Leaderboard

Popular Content

Showing content with the highest reputation on 03/29/24 in all areas

-

Fixed the rust hole, no pics cos boring. Made a heatshield for the alternator, first drilling and tapping some brass hex to stand it off, then some CAD, then some shiny so it reflects heat; Then I grabbed the pretty non functional catch can that I made for the truck, modified it so the wire wool was less in quantity and right before the outlet rather than at the inlet, which is why I suspected it didnt work well, then gave it some chode so it would fit in the engine bay; Went and filled it with some 95 as it was pretty low and it definitely needs some time spent on tuning, the low throttle popping and banging sounds good but the afr tells me its not right. Man it feels good to drive tho, the combo of the gogo and the noise is pretty great. If anything it sounds better now the air filter is on, a really purposeful growl.9 points

-

7 points

-

So I took the tank to get pressure tested and it had a crack where the motor plate is welded on. I decided to see what was available on the tard and a perfect (almost) tank was for sale for a price less than another pressure test and paint so I bought it. Is 300L, made in 2014 and comes with a pressure switch and some fittings I don't have. The only problem is the inlet port from the compressor to the tank is in the middle. I don't have a pipe long enough to plumb it. I need a new pipe for that, probably about 900 long. I'll try to mount everything into the tank today and get it running without the pipe. Let's see how far I get.7 points

-

Had access to a large plotter table at my last job which was super handy for reverse engineering or taking prototypes from the computer to the real world, could print notes and datums to cardboard before cutting out for test fits or confirming bolt holes before longer/expensive processes. Today step one of bringing that capability home began, a vivid/sharpy holder for my cnc router. 3/4" mm seamless tube offcut has the same id as the markers, weld 1 stainless washer to the end completes the holder body, complex eh! All I needed was a suitable compression spring to ensure the marker holds a constant pressure without needing a perfect level bed. Awesomely, big green and big orange hold stocks of these things, sadly they are both closed today, buzzkill. Wanting to test NOW a full workshop search was initiated with a suitable donor found in an old BB gun, the slide spring happed to be 110% perfect for the job. Length is set to hold the two types of marker I usually have littering every corner.... Fitted up into a tool holder and good to go6 points

-

So the car has pretty much been all sold. *Motor is going into an escort. *loads of parts are going to others to keep other st170s on the road *and the rest of the car is going to palmside to be a race/rally car ....so thats awesome.....no waste6 points

-

Yeah .. I could have held for way more money ..but I got the car back cheap and sold things for what people offered..... I made my money back and enough to get my mk3 all legal.... so happy as with that5 points

