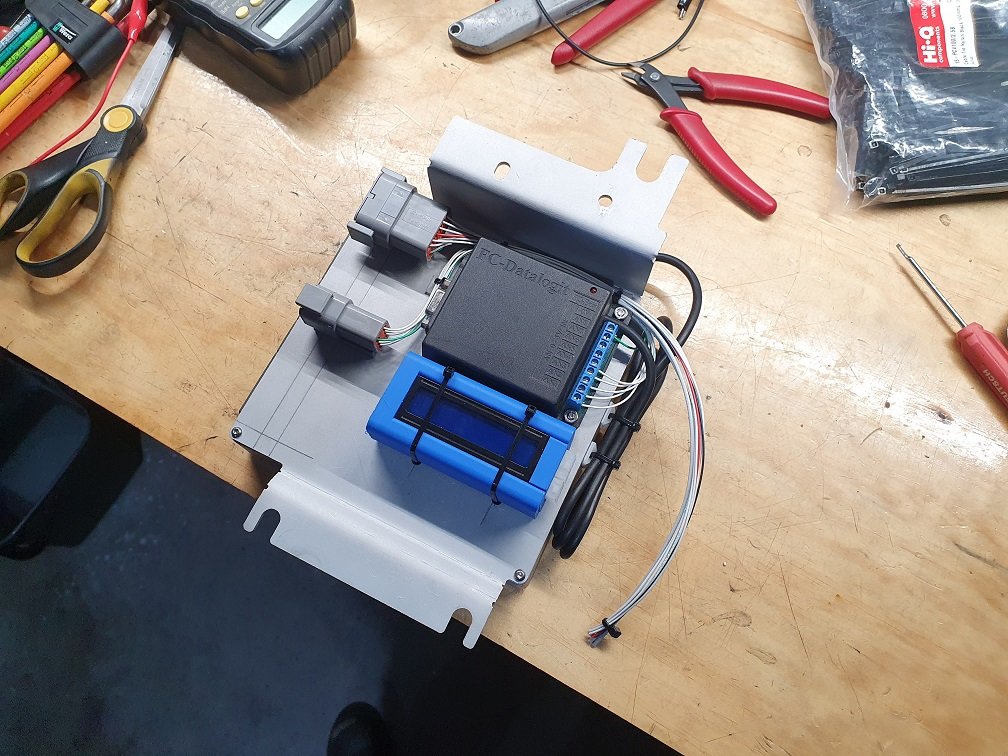

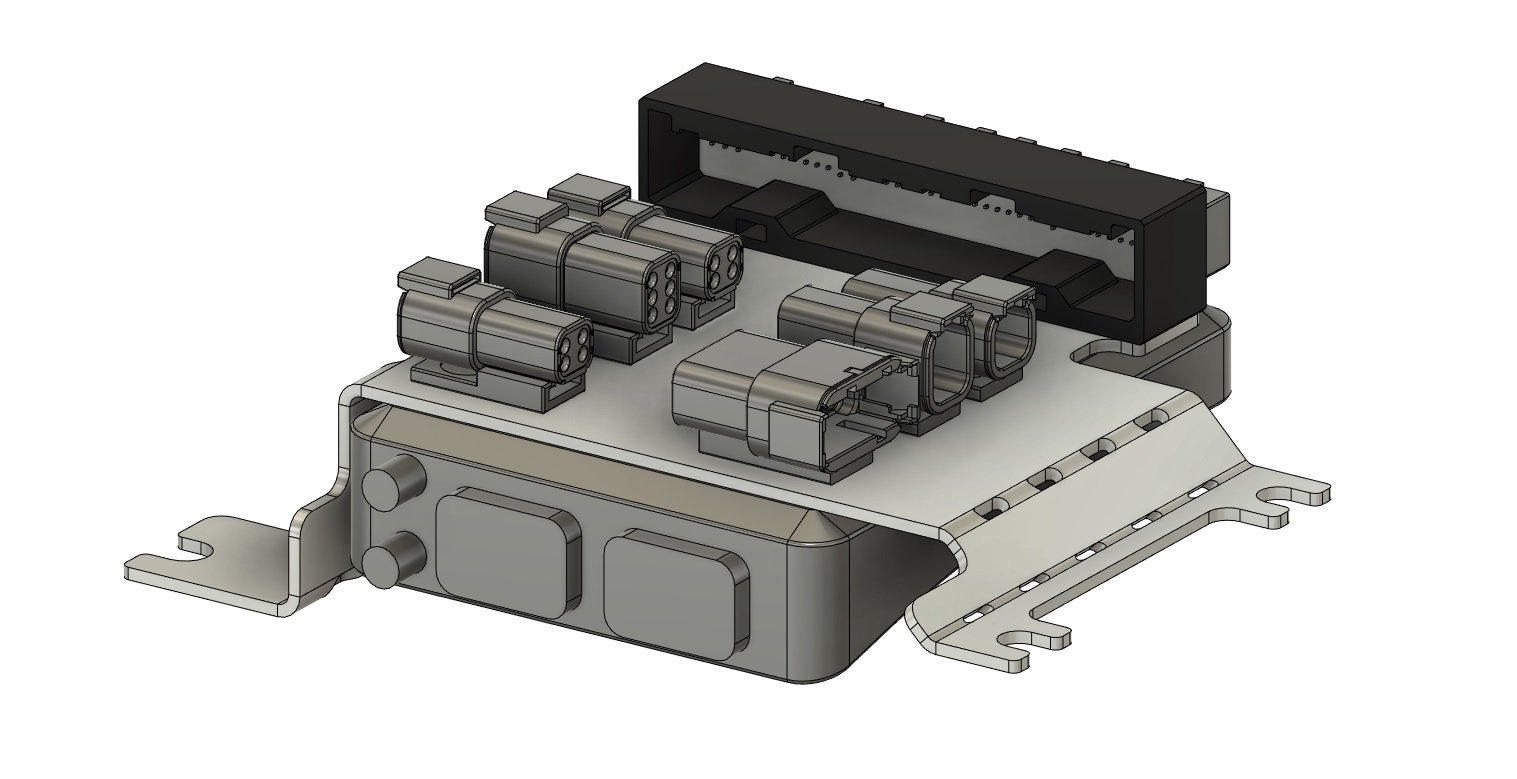

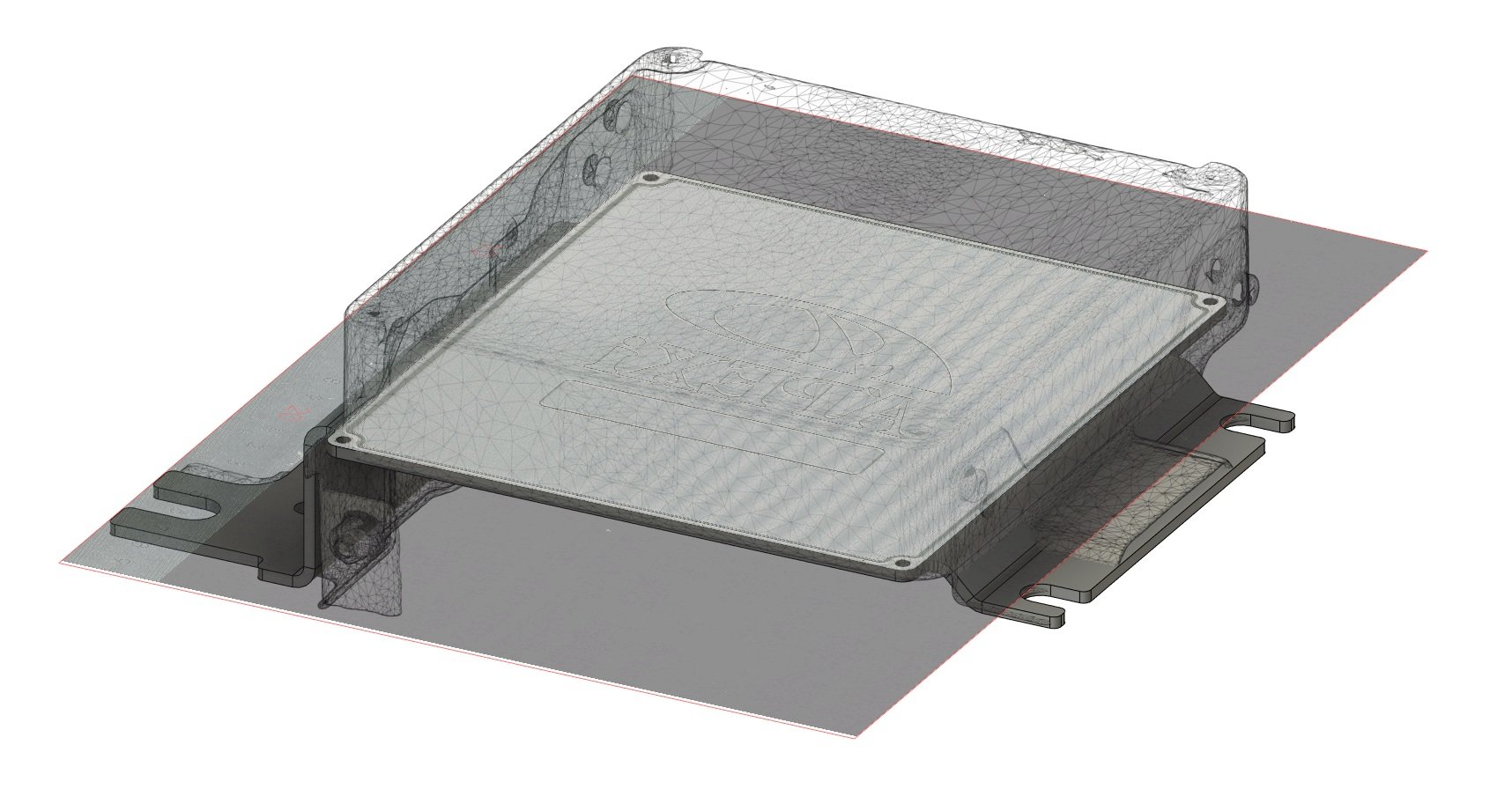

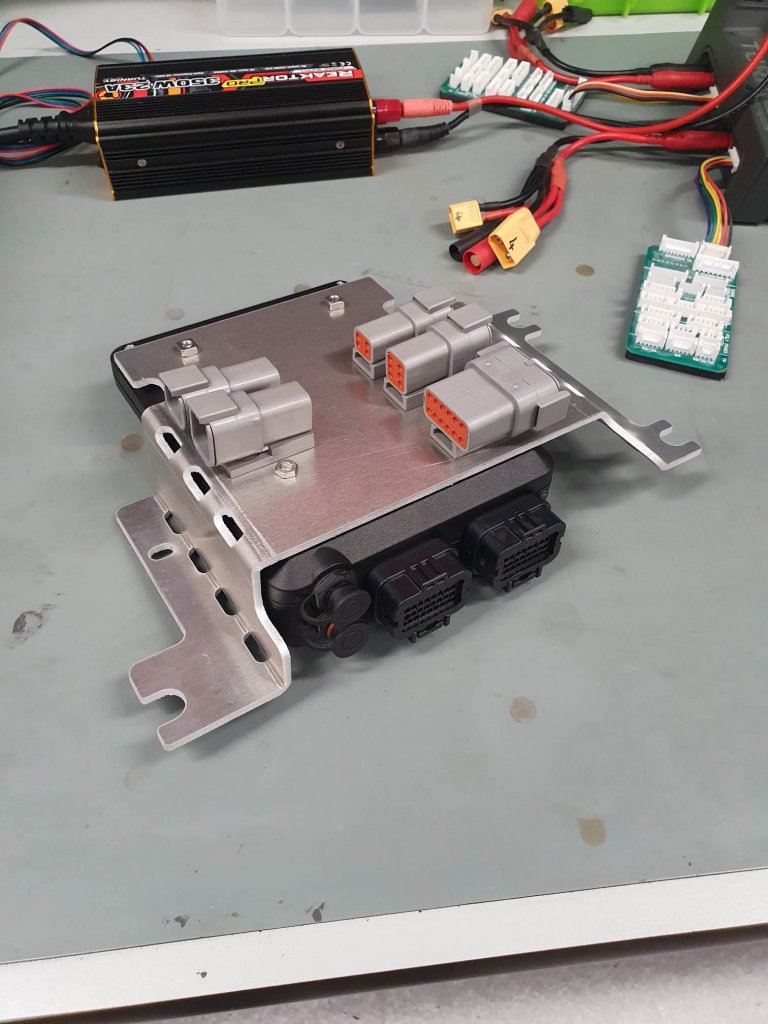

I started building the wiring harness this thing actually needs! Sooooo, let me immediately pivot and tell you a story of ECU's and their mounts. I've got 3 ECU's planned for this thing. To get the thing fired up, leak checked, heat cycled, maybe a couple of drives around I've got a stock super early S6 8bit POS ECU. I've actually got a couple, once with a case and one without. To drive the thing a little longer term, and maybe get a little more jam out of it I've got a Power FC. yes, I can *hear* the eye-rolls, they're antiquated, old, past their used-by, and all that... But, TBH, that still work just fine in a pretty mild setup. Add to this that I've got (borrowed, as they seem to be genuinely hard to buy?) a datalogit to go with it, and there is still pretty active development around tuning these, I should be able to get the thing going pretty well on this :-). In its final form though, I want an e-throttle on it, and I've had a Link Fury kicking around on the shelf for a couple of years, so this will find its way in here. This also has the benefit of a built in wideband controller. I don't really like external wideband controllers that rely on analogue voltages :-/.\ I only want to build one wiring harness for the thing though, so it has to cater for all three conditions. This has driven the design of a harness that uses the original style of connectors at the ECU end, but also quite a few 'auxiliary' connectors in the cabin to cater for mods and the different installations. When I stated building the harness, it was pretty clear that I really, really needed to know where these connectors were going to be mounted. I contemplated just eyeballing it, but know I'd be annoyed later... So, needed to mount all this crap, for all the configurations! Obviously the stock ECU is easy, it just bolts in. Its mounts are actually a little hacked up, but as I'm not going to keep it in there long, eeeeehhhh, its fine. Having this is pretty crucial though, as it let me see how much space is under the passengers kick panel there for mounting all sort of crap. Pleasingly, and quite uncommonly IME, there is actually a heap of space! I scanned the OEM ECU, got a decent mesh out, aligned it in CAD and used it to get the mount point locations. This let me CAD up mounting plates for both the