Leaderboard

Popular Content

Showing content with the highest reputation on 08/12/19 in all areas

-

8 points

-

8 points

-

Sunday evening update time. Fuck the weeks go past fast, I must be getting old. I made some hatches for the rear openings; I added some covers for the drawers so my tools don't fall out; I have yet to find a really good lock system for those big drawers yet... I then made a bracket to hold a power steering reservoir in a place where it was easy to access; I made some radiator supports; After I made these I found the Dyna rad supports in my box of shite, so now that I have adjusted these into the correct position with the cab on I will probably change these over. The Dyna ones have some isolation built in which is a good thing. The rad itself is sitting on two M8 isolation mounts on the underside, connected to that bit of angle. I will cut the angle into two smaller brackets, that shit was just to get them in the right spot during the setup. All snugly in place. The reservoir cap does hit the cover so something will need a cut and shut. I then stood back and admired the goodness; O fuck yes.8 points

-

Not one to let a nasty cold get in the way of progress, I did some more work on the TVR today. The first course of action for the day was to see how the car starts. After a couple of splutters and a bit of cranking (much less than yesterday), it fired into life. Not perfect, but better. I couldn't help myself and had to take it for a quick run down the road and back. This uncovered a couple of things. One, the steering wheel is WAY off centre (which I didn't know whilst trying to back up my driveway), and the brakes pulsate a lot. Hopefully, an alignment will sort the steering issue, and some hard braking might clear the brakes as I suspect they are covered in rust/dirt. On the plus side, it did go down the road in one piece. I didn't get out of first gear (very short road), but the clutch seems to work well. Its too wet outside to go further, with no wiper, and a very un-weatherproof roof. When I returned from my maiden voyage I wanted to have a look at the plugs. I only removed one, but that was enough for me. They don't look that old, but very black. Not wet which is good. According to my records, they are the wrong heat range and should be BPR5ES I'll grab some new plugs and swap them out. Hopefully, that sorts some of the niggles when starting and running. Not to be deterred, I pushed on with some other little jobs. First was to upgrade the radio to work with my phone, and crank some Spotify. It was a quick and easy upgrade. Aww yeah, A cassette adaptor I had kicking around for years (see, hoarding works!). Actually works surprisingly well and doesn't sound terrible. All speakers work, and the flash EQ works a treat This can stay for a bit. Does what I need it to do, although I need to work out how to get the antenna up so I can get FM stations too. It's not like I really need music though, the engine is music enough. With that success, I moved onto the next thing on my list. The dodgy headlight switch. Two things bothered me about it. First, the wiring was dodgy enough to need wiggling to work, and second, the switch was upside down. The icon was on the bottom, and the switch was up for off and down for on. The switch pulls out the front once the connector is removed, but there is also a white plastic sleeve that pushes off. The sleeve is to illuminate the icon via fibre optic cable, but mine isn't currently working. The reason for the wiring being a bit dodgy was that the connector has obviously suffered some high resistance and the plug housing is damaged, allowing the terminal to float freely I pushed it firmly into the connector on refitting, but I may need to close the terminal a bit to make it a tighter fit. I also need to look into using some relays to re-wire the headlights directly and take the load off the switch. The switch its self had some minor corrosion on the terminals, but nothing a quick scrape with the screwdriver couldn't sort And refitted the correct way around. Down for off, up for pop-ups UP. The next thing that bugged me was the interior light switch... which seemed to be missing everything but the surround. The interior lights didn't work. I removed the surround and found the guts of the exploded switch had been pushed down into the center console. I carefully fished the switch block and connector out. The rest of the springs etc are stuck down there and can stay there until the console has to be removed You can see a good example of the black wiring in this car. Each wire is black, but does have a coloured collar at each end to identify it. Its not actually that bad to work with, but coloured wires are still preferred. Using the handy diagram I checked which terminals did what on the switch Obviously the two bottom ones are a joint +12, and the two other terminals are either "door open" or "on" settings (grounds to turn light on). I tried bridging them with wire and got nothing from the lights. I popped one of the lights out to check the bulb (there was one, it's removed in photo) The bulb looked good, so out comes the multimeter. No power at the light when the switch terminals are bridged. No power at the switch +12 terminals. Hmmm. Ok, what's upstream of the switch? The fuse. I had checked the fuses visually yesterday and they all look good, but something was obviously up. Interestingly I note that fuse 6, which powers the interior lights, also powers the hazard lights, which also are not working. Interesting. This is the fuse and relay box. Lovely. Fuse 6 is the red one about halfway down. It wasn't blown, and the multimeter said I had power on each side of the fuse. The power comes into the fuse on the RH side of the photo and out on the LH side, through the fuse. I disconnected the wiring, removed the fuse, and cleaned everything up. There was some corrosion in the terminal, and everything is very dirty. The result was this Hazard lights! A handy thing to have on a British car. Which also means, I now have power to the interior light switch. I popped an LED bulb into the holder, and bridged the terminal Ooooooh, light. Only one was working, so I jumped onto the passengers' side, popped the light out, and found that the wire hanging under the dash was from that light. I popped another LED bulb in that one, reconnected it and BAM, let there be light! Because the switch was buggered, and there was no point in finding another. It only operates these two "knee" lights, so when am I ever going to need to set them to "on", and they are LED so no point in turning them "off" when they turn off when the doors are shut anyway. I decided to bridge the terminals and leave it. I made up a jumper, using a pair of specially modified (squished in a vice until they fit) bullet terminals and some wire. To make it pretty, durable, and safe, I wrapped the lot in tape and then stuffed it into the center console TVR-Parts still sell the switch blanks, so I'll grab one of those and replace the interior light hole with one of those Unfortunately it wasn't all quite straight forward. The door switches weren't quite playing ball. The passengers side wasn't hitting the pad on the door correctly so wouldn't trigger the lights to turn off when shut, and it turns out the drivers side one had been unplugged. I swapped that over, so the passengers side is unplugged, and the drivers is now plugged in and working correctly. So, I now have sweet interior lights, and working hazard lights. Isn't it inviting? Love the warm white LEDs. Much better than the usual cold white, or incandescent bulbs. Also puts a lot less strain on the wiring and battery. Its small things, but in the world of British cars, it's a big victory to have things working.7 points