-

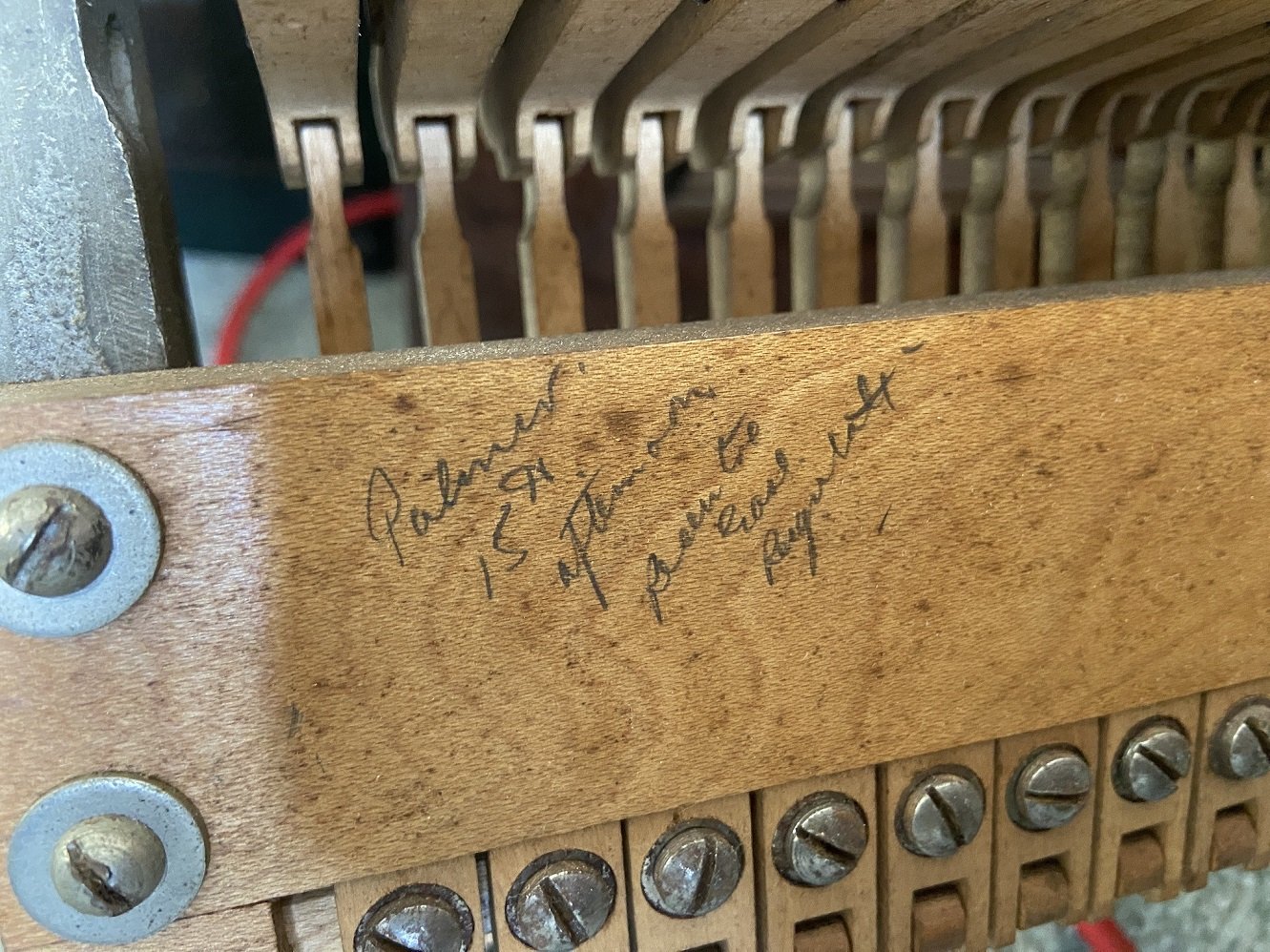

Interesting. A guy from my industry randomly decided to retrain as a primary school teacher, but he didn't last long in the field. I used to flat with a primary teacher years ago, and I remember her making strong vodka jellies to take to school and share around the staffroom at lunchtime - presumably those helped the teachers get through the day. I had David Jenkin assess my piano years ago. I found it interesting and I was sorely tempted to throw money away on a rebuild, but instead I bought a new piano for some reason. Now I have two pianos, because of course I can't get rid of the old one. More than a decade ago I was already finding it difficult to book piano tuners - they were busy, which meant they would tell me their one and only available time slot a month or two in the future, and I'd have to make that work. Then they'd decide to specialise in tuning expensive Steinway grands and stop accepting jobs for old British uprights. The piano tuner I use now is someone I was forcibly transferred to when my previous tuner basically said he was too busy. She's not the norm for the industry as she's about a decade younger than me. She was able to bring forward her return visit to finish the hammer bushing replacement to earlier this week. So that work is mostly done now, but it has an annoying short-term downside - as Tim Finn would say, what I need is a positive action, but there's a fraction too much friction. Ooo, and I noticed this written on the back of the action: I think it says "Palmer. 15th afternoon Recentre Ease Regulate". Palmer was my great grandfather's last name, and ironically he must have been getting the same work done to the action as I've just had done.5 points