Power FC and the Link Fury. I went a little ham-spec on the Link Fury mount, as its the final one the car will end up with, so should be a nice piece of kit. The Power FC one is a little more 'thrown together', but still tidy enough. Low res version of the scan of the original ECU. Combined with a 2D scan of the power FC backing plate, and a sheet metal replacement modelled up. Quick and dirty. It *just* fit within the work area of the water jet at work (its a baby). Cut it out, folded it up, and screwed it in place of the original ECU cover. After a quick test fit, its a go-er. There is heaps of space on the other side of the new mount for other items too, like the datalogit, and wideband controller. Bit of jiggery-pokery to get everything lined up, drill a few holes... Waiting on the molex connectors for the wideband (14point7 SLC Free 2) to show up so I can finish the wiring. Not worried about the display on it being totally hidden as it'll send its linear output to the datalogit where I can view it on the laptop, and its simulated narrowband output back to the OEM ecu or Power FC via their main connectors. The trim even still fits! Score! ;-). 100% going to have to get/make a torch to go in the holder that looks like an original flare. Right.... One aftermarket ECU down, the other one to go! Little bit more thought involved for this, I wanted to integrate an OEM connector body onto the ECU mount, along with all the auxiliary connections for additional sensors, e throttle, accel pedal, CAN, and the rest. It's kind of a plug-in adaptor and mount all rolled in together. This is what I came up with. I bought an OEM connector housing, and have trimmed the pins (they're only available in a PCB mount version). Have designed and 3d-printed a backshell, and after the wires are soldered to the pins the whole thing will be potted with RT125 or similar. This one actually too two tries, ECU wasn't high enough to clear that plastic wiring channel the first time. Second time was a charm though, and the trim still fits! Have done the wiring design on this... Actually doing the physical wiring on it will be kind of a chore, there is quite a bit too it. Worth it for a nice solid solution though :-). Will start of the wiring of that tomorrow I think, atleast do all the power supply, CAN and any shielded stuff on it what requires annoying splices. Soooooo, I can get to building the actual harness... ummm, soon? Honestly, excited about it :-).- 50 replies

