-

Posts

5,606 -

Joined

-

Last visited

-

Days Won

1

shizzl last won the day on December 8 2022

shizzl had the most liked content!

About shizzl

- Birthday March 31

Profile Information

-

Gender

Male

-

Interests

Wasting money on shit cars

Converted

-

Local Area

Auckland

Recent Profile Visitors

8,223 profile views

shizzl's Achievements

Committed (5/5)

9.4k

Reputation

-

C@nts. Their only response “triple check your system as our supplier has sold over 3000 of these in Australia and yours is the first warranty issue”. total bs btw.

-

Pretty bs when you’ve sunk over 1k on a component and don’t even acknowledge your customers

-

Photoless updates are pointless *sigh* but she’s been at SprintRE for the last 8 weeks. the new engine looks epic, and is ready to fire up. stopped by today to catch up with them. exhaust is complete and looks so damn good. looking forward to hearing it on Friday . had many curveballs get thrown around so far, mainly with the faulty Wilwood master and the fact that StealthRide don’t seem to acknowledge emails or follow up with warranty stuff. Wankers

-

Just build your own deck to suit your needs. ones like m2 overland etc are awesome but so expensive. if you find correct sized deck that doesn’t work, just relocate the mudguards and relocate the mounting points , it’s actually not hard. often it’s better to just throw an extra couple of grand to a more suitable already set up unit. i would stay 10 fathoms clear of that towbar set up off the deck.

-

Sweet, thanks @RXFORD

-

How critical is tyre load rating at cert time? my ute on carjam has a gvm of 1999kg but will never see that weight in its lifetime, definitely not going forward anyway. the only tyre I can find that is going to work has a load rating of 82v. Which I’ve deciphered at 487kg most other tyres in the same size are not 74-78v a stupid balloon tyre or LT won’t work whatsoever

-

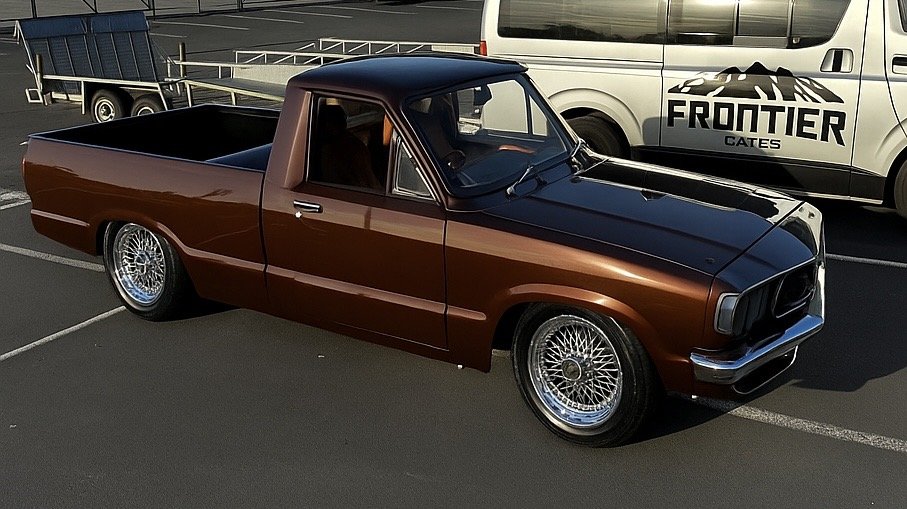

If I was rich I would for sure chuck on a set of SSR meshies. Don’t reeeeally want to sell the MS-01s to fund that

-

-

-

- 148 replies

-

- 11

-

-

Caught up with the boys at Sprint RE today. engine goes together tomorrow. It’s looking so good too. o ring groove is perfect and still uses a stock Mazda water seal. ports cleaned up and matched, rear plate was replaced, housings port matched and tidied up, water jackets filled. ida has been stripped, cleaned and rebuilt, fuel bowl modded too. Jason, Chris and Ryan are bloody good buggers too. rear calipers were sent away to Stirling to be rebuilt, and I dropped off the new rotors. all new rod ends and pitman up front, new ball joints . bump stops added and a couple of sweet alloy A Arm pivot covers fitted. can’t wait to get this on the road now. oh and check out this pic of the OG ute that popped up on FB. Never seen this one before

- 280 replies

-

- 10

-

-

Right o lads. I’ve been chatting with a couple of guys about this topic and keen to know the answer to report back. is it legal here to “flip ball joints” .. relocate the ball joint above the lower arm using a spacer on top of the arm and a spacer to fill the void the ball joint took up. Obviously using higher grade bolts. im sure I’ve seen this posted somewhere but search results net zero. thanks in advance

-

A TIKing time bomb?

-

Wasn’t so much the pinning, but the fact that the water jacket in the housing wasn’t filled/blocked off. So the sealing surface was super narrow and probably never sealed at all from the start. so Jason will rectify that and machine in a new water seal groove so the inner seal isn’t cut like these traditional time bombs. what he explained was awesome and should be standard practice.

-

I’d have more hope dumping into the Waikato river for a week