-

A clutch line. Bent by hand so not robot straight. I made it a little longer than required just in case I need to redo the flares. Hopefully having it go higher than the reservoir do not cause issues bleeding. The reservoir is just on a hose and bracket, so I could make it higher if I needed to. And the hose bracket I made. With the hose like this it keeps out of the way of the wheel and it doesn't get tight from lock to lock. The hardline originally went under the chassis rail, but it will be way too close to the exhaust, I'll run it through the inner wing.5 points

-

4 points

-

4 points

-

Yo, Long time no see, I figured that because im about to embark on phase 2 of this heap that I should probably make one of these. Anyway, I needed a new daily so I went shopping and found this sweet 82 long bed, I was after a long bed specifically as I needed/wanted it for my shop truck to haul choppers round with. The 350 had a sweet cam and gear drive so it sounded cool and had the requisite chop chop but the 4km/l fuel consumption meant that the daily part of the new car purchase didnt work quite so well. Luckily I had done my due diligence before the purchase and also bought a 2005 Mercedes Benz E320 cdi. Anyway @98cc hit me up and said he wanted to come visit so I put him to work and we pulled the 350 out and swung the OM648 in. Then at some point a @peteretep came and visited so we did some more work, anyway, I had a deadline, I made it, the truck got its maiden voyage with its new motor around Norway chasing a bunch of bikers, good times. Basically the rundown of the swap were: OM648 3.2l inline 6 diesel, the same one the Blacksmoke Racing dudes use. Baldurs Control Systems DID1 stand alone ECU 722.6 Mercedes 5 speed Auto with lockup OF Gear TCU 3 inch intercooler Built 10 Bolt with 30 spline axles, 9 inch housing ends and bearings, Eaton Trutrac and 3.08 gears. At this point it turned into my summertime daily and did truck things Then doing the usual facebook marketplace thing late at night I found a truck camper for sale, so of course I had to have that... At this point I found the limit of the 1/2 ton suspension so with the camper and the 6/8 drop that it has, so I had to do something, I made a bag over leaf setup in the back to help with load carrying capabillity. So about here is up to date, the engine swap is legit, it now gets 14 km/l and will happily cruise at 120 on the highway, because of the 8 foot bed it hauls all manner of things without asking, and does a skid. Discussion3 points

-

It's the hassle factor more than anything. What makes a 2000 car safer over a year than a 1999? Nothing, that's what. It's a stupid rule, but I don't expect a change.3 points

-

3 points

-

3 points

-

Pulled the floor and tunnel panels off to change the detent springs last weekend. Didn’t know what to expect or if the old ones would be in bits/not even there. But they were all present but a bit more compressed than the new set. Turns out I didn’t need 3 seals, the top one had a recess in the nut: Tightened the gear selector grub screw as it had backed out slightly. It’s no short shift kit but it’s certainly better. Scored a genuine Land Rover tow ball with hitch pin on the tard for 80 bucks. Old one may have become compromised using it to pull tree stumps out a few years ago… Saw a neat trick on Instagram to keep the soft top sides tidy when rolled up. 3 wooden broom handles slipped into the hem of the soft top.3 points

-

Old man had a Kingswood wagon when I was 7 or 8. He swapped a Chevy big block in, not sure exactly what size but it was rowdy. I remember when he sold it, guy who bought it was in a wheelchair, had no legs, tried to pay in weed. So yeah the 90s were interesting2 points

-

I have updated the main meet thread. 7pm Wednesday 3rd April at Spitfire Square2 points

-

2 points

-

I’ve just started building USS Voyager. It’s not 1/24th scale but I’ll punish you all with my terrible slow progress anyway. You’ve been warned!2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