-

- 24

-

-

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

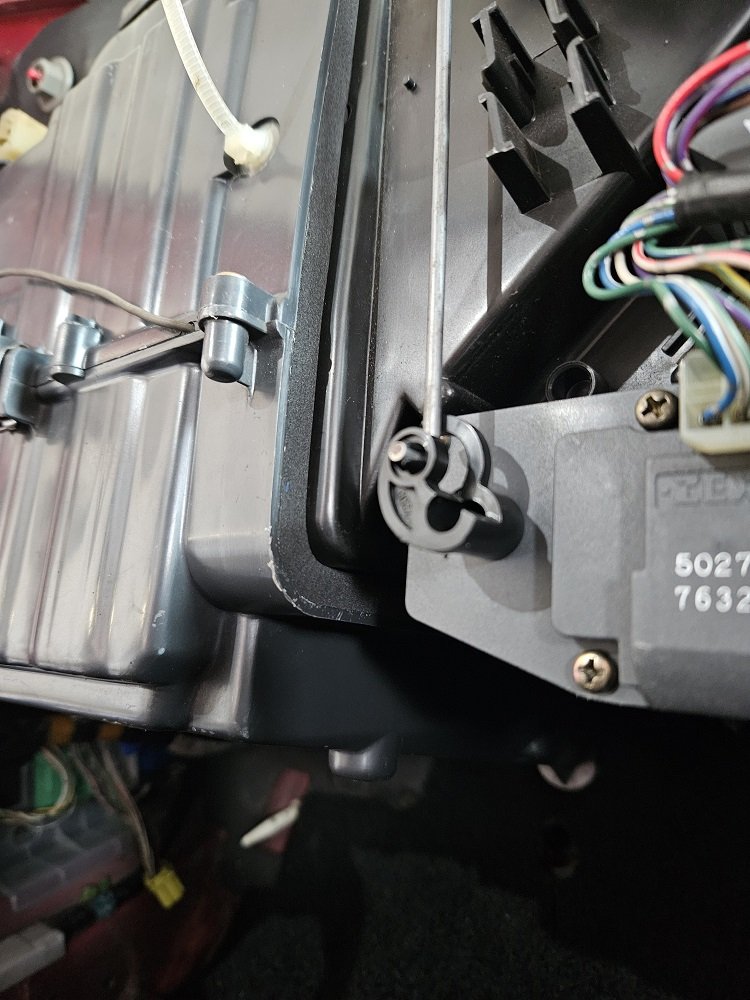

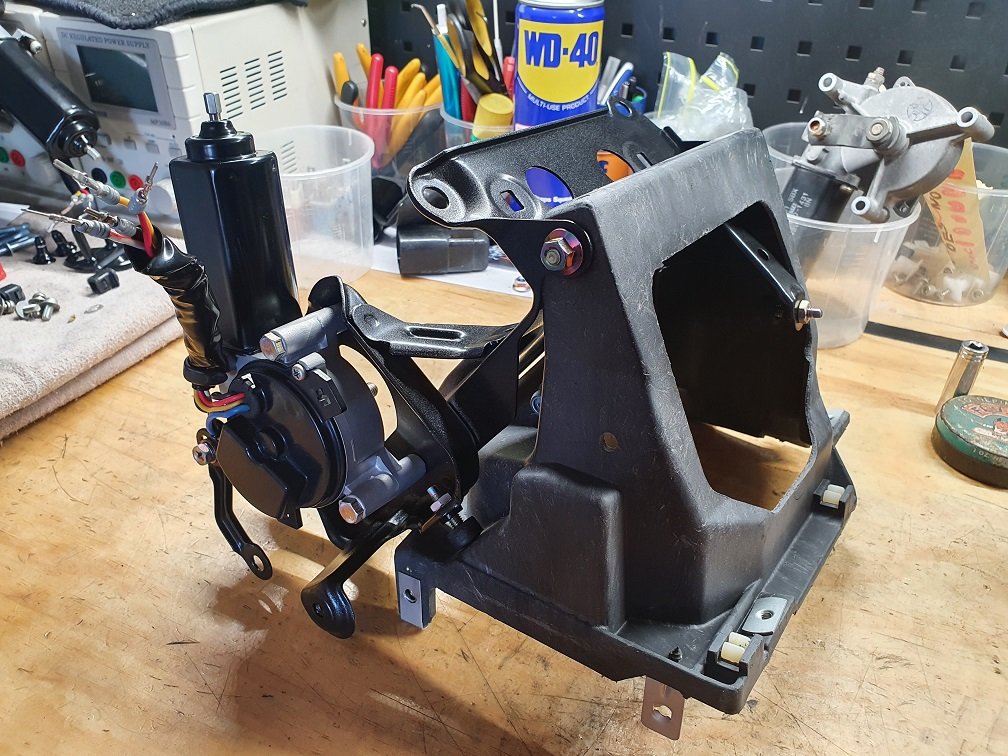

The headlight mechanisms on my car are a bit of a mess. They work, they're straight, but they are caked in red and clear overspray, really bloody ugly. Picked up another set for pretty cheap, and well, you know the deal by now... strip, repair, clean, blast, plate, coat... The motors were kind of interesting to get back together... They were really tight on reassembly, like completely jammed. I'd paint stripped and powder coated the cases (didn't blast, as didn't want to deal with grit in there), so couldn't see why they'd be tight on reassembly. I'm thinking maybe baking the powder (215 degC) might have burned any residual oil in the bushings at the end of the case, and made some sort of hard film? Honestly, I'm at a little bit of a loss as to why. In any case, some time with rolled up 600grit sandpaper and the drill made the clearance needed to get them assembled cleanly again. All tested and working as they should. I'm a little worried they're going to work at different speeds, but can play with that later when they're fitted to the car. One of the connectors had a broken pin retention tine, so might just swap them out for DTMs. Will need to sort out the end stop adjustments also, but just put them back together as they came apart for now. Interior rebuild continues. It's dangerously close to being complete even! For reference, this is what I was starting with: I got another handbrake handle assembly and stripped it down, repaired some sloppy-ness (made new pivots) and got it all back together. Dropped that and the steering wheel to a local upholsterer, along with the old gear shift and handbrake boots to copy as well. Handbrake handle looks excellent. Need to turn up another button for the end, there is some black delrin at work that I can pinch an offcut off. Seams in the steering wheel are a little lumpier than I'd like, but overall its a massive improvement! Nice leather, and managed to find some perforated stuff too to match the original way it was done. I've got a boss-kit and am always looking out for nice steering wheels, so I'll likely run a few different aftermarket wheels on this from time to time, but its nice to have the original one all tidied up again. Lots of other balls up in the air with it, a little scatterbrained at the moment to be honest, need to just tick some jobs off the list and re-focus.- 50 replies

-

- 19

-

-

Same answer unfortunately, a little too non-Starion for me alas, not in my wheel-house. Cool project, though.

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

It's been a hot minute since I've done anything on this. Work has been pretty mental with preparing material for remote delivery due to..... reasons, and I've really not had a lot of garage time! Needed an easy win, and I have to get the rear bumper back on so I can reassemble the rest of the interior, figured it was a good box to tick off. In their infinite wisdom, Mazda have designed things such that you have to remove pretty much every piece of interior trim behind the FRONT seats to get the rear bumper off... So clearly the bumper needs to be back in place before it can go back together. I'll caveat all the following work by saying that it'll be coming apart again in a couple of years when the car gets painted, but I wanted to make sure that would be as easy as possible. Part of this is making it so I hopefully don't have to deal with rust fasteners again... ever. Pretty much every fastener on the rear bumper was a rusted mess. Weirdly, the body of the car itself is fine, but the metal brackets on the inside of the bumper were in many, many pieces... Many of the bolts below the tail lights holding the skin on there required hammer and chisel action to remove, and the speed-nuts / screws holding the rear valence on were pretty much unrecognisable as having ever been fasteners in the first place... It was just all a bit of a mess. I bought new bumper brackets from Mazda. These fuckers were NOT cheap, around $230 per side! But, the bumper skin itself is really really tidy, and people seem to want moonbeams for a good rear bumper, so I just went with it. They are originally riveted in place, and I was careful drilling those out to remove all the old rested pieces. I've secured the new ones with M3 stainless screws and nylocs. I've also omitted the clips for the moment, as they were a complete ball-ache to get popped loose when I removed the bumper so long ago... When It gets painted in a couple of years I'll re-fit them. The lower valence is not to shabby on this car, a little warped in one place, but I'll be able to make another couple of clips to hold it in place. Some time in CAD, and then the waterjet, and then the finger folder and I had some replacement speed-nuts (with separate nuts, so thus nullifying the 'speed' part, hah). All stainless to hopefully never give a problem in the future And some new fasteners for the top of the skin. I would have liked to find torx head ones for this, as they were originally, but these were easily available and I've convinced myself they're fine. Yeap, that spoiler is a completely different red... It it, however, not cracked, and in one piece, which is much better than the one which WAS on there when I got the car. Future problem, hah.- 50 replies