-

With the head sorted i can put the camshaft in and check piston to valve clearance. But first I need to dowel the head to the block. These old beast come from the factory without any location other than the head bolts. So I center off one of the head bolt holes and drilled it to 14mm. Then bolt the head one without moving anything and drill the head bolt hole out to 14mm. Then fit the head on the dowel and drill the other head bolt hole for the second dowl. So dialed the cam in. Then bolted the head on and found my rockers where a little worn so gave them a tidy up. Forgot to take pictures of the head fitted. But basically fitted the head, put two layers of plastersene on top of the piston in the valve cut outs. Then turned the engine over to get the valves to in print into the plaster. Then I cut half the plaster away to see how thick it is. This gives you a good indication of the piston to valve clearance.5 points

-

It's been a long time since i've done a post, because it's been a long time to get me motivated to install the wiper linkeages. I ended up just buying some M18 x 1.0 pitch nuts off ebay for $15, and a week later they arrived. instead of procrastinating about it for 4 months i really should have done it sooner.... Since last update: Installed AE92 FX-GT front seat belts Installed previous exhaust from old KE30 which is 2.5" to the extractors and a nice dumpy at the end Rebuilt front brakes, it's nice when they work properly. installed a new healthier 4K motor and went to a chinese carb from eBay that actually performs quite well. I will go with a weber 28/36 if I can find one but it's good for the interim New Coils, plugs, leads, fuel filter (the other new one i bought has clogged up with garbage. Not surprised) Installed 3.9 ratio diff head from a KE70 to fix it's awfully high revs with the 4.3 Fixed rust on the under chassis rail TODO: Fix brake pedal on the brake switch because sometimes it doesn't disengage Get centers repainted on the SSR Mesh's Get underside sand blasted and painted/under sealed Find center trim chrome for rear lights ugly photos. will get some nicer ones this weekend I repainted the plates with satin black paint, it looks really good, I didn't completely sand it back to the bare metal which i'm actually happy about. makes it look a bit dated in a way with some of the left over paint overtop Then I went to VTNZ. The guy loved it. He also stuck something on my windscreen.. Time to fix the small issues with the car, and drive her around for a bit. happy with how it's come out in the end, proud for a first time project of this scale for it to have come out so well. Looking forward to starting on another! Build discussion:4 points

-

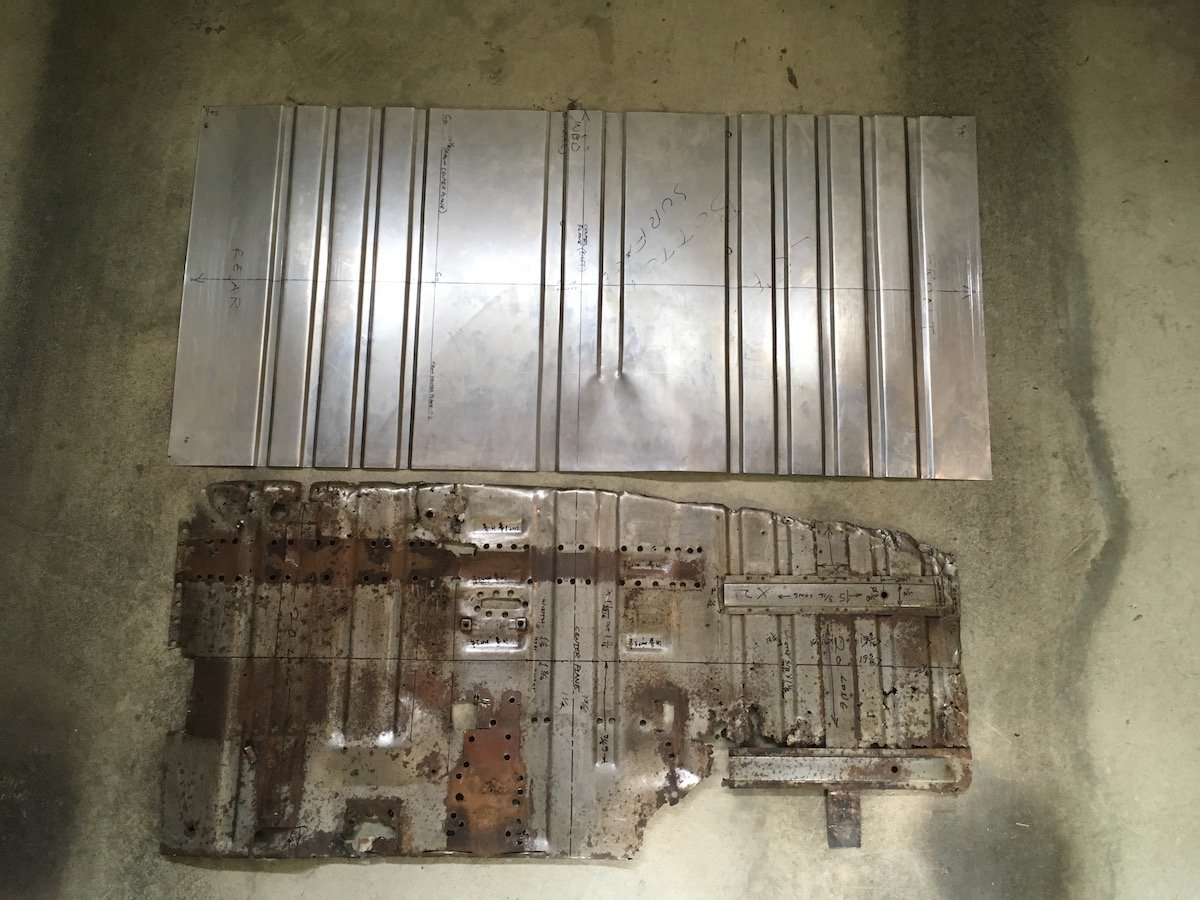

Back to work on reproducing the '61 310 Bluebird left side floor pan. First, I drilled out the spot welds to all the bits I wanted off the original floor. Top side Bottom side My collection of saved and de-rusted parts; including the seat bracket, longitudinal stiffener structure, hand brake reveal, B-pillar body mount bracket, and a couple of other brackets that are too far gone but get in the way. Bought some more steel sheet. Four foot by eight. I cut out a 26 by 56 inch blank and made some corrugated steel with a bead roller Scraped most of the under seal off the old floor pan bottom surface, did some measurements and began duplicating what was left. The bottom surface was more useful for measuring since it was much less rusty than topside. I'm leaving an extra inch or more all around to accommodate fit and trim later. Side-by-side compare Now I have to figure out a way to form some of the 3D shapes around the where the B-pillar body mount goes and the shallow depression under the hand brake lever. Hammer form over a wooden buck? Or form separate parts, cut the floor and weld in? Still have lots of work to do. Discussion: https://oldschool.co.nz/index.php?/topic/60267-marts-pl310-61-datsun-bluebird-sedan/4 points

