-

Posts

37,235 -

Joined

-

Last visited

-

Days Won

344

Everything posted by Nominal

-

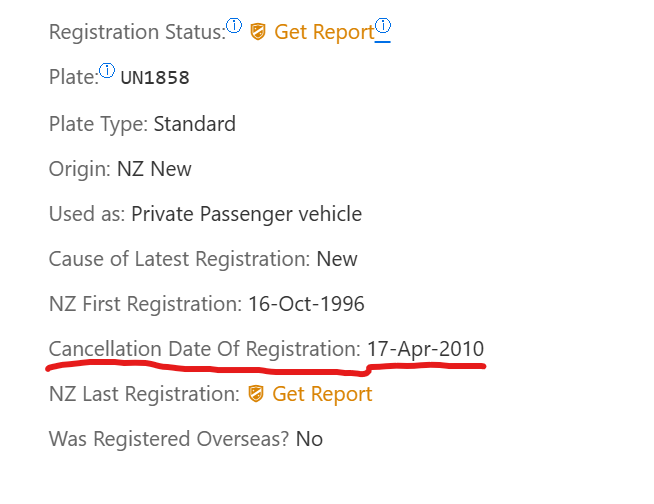

If it's dereg then the plate means nothing. Registered owner doesn't equal legal ownership anyway. All you should need is a receipt from the current owner I think, then work through the entry cert process

-

I thought you had a Falcon wagon? Or build a Dynafari?

-

Steeb always has dudes available.

-

Have you been reading the unofficial lvvta page on FB again? Man that place has some numpties.

-

What, you mean I can't run 185 radials on my Morris Minor any more????????

-

Shots fired!

-

I assume it would have been spot welded at the top and bottom flanges. A spot weld cutter would probably get it off.

-

How would you manage to weld all the existing parts to the new T piece? They all need to be connected for strength I assume. Apparently looks like this So there should be 3 layers in the sandwich, flange on floor, stiffener and outer sill, the inner sill is flanged to the floor. If this is a proper keeper car (which it seems to be) you should do a proper job, remove the outer sill, and stiffener, the cut back into the inner sill and floor enough to weld on new flange pieces, them replace the stiffener (which looks just flat, maybe just weld a new bottom edge on), then replace the outer sill (again you might be able to just weld a new lower flange on it.

-

How do you know where to put all the bits / loom etc? Working off a manual, or the other car?

-

They are such teeny cars, can't be much built in the last 30 years that is so small and RWD IRS?

-

Just get an MX5? What are you trying to achieve with a 200hp GT6? I've found that simpler projects are more likely to get done in a reasonable time and I somewhat regret launching an 'all out' project.

-

Chris' (in)practical daily and every expense spared musso

Nominal replied to chris r's topic in Other Projects

What's happened with the panzer wagon - pushed to the unloved corner? -

Invers peeps, need someone to pick up and hold a car asap!

Nominal replied to DoBro Jesus's topic in South Island Region

-

Yeah, that's about how often I use it too.

-

Engine hasn't turned since 1987? That's going to be a challenge. Have @ajg193 or someone make you something that you can bolt in place of the crank pully and weld and old 3/4 drive socket to it? 1/2" might not be enough

-

Truenotch's BEAMS AE86 racecar discussion

Nominal replied to Truenotch's topic in Project Discussion

How thick is the housing where the caliper bracket is welded? Seems odd that there would be a hole right though that could leak? A good degrease / brake clean session should allow it to be zapped with a mig. Maybe tickle it up with a grinder first to identify the hole? -

-

The pics that are gone are FB links so not permanent usually. Best way to make them permanent is to upload them to the forum.

-

Pallet packing made me twitch too.

-

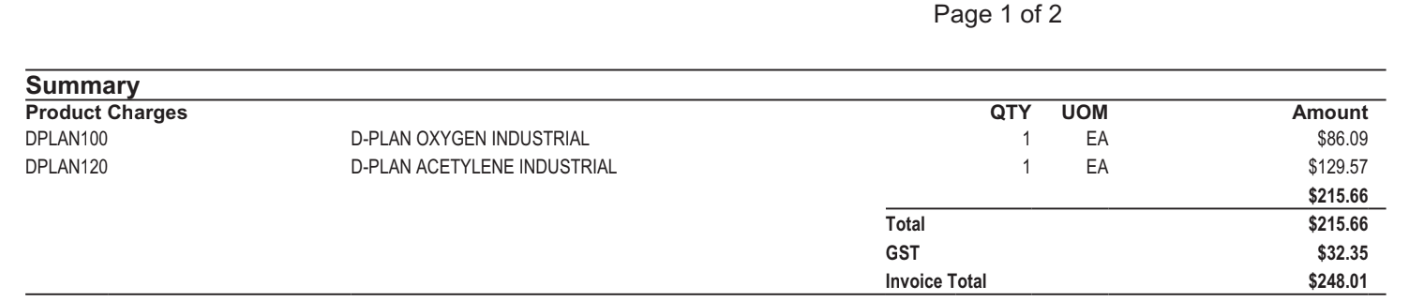

There is a lot more chat in the welding thread. If you really want the cheapest you'll have to do some legwork. I just go with the BOC D-plan coz easy, not big outlay to buy the bottle. Look at Bunnings too. e.g.

-

Hydrofluoric acid is nasty stuff, can go right through your skin.

-

Discuss here about Yoeddynz's little Imp project...

Nominal replied to yoeddynz's topic in Project Discussion

-

-

Get some new wheels?