Anything from 2000 onwards gets 1 year WOF, it's not a sliding scale.2 points

-

Now we know it runs, next step is to make it worth driving The interior was pretty good condition but there was a lot of evidence of rats eating and storing snail shells in the engine bay and mice droppings in the interior, but no evidence they lived there long, and the shed it was in wasnt water tight so it was all a bit smelly and musty Anyway, all needed to come out for a clean & deodorised the seats, throw away the original horsehair underlay and to make it easier to do a few other jobs, like... Improve the shifter opening, replaced the galv flashing and countersinks that dind really cover the hole with some alloy sheet (from the Sign of the Year! - now in 5 of 5 of our classic cars!) and a rubber boot - adding my first FIAT part Removed everything else and give it a good cleanup. Floor condition is excellent, no rust at all! 'New' Underlay (free second hand stuff) to replace the original horsehair stuff that was a bit smelly and flat. I think the front carpet might be ex-torana too, it doesn't quite meet up with what im pretty sure is the original HQ rear carpet. Both carpets are in nice nick, and we will cover the gap (which under the seats) with some cheap nylon outdoor carpet from m10 that we will also use for the parcel tray that is also unmolested by axe holes for 6x9s etc. Rear came up nice as well, car has a tan interior with dark brown headlining - class! Removed the steering wheel spayed the steering column black (was grey and still has the column change mech in it) and tidied the (omg its so janky!) dash up a touch, and the wiring behind it mainly by removing anything that has added in And then remove the dead weight out of the boot to make room for bodies and crates of DB Its easily 80kgs, empty Things will likley slow down a bit now, as from here its time to start spending money on parts, most likley starting with brakes which i have not even had a wheel off yet to even check what they are apart from being discs up front and drums out back) I suspect the weird too easy/dead stop half way pedal/no brake function issue is the piston is jammed halfway down the master cylinder, as there is no leaks from any soft lines, and lots of fluid in the MC.2 points

-

On the way back the LF tyre was going flat fairly quickly, and needed some air every couple of hours. All good until Levin when the core of the valve blew out while I was putting the valve cap back on. Spare is an original 14" and doesn't fix over the discs. I think my plan for this situation was to put the spare on the back, and swap a back wheel to the front, but that would be a faff as the rear tyre needs to be deflated to get the Radir wheel off, then pumped up again from the air bag system. There happened to be a tyre shop nearby so I humped the wheel over there and got the valve replace (for free - thanks Advantage Tures Levin) Even thoug I just got a fresh WOF one of the mufflers gave up the ghost on our travels. It might have involved a bit of road contact but I'm not sure, these have been on the car since we got it in the USA in 2003, so notbad.jpg Got it off without too much effort, will replace both sides. After driving it a lot over 10 days I realised I have been ignoring a lot of small and not so small issues so I made a list.... have already ordered some bits off rockauto, so will pick away at this while we wait for a house sale.2 points

-

Went for a decent blat into town tonight. A few things to note before I forget. Cruises at 2200rpm at 100kph and has buckets of power upwards from that so the gearing is spot on. Maybe because Im used to a shitty old slow chevy but it feels like a rocket. Makes a weird noise for a second on startup. The sump is too low. Either I have to put in stock springs or modify the sump. @cubastreet got any spare sump pans? The oil filler pipe is now hitting the firewall so I have to modify that again. Second is a bitch to find from 3rd but I'll get used to it. It has enough torque to take off in 4th but I'll leave the clutch alone. I might make the aux water pump booster linked to the ignition as I forgot to turn it on. It's criminal me having this car and living 10kms from a decent corner. It wants to corner.2 points

-

2 points

-

in new zealand it always needs to be licenced/rego paid to be on the road at 40 years it becomes "classic". this means a slight change to "continuous licencing" in that it takes a little longer for it to be come deregistered if you forget to put it on hold2 points

-

My Datsun has a haltech and running std tacho with inductive loop, i just ran the power wire for the coil, coil no1 in your case, through the inductive loop and it works mint.2 points

-

Nope. Which is kind of weird as you can't read speedo at night without a light Has to have high beam light and something to tell you the indicators are on, that's it1 point

