-

Posts

19727 -

Joined

-

Last visited

-

Days Won

32

Spencer's Achievements

Committed (5/5)

23.7k

Reputation

-

The modern v8 motor of the moment in street car drag racing is the Ford Coyote DOHC v8. There has been lots of development from these guys racing them, but they spin them to 10k RPM and 3000hp on stock ford block and heads which is insane. This guys car is pretty famous in the extreme/outlaw street classes (which are like 3/4 of the way to a pro-mod but steel bodies and street car bits like coolant and headlights). Older video but this thing has gone 6.20's, its amazing, it won like everything last year.

-

The normal behavior for expoy primer is about 20-30min pot life at like 22 degrees (sets faster when its warmer), so you have that long of it being spreadable from the pot. It will start setting up very fast on the panel so you cannot play around with it just get it on, that is why brushing is shit house but it works. I have done it on rust panels when I had some reason why I couldn't get the gun out, it will have brush strokes in the finish and need to be sanded back for sure. If you really need to mix the 4L tin up you can get a little paddle that goes on a drill but like 10min of elbow grease should do it. For a air compressor the max you can run on a 10A socket is about 3hp, then in that class of 3hp some are more efficient and have better designs than others but most 3hp compressors will be fine. If you have a 15A plug then you can get 3.5-4hp ones but the price goes up. More air the better, look at one of those china guns posted above I use mine ona 3hp and its mint with the paint and the air turned down.

-

You want clean "white" metal for best adhesion, its a cunt of a job on complex panels like under cars etc so, if you have more money than time get it sand blasted and they will epoxy prime it for you. It will save you like 100 hours of messy work. Or if you have the air power then a ghetto sand blasting setup outside can be awesome. So yeah strip discs, wire wheels, chemical paint stripper, DA sander, detail sander etc are all tools in the toolbox to get paint off and metal clean. Usually they all leave a residue on the panel (i guess apart from sand blasting and sanding) that wont come off with prepsol, wire wheels leave the metal a gray colour and that shit never comes off unless you scrub it (paint don't stick to that wire wheel finish at all), I usually finish complex/annoying panels with the green scotch brite pad (whatever the harshest one is depends on the brand) get a big roll from the paint shop as you use 1 million of the stuff. I use a spray bottle of prepsol/solvent and polish the fuck out of the panel until its white, if its a big flat panel you can polish it up clean and white with the DA sander easy as just dont go crazy and get it overly hot. For rust pits get rid of it with acid wash, buy some phosphoric acid from bunnings "ranex" you can dilute it for soaking or use neat as spot treatments read the box, wash with water then polish it up as above as it leaves the metal gray and dull (bad for adhesion). As some discussed above there are more modern enzyme rust eaters around but old barry spec I get the acid out it works fast if you use the phosporic (you have to keep it wet to work so using a weaker acid like vinegar takes ages and lots off applications). Oh and try not to use the acid around body seams as it goes in there and never comes out (and keeps eating the metal whenever it gets moisture), people also freak out about washing a bare panel with water, if you wipe it down with prepsol after (you need to polish/sand it white anyway) its fine it will only flash rust if you wash it off and then leave it around.

-

OK quickly typed burb of text... The concept stuff would be fine, I would try find some protec epoxy primer specifically epotec 408 (called PPG epotec now as bought by them like 8 years ago) just because a bunch of us have used it and I can vouch for it. The concept stuff is basically the cheapest brand, I have heard mixed results from the base and colour system they have so I would not use it. But its probably 100% fine. There are so many brands of paint and different systems, its never ending. So like a old barry I just use what I know, apart form clear coats I fuck around and try different ones in that department. Epoxy primer on metal, then 2K urethane (base+clear or single stage colour) on top is fine for engine bays, under cars, inner guards, interior floors etc. 2 part high build is urethane primer and sands 100x nicer than Epoxy, you use it to block down panels before applying your exterior top fancy finished coats, I only use it on exterior panels generally unless you were going show car spec on your engine bay. My favorite for engine bays etc is to wet on wet apply epoxy then a industrial spec black gloss 2K single stage urethane (because cheap and tough). You can paint 2 coats of epoxy, then after its set up wet coat the 2K colour straight on top, no in-between waiting or sanding stage you go from bare panel to painted in one go. This only goes to shit if your paint system doesn't work this way or if you do not wait enough time (it will wrinkle up) I can vouch that the protec epoxy and 2k top coats all work fine this way even though its not in the tech sheets. Don't have any advise on under-seal being thrown in the mix, most people just do epoxy and colour under the car if they are going for under car colour. I would just do the industrial 2K black as per above as underseal is kinda gay.

-

Awesome dude, this is great. I have dreams of building a drag and drive car as the next deal for me, the street car rules here are gay (for cages etc) but keen on some turbo big block goodness in my life.

-

Just came here to say you are insane if you swap out the big block, the 390 is so good.