-

You would have to look into the laws in your area, ie here in Brisbane the law is vauge and some spray painting at home is allowed as long as it is not commercial. You have to look it up, It was legal to spray my car in the driveway and I asked/told the neighbours about it. I mean guys reseal roofs with spray in open atmosphere, I have seen the exterior of homes spray painted. Case by case for your council. Bling phosphoric acid is not hard core, I buy the bunnings shit and dilute it a little further depending on the job. It doesn't sting the skin and fuck all fumes unless you boxed yourself in with a bath of it working. You can do the same thing with citric acid or vinegar for sure but the phosphoric seems to be just the right zing for panels where it takes 15-30min instead of 4 hours, when I was soaking shit in citric acid baths it takes 24-48h to work. Unsure about anything else as using acid is the gold standard as far as I have learned. As for spraying safety I had looked it up a millon times but looked again. Modern 2 part epoxy primers are only considered mild irritants and only fuck you up over long term exposure without correct PPE which can give you allergic type reactions, they do not cure with isocyanates. They are just as shitty as exposure to single stage solvent curing paints basically so wear a mask and its all good. Its the polyurethane ( urethane primer, single stage top coats,clears etc) that cure with isocyantate and are considered extra death spec which gets absorbed through the skin and can build up toxicity.4 points

-

So I guess this is where we start then. The first port of call today after having the car delivered was to work out why we had no power. I popped the bonnet, and yes there was a battery. Ok, let's remove the battery and see if I can throw some charge into it. Ctek says NO. With the charger connected to the battery, nothing. No lights on the charger, and if anything, the charger started acting weird. Guess that's no bueno then. Hope my charger is OK. A quick trip to Supercheap sorted out a battery for me. There is very little space for a battery, so a bit of digging in the Century Batteries catalogue yielded the biggest battery that would fit the same footprint, an NS60LSMF Connecting this up showed that we finally had power. The dash warning lights come on with the key, the driver's electric window is working, albeit slowly, and the central locking works. Strangely the headlights did not respond to the switch, but some wiggling of the wires behind the switch sorted that out (yeah, I'll need to look into that). The next obvious step was to see what was up with the fuel tanks. Now that I had power I could see the fuel gauge was reading empty. I decided to take a risk and try dumping some of BPs finest 98 and injector cleaner into the tanks and see what happens. I split the fuel and cleaner between the two tanks as evenly as I could. Since I had been told it was possible the accumulator had failed, there is a trick to work around this and still have the car start and run normally. The accumulator works to hold fuel pressure in the lines when the engine is off, but when it fails the lines no longer have pressure, and the fuel pump only runs when the engine is turning, so it takes ages to build that pressure back up. The trick to work around this is to have the pump run when the key is turned to ON so it primes the lines. The simplest way on early cars like mine is to disconnect one connector from the side of the fuel distribution unit. This causes the pump to run when the key is on. Easy. Its the blue connector in the top photo, and the green plug goes onto it (strangely... why arent they matched colours?) I connected the battery and turned the key. Sure enough, I heard the familiar whine of a pump turning, and then the woosh of fuel heading down the lines into the fuel distributor. Now it was the moment of truth. I turned the key, and the engine turned smoothly over. It spluttered a couple of times, but wouldn't start. What a tease. Eventually, this happened. It was rough, but running, and even idling. I ran it for a while, and everything looked good. No obvious signs of leaks, but blimey does it make a noise! The longer I ran it, the smoother it was getting I checked and it seems to have gears, and a clutch, so that's a big win. It still hesitates a bit, but that's to be expected for an engine that has been sitting around. I'll take the plugs out and give them a clean (or replace), and check the cap and rotor condition. If everything looks OK, it may even be time for a quick run around the block. One must wonder though; if I can get it running with little effort, why couldn't the "specialist" have it running for the truck? Oh well, best not to dwell on it I guess.4 points