-

Oh yeah, I do intend to 'seal' it all with a clear coat, but just wanted to check if any were needed prior to decaling and weathering etc. Going by what i have seen online, it sounds like the idea of the clear coat is to lock it all in place and protect it down the line etc.1 point

-

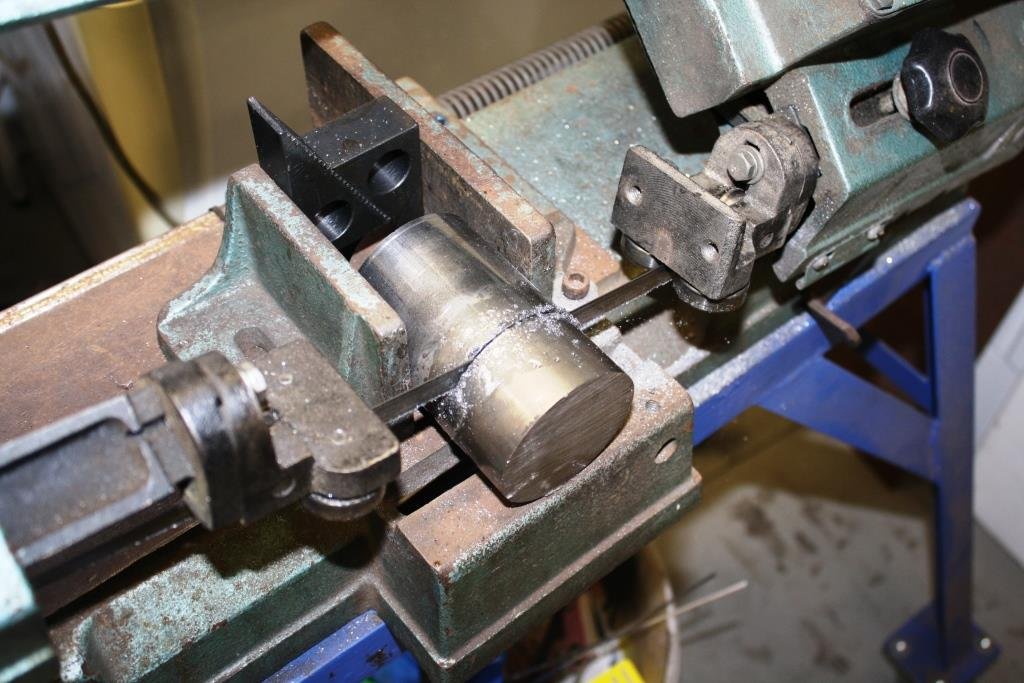

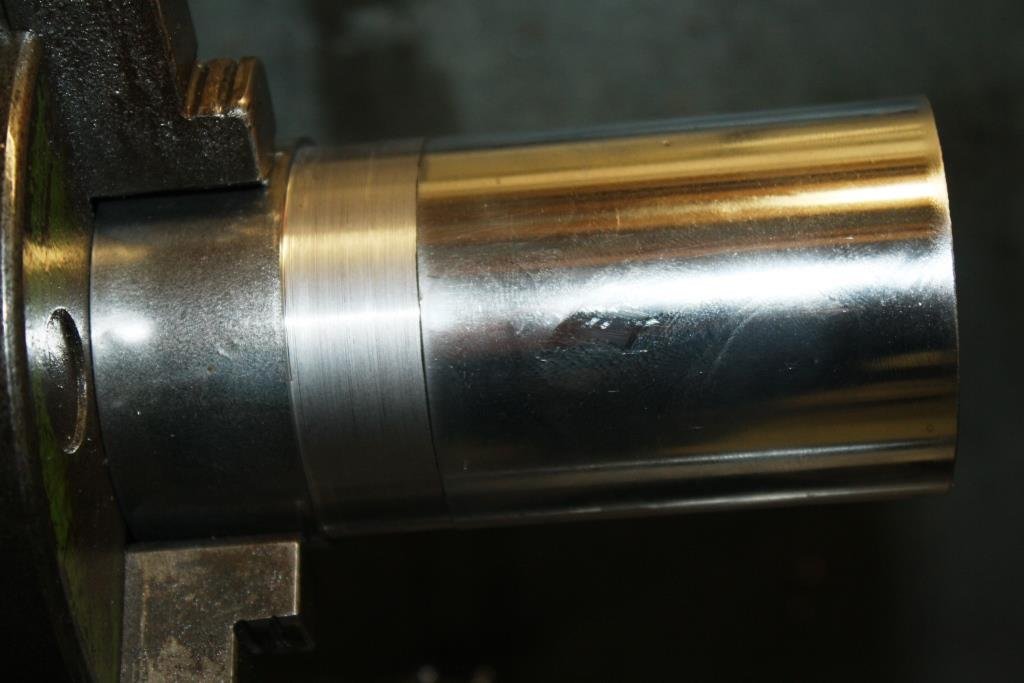

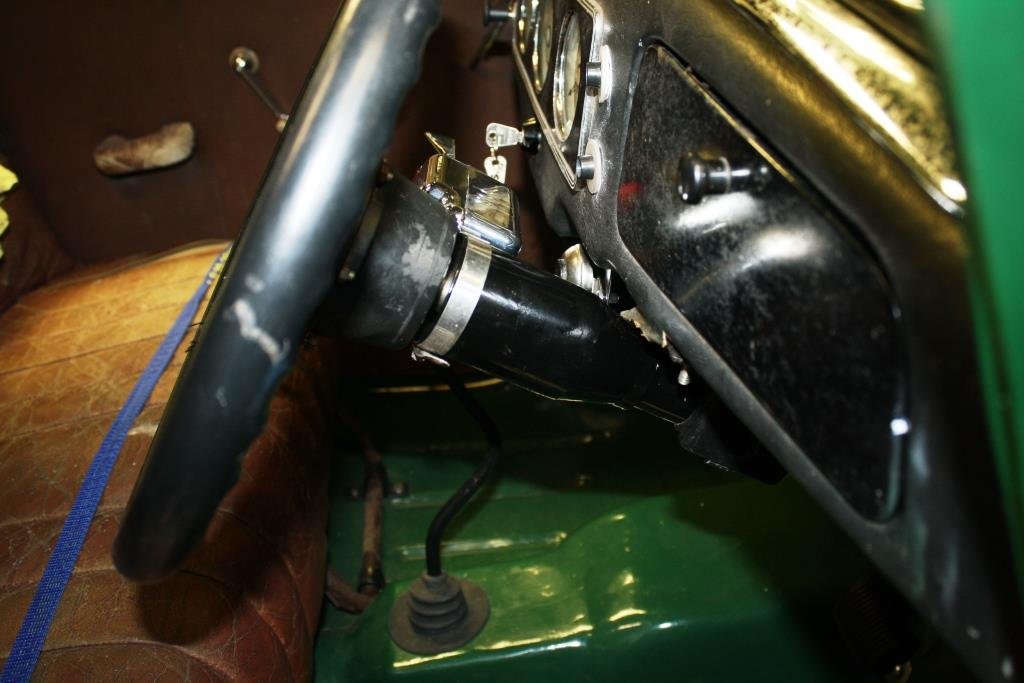

A while back I spent quite some time making a sleeve to tidy up the gap between the steering column and the steering wheel. Problem was the top bearing just had too much play in it for my liking. When I pulled out the bearing I found it was a piece of pressed sheet metal rubbish that was close to impossible to replace. The solution was a trip to the local bearing supplier and the massive investment of $13.50 (and to think the “ever lovely Mrs. sr2” accuses me of being cheap!). I bought a large piece of mild steel round and chucked it in the Emco. I bored it for a firm fit to the OD of the new bearing. I flipped it over and cut it to size in the bandsaw… I then line bored it to fit the steering Column tube. That’s an end I cut off from an old column; you can see how light the original bearing was. I double checked everything still fitted…… …… and then turned down a piece of scrap water pipe to act as a cover between the bearing and the steering wheel. I then turned it down to the same OD……. …. Took the cover off and turned a taper at the other end…… All set