-

- 16

-

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

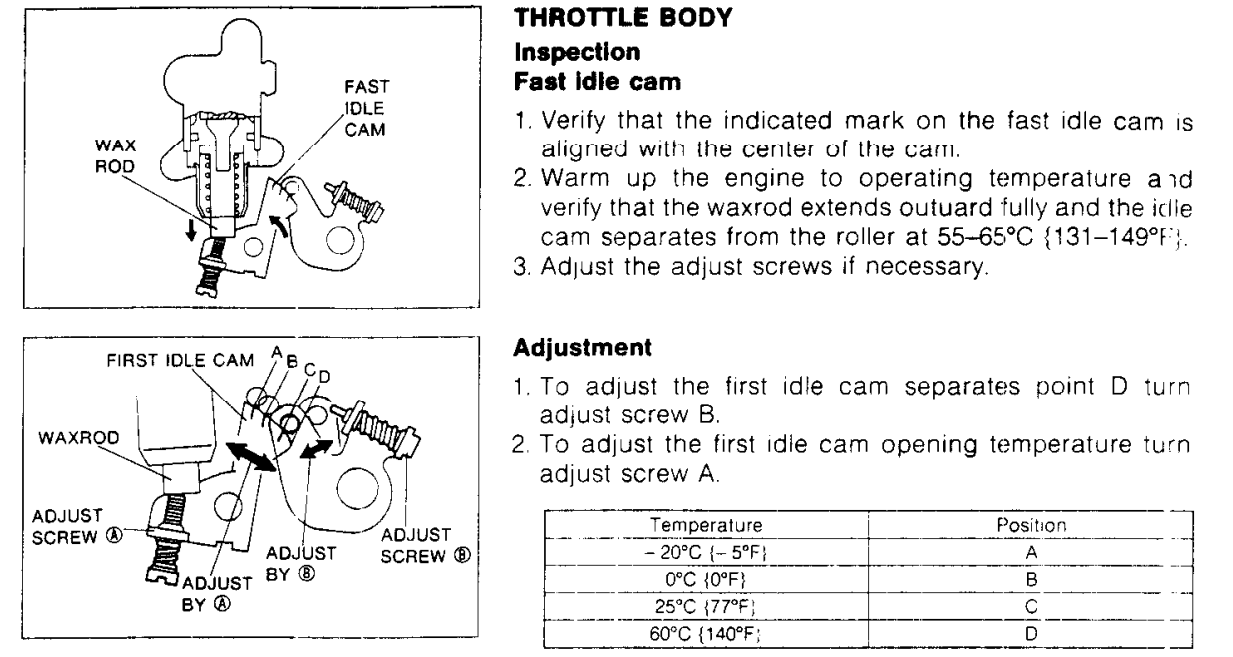

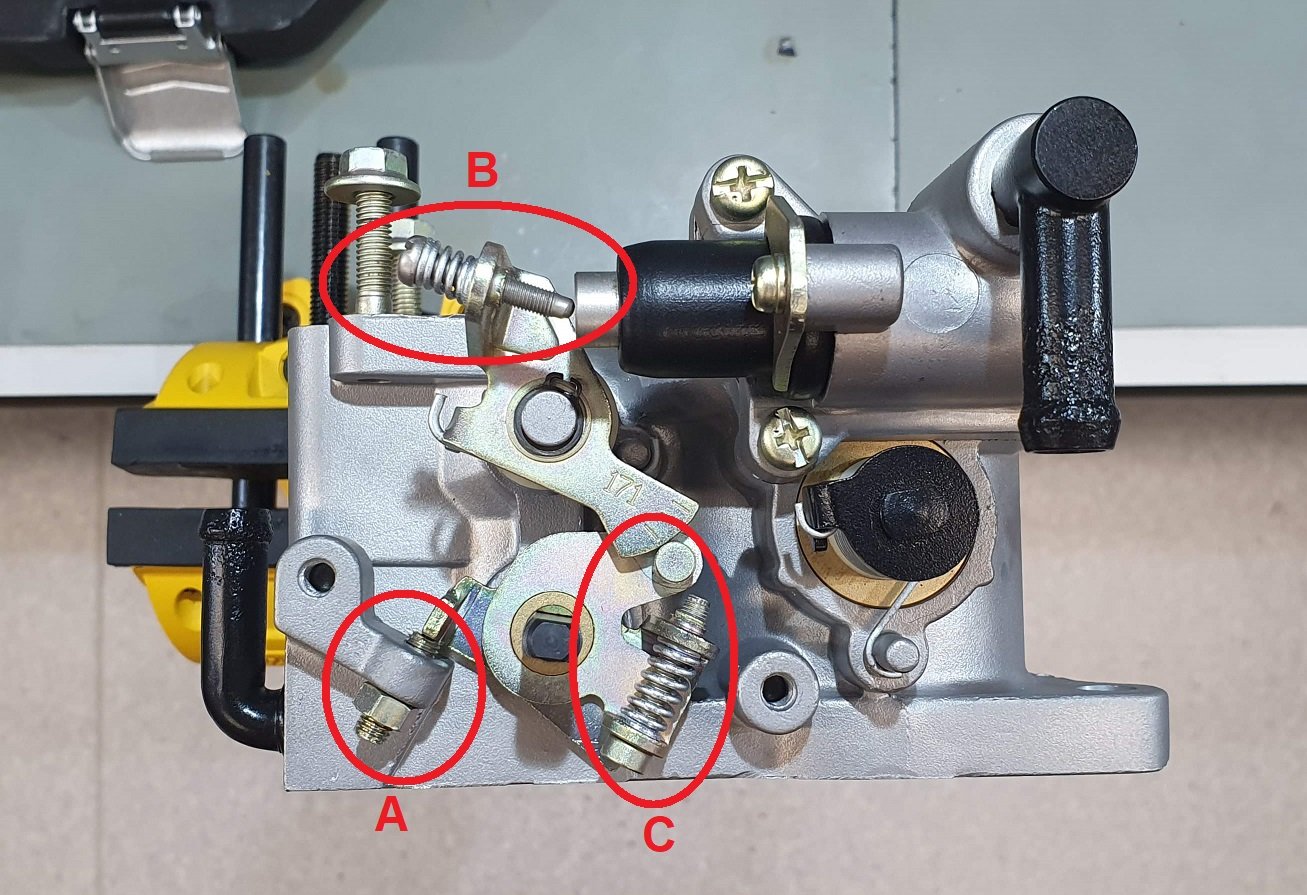

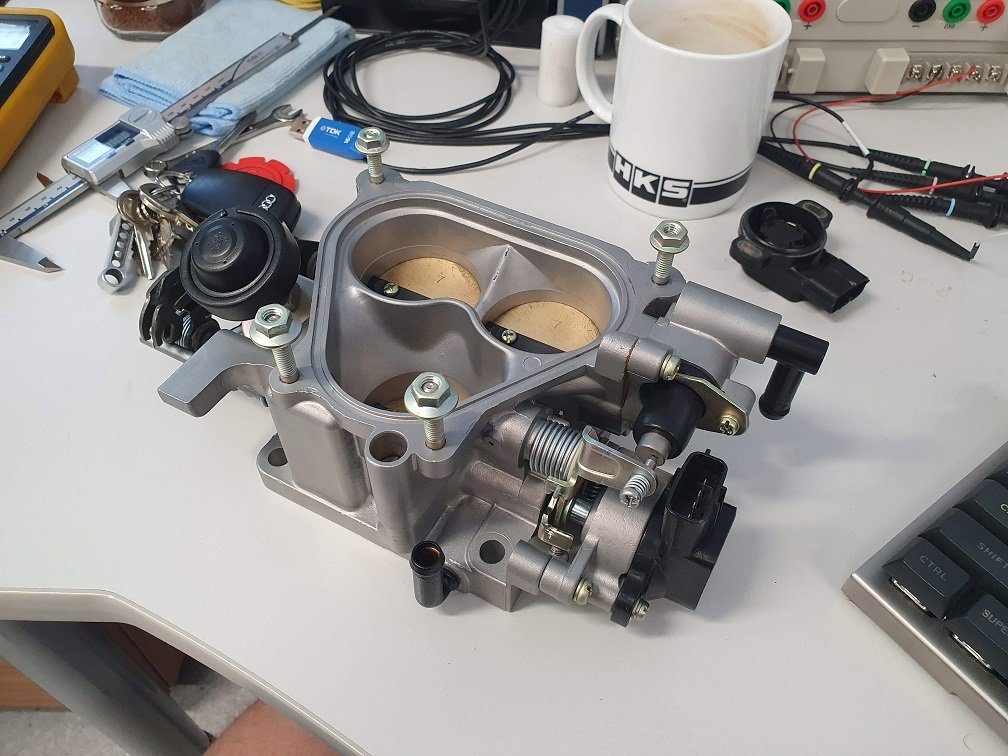

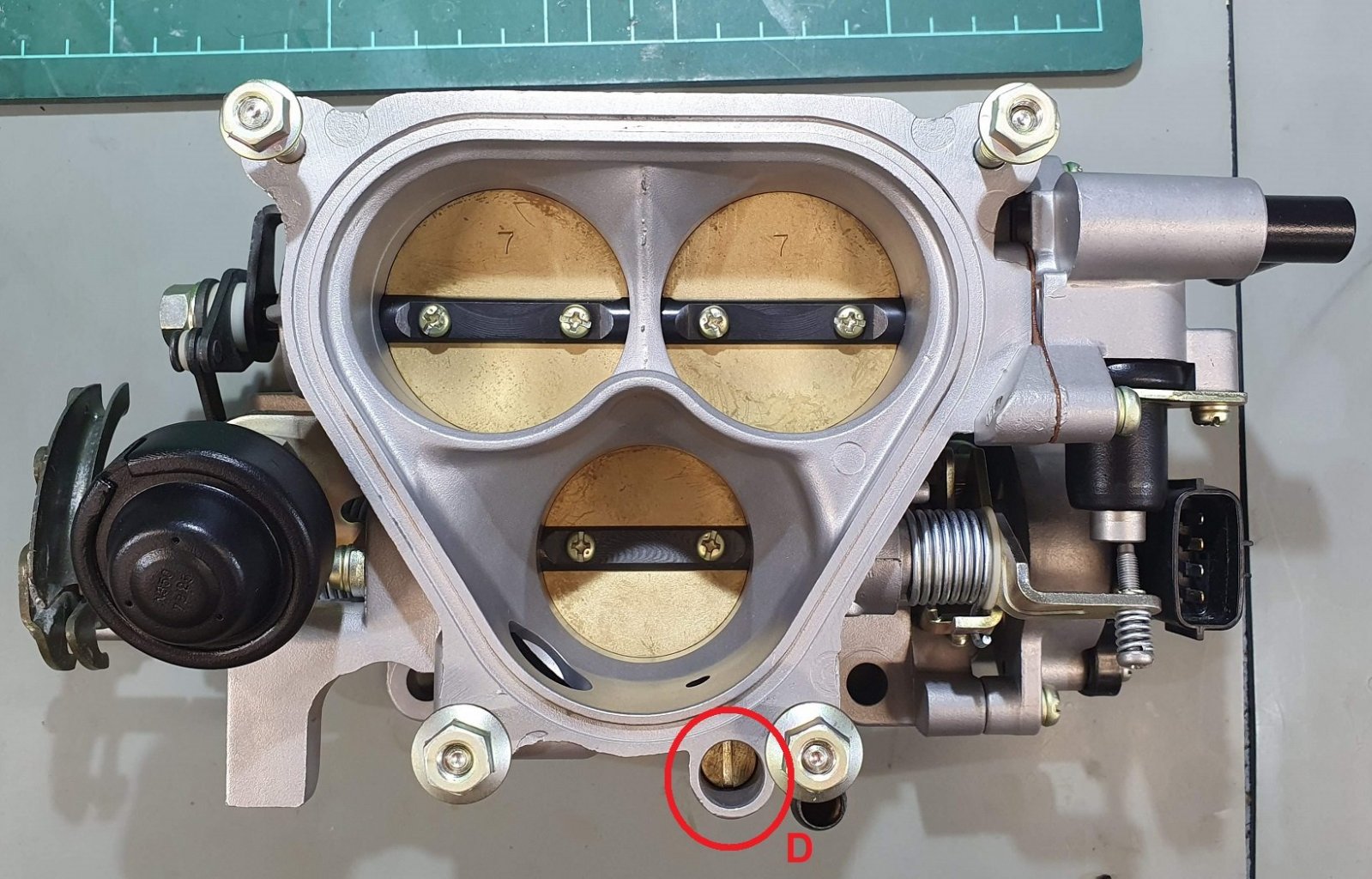

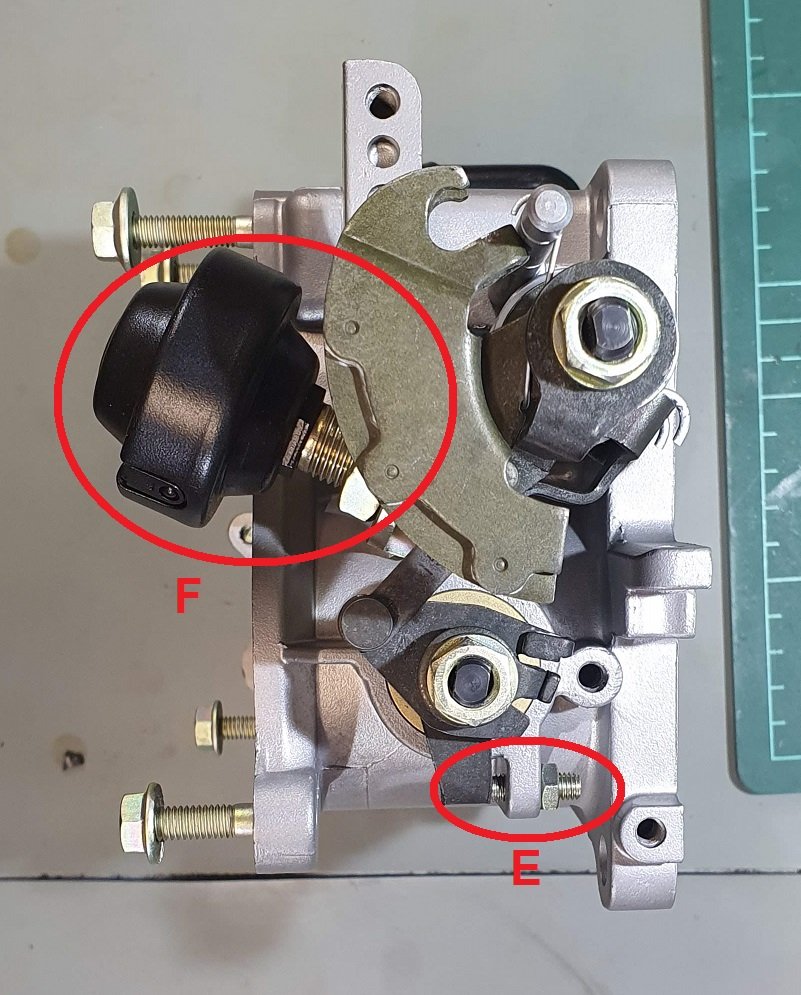

Whoa, the throttle bodies on these things are a..... thing. I got the above jigsaw all back together. Turns out I'd lost one of the plastic spring bushes, and the flange on the other was cracking off, so I grabbed an off cut of acetal from work and turned up a couple of new ones. That let me get the thing reassembled. I took a heap of photos of how everything came apart, so getting it back together wasn't too much of an issue. Kinda fiddly in spots, but follow your nose and it goes back together reasonably easily. The throttle shaft seals still seemed pliable and plump, so I didn't replace them... Time will tell if that comes around to bite me in the ass. Ideally I'd like to go with some sort of e-throttle setup in the future. There wasn't actually a complete throttle body with the car when I got it, so I purchased this one secondhand, and it was pretty filthy: But, it was complete, and moved smoothly :-). After stripping, blasting everything (lots of careful masking involved), kind of a pain in the ass.... Much better. But holy crap, there are a lot of adjustments on these things! There are threads all over the internets of people having problems setting these up, so I thought I'd better develop a plan to follow. Not saying the plan is a 100% way to go, but I need something to follow so I can go through a process and collect data, and iterate from there. Going to write this plan out here so I can refer back to it later when I've forgotten all this again. The first screw I've set is screw A. This is the stop that the single butterfly stops against. This single butterfly feeds the primary intake ports. As it's in the name, these port are the primary ones, so they're used all the time, along with the primary injectors always delivering fuel. My initial setting for this is that the primary butterfly stops against this when it is fully closed. After aligning the throttle blade, and thread locking the screws in place, I let the throttle close as far as it can against the housing. I then advanced this screw till it was just in contact, then about 1/10th of a turn more. This should mean the throttle blade is never eating the throttle body housing, but closes as much as possible. Screws B and C adjust the cold start warmup system. You can see the two black pipes in this picture. Coolant flows through these, which warms up and extends the wax pellet push-rod screw B is pushing against. Unfortunately they're a little corroded on the outside, but there is still heaps of metal there. Will always run anticorrosive coolant in this, so should progress any further. This wax pellet rod extends as the coolant gets hotter, and retracts as when things cool down. This screw is threaded into a cammed bracket, which has three marks on the cam (one of them is obscured by the red oval I've drawn, but its there). The FSM has specs for the relative positions of the roller on the bracket screw C threads into (we'll get to this one in a minute) and the cam at different temperatures. The upper most (in my picture) mark should be central on the roller at -20degC, the next one down at 0degC, the next one down at 25degC, and finally off the lower edge of the cam at 60 degC. It's pretty hot in my