-

Posts

5,601 -

Joined

-

Last visited

-

Days Won

1

Shakotom last won the day on July 17 2022

Shakotom had the most liked content!

About Shakotom

- Birthday 10/01/1994

Profile Information

-

Gender

Male

Converted

-

Local Area

Auckland

Recent Profile Visitors

4,801 profile views

Shakotom's Achievements

Committed (5/5)

9.6k

Reputation

-

K-Trips 1982 Holden Commodore VH Discussion

Shakotom replied to KKtrips's topic in Project Discussion

Very cool -

- 138 replies

-

- 7

-

-

No welding of steering or suspension components but can I weld new mounts for brake hoses/abs lines to the bottom of a adjustable coilover body? - mounts for these differs from what car needs

-

Got a couple of genuine key blades ordered and cut to replace to one I had which was sticking in the locks due to wear more roof rack use -best mod so far

- 31 replies

-

- 11

-

-

- 31 replies

-

- 12

-

-

-

Aerodynamic. - wheels are AME Windmuhles in 14x6 and are directional lefts and rights. Tread pattern combined with the roofracks from @hampie (and the ride height ) give it more of a rally car vibe than intended…. Would really like to get to a track day or something in this sometime soon. -Oh and have a AutoSport bucket seat sitting in the garage I need to figure out how to attach to some seat rails but thats a story for next time…. -And looking for another cheap set of cool wheels to put aside for getting some track tyres eventually ( 14s or 13s)