-

Well, it happened again. Somehow awesome old British cars that need loving find me, and of course who am I to turn them down? This car has a bit of a weird story, but I guess it adds to the history of it all. It all started when I had the M328i listed on Trademe, back in March, and in amongst all the useless time-wasters asking me dumb questions, I got asked if I wanted to swap the black leather vaders for white leather seats from another M3. Of course this was a no, white leather is one of the worst wearing colours in the E36. The fellow wasn't done there though, he wanted my seats. The next question he asked on my listing immediately had my ears perk up, and suddenly I was intrigued. Yes, that's right, a TVR. After a bit of googling I worked out an 80s TVR would be a Wedge. Not the most loved TVR, but I like them, and any TVR is a good TVR in my books. It's 80s, it's British, how bad can it be? Of course I was interested, and let him know. Later that night I get a call and discuss the car. Its been off the road for a few years getting some work done at the "local" TVR specialist, in Auckland. Ok, no problem, except the owner is down in Christchurch (about 1000km and a large body of water away from each other, and I'm somewhere in the middle of that). It turns out that he wanted my car, because he was buying a convertible E36 M3, and wanted to swap my black leather into it. He also had thoughts of "Trevors last drive" by flying up to Auckland, picking up the TVR, driving it down to me, swapping to the M3 and for him to continue on his way down south. As I found out later, this would've been a big ask for the TVR. We discuss the ins and outs, and I'm recommended to contact the specialist and discuss the car. I give the specialist a call and discuss the car. Apparently it's all sorted, and basically ready to "fly through" a WOF and to hit the road. Its had various work done, including most of the hard work like suspension. He noted it does have an issue starting, which is possibly down to a failed fuel accumulator, but does run and could be driven onto a truck. His description of the car was that its a good solid, tidy car, but may need some carpets as they are a bit worn. I was very interested, but needed photos to see what condition it was in. Ok he said, he will try and sort some for me. To cut a long story short, I tried for months to get photos of the car, with every reason under the sun for not getting them from the specialist. On the other side of it, the seller of the TVR decided not to buy that M3, and couldn't find one he wanted, so no longer had a need or want for my car. I let him know I was still interested in outright purchasing the car but would need photos. Both him and myself followed up with the specialist, to no avail. Just before I went on holiday at the end of June, the BMW sold, but I still had no proof of life that the TVR even existed, so just left it hanging whilst I chilled out in the UK (more on that in a later post). When I returned, I already had a list of cars on Trademe I wanted to look at. I had basically given up on the TVR at this point, as during the month I was away, still no photos had been sent. I looked at a couple of cars, including an Evo 4 (which I came very close to buying, but the second viewing showed too many issues, and the unmistakable smell of weed inside) and a C55 AMG (nice car, if a bit dull). I wasn't quite set on them, but noticed that the TVR specialists website had been updated, with new photos, and what happened to be dead center in the photos, but a silver Wedge! Well, there was my proof of life I guess; the car did exist! I contacted the owner and confirmed the car was still for sale, and then did the stupid thing; making an offer for the car as it sits, without so much as a real photo. Offer was accepted, and a call was made to the specialist to make sure no money was owing, that the car could come with the spare parts, and that it would drive onto the truck.... oh wait, what's that, it suddenly doesn't run but you will "try to get it going"... I pushed forward anyway, sending my hard-earned money to the seller, and booking my preferred transport, letting him know that the car doesn't run but the specialist will "try" to get it running. After a long week of waiting, this showed up this morning. Yes, that's the proper good fella Brent from Classic Towing dropping off yet another project to me. Can't recommend him enough, as even when things go a bit pear shaped, he has it all under control, and he loves weird cars almost as much as I do. My first question to him was "did it run?" to which he replied with a no, and tightened the winch ready for laying the bed flat. Such a cool truck, it lowers the bed right off onto the ground. This is half way down Brent pushed the car whilst I jumped in and steered it carefully into the garage. This was harder than you would think, being that it was raining on the outside, and inside of the windscreen, and the wiper didn't work (well, it's not even fitted). We made it safely into the garage though. The brakes work, which is something. So, what is this weird little thing? A 1980 TVR Tasmin 280i It's more or less a Ford Capri in a fibreglass body with tube-frame chassis and some weird and bespoke parts. Powered by a 2.8l V6 Ford Cologne engine topped with Bosch K-Jetronic mechanical fuel injection, backed by the latest (for the 70s) in Ford 4 speed manual gearbox technology, and driven via the rear wheels through a Jaguar XJS diff with spiffy inboard disc brakes. The pinnacle of technology, and a real parts bin special. On the plus side it does get some pretty advanced gear for something that is the same age as my green Mini. Independent rear suspension, four wheel disc brakes, fuel injection, electric windows, bonded windscreen and a targa top convertible. It does have a lot of known quirks though, such as a multitude of wiring issues, a wiring loom that consists of only black wires (seriously), diabolical K-Jet fuel injection, and a dual fuel tank system that is no end of troubles. Anyway, this car is the 106th Tasmin off the line, and appears to be the 4th DHC (Drop Head Convertible) made (1st was a concept made from a chopped up FHC). Before the DHC was in production, the FHC (Fixed Head Coupe) was the TVR to have. The FHC was soon phased out though and only the DHC survived until the end of production, albeit with some big changes. Being a very early car, my one has some specific early only "features". The first, and most obvious, is that its a TVR Tasmin, not a TVR 280i. TVR dropped the Tasmin name later on and left the names to just be the displacement of the engine (280i - 2.8 V6, 350i - 3.5 V8 etc). A couple of other early features are the weird little mirrors hanging off the doors. Later cars changed to pods in front of the side windows, like a normal car. One of my favourite really early features though, has to be the gorgeous Stewart Warner gauges The later cars got boring, but arguably more readable (and probably reliable), VDO gauges. There is just something about the way the SW gauges are clocked, and the vertical odometer. So, now that the car has been delivered, how is it? Did i win the blind buying game, or get screwed? It's not as tidy as described, and it doesn't currently run. The battery was completely dead (to the point my ctek charger won't even detect it), but with a replacement battery the electrics are slowly coming to life again. Unfortunately, it leaks like a sieve and is full of water. I tried to dry as much as I could out, but the dehumidifer will have to do the rest. The roof seals will be the major contributor to this, as they are well buggered. The water ingress is what has ruined the carpet, it's literally rotting away. The boot, once I got it open, wasn't much better, with the lid being full of water and covered in condensation on the inside. The seats are in good condition, with no obvious rips or tears, as is the rest of the general interior. The wood grain has some cracks, but overall for a car I suspect spent a lot of time sitting outside, its in good shape. Apparently blue velour and vinyl stand the test of time. Bodywork is very good, with only some stone chips on the front. The rest of the paint appears to be good and will come up well with a polish. The top is also in good condition, with only some damage to the fabric on the removable section, and the rear window is very cloudy. Hopefully, I can polish that out, but it may need replacement. I don't know how the car is mechanically as it does not run. The previous owner advised (only after I had paid for it) that there is a strong fuel smell from the tanks when sitting, but it drove well otherwise. The fuel in the tanks smells like varnish, but cannot be smelt without opening one of the two fuel caps. I will need to drain this out and throw some new fuel in before trying to start. The starting issues could be a few things, but I will get to that in due course. One cool thing about TVRs is the convertible roof with a removable targa section. You can either have the roof up, down, or the rear section up but without the targa section, which fits into the boot (roof isn't locked in this photo, so looks a bit baggy) So that's the TVR. The plan is to get get it running, get a WOF on it and then take it to the British Car Day show in Feb. In between that, just take it out for some top-down Summer cruising. Oh, and keep fixing it. Can't forget that.3 points

-

Oooohhh. It is suitably wedgey to go along with your previous cars isn't it. I'll find some pics when home but my brother owned a TVR S3 with the later 2.8 efi cologne engine. He had it since about '96. Was the second owner and bought it from Paul Matty cars in chch. I'd drive down to chch from Blenheim on a Friday night in my supercharged MR2 and we would spend all weekend hooning around the hills in banks peninsula and do midnight drag racing with all the lads along Moorhouse Ave etc. Dems da days He moved to Blighty so hannah and I would look after the TVR. Some sweet drives over to Nelson etc. Taught me many things about power oversteer in the wet and being quick with the wheel. fuck it was fun and the v6 sounded fantastic. Low point was being fair and squarely beat in a drag race against a (twin turbo?) v8 diesel prado thing up the gentle Annie hill out of Nelson. Oh how they laughed. Red faced me. We sold it to some fella from chch who had started a TVR club I think.3 points

-

3 points

-

Some wiggling of wires behind the light switch (yeah, ill need to look further into that) and this happened. Thankfully headlight motors work perfectly.3 points

