Leaderboard

Popular Content

Showing content with the highest reputation on 03/21/17 in all areas

-

Shes a pretty big job. Been at the machine shop for a week. 1 more week to go! Casting is looking good. Yet to find any lumps of sand or porosity apparently!13 points

-

Ok.. so after having typed all that the night before and having had some good replies in the tech thread I decided I needed to bench test it and do some chin scratching. I'm glad I did. I found the main problem. out from car and jury rigged up on bench... I discovered that the lift pump was hardly dribbling anything out. Hmmmm. Whats that pre filter like then??... oh.. I removed the filter and wow- proper flow again. I'm amazed the engine was able to run at all!!! So Hannah was heading to town (the big smoke) and would pick me up a new filter. I then decided that while the pumps were out I might as well pull the tank out and add a second return so I have options. First thing was to make things safe before I touch the tank with items of spark or flame. I taped the tank filler onto the trusty old Hiace exhaust and ran it until the tank was purged out of traces of fuel or vapours.. I machined up a little fitting with a nice flat thin section that would provide a good surface area for solder.. I soldered that in place and sat the tank aside. Now since the tank was out I thought it might be a good time to get rid of the horrible large ugly plastic battery box taking up space in the boot and do a similar recessed box like I did on the wagon. I measured the battery and made a box.. Then I cut a big hole out of the boot floor. I did it in that order because my Co2 bottle is about empty. I did not want a large hole that I could not fill. The box is in place now and just needs some paint. I'll continue this very exciting update tomorrow with a photo of some paint drying8 points

-

5 points

-

First post on here, so more testing how this works? Picked up Pete's velo bike. It has appeal, as I'm very much a 2-stroke fan. I've made similar projects myself in the past...and hopefully I can get this bad boy going again? Mocked up for inspiration, will get onto in as time allows. Kj3 points

-

I wasn't happy with my first attempt at making a drift trike...so I made version 2.0 There's well over 30hrs put into making this bad boy. I started with a kids drift trike, and there really isn't that much of it left untouched. I won't bore you with a step by step...but there were many. Its a tad underpowered, but in saying that...its got enough to get you into trouble Crazy fun for something so simple! Kj2 points

-

This only lasted a trip down to the bmx track and the monthly meet before I got stuck into it again. The passenger floor has always bugged me so it was time to get into it and repeat what I had done to the drivers floor. The passengers floor was covered on the inside and outside in bog. Underneath were just patches tacked on top of the original floor. Ive cut most of this out. I've replaced the lower section of firewall with new metal, put a new piece in by the gearbox tunnel and now I'm here. After the floor is done, I'll put in the new seat rail and take the sill out. It's rusty from the front to the rear, so I've decided to replace the whole thing.2 points

-

@yoeddynz I couldn't find your discussion thread on my phone. But something someone once told me to do was this, I ran a holley blue(?) Pump on my datto. As this could move a fuck ton of gas, I was told to run a second hose tail out of the pump (pre regulator) and plug the end. Then drill a 60 thou hole, and run that as a return to the tank. This reduced the pumps internal bypass thrashing the fuel around for too long and warming the fuel up when the motor isn't sucking lots of gas. That's all I have to add.2 points

-

2 points

-

I don't understand why you're doing things to your driveshaft as you've already borrowed another shaft to no avail. If this problem genuinely wasn't present prior to taking the car off the road then it's most likely a result of something you have changed during the rebuild . Despite the problem being road speed related I'm still thinking the gearbox input shaft to pilot bearing could be worth checking. As you are feeling less vibration under acceleration it's possibly worth putting some weight in the very rear of the boot to simulate the change in suspension geometry under engine load . ... but I've never tried that so it could be a waste of time. What part of Wellington are you in? EDIT: I hadn't read that there was no vibration when towed without a driveshaft . That's awesome news2 points

-

Then your lift pump is just too small... Lift pump should still flow enough to keep the engine running, its just designed for flow, not pressure... but should still be spec'ed so it's big enough...2 points