to assemble……. (The tube on the left is just for setting it up). Checked it with the Triumph steering assembly…. …….some plug welding…… A bit of paint………… And I’m back to where I started, (story of my life!) but with no play in the steering wheel. The only thing I don’t like is the cheap, shiny, aftermarket “hotrod” indicator switch. To its credit it works well but looks very out of place - far too new and shiny for Rigamortice’s discerning taste. I’ll keep looking for something old and quirky to replace it with. Any suggestions gratefully accepted… https://oldschool.co.nz/index.php?/topic/49843-sr2%E2%80%99s-1947-vauxhall-%E2%80%9Crigamortice%E2%80%9D-discussion-thread/1 point

-

Anyone else planning to attend the Waiau Pa Hop on the 7th April? held at the Clark’s Beach yatch club at the end of Torkar rd. register before midnight to have a entry sticker mailed out. entries close on the 6th April but must print out an entry number if entered after midnight tonight (27th March). approx 200 cars entered last year. Http://www.pahop.org1 point

-

1 point

-

Nah 20 years is a new car that only needs a wof once a year.1 point

-

He’s quite right obviously. I’m pretty confident that this aspect is good and the initial measurements I did tended to prove it. Will re-measure more accurately before refitting and may even plot a graph….. Other thing is that I have had it working beautifully in the past ….. Even this particular collection of scrap worked very nicely when first installed. I’m coming to the idea that this failure was mostly due to crap parts.1 point