-

2 points

-

2 points

-

Yeah have to be careful. If you look into it most epoxy primer isn't too bad, its the urethane top coats that have max isocyanate and will murder you. 3M face mask with the correct filters and some eye protection and you will live, its only primer so do it outside in the driveway for extra safe points. In straya you can buy phosphoric acid at Bunnings in the paint thinners section under the name ranex, its expensive but convenient. Problem with single stage solvent cured paint is its million years old technology. Nothing beats a good 2 part epoxy primer for adhesion to metal, same for top coats urethane lasts for a zillion years and is low upkeep.2 points

-

Take care spraying epoxy - get the right protective gear. When I started spraying I stuck with single stage paints for safety reasons.2 points

-

Also started on the floor this is the worst of the rust on thepassenger side drivers side is good. it was cold as all fuck today so this was the best place for a coffee break2 points

-

2 points

-

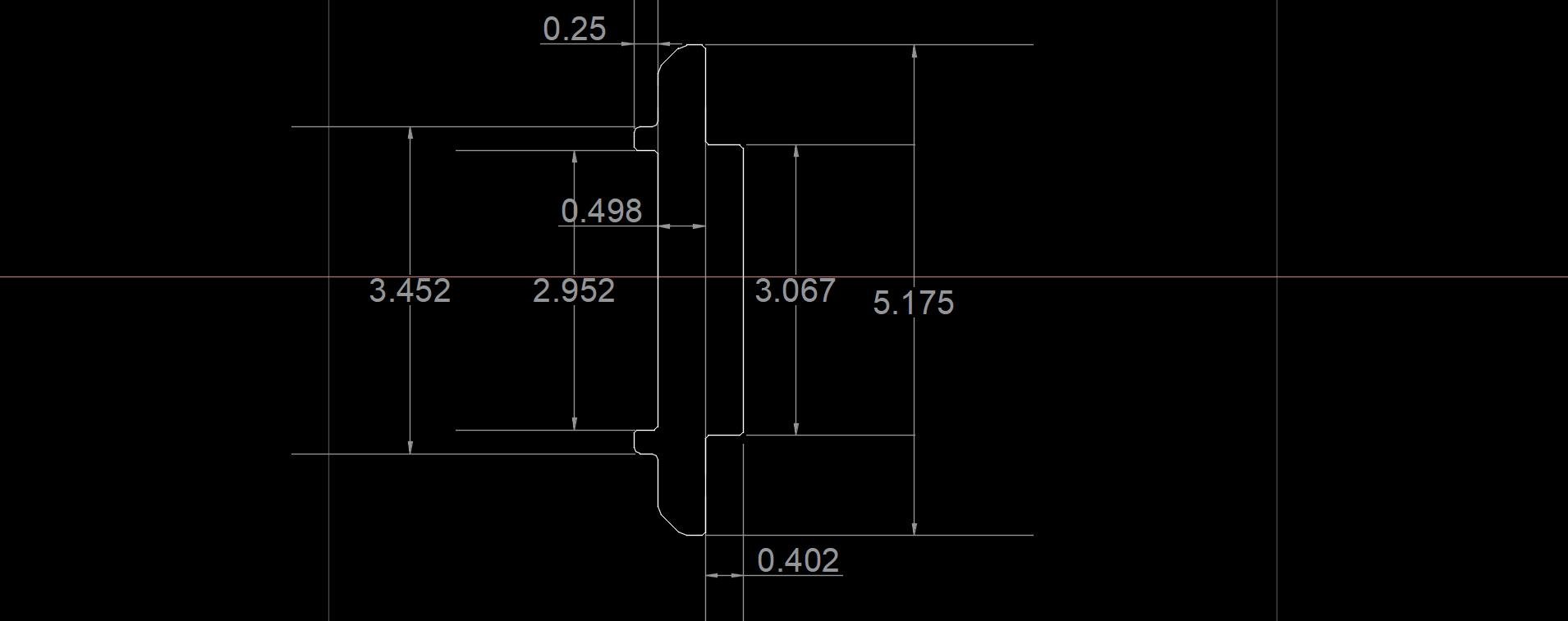

So now here we are six months later and I've come to my second of two one week holidays for the year. This whole time I've still been mentally working on the car, thinking through all sorts of different problems and making plans and drawings along the way. Now I've had some time off from school, I made a trip back up home and put one of these plans into practice. However, before I can get into that, we have to go through a little story time first... It's long been playing on my mind the fact that I'd still not fully completed the V6 RWD conversion. Sure I'd made the adapter plate, engine and box mounts, intake setup, and sump etc, but the actual connection between engine and gearbox was still missing. The flywheel and clutch situation has been through a few revisions, both in my head and in physical work. You may remember from these posts: that I planned to use the standard V6 flywheel with an extra ring added to increase the outer diameter to take an RX8 ring gear as well as a spacer to bring it out the correct distance to take run the RX8 clutch and pressure plate. After making the spacer (which if I'm honest now I wasn't particularly happy with my workmanship and tolerances anyway) I found that the RX8 friction disk wouldn't work with the V6 flywheel or pressure plate, meaning I would have to adapt the RX8 pressure plate to the flywheel. So upon taking it to the machinist to get his opinion on making the adaptations for the larger ring gear and pressure plate, we found that pressure plate bolt holes would end up directly on the junction between flywheel and adapter ring. This was doable but it was far from ideal. Also, the labour involved would have cost similar amounts to a fully custom flywheel anyway and thus the whole plan was put on hold for a while. You may indeed have noticed this in the complete lack of a mention of the clutch and flywheel in the following posts. And so came about my next plan. Ever since reading @yoeddynz's viva thread, I'd been pretty keen on using a lightened flywheel to help unleash the engine's propensity for revs. Luckily, this was going to let me kill two birds with one stone. I'd decided long ago that I wanted to keep everything inside the bellhousing exchangeable with standard RX8 parts. This will allow me plenty of potential clutch upgrade options in the future. With that in mind, I went looking for RX8 lightened flywheels. Almost exclusively, lightened rotary flywheels are designed to bolt up to the automatic counterweight, rather than using the integral counterweight cast into the standard flywheels. This made my life much easier. Now I could make an adapter that picks up the six holes in the flywheel, spaces it the correct distance to use the standard RX8 clutch and pressure plate, and bolts to the end of the crank like the normal V6 flywheel. Essentially I can make a counterweight emulator. The next step was to decide the material to make my adapter out of. I could of course just use any old steel billet lying around the shop but my fondness for my feet kind of convinced me not to go that route. So I looked at what material is usually used for steel lightweight flywheels and found that 1045 is common. I figure if it's strong enough to take the forces on a whole flywheel, then it should be well strong enough for my much smaller diameter adapter. Next, I had to take measurements of everything and design the actual adapter itself. And this is what I came up with. You'll have to thank the American's for building the majority of commercial aircraft in service for my use of imperial measurements. Almost all the tools used in the industry are in imperial and because of that, all the tools I had available at school are as well. Anyway, according to these dimensions, the ring gear should end up in the same position as the RX8 relative to the bell housing face and starter, and therefore the rest of the clutch system should work as normal as well. With all this done, I could finally go home and get stuck into it. Step one, of course, was to get the raw material into a useable state by facing it up and generally roughing it out. Thank god for power feeds and tungsten carbide tools. Next, I turned the recess that fits over the end of the crank concentric to the outer diameter of the material. With that done, I turned the piece end for end and dialed everything back up in the four jaw to turn the spigot that that flywheel runs on. This is also concentric to the outer diameter and, by extension, the recess as well. This is obviously crucial to avoid vibrations and undue wear on bearings and so forth. You'll also notice the stepped section on the front of the spigot. This is designed to fit the inside of the standard flywheel for reasons that will become clear later on. With those surfaces all machined, the crucial dimensions are done and I can have a nice big exhale. This means I can move on to less nail-biting procedures. One