-

2 points

-

2 points

-

Bit more progress, I was trying to get this done so I could take it to the grasskhana that the Nelson car club ran today, but didn't quite make it, part of the reason is this When I was getting the front panel lined up ready for welding a crack opened up about 50mm from the join, so while I was cleaning up the welds I had made I did a little bit of investigating and found this. Left side Right side So it appears that I was not the first person to chop off the front sheet metal, I was however the first person to weld it up properly.... apparently a few spot welds and heaps of bog was the order of the day for that particular repair, in fairness they had used heaps of underseal behind it which kept the rust away so it was just a matter of cutting the welds re-aligning it all and welding it back together. Next up fitting the fan to the radiator, I got a bit lazy and just used those push through tie things And engine back in, oil cooler and radiator fitted, fan re-wired with a digital controller as the analogue one was a bit huckory So all that work was basically just for this Before After I have some bits turning up for the exhaust tomorrow so have decided to build the new one rather than fit the old one back on2 points

-

So, been busy the last few days, got the doors, guards, boot and bonnet paneled and primed. Now I need to move on to the body. Then get it all painted and move on to the more exciting stuff. I'm on the hunt for another 4k or 3k motor. I'm going to pull down the current motor and inspect the bores, possible get away with putting a new set of rings in it, but don't have high hopes.2 points

-

2 points

-

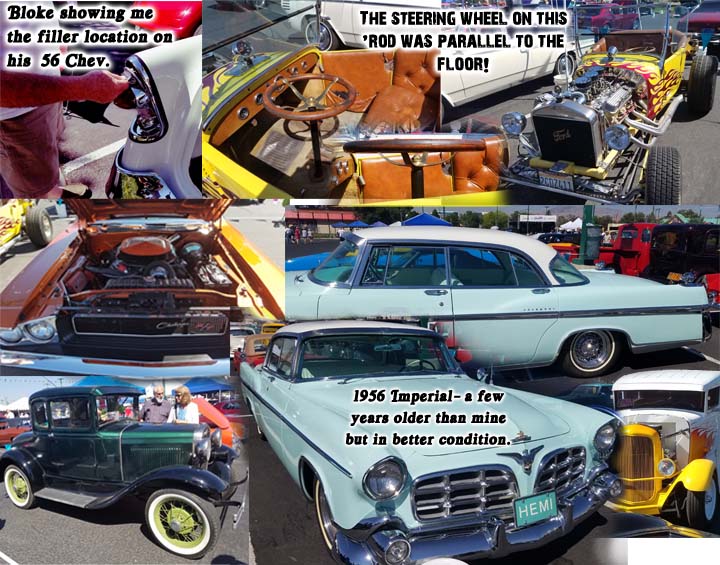

An event that runs throughout that month between Reno's infamous hot chicken wing festival in July and the Zombie Crawl in October, a calling for car enthusiasts from far and wide is Hot August Nights which takes place across the whole town and spreads into Virginia City, Carson and the City of Sin itself (6 hours away to the east!). Whether or not I'll still be in Reno to see it in 2017 is another matter, but I took plenty of photos from last year's run and met some great people *this was just before I bought my '59 Impy so I was still project-hungry at the time*. If you're in the States midway through this year I'd recommend checking it out. A dinner at Mel's diner after spending the afternoon burning to a crisp walking around looking at old yankee iron is a must-do experience. -Benperial1 point

-

Hello all, so as some of you may know Kane Munro finally parted with his Mark ii. I picked it up from welly on the weekend of seafest and drove it back to Christchurch. Even as far a bringing it back to his old flat where it once lived. Now most of you know the history of it. Originating from the hands of cute wee gem. Where it got a new heart in the form of a 1ggze mated to the factory w57 gearbox through to an f series irs rear. A new lick of paint and some cusco coilovers in the front with some rcas. Now I won't have much to post till I get a job/some money since I've been on ACC for a couple of months after Losing a finger but it'll get there. Starting with new wheels. Looking at some 15x9 or 10 Japanese wheel alloys. Upgrading all the suspension to some bc golds all round. Doing all the necessary protective mods, chassis sliders, sump guard, get the exhaust up and out of the way. And hopefully the main one I've been looking forward to, a smaller pulley for the supercharger to squeeze a few more psi into it so I can keep up with fresh. Probably accompanied by a sneaky wee intercooler setup I'm yet to figure out... I also have a digi dash that I would absolutely love to get wired up to finish off the lush porno interior. So far I've done all the basic fluid changes, coolant, thermostat, oil and filter. I even swapped another altezza lsd into it with fresh fluid for more fun in the wet. Will update with pictures etc once the internet is back on and I can jump on my laptop.1 point