-

-

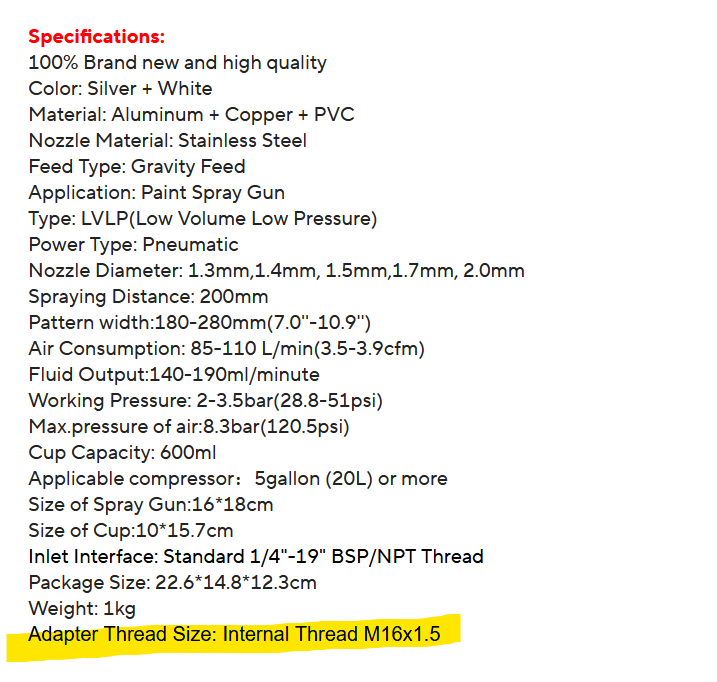

Hey dude. I have one of these, works good but I am only doing base and clear fix ups with them at the moment no resto stuff. You might want something else or a set of tips for primer. This R500 is the common one on the HVLP youtube vids, its not a real "HVLP" or whatever that means, but its a Iwata clone that does use a bit less air than other cheap shit. Should be fine on 2.75hp, turn the paint down and run less pressure, works best that way for me (less overspray, less air use, tradeoff its slower). Think I got this rather than the genuine rongpeng as it had free shipping, there are like 20 versions of it. https://www.aliexpress.com/item/1005005767569627.html?spm=a2g0o.order_list.order_list_main.65.3b441802SWe4lY I got one of these adapters https://www.aliexpress.com/item/1005005411806645.html?spm=a2g0o.order_list.order_list_main.69.3b441802SWe4lY and these cups https://www.aliexpress.com/item/1005005663483568.html?spm=a2g0o.order_list.order_list_main.70.3b441802SWe4lY

-

The paint thread, but we have worn over the same topics 100 times its a roller coaster. Avoid all rust conversion primers, they are all shit. yes remove paint first, paint stripper or the sanding methods whatever works. Acid basically eats the rust off the steel (and eventually the steel itself), you can use all grades of acid. You can use citric acid for big baths, its cheap for high volume, its similar to using vinegar as in its slow as fuck but its cheaper both are weak acids. Skip that though and get phosphoric acid from bunnings (or somewhere else cheaper) you can use it neat and it will treat quickly as its quite strong (as per instructions) or you can water it down and bath parts in it. Again anything cast will melt, high tensile bolts will be ruined, we are talking shit steel panels and parts only. I am a fan of soaking parts in acid etc but if we are talking on the main car body usually get the grinder out so you don't have the mess of acid in body seams and gaps etc. You cannot really clean out the acid if you get it in body seams and it will start reacting again every time its wet or damp. So for that reason I usually only bath parts that come off and fit in a bath, its slow/quiet and low labour for those bits, I just did another lawn mower like that it is amazing for that job. Its also good on a pitted big panel like a roof maybe, internal floors or doors not so much. As said make sure the steel is "white" before you paint, the finish you get from sanding or I usually scrub with green scotch bright pad (you get from paint suppllier in a roll). You do not want to paint on gray acid treated steel or gray steel after grinding/wheeling you will see this when you scrub them up after. This is lots of work getting panels clean even after grinding and acid dipping, still have to scrub them all clean. Don't spray the can epoxy you need 2 part, go to a pain shop get 1L kit and paint cups to mix it. Get all your repairs clean at once, then brush it on (or spray with a 3M normal mask its fine). You can sand the epoxy primer then use some shit rattle can top coat paint to cap it off, this is like minimum viable process. IF you can use 2k top coats the durability of the repair is like 100x. If you can get shit blasted and primed then do it. Obviously if its the body and its not a ground up resto then DIY methods it is.