thing I did learn from the first spacer I made way back in the day is that measuring and drilling PCDs is a right royal pain and very difficult to do accurately with the tools I have available. So this time around I decided to forgo any and all measuring of PCDs entirely and use a far more analog method. I already have the PCD that I'm trying to match. Why would I not use it to guide my drill bit? So with that in mind, I made up some bushes to guide the pilot and tapping drill and protect the aluminium flywheel. Next, I clamped the flywheel and adapter together and shifted everything to the drill press. You can see the bush already in place in this photo. Once I had the first hole drilled to size, I tapped it to M10 x 1.25, which is the thread used by Mazda on the automatic counterweight that this flywheel is designed to bolt to. With the first hole tapped, I bolted the flywheel to the adapter, which let me get rid of the whole clamp setup and drill the subsequent holes much more simply. I used a similar setup for drilling the crank bolts too. I wasn't nearly as worried about damaging this flywheel since I won't be using it once it's done its jig job, so I only used a bush for the pilot drill and just threw the final drill through using the flywheel itself as the bush. Now that all the holes were drilled I decided I ought to check my tapped threads for strength now, rather than do all the rest of the work just to find that they strip as soon as I try to put any torque on them and junk the workpiece. So I throw the first bolt in and torque it to the high limit of the 32 - 45 ftlbs recommended by Mazda for the flexplate bolts. It goes tight, tight, tight, still tight, still turning, still turning, shit. I figure its stripped and fucked. So out it comes and sure enough, the bolt thread is gone burgers. However, the female threads are still pristine. Stoked. So in goes round two. Tight, tight, tight, still tight, still turning, still turning, shit. Again. So, out she comes and another bolt failure. This time it stretched the crap out of the bolt but still left the threads perfect. Third time was the charm though and all the threads eventually took the torque like champs. Guess that teaches me for using the first bolts I find lying around. Finally, I put everything back into the four jaw and faced something like 15mm off the spigot to bring it back to flush with the flywheel face and finalise the outside dimensions. Here you can see me checking the runout of the flywheel when mounted and it was well well within the 0.008" tolerance specified by the Mazda service manual. Finally I bored the recess for the spigot bearing. I decided to use the MX6 spigot bearing, mainly because I had one available, but also because it fits the RX8 input shaft perfectly, and it was much easier to machine the larger bore for than the much smaller stock roller bearing used on the RX8. It's a very light press fit, able to be tapped home with a mallet just like the fit in the original V6 flywheel it came out of. Finally, after two straight 14 hour days on this thing, I was ready for a dry fit. I used the longer crank bolts that I bought for the first spacer which gave me shed loads of thread engagement, as well as a couple of M10 bolts I had lying around for the flywheel itself. I'll get some proper high tensile ones later on. Next was the clutch and pressure plate which I eyeballed the alignment of and used some more M8 bolts I had lying around. Finally, I muscled the gearbox around and offered it up. With the engine and box somewhat leveled the input shaft slid right in and home over the adapter plate dowels. A couple of bolts later and I stood back to admire my handiwork. It is a beautiful thing indeed. I couldn't help myself at this point and threw a driveshaft in the back end and a ratchet on the front and low and behold we have drive!! I have to apologise for the photo quality at this point. I think there's a smudge on the inside of my lense somehow and it wasn't having a great time with the fluorescent lights at 1:30 in the morning. I ran it through all the gears and checked the disengagement with the BFC in the bottom of the frame, and it does indeed stop spinning the driveshaft with the clutch in while still having a small amount of wiggle to the arm when out. I also checked the starter engagement with some white paint pen and it looks to be exactly where the existing wear marks are on the starter gear. I'd have loved to hook up a battery and some jumper leads to spin it over with the starter but I did end up running out of time. With all said and done I am absolutely stoked with how everything worked out. My measurements and calculations were apparently right on the money, and my machining workmanship and tolerances are leaps and bounds ahead of the spacer I made initially. The final setup for my adapter situation comes out to this: Custom 12mm steel engine to gearbox adapter plate of my own design Custom 1045 steel flywheel adapter of my own design Aftermarket RX8/Turbo RX7 lightweight aluminium flywheel 6 speed RX8/Turbo RX7 clutch and flywheel MX6 spigot bearing Stock RX8 clutch arm/release bearing If you've made it this far though what was a whole afternoon of typing then thank you very much for reading. I'd appreciate any comments or feedback on my discussion thread which you can find here: That's it for now. Hopefully won't be another six months before the next update but we'll have to see what happens. Cheers.2 points

-

2 points

-

2 points

-

2 points

-

I think a trv specialist would be like a paid to hoard Barry. Someone with an oily old pair of overalls and a chipped tea mug permanently in hand, a mechanical pencil in their chest pocket and long grey hair twirling from their ears, fully ensuring that they never hear a word you say and just hazard a guess when they start replying. The trv Barry keeps their workshop clean as no work is ever done here and takes pride in the cut to fit furniture blankets covering each car.2 points