-

Yep. This. Tank did have some crap in it. But my dumb fault for not checking filter earlier. I have learned.. Tank now clean and cleared out. It does show sign of light corrosion so at some point I'll buy some tank seal stuff and seal it.1 point

-

This still happening in palmy? I just moved down hea from auckland will be keen to come along if it is1 point

-

Thats pleasing to hear.....I'm glad people took the chance to purchase when the opportunity came rather than looking wistfully through the fence.1 point

-

1 point

-

^ Caster adjustment can be done using big washers on these cars. One can cut a slot into a few washers and mess around with caster pretty swiftly as the McPherson struts basically hang down from the inner guard and are kept from spitting aft under braking by only the swaybar.... but having said that I suspect this vibration issue is more related to a rotating thing. WRT the gearbox to driveshaft: There's a soft metal sleeve in the gearbox that the driveshaft nose rotates in. That's the extent of the driveshaft bearing. The gearbox mainshaft itself has roller bearings which can wear and vibrate, but more than likely the gearbox would sometimes pop out of gear too (once those bearings are stuffed). The answer to this dilemma is most likely in the first few posts. I'll try to re-read them soon. Everyone wants this fixed!1 point

-

@Nick Ritchie fuck i just remembered the other chev at home has the lushest sheepskin covers they would be magic in the honda1 point

-

1 point

-

Was a good day out, great to be able to put some faces to names.1 point

-

I like that as an excuse - to be honest I just wasn't smooth enough - some of my lines were terrible, walked the course afterwards and discussed what we were doing differently. The plan is that the 180SX will be the tarmac car. New engine and gearbox arriving this week for the 180 So much fun, and really any car would be sweet - your sump height would definitely be the scariest thing. A grass event (or tarmac event for that matter) could double as an OS meet. http://www.nelsoncarclub.co.nz/events-calender/nelson-car-club is the calendar of events.1 point

-

The Drury BP Is always good as it has a direct onramp onto the motorway, so no chance of the group being split up so early on. Shall we lock it in?1 point

-

1 point

-

second event for the year smacked out on the weekend. This time a short 2km there and back shootout sprint similar in style to the ashley forest rally sprint. I was a bit hazed after 2 weeks of drinking baiju / soju in china / korea on a business trip so didnt think i would preform well, that all soon disappeared after a coffee and a redbull. I took the first run pretty casually and then started feeding it. the official results aren't out yet but looking at them on the end of the day I was fastes (only) A class car, i beat all B class (0-1600) cars other than a motorbike engined hillman imp. Which i was pretty stoked with as there was a very flash starlet with a 1300cc 2age and some pretty serious suspension mods (equal length 3 link with watts link, motor set right back into firewall etc. I was 3rd overall 2wd behind the imp and Peter in his BMW. I even managed to beat 2 imprezas. All because of the road really, the starlet loves tight twisty shit being light and short wheelbase, and with my 5.1 final drive it just loves second gear stuff and puts the power down really well, once to get to more open 3rd - 4th gear roads i drops right back in the pack. Anyway here's a video and some choice photos from Jeff wells and Gayle.1 point

-

Lucky gas Is cheap over there! With the low roof/big stove I reckon kitchen at the back then so you can stand at the stove, instead of kneel. You could still have bed at the back (I like being able to jump into the side door and get changed and hang out and stuff in the lounge in car parks, its abit less obvious and requires less room) just make the kitchen 'slide' out from under the bed, and/or make a section at the end fold up as a splash back/stop crap going in the bedding - you wont be frying and driving or cooking and sleeping atht same time! You may be able to rig something to hand the bikes above the bed? Just don't sit up in the middle of the night! You might need to get the sketchup going. Also do this:1 point

-

And if anyone needs an identical motor/pump to try this on, there may still be one or 3 left.1 point

-

Managed to loosely assemble some bits while horribly hungover. That was it for the weekend...1 point

-

1 point

-

1 point

-

1 point

-

Cleaned up a better heater bubble I had cut off a wreck a few years ago. Plug welded this in, rattle canned it, seam sealed it and canned everything one more time. 100x better. Every new panel was painted inside and out, sprayed with this 2k epoxy everywhere and seam sealed where nessecary. Its so much more solid and the cunty repairs are now finished. Long story short, it failed a warrant and I changed chicken mesh into metal to gain road legal status. Stoked. Most of the garbage I replaced.1 point