office today, so I've adjusted screw B such that the roller is lined up with the third mark. Screw C adjusts how much effect this cam actually has on the throttle blade position. As you screw this in more and more, it opens the throttle blade more and more, as long as the roller is contacting the cam. I suspect the final setting for this will be such that the roller separates from the cam just as it is passing over the lower edge, with without a sudden jump in its movement. Currently, I've set it so the roller is only *just* touching the cam at this 25degC position, for reasons that will hopefully become clear :-). Cold start systems are important, but they're only ever going to work properly if the base idle speed with the engine at normal operating temp is setup correctly. The throttle obviously has adjustments for this as well. Screw D is called the Air Adjust Screw (AAS), and screw E is called the Throttle Adjust Screw (TAS). Screw D has a tapered end on it and fits into a matched tapered orifice. This orifice is connected across either side of the primary throttle blade, so as you back the screw out, it allows more and more air to bypass the throttle blade. Screw E is the stop for the the secondary throttle blades, and sets their closed position. In practice, these screws have the same effect on the idle, in that they will let more air into the engine. There is a slight difference though, as at idle the ECU wont be using the secondary injectors, so adjusting the idle with screw E will let more air into the engine via the secondary ports, but this wont have any fuel injected with it. This wont be an issue though, as at idle things are happening very slowly, and there is heaps of time for the charge to mix in the combustion chamber as it whizzes around to the other side of the motor to make brap brap noises. Reading the FSM, what I can parse out is that you use screw E to broadly set the normal operating temp idle speed, and then screw D to fine tune it. I've set screw E in the same way I set screw A, such that the secondary throttle blades fully close to within a bee's dick of the throttle body housing. I've wound screw D all the way in, so there should be no air bypassing the primary throttle. The last adjustment is the damper dashpot, F. This is a damper the throttle closes against. It's hard to push in, but extends with no effort. Lots of bump damping, no rebound damping. This needs to be set with the motor at normal operating temp, and such that the throttle breaks contact with the plunger at an engine speed of 2600 - 3000 rpm. Obviously this will need the engine running properly at N.O.T. To setup, so I've wound it out so it doesn't contact the throttle at all. Reading through that, there might seem like some odd decisions, as I've essentially set the throttle up in such a way to ensure the thing isn't going to idle. It's going to have almost no air bypassing the throttle, will starve and die. This is for a reason however, and comes back to how I like to tune a setup. First thing is to get the engine firing and running, probably with some throttle manually applied. Then I can get it up to temperature, check for leaks, fires, all those things. With the engine up to temp I can use screws D and E to set the normal operating temp idle. It's really important this is done without the cold start system having any effect whatsoever, as if it is, when you go to set the cold start up, your normal idle setting will also be effected, and you'll