-

Many ways to go about it, some quick cliff notes below. Ask more stz for more detail. You can use abrasive methods, sand blasting is number one gives you clean parts no rust basically ready to paint. Then down the list you can use wire wheels, stripping discs, sand paper. This gets messy but works well, need lots of labour to get it all clean "white" metal after which is what you want to paint on (as in the wire wheel etc can leave lots of material that needs to be sanded clean after). Chemical you can use paint stripper, if you do lots of prep work it can be pretty clean, works great on old single stage paint and shit on modern 2k paint. Chemical rust treatment you want to use acid and you absolutely cannot use it on cast or high tensile parts it will ruin them. Buy some rannex from bunnings, you can dilute it in a big bath and soak parts (keep your eye on them) or you can follow the directions and spot treat areas. Again after you want to scrub down with scotch brite and clean things to white metal after soaking. You are in for a bunch of manual labour any way you go about it hence you should weigh up dropping off parts at the blaster man its more efficient paying for it and its perfect result, they will even paint it in a zinc epoxy primer. The stuff you cannot drop off you will be in for time to manually grind/sand it or chemical treat it. I like the acid bath, very weak solution and leave over night, then sand and paint with epoxy primer. Don't use any rust conversion primers or paints they are shit. For the hazardous shit comment I take it you mean for the paint? IMO you have to stump up and paint with modern shit like epoxy primer (which is fine to spray at home, you could brush or roll it on if you had to) then some top coating. Top coating is the harder DIY part, modern paint to use is 2K urethane which has the bad stuff in it isocyanate, however if the car is lacquer and you are keeping that you can touch up over epoxy with shitty 1K paint. Doing a bunch of rust repairs and then painting it with rattle cans is the biggest waste of time ever so don't do that, do epoxy primer then shit 1K top coat at a minimum.

-

Don't go past the JZ autos either the A340 is awesome, especially one from a turbo car IMO. They turbo ones seem to bang through the gears pretty sweet and there are a bunch of ECU that can control them now. I had a auto turbo JZA80 and loved the slushbox in it, driven a few others also (aristo etc)

-

Yeah man if you have a crown its the path of least resistance, unless you are keen on a big fab project. Or if you are crazy like Sheepers then a old school 5/6MGE are really sweet engines (when working and not popping head gaskets etc) they sound real cool and drive real nice in a cruiser. Hardest part these days is probably tracking down a genuine crown JZ mid-sump for a real tidy slam dunk conversion. You can add a turbo or ITBs to spice things up later on also.

-

You do not weld through the epoxy, you paint (cure) then line up the parts and remove the epoxy with your spot weld drill, I am talking for spot welded seams (or the back of a patch panel) the cured 408 holds up incredibly well next to a spot weld when you open them up. I did a shit load of paint testing and leaving stuff outside and I have no confidence in weld through primers, I tested a couple different ones and they all go rusty in a month or two where 408 is fine, sand it back metal is clean. Its a slow method though with the cure time and prep. There are 1 million types of epoxy primer so you have to figure it out yourself and I do agree generally automotive primers are made to be coated over but many of them hold up to weather amazingly well. Chemically there is nothing stopping 2 part epoxy itself from being waterproof there are advertised weather proof epoxy primers especially in industrial paint lines, depends on what the paint manufacturer mixes up for each application. Anyway I am a fan of the the protec 408 though it holds up well, you can buy a protec epoxy with zinc phosphate mixed in if you were concerned but I have not used it. You would guess it would hold up even better to weather, its what the local sand blaster dude chucks on everything and then leaves outside. Do your own testing etc.

-

Its absolute junk IMO, all 1K "rust converters" or "rust primers" are junk as is POR15. Prep and Epoxy primer everything, if you cannot reach the area and it has surface rust then just cavity wax it and forget about it. Epoxy primer works better than weld through primer in a can (junk) also, you just have to be able to wait the 48h for it to cure fully. Think I have said all this about 50 times in here

-

After someone mentioned HVLP guns in here I also went down the rabbit hole of seeing what the hell they were. Turns out they are just china clones of some of the brand name guns that are known to use a little less air and have a finer spray pattern. The main one you see is the R500, its basically a W400 clone, which with a 1.3 tip uses like 5-7cfm. I think the R500 is about the same air consumption as the W400 if you run it at 30psi with full paint flow (not the 2cfm and other bullshit you see) if you turn the paint dial down you can run very low pressure (like 25-27 psi) and get a real nice finish with minimal over spray so its a great garage gun for $$ it cost me. If you are used to big fans and decent guns (in a shop with lots of air) then its junk, but its a decent clone and dirt cheap. They have the next version up (R830 or R600) which is a kiwami clone and basically is the same thing with a bit of a different spray pattern and it looks cooler, again works well with paint dialed down and low pressure (I got them both). These guys Rongpeng make the two clones you see everywhere sold under different brands, you can buy the original guns there. There are other sellers than have them even cheaper than the factory (my R500 was $57 shipped) https://rongpeng.vi.aliexpress.com/store/3009028/pages/all-items.html?productGroupId=511210255&spm=a2g0o.store_pc_home.smartGrouping_2009187456512.511210255&storeId=3009028&sortType=bestmatch_sort&shop_sortType=bestmatch_sort So yeah in short the clone china guns have got way better over the years, those are just the falsely marketed "HVLP" ones which are probably the best for the 3hp compressor crowd looking for a cheap gun that works. From what I have seen if you have more air they make decent clones of everything now SATA, Devilbiss the whole shebang, just have to wade through all the shit to figure out what is good. There is a barry on youtube who reviews almost every spray gun in the universe, he is the most barry chap ever. https://www.youtube.com/@peteshobbies5383

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)