-

I'm a bit over cleaning dirty/rusty bits of metal. Got lots of little bits cleaned up and chucked some paint on them Sunday arvo... and went home at lunchtime today for another coat... Still got control arms to pick up from blasters to paint but getting closer to putting it back together...1 point

-

I've been pretty slack, Perth summers are way to fucking hot for being in the garage. Finished stripping the steering and suspension today, it's all fairly tidy under the dirt, grease and surface rust. Am buying the parts new that I can get, inner tie rod ends could be a mission but all the other steering stuff is available, UCA bushes also seem to be a questionable item but I'm not sure if it's just a listing issue. Will clean up and paint the control arms, strip and check out the steering box, then clean and paint the front of the frame. So much parts to take up space! I measured up my old sedan chassis, not bolt on, and it was way more fucked than I was hoping, so I'm keeping an eye out for something with better front panels to grab, partly because I am missing most of the front end bolts and lights and shit like that. cheers Matt1 point

-

1 point

-

I think there are some pics in this thread already? anyway I built it a few years ago1 point

-

You never forget how to fall off a skateboard.1 point

-

1 point

-

1 point

-

More progress on the old girl. Still chipping away on the wiring but with engine in, I can now start the engine loom also.1 point

-

so after the weekends event and deciding i def need some decent front suspension so got started on my coilovers. The bilsteins are too long for the starlet tubes which is ideal cos i want a taller strut to do the opposite of everyone else on this forum so im going to use the mitsi tube over the starlet tube. I got some standard starlet struts to cut up thanks to the guys and olds-cool autos. Cutty cutty and very conveniently the OD of the starlet tube fits perfectly inside the mitsi tube. so I have the mitsi tube slotted over 80mm of the starlet tube to give it enough strength. It will be welded around the bottom and plug welded in 4-6 spots by someone that can actually weld as these will need to be road legal. all mocks up alright, just need to get it welded. Pretty keen to do a brake upgrade while im at it as the starlet ones are not the best.1 point

-

k so i managed to get the hatch to clear, by using the bigger hammer method. used the rubber end of my bacho rachet as a dolly and smacked the panel till it cleared. it put a few bows / bends in the roof line as seen here below, but i didnt give a fuck at this stage / its only a rally car. so hatch is hung now, and its all ready to go to my mates booth for top coat. Now that the body is out of the way i got to a few other little jobs, made an alloy mount for the batter isolator switch now that my battery is going in the back. this will go just behind the handbrake. also made new seat mounts. the old ones were mish mash fucking ugly / unsafe things that came with the car that have the worst birdshit welding i have ever seen, are made of so many different pieces and some of them are panel steel!! the rules are the must be made of 3mm steel at least, i made them at my cousins workshop and the smallest flatbar he had was 5mm, so they are overkill but meh they will be safe and are a bit more simple than the last ones. now for the exciting bit. Father in law just sent me this photo of the diff assembly he has built for the car, so stoked. Its an escort diff with a 4.4:1 CWP and Quaife ATB LSD, he made a jig for the starlet mounts and swapped everything over. He has re drilled the stud to 4x114.3 and lowered the bottom arm brackets by an inch to help with squat / traction / i dont know but he does. cant wait to get the locked 3.7 out of the car and get this bad boy in!!1 point

-

soo no update for a wee while, I have ditched the 3k-b bigport head, the corrosion is too deep and the head doesnt have much fat left on it to mill, the ports are wayyyyyy to big for this engine and it also stripped 3 rocker bolts due to excessively had double valve springs, doesnt need them as my cam only has 260 tho of cam lift, shes only mild. Anyway i have given my engine builder a mint 3k-b small port head, so hes throading under all the valves, porting the exhaust ports a fair bit and just tidying up the inlet ports to try and match them to this - goodbuy single side sucker hello double doort doorts! i have two DHLA 40s to go on here but the mani needs a bit of work before that, its been ported to suit 45s so its getting built up and it has a corner broken off the head mounting flange so that needs repairing, all worth it as i got the manifold with linkage incredibly cheap. it does have a terrible port entry angle, like almost a right angle, but engine builder will port the head to try and reduce this. so yea just waiting for jimmy motorsport head work now and should be doing skids in a month or too, also have acquired a new cool piece of gear for this but i wont post it up until its in my sweaty little paws!1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00