end up chasing your tail. Now, the FD also has an ECU control idle air solenoid which can allow varying amounts of air to bypass the throttle, but for all this initial mechanical setup, I'll keep this unplugged to eliminate it. AFAIK the ECU only uses it to idle up the motor when the A/C, power steering, or alternator are loading things up. There is also the TPS to think about. The FD TPS is a little odd in that it has two analogue output channels, narrow range and full range. Talking to Ray (arghx), it sounds like this is a throwback to the FC3S days, and probably something to do with Mazda re-using existing code in the FD ECUs. Total speculation, but having been an engineer on a few evolving projects, this is totally something that would happen. The FSM has specs on setting this up. With the throttle closed, adjust it so the narrow-range signal is between 0.75V and 1.25V, and the full range signal is between 0.1V - 0.7V. I powered up the TPS from my bench supply and set it thusly. Strats: Stock ECU initially, to get things running, proof the rest of the system, and ensure it doesn't burst into flames. It's a 'known quantity' as such. Make the thing run, will need the throttle manually opened to keep running. Get it up to normal operating temp Make sure everything is functioning like it should. No error codes from the ECU, so no limp modes or anything (exception to this is the idle control solenoid, but I can trick the ECU into thinking this is fine with a resistor in its place). Adjust the warm idle speed to just below target (~750RPM) with screw E Adjust the warm idle speed to the final target with screw D. Adjust dashpot F so the the throttle breaks away from the plunger at an engine speed of 2600RPM. Turn the thing off, go inside and have many whiskies. Recover from hangover. Remember: You're old now, this might take a couple of days. With the thing dead stone cold, try to start it with no throttle applied. Expectation is that it will not start. Advance screw C 1 turn, try again. Repeat this procedure till the engine starts with no manual throttle opening. Idle speed should be higher than warm idle target. Allow the engine to warm up, idle should reduce gradually as it does and the wax pellet rod extends. Iterate from here. The only screw that should need adjusting at this point is screw C. Hopefully I can pull that off. In other news, most of the supplies needed to build the EM (main engine) harness have shown up! Huzzah! I'm going full ham-spec on this. The car doesn't need it at all... But I've built lots of high-tier harnesses before for other people, and I really want something totally schmick for my own car for once. M22759/32 throughout, twisted, DR25 sheathed, booted, sealed.. All the good things. As much as can be with using OEM automotive connectors also. I've designed it with lots of extras in mind down the road, as I don't want to have to build another one for this car, ever. When I want to change out the ECU for something other than the stock one or a power FC I can just make adaptor harnesses at the ECU end, nice and easy. Just got through the design process for the layering, built a test section for the main core to make sure it was going to lay up nice, looks lovely :-). Progress is progress?- 50 replies

-

- 26

-

-

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

Time for a quality Christmas jigsaw! Need to find the corner pieces... Actually I think I'd prefer they stay inside the motor ;-).- 50 replies

