Leaderboard

Popular Content

Showing content with the highest reputation on 04/04/20 in all areas

-

Looks like i should be able to fix engine back to pretty much 100%, lockdown spec The bad; it has spun 2 big end bearings, shells in pic below were worst. All the rest of the bearings in the engine look pretty tired as well. Crank isn't too bad, but would need a grind to be usable. plus seems it has already be ground in the past, so in the bin it goes. Oil pump hasn't let go or anything but some bearing material has gone through it, bin as well. from there onwards everything looks clean, oil filter has done its job Good news is I have a bran new crank and oil pump. Both are for another project Ive been collecting parts for. Means that goes back down the list, but rather have this thing running. Rods are all good. some very light marks on one of them, shouldn't be an issue. pistons and bores look perfect, although i haven't taken pistons out as may not be able to get hold of a ring compressor. Have managed to sort some new main and rod bearings, should be here early next week. Have also done the oil restrictor mod, to the oil gallery that feeds the head. keep more oil in the sump at high rpm Tl;dr : putting this junk back together with new crank, oil pump & bearings.19 points

-

15 points

-

15 points

-

12 points

-

Earlier this year I went for a 4wd mission to scope new hunting areas and came to the realisation that I was choosing spots based on where the Niva could go and not where I wanted to go, the big barrier on the east coast is rivers, and the fiat motor hates water! We managed 15min up this valley before being forced to cross the river, issue with the twin cam is the spark plugs are located in the valley between the two cams, any splash of water is directed here which promptly kills the engine, normally mid-current. We turned around and headed home, on the way back I was pondering methods to prevent water but nothing was simple or failsafe. What I needed was a snorkel, diesel, raised breathers, longer wheelbase and bigger wheels........ With this in mind I set to work.... The snorkel was easy, pretty much bolt on Diesel pump to fiat twincam was tricky, but with a big enough hammer it went into place Bigger wheels needed clearance, overload springs were installed This all took quite some time, and the result somewhat best enjoyed with a cup of tea in hand Unfortunately i've replaced the Niva with a more suitable vehicle for my current needs. I have access to a garage not too far from home that once lockdown is over it will be tucked into, My mind says I should sell it and move on, but I can't bear the thought just yet of parting, its been a great toy over the years and really is a hoot to drive, sadly I just don't have the space for so many cars! Before parking up, I plan to carve out some rust to be sure there is no deterioration, parked up in WOF condition is the plan, ready to hoon should the urge arise.11 points

-

Carol said she fancies black (like her men ?). Not smooth enough for that. The truck, not her. Or me. Or something. And a bit too BTTF n'all. Anyway... Yeah, I reckon 70's stripes. Now I've got the slot mags I'm starting to feel like a bit of brown metallic might be fun. But to refresh, something between this and this Gonna do some doodles and see where it goes9 points

-

I’m not the most knowledgeable fulla out there, just a little bit of knowledge and experience on things. I’m sorta hoping my thread will encourage others to tackle those jobs we usually think as too hard or for specialists only. Don’t hesitate to gimme a nudge and ask how I tackled things, or how/why I made the decision I did to do things. I’m all about sharing and expanding everyone’s knowledge, experience and capabilities. Nothing is off limits or a secret In my world. head over to the discussion page I started and fill your boots.8 points

-

The wife commissioned me to build a swing for the child. I started pre lock down, so had all the steel/chain/shackles/hose already. I didn't get paint, so it ended up silver, as that's all I had. Made the baby spec seat out of some rubber I had laying about, and the adult side is made out of old conveyor belt. I had to make it in three bits so I could get it out of the shed/into the back yard. I've also assembled a hut the father in law made, and reconditioned a see-saw the wife had as a kid. Next up is reconditioning/modifying the old slide (also wife's) in the background.6 points

-

All cells fairly even after a charge so wrapped battery in foam... Put some plastic card over BMS as protection, foam on all sides and some layers of heat shrink... And yes, fits in the canvas bag like a good'un... Very snug but I'll take it...5 points

-

Found the boost leak, one of the threads on the inlet manifold inlet was stripped and my rubber gasket was flapping like a my arsehole after a vindaloo. Must have done it up Archer tight - tighten it til it strips, then back it off half a turn. Managed to get an m8 recoil kit and sorted it, no more funny noises. I took it for a spin just now, it is boosting to 10psi which feels really quite lively. The EGT's are getting up to 600deg which is a bit much considering it's only acceleration load, it really needs a boost compensated fuel pump but this will be a lot later I reckon. I'll dial it back a tad and see what happens. It might need a fan on the intercooler, I have wiring for it now. The power steering is still playing the game, now I just need a functioning alternator. Good times. Pic edit for interest5 points

-

5 points

-

pulled the pin yesterday and painted the exterior. the basecoat went down beautifully. but i really made a hash of the clearcoat. quite alot of sags, and in hindsight, the lighting in the garage was shit so i couldnt see them forming and i think i was holding the gun too close. really took the fun out of it, however all it means is a bunch more colour sanding which ill tackle in a while once its gone nice and hard. on the plus side, the thing looks dead straight, really happy with the sanding job. have un masked it, which was a tour of all my fuckups, but ultimately itll come up awesome. the colour is amazing and i cant wait to see it in the sun.5 points