-

1 point

-

When I sold my first rx4, I kept the blower, and eventually sold it to my mate and well known drag racer Tony Markovina. For fun he strapped it on to HVATOS drag car with a JC cosmo 13B J port, cranked the boost up fed it methanol and ran a stout 9.84 1/4 mile with it! Until one fateful night they were revving it up in the shed and the front fell off the motor..... Massive amounts of damage, the motor was removed, and sat in the corner until I bought the lot back 10 years later. I have quite a few repairs to do, more pics to come, but I won't be reinstating the JPort for this build.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

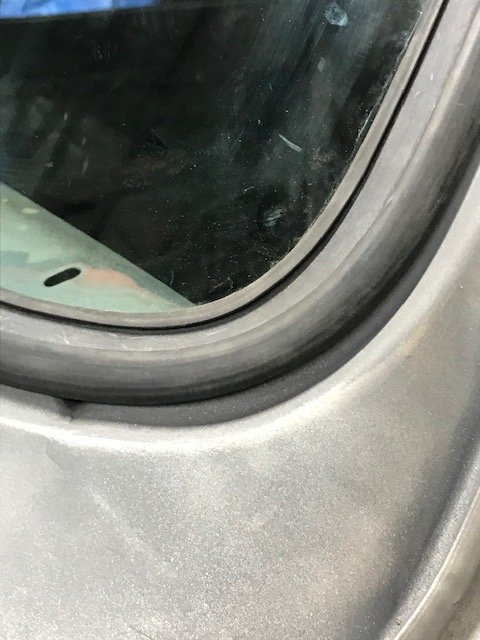

Went and check out the rubber issue today and both front and rear screen rubbers don’t fit good and the rear quarter glass rubbers are average as well compared to the originals. Need to do some research to sort the best rubbers. Rear bumper I had rechromed has a couple of ripples in at as well so it’s off to get stripped and sort the ripples and chrome again argghh. It looked very straight when I dropped it off but the new chrome highlights any defects. The moulding fit off has paid off big time as quite a few of the mounting holes have had to be welded up and redrilled to get it bang on.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.png.b2aee08688778d18bdc7b3e3c1852d9c.png)