-

After making the call to take the block out to 60 thou oversize (hard to argue with an internal micrometer) the hunt was on for suitable pistons. Problem is these motors were designed to run on leaded 100 octane petrol (yes real lead, the stuff pre-millennial ‘real jokers’ used to have in their pencils!) and the best we can buy in our modern times is BP98. To add another problem both the head and block had probably been decked a number of times and I was now planning on pushing 208 CI displacement into a 186 head. With flat top pistons off the menu I managed to track down a set of ‘new old stock’ .060” over JCC dished pistons in Australia complete with pins and chrome moly rings. You have to love the 30 plus year old tea cup stain on the end of the box, if they could talk I'm sure these ‘new old’ spares could tell some stories.2 points

-

2 points

-

I assembled a store bought kit, incorrectly.2 points

-

Back again with another gx61! Purchased this about 4 months ago from Christchurch. Listed as a 4 cylinder on trademe so I never paid any attention thinking it was a poverty spec sx60. It then halved in price as the cambelt broke. So I did what any sicko does and bought a car that doesnt run at the other end of the country. Had my legend friend Todd collect it and replace the cambelt and waterpump on the 1geu (non interference) ready for me to fly down and sail it 1000kms home.1 point

-

1 point

-

1 point

-

1 point

-

Will be interesting to see what the center section is like, you might be able to return it to lsd easily From memory all the parts for the diff are quite cheap on rockauto, apart from spider gears. I ended up finding a lower km one at pick a part and got another set of spider gears which were good. They seem to be prone to damage I got stuff for mine off rockauto and found mustang cobra has better lsd bits so got those instead of exploder ones1 point

-

Major diff sharn for this weekend... So I bought a new diff, and it came attached to this: Explorer was in Aucks with a dead trans for the same price as wrecker wanted for a complete disc to disc diff outa the same, so thought I'd drive up from Hams and transport back. Ring the dude up and get him to climb under the truck and check the tag, 3L73 yuss it's a 31 spline LSD 3.73 8.8, perfect. Mad mission up there showing up after dark, bundle it on the transporter without really any inspection getting home late last night. Then while basking in the 90s luxury Ford cockpit this morning I notice this on the centre console: Initially super excited holy shit has a moonbeams air locker in it, but then dawned on me I drove all the way to Aucks to pick this thing up and now I still have no LSD, as open/full locker setup less than ideal for what's sposed to be a fast road ute. So now can't decide if it's a win or loss, prolly come out ahead if I sell it to fund another diff (or new internal bits for this one) but mo time and wheeling and dealing while I should be trying to get this damn ute finished... As an aside also found this wedged under the truck, looks like someone's been explorer red necking1 point

-

1 point

-

so now the motor and box are back in i can make a start on a couple of things one being the tunnel...just need to put the clutch fork and slave cylinder in on the passenger side and the starter and clutch pedal on the drivers side and i can finish it off.. and the cold air feed/air box...i want a sealed box feed air from the outside but when you one the bonnet you can see the ITBs (other wise whats the point ay lol) all so regardless of the colour i paint the car i all ways planned on painting the bonnet the same as the falcon XAGT. i looked around at bonnet scoops for ages and wasn't keen on the wrx scoop on your mums honda style ...had to be long low and slim.....so went with the falcon XWGT scoop so it looks like it will fit the plan is to have the scoop on the bonnet with the filter on the otherside of the bonnet so when you open it you can see the filter and then when closed it will seal onto the box around the trumpets. now the easiest way for me to do this is to make it all out of the car then cut a section out of the bonnet and weld the whole thing in so i made a cardboard template and cut some steel out of the sheet and bead rolled around the template flip it over and it means the scoop will be recessed into it. i did some searching on the interwebs for panel filters and it turns out i might have found the perfect one......size and price. ....so i ordered a Porsche 928 k&n panel filter 517mmx157mm and around 20mm thick. and this is the room it will take up. cheers1 point

-

So i thought about this way too much. My floor is fixed but at the right height so that i can open the door, park the wheelbarrow under the opening and scrape the contents straight into the barrow so it can be taken to compost or garden whatever. Made nesting box today. Sits just inside big door(so back of nest boxes are closed in when door is shut) room so we can drag old bedding out under it with a rake type tool, or can lift whole nesting box out and turn upside down into the barrow to clean/ empty it fast. Also.. i gave it a flat top. Videos said to have an angled top so they cant sit up there and make poose. But i dont care! If they like it up there and want to cuddle up high then good on them. Also in photo is my circular saw guide thing/square. Best thing iv made for the saw, omg. Just line up the right hand side edge to the cut line and use the left edge to guide the skillsaw. Cuts perfect square and accurate to the line every time. So good.1 point

-

Fitted up the nearly brand new tail light, and had a few hours on polished the existing good one, 800/1500/2000 grit sand paper and then some cream polish, came up pretty close but there's still some in it I think. Will pick up some actual plastic polish. But if it gets no better than this I'm still stoked. Miles better from where it started. The tail lights are one of my favourite parts of the car so it's great to have them sorted and looking mint1 point

-

Turned my attention towards the motor again, while I'm waiting on this to dry: The motor drives it's own internal water pump via an o-ring as a drive belt. Over time, these stretch and your going to lose tension on the drive pulleys. As a precaution I replaced it, and side by side it had stretched quite a lot...so possibly a lucky save there! Said o-ring above. You can see the water pump pulley here (smaller one on right). And o-ring installed on water pump pulley and to the pulley that is behind the flywheel. Job done!1 point

-

Yeah, a lot of people struggle to understand how the K-Jet works, but over all the whole setup is pretty simple and the same as used in other cars of the era, so lots of experience and knowledge out there. The base engine its self, as you say, is as simple as a v6 can get.1 point

-

Mine has a slide out floor for cleaning, and I penned in the area underneath so they can go downstairs and be out of the rain while still being locked up1 point

-

Machine them out and fit new ones? Or heat will probably do it, the wheels are alloy right. You could also use ammonium aluminium sulfate (alum at bin Inn) it will dissolve steel but should leave aluminium alone1 point

-

Thankfully not, was done down in CHCH. The specialist is actually good as far as I know, but I suspect he gave up on this car when the owner just dumped it on him and forgot about it. Well, that's the only reason I can come up with, anyway.1 point