-

- 17

-

-

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

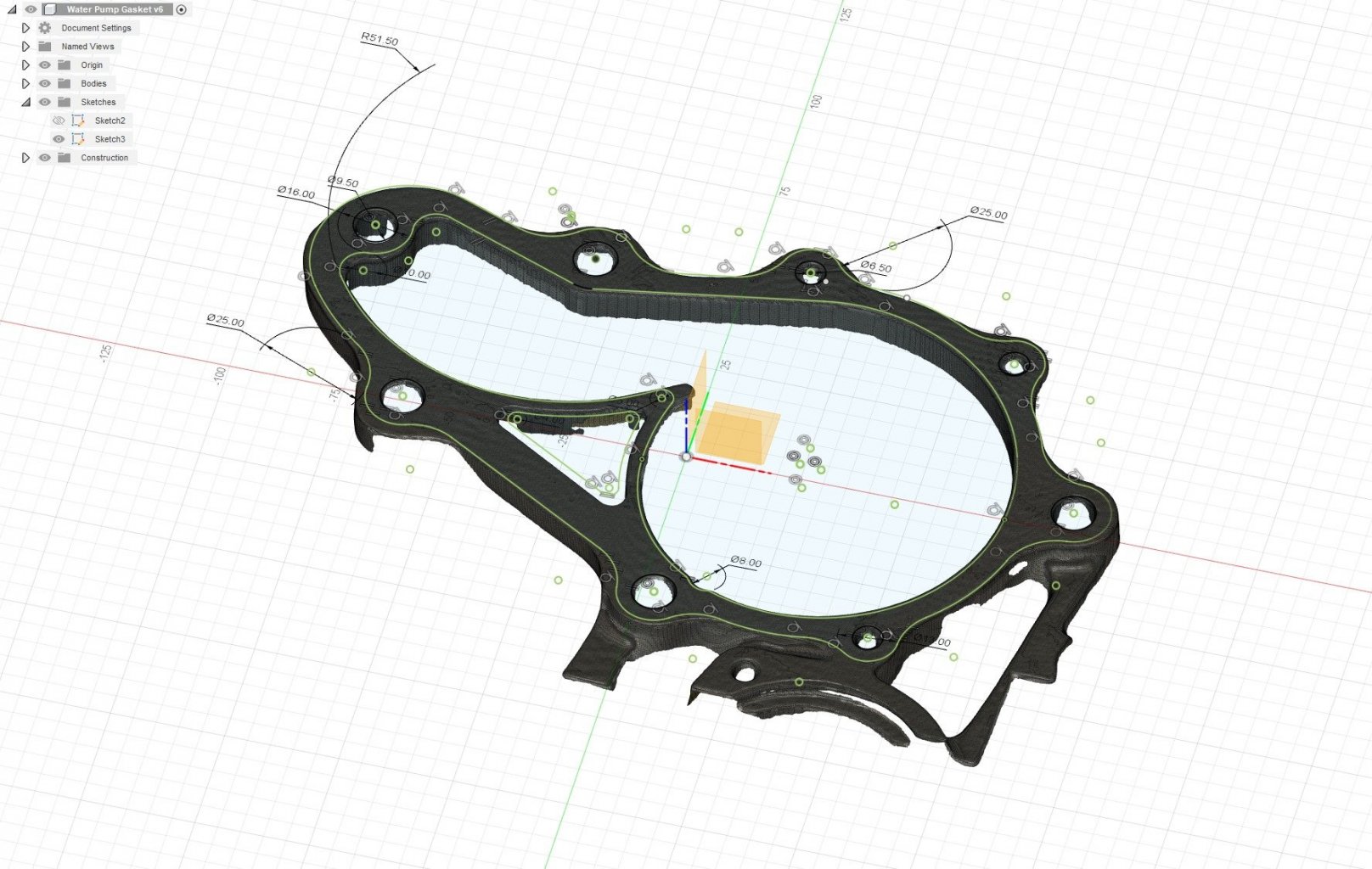

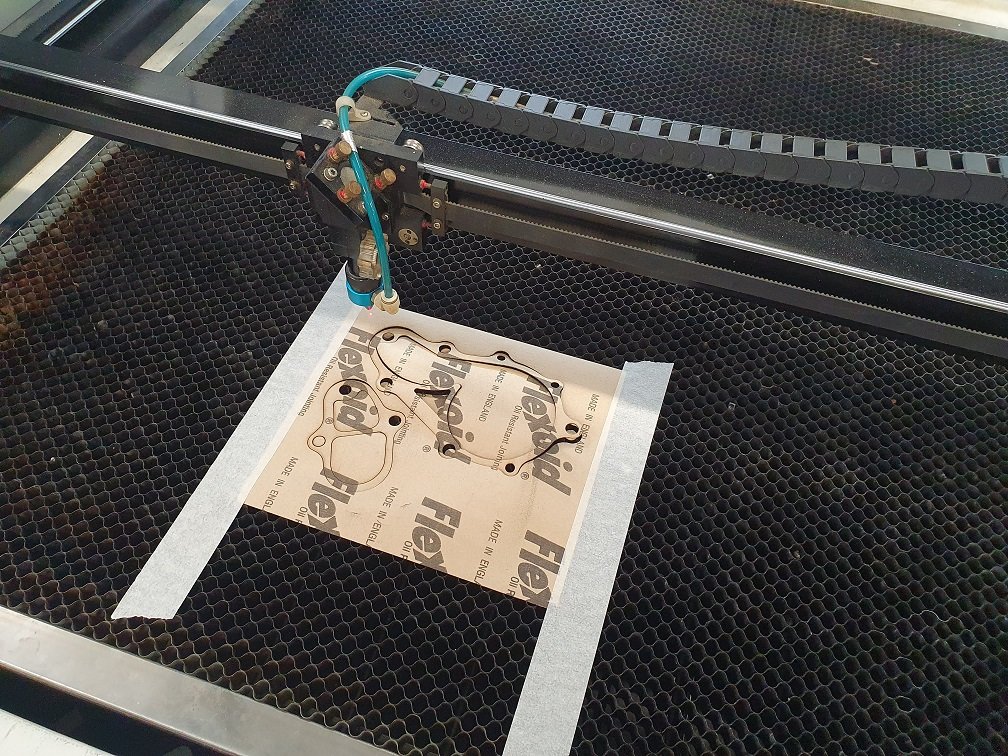

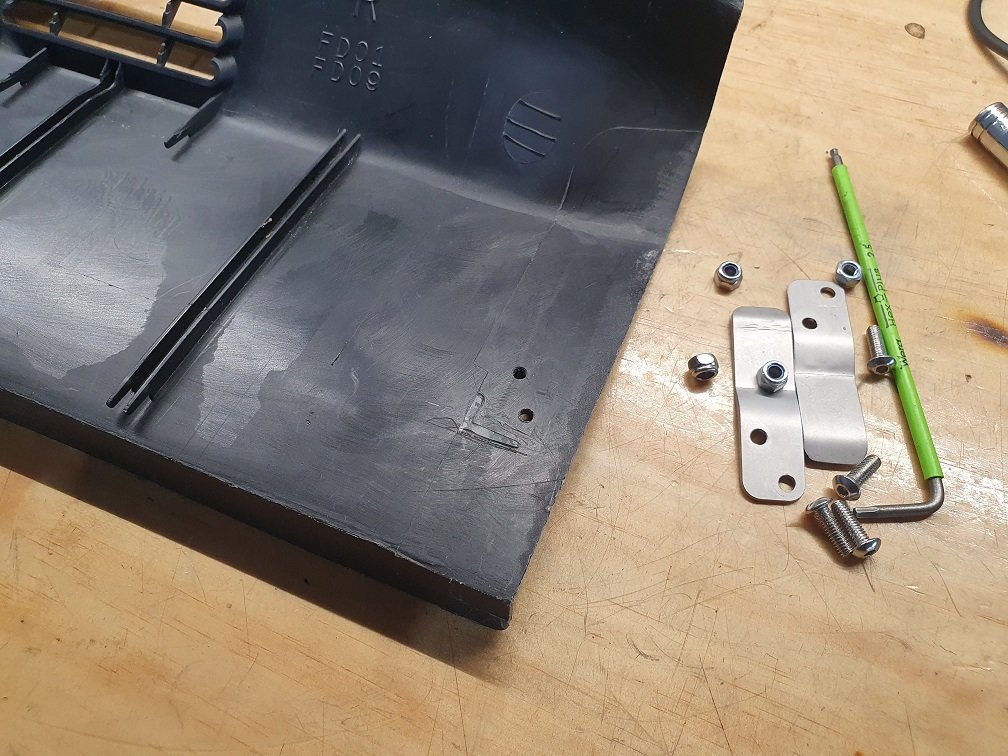

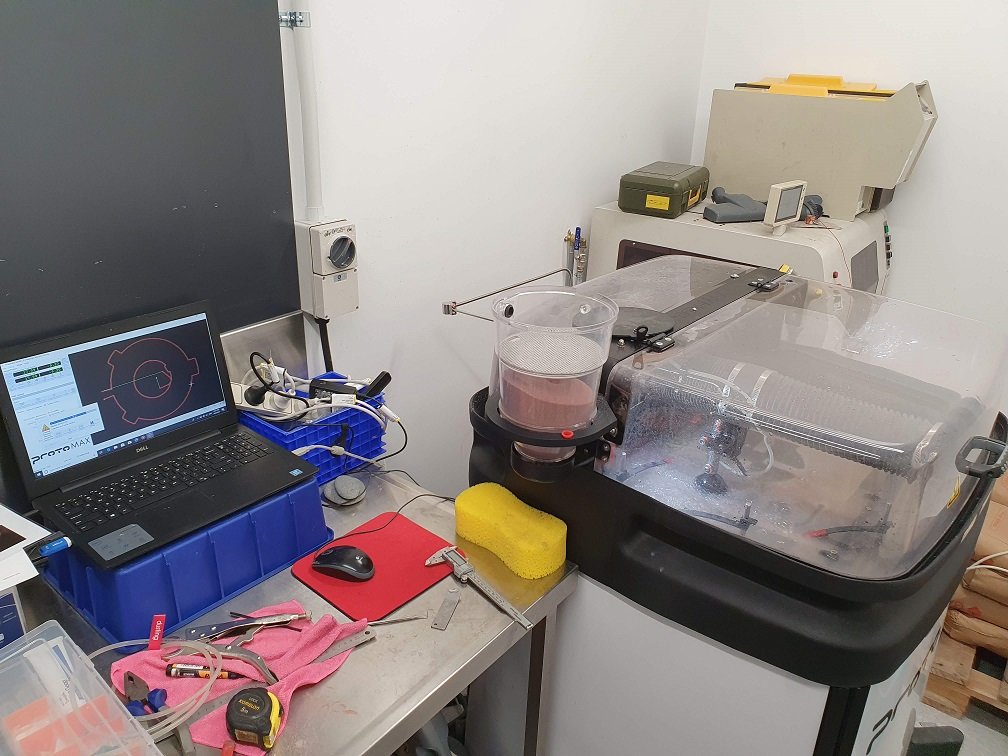

I have been working on important engine things, honest! Part of that has been getting all the gaskets sorted, making emissions block off plates, re-kitting the injectors and manifolds... etc, etc. Will tidy all that up and post about it. Nothing like using a 6 figure bit of gear to make a $3 gasket though... Usually I just use a flat bed scanner, with a ruler in the frame as well for scale, but this wont lie flat on the scanner. Some CAD: And the laser cutter. I've cut all the other gaskets I need basically the same way so I don't have to nickel and dime around waiting for them to arrive. Plenty of ways to skin this cat, but I've got access to the gear, so may as well use it. The small win project was the rear boot trim. The piece at the very back of the boot space is broken on most FD's that I've seen. They've meant to have these clip pieces to help keep them from flapping about: (Image stolen from the nets). Both of those were snapped off on mine, and the one two I have also... I suspect you can see where I'm going with this. Obviously the fasteners stick out like dogs bollocks at the moment, but I've got something in the works for refinishing all those boot plastics back to as near as OEM as they could get, and I'll powdercoat the heads of those fasteners, and the clips themselves when its all apart again. It's..... terrifying when something works first time, but, well, hmmmm, here we are? I could cut them again, and do a better job of bending them in the brake, as opposed to bashing them in the vice with a hammer..... But really, they're fine as is.- 50 replies

-

- 18

-

-

-

Zac's rotary redux project, because he has too much spare time.