- 31 replies

-

- 10

-

-

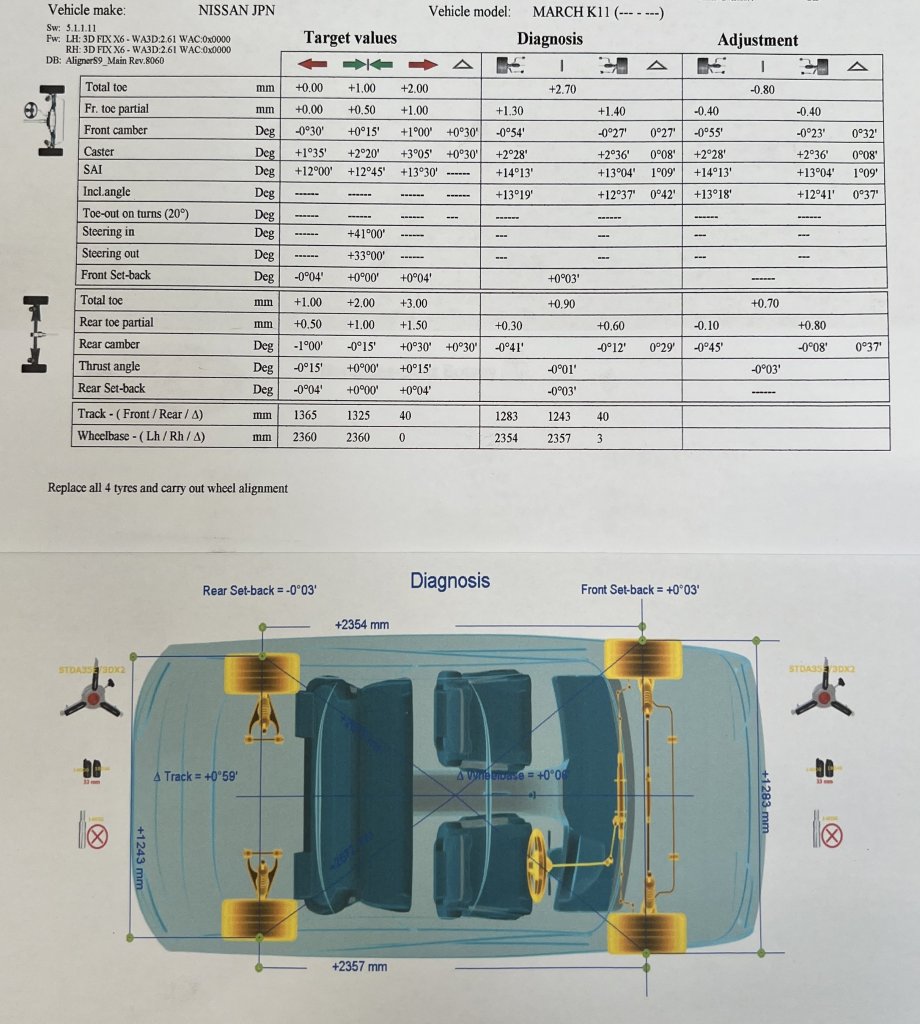

Tyre guy fitted them all up, and aligned it (we decided we would try an ‘fast street’ setup to give it good turn in when your rushing to get the groceries and need to dive into a carpark at pace) -He’s also suggested I need to get a adjustable panhard rod and some rear spacers to even out the track width so they’re next on the list Then road test - Definitely has more grip than the old hard supercats it came with and turns in pretty well now. + 10 go kart improvements

- 31 replies

-

- 10

-

-

-

I got the tyres stripped, asked tyre guy at work to keep them aside so I could put them back on he and said nope, they’re old and shit then promptly disposed of the tyres. I ended up doing a pick-a-part mission, and grabbing a rear hub then dropping the wheels and to an engineering shop and said make these fit that. Picked them up a few days later and with my wallet lighter tried them on the car and was happy that they fitted. -I’ve got intentions of getting them dipped, the kerbing welded up and machined back to OEM edging, and then repainted/powder coated with new decals, but my budget does not allow for that at this present moment in time. I requested the tyre guy at work to find me some tyres to exemplify the go kart handling characteristics of the might K11 -we had settled on a set of Advan ad08rs but came to find his supplier had no stock. So ended up with a set of Yokohama Advan A539s in 175/60r14 79H -which were budget friendly and not a super low quality tyre like most else in the segment. proceeded to fit them to the alloys

-

ALRIGHT AS I PROMISED. I found this set of wheels about 3 days after I’d told Alex I’d take the car -considering I’d been on and off hunting for cool 4x100 low budget wheels the whole time I had my AE92 as a daily and not had any luck makes me think the universe works in mysterious ways… I had a mate in Christchurch pick them up for me and store them until I got down there to grab them, Nearly bought tyres to fit them for the drive home off his mate in chch - but had none on the shelf, so just lugged them home in the boot much to my wife’s delight… I got home and excitedly went to fit them only to find the centerbore was too small to fit a Nissan resulting in me sitting in the driveway pondering my decisions.

-

Eastcapescapade #6 2022 November 11th, 12th, 13th

Shakotom replied to johnnyfive's topic in Upper North Island Region

Life’s getting in the way of small bike stuff at the moment. CG125 is there and works / just need a backpack , just dunno if I can commit eh -

Then @Mop Head featured me on his Moving the world channel https://www.movingourworld.com/volkswagen-beetle-stanced-edition and now it’s back in the shed again….

- 16 replies

-

- 23

-

-

-

-

Put some ribbons on it, what a combo!! Polished up well. Did some more polishing on the day All set for the big exit and off to start the honeymoon the next day!

- 16 replies

-

- 20

-

-

@GuyWithAviators took a beautiful rolling photo on the way to my wedding - which is now framed and on the wall in the hallway

- 16 replies

-

- 23

-

-

Life moved on, and it just sat waiting. I got married back in March, and we decided we wanted to use the Bug as a wedding car. Dragged it from its slumber, changed the oil, new set of plugs, fixed the coil wiring, drained the stale gas, a new battery and got it running! Ordered some bits to fix the play in the link pins / regreased the front wheel bearings, found the RF wheel cylinder had stuck from sitting so replaced that. Dragged it back home and spent three quarters of a day polishing the paint and the chrome.

- 16 replies

-

- 10

-

.thumb.jpg.b5491dbec1053270a4d99ed376fc2c36.jpg)