-

1 point

-

Hi, I’m Shakotom and I have a Motorcycle addiction. It all began with just one FA50 and I’ve been addicted ever since. It just starts with something small and then next thing you know, it spirals out of control and your looking for a bigger fix and that has led me to where I am today. A while ago I had a Suzuki ax100, I really enjoyed the classic aesthetic of that bike but it was punishingly slow for paying $500 a year in rego. I sold that and purchased a ‘87 2KR FZR250, and that’s a weapon of a bike, but sportsbikes aren’t really my jam, and I’m still to cheap to be paying that much in rego. Ive pined over the timeless styling of a Honda CB for many years. I think there a beautiful bike in stock form, and a versatile canvas for creating everything from a full blown classic race bike, A scrambler/Cafe racer or if you get wild enough with a welder, a chopper. Id been looking on and off for a while, I’d decided I wanted a Twin cylinder -either a 350 or a 360 just to keep the weight down. It had to have a minimum of Rego on hold and be pre 79 for cheap rego. Back in April I found a bike that happened to meet all of those requirements at a pretty good price, but I was due to fly out to America in 4 days. So I did the only sensible thing I can think of and went to view it. 8 hours before I was due to be at the airport I was dragging my new acquisition home... It’s a 1974 Honda CB360, black plate, rego on hold, failed cafe racer attempt, that’s been sitting since 2012 that I am very happy to call my own. Its not the prettiest at the moment, but it’s got good bones. I’m fairly happy with the fact someone else has done the initial job of ruining what was a tidy complete bike at some point in its life so I’m not going to have any second thoughts about changing bits and pieces on it to make it fit my requirements. Basic plan is getting it running again, do the basics to it to get it in to see what it needs for a WOF, and ride it a little bit before getting to carried away. First step is sorting out this rats nest of disconnected cables, horrible clip ons, hoses that are the wrong length, loose everything and general terribleness. It’s had the generic cheap clip ons that move if you pull on them fitted, along with headlight and indicator mounts that don’t really hold anything securely. I got a few minutes in the shed and wanged the original bar clamps back into the top plate, and a set of old bars to allow me to throw the clip ons in the rubbish bin. These will do for now to initially ride it on when I get it running, but end goal is some nice Chrome bars. So that’s where I’m at currently. I have the carbs apart and soaking as they’re filthy, waiting on a few ignition parts to fit to replace old junk, wiring for the lights and switches needs a going over, and so do brakes. Basic stuff to get it running and riding and then I’ll write a more comprehensive list once I acquire a WOF. For now however, I’m just happy to have found a bike that fitted all my requirements and here’s to hoping what I’ve learnt from playing with smaller bikes helps out with this one. At this present moment in time, my end goal is to have a fairly clean, simple and reliable bike I can ride daily that will do everything from looking good outside a cafe in Ponsonby to chucking a backpack on to going and find some gravel back roads for an adventure. Stay tuned as I get in over my head and realise I have no clue what I’m actually doing...1 point

-

1 point

-

by gee by jingo by crikey, i have been beavering away for a few weeks smashing out some work on this bad boy. Made some good progress, accumulated all my parts and proceeded to smash it all together. Assembled front brake, bled system and got the front end fully fitted. The aliexpress master cylinder feels like garbage to in all honesty, but still more inspiring than the original excuse of a master cylinder they came with. I then proceeded to reassemble the rest of the bike. Motor went in no dramas, but shag me sideways, there are some things on this bike that drive me bananas. the exhaust has a small stud which located on a tab at the bottom of the frame. usually most of these bikes bolt up to the cylinder and then a support to the swing arm bolt, but this extra stud/locator thing makes fitting this exhaust a cunt. The footpegs also have to come off for removal of zorst, and those are also a pain in the ass to remove. But alas, we pushed on and got the bitch back together. To be completely honest these bikes are so much more pointlessly complex than its competitors, honda cb125 suzuki gp125 etc. While i was in p naughty for swap meat, i popped over to see @Flauski and he gave my carb a hoon in his ultrasonic cleaner. Turned out grouse. I then smashed a carb rebuild kit in it and slapped it on the motor. lastly was a new chain, and the bike was back together for the first time in 6 months! i proceeded to get it running, and it would idle all on its own which was great, but the carb leaks badly, so investigation is required. But sounds healthy, throttle response is acceptable, and the smell, oh by crikey the smell of mineral 2 stroke being consumed at an alarming rate. pretty stoked at how far this thing has come, just need to finish putting bits on like the clutch cover, button cables up and do a bolt check, then take it for a hoon!! pinch me im dreaming.1 point

-

Proof that I am now an auto sparky and fuck anyone who says otherwise; Should have cleaned the smeg off my lens for that last one. Then on to the engine cover, but first I had to build a bit of the intake to make sure I could get it all to clear. There is a sweet spot just behind the cab that will fit a 600x 300 intercooler, I am hoping I can get to that area without modifying my gear linkage too much. Made a rim for the cut sheet metal so the floor was stiffer and the cover had something to bolt to. The intake had to be low otherwise the folding rear seats would hit it. Welded and cleaned up. Looks kinda cool. Then some time honoured 'frame it up in solid round then smash sheet metal onto it' fabrication. It's tight. There was a wee bracket thing that hit the cover when the seat was down so I whipped it off with the grinder only to immediately realise it was the hook to keep the seats up. So now I need to replicate it. Like a cunt. I initially used some real thin galv sheet I had but it was clear I was never going to be able to fully weld it without chasing holes all over the place, plus it already sounded clangy and tinny, so I found some 1.5mm mild steel in the rack and used the thin shit as a template. This meant I could get a nice fold where I needed it using the finger bender. Still yet to do the other side and fill in those gaps, but good progress. Front driveshaft assembly is in getting shortened and balanced at considerable expense. Still yet to hear from engine man. I might have to spend that money on coating the chassis etc and hope I can find some more later on. Or find some more shit to sell. As you were.1 point

-

A few more pics of the inner sill. Construction the inner sill was simple. Carve it out and run it through a bead roller to make the step that the floor pan flange nests into. Except, in this case I had to do it twice because I made the mistake of using 20 gage instead of 18 gage. Second one turned out better anyway when making the bead rolled step. Welding action on the inner sill. Screen captures from my videos. Starting at the aft end and working forward. First attach to new side-of-seat floor pan.1 point

-

Cut the shift gaiter washer off a legacy shift knob and snagged the rubber accordion boot from the soarer since it was from something else anyway both are temporary items untill I have a leather boot made. This pic also really brings out the colour difference from centre console to dash1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00