ProZac replied to ProZac's topic in Other Projects

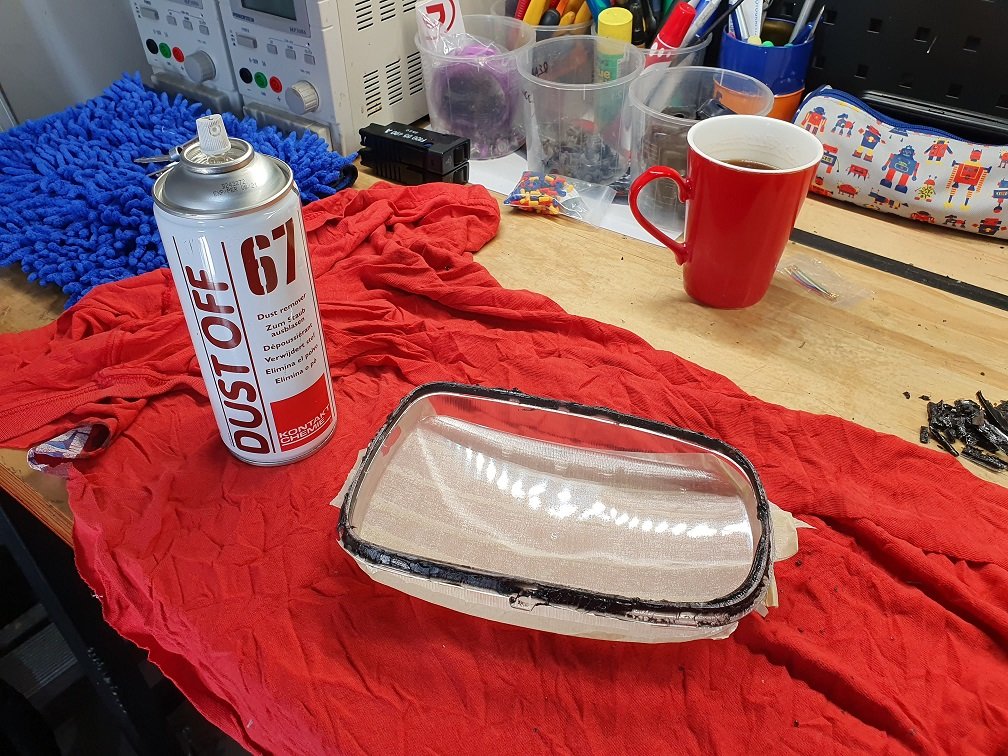

I'm going to technically claim that this counts as working on something the car critically needs to work, as headlights are pretty important, really. As should be pretty obvious, this thing has had a home-based re-spray at some point, and the person doing the job was not exactly clinical with their masking, so its dusty red and dirty clear overspray just.... everywhere. Including all over the headlights. I've sanded and polished a few lights in my time (including every other exterior light for this car...), so was anticipating a relatively smooth, if somewhat tedious job... Instead, I veered hard left (well, actually, I made that turn a long time ago, so I just stayed on the road I'm already on...) and decided to do a projector retrofit. I don't really have any defensible reason for this, other than I think they look cool :-)... Well, and I remember the headlights in my last FD being just terrible, even with replacement higher wattage bulbs. There are a couple of places that sell these ready made for FD's, but I'd be looking at around $1500 kiwi, and that's not money I'm willing to part with for something I can do myself (this is always flawless logic...). After researching a bit on the topic, It looks like the way to go is to use a pair of the available aftermarket headlight housings that shift the beam pattern generation onto the housing itself, and use a totally clear lense. There are a few places selling these, but they're all the same SONAR housing. I found a pair for sale cheap on ebay, so was around $180NZD into things. Getting them apart suuuuuuuuucked. Well, that's not strictly true, it wasn't particularly hard. Remove the spring clips, heat liberally with a heatgun, and pry slowly and gently... what sucked was dealing with the adhesive after the fact. This shit is sticky, and gets everywhere. It is reusable however, so if you can get them apart cleanly, you'd be able to re-heat the glue, reassemble and have them nicely sealed again... This is not what I did because.... reasons. Instead I decided to clean off all the glue, and will re-seal them myself using some butyl tape... I regret this decision. Prying all the old adhesive out with a screw driver took ages, and removed a lot of the chrome finish. Petrol was pretty decent at dissolving the residue left behind. I managed to slip with the screw driver and scratch one of the housings on the inside pretty decently. Guess I'm painting them then! The lenses are polycarbonate (I'm pretty sure, anyway), and solvents will mark them. The best way I found to get the glue off these was to freeze it. It would then chip off pretty cleanly, and the residue could be removed with some citrus goo-gone type stuff. Dispose of this shit while it is still frozen, because once it warms back up to room temperature, its fucking annoying to deal with. With the housings apart and cleaned, I started measuring things up, and settled on some 2.5" bi-LED projector units. These set me back around $80, and a two month wait. Lots of sellers of these on aliexpress, but they all look like they're made in the same factory: https://www.aliexpress.com/item/1005002797444025.html?spm=a2g0o.productlist.0.0.177c7147zgorov&algo_pvid=9558ac48-7b09-434a-802a-155a9e69b03d&algo_exp_id=9558ac48-7b09-434a-802a-155a9e69b03d-4&pdp_ext_f={"sku_id"%3A"12000022229395886"} If you're ordering any, make sure you get them with the correct beam pattern for the side of the road you drive on. Left in this case of course :-). From the measurements, I figured they'd fit inside with a few mm of clearance to the front lense. They come with an adaptor to mount where an H4 bulb originally went, so that's a score. Once they arrived I mocked them up, and immediately found that the adaptor mounts put the projects at totally the wrong angle, and the beam pattern was rotated along the axis of the car by around 20 deg. I 3dprinted some other adaptors and for them nice and level, and things were starting to look good. 3d printed adaptors aren't going to cut the mustard though, as they'd soften and melt with the heat of the projectors. Luckily we got a little waterjet cutter at work a while back, and its just bloody perfect for stuff like this :-). Cool. Now the rotation of the beam pattern was correct, I gave aiming them a go, and discovered that to get them level I was running out of adjustment on the bottom adjuster. Cue some more 3d-printing to make another insert. This bolts on using some existing holes so everything is totally reversible down the track. See all that dusty overspray? It's literally everywhere, that's the shit I'm dealing with. Phew, now I had enough adjustment I could get everything squared up. As I munched the housings pretty good cleaning them up and generally fucking around with them, they needed paint to look presentable again. cue some blasting to prep them... And some gun-metal touch up paint. Side note, seems repco isnt stock these little cans anymore. Shame, its really good paint, dries in like 5 mins with a heat gun, sprays out really well, and is just excellent to work with. It's more of a semi-gloss finish once it's dry, which looks really good in the housings. Time for final assembly and another test-fit! Hmmmmmm, frog eyes. I like them, but... honestly, it was a hell of a lot of work for maybe a questionable result? Hah. At least I had fun. Obviously haven't driven with them yet, but testing at night in the driveway shows a hell of a lot more light, in more distinctly correct places than the factory ones. That being said...... I also restored the factory housings. You know, because the projector ones are probably not even vaguely legal, and maybe these will actually work okay with some of the new-fangled LED replacement bulbs that are apparently not-shit?- 50 replies

-

- 20

-

-

.thumb.jpg.b3b24bc64011b653edea363649a1b871.jpg)

.jpg.5d94bba64e109d2c88eca846cf298e20.jpg)