-

So Yeh nah, the norgren air filter things didn't work. I took it for a blast on the beach, was probably like 10km away from my car, and it lost all power. The little filter things had got saturated with gas and stopped breathing. Luckily an easy fix, I just cut them off and it ran sweet again. So I thought I'd give plumbing them into the air box a try. I've welded a nipple on the very bottom of the plenum to connect too, this will also act as a drain if a float sticks and floods the plenum again. I also replaced the restricor tape with a bit of flat bar. I also did a dodgy patch on the exhaust, and put some flat bar over it to protect it a bit, as it's the lowest point. I also started building a simple trailer for transporting this thing. It's not going to have springs, and will have a hinged draw bar so it can tilt, so I don't have to have ramps. Regards, VG.4 points

-

Hey gang. Faced with being allowed to do sweet FA until at least July, looks like the Hilux is going to get a bit of lovin'..... Time to get the roller and the house paint out. Although it looks as rough as a badgers arse, it's only got a few dings on it. Both doors, a few on the bonnet and that nasty old war wound on the drivers side B pillar. Bonnet first Did the doors too, only a couple of little dents. Next job is where I got hit by a bus about 20 years ago. It's never bothered me ( I got paid out & took some mates to the pub) but if I'm going to fancy it up it needs sorting. Borrowed a decent slide hammer and had at it... Pretty pleased with that, especially considering what a lazy cunt I am. First coat of filler and a bit of a sand, I'll skim and paint it manana So that was the easy bit, next up is wet sanding the whole flipping car. Woo.....Hoo. When I borrowed the slide hammer I blagged a few cutting discs so I hope to get the push bar cut to size tomorrow n'all. Then I'll have to make an essential trip to get it welded up, while maintaining 2 metres social distancing, having a shower when I get home & burning all my clothes.4 points

-

Clearly that was going to be too big for the vacuum line so on to plan b. Drill out hole to 4mm, flare a piece of 3/16 brake tubing, turn down end of tubing with mini lathe (cordless drill in reverse and a file), smear with brush on electrical tape (cannot find my shellac anywhere), and tap into hole with greatly oversized hammer. Et Viola3 points

-

one day Ben im going to get you for all this heresy!3 points

-

Engine mounts are one of those things that there are so many different combinations of shapes and sizes that its impossible to have a set rule on how they must be done But as a very general rule, 3mm steel with gussets. You can come up with a design yourself no problem, post up or send me a pic if you want some input on if they are ok or not One thing to remember when designing mounts, is if the rubber breaks, the engine should not be able to rock over and jam the steering. So for example if you have limited exhaust manifold to steering shaft clearance, you may be better to use a locking style rubber mount instead of a round cotton reel type one3 points

-

3 points

-

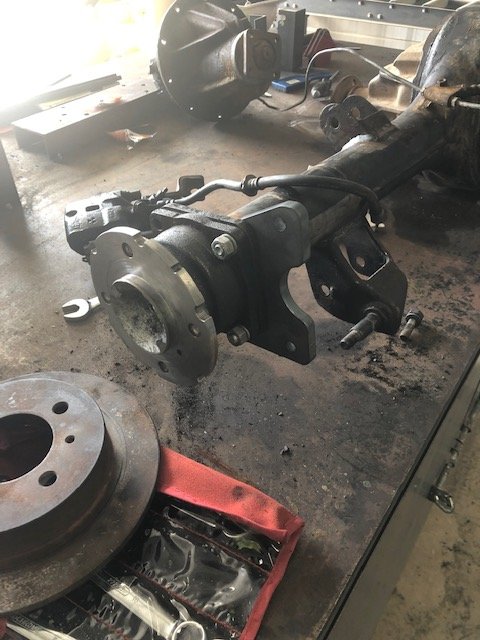

Time To drop it all back in and see if my 12 hour day was a success!!! too right it was!!! In other down times I machined the universal joint/yolk off the driveshaft that came with my LSD head, as well has have some spacers Lasered for my callipers to mount. now I can say the diff is all but done!! Just a lick of paint, seal the head to the housing and install it ready to fill with oil3 points

-

3 points

-

3 points

-

2 points

-

Thanks for solving the mystery Sheepers. First time I've encountered one of these. Luckily the sump on my mock-up engine doesn't have this so I'll swap the sumps over and get rid of it. Looks like I could do with a new sump gasket anyway and would be good to give the bottom end a bit of an eye over at the same time. Bryan, the dipstick is about the only thing I can get to with the 4Y fitted in the Thames LOL.2 points

-

The metallic went down better than I could have imagined, just the clear went to shit. It's prety bad, the photos don't show it up that much/have only photographed good angles, but you can look through the runs and see the panels are dead straight so that's awesome. And I'm really hoping that with yet some more sanding it really will look as good as hoped it will. I think it will. I'm also pleased with how the bronze works with the blue interior. And am undecided on wheel centre colour. Initially I was going to paint them r32 gtr gun metal grey, as a mate painted his r34 rims this bronze on my recommendation and the colour combo looks great. But open to suggestions. Really need to clean all the sanding dust of them as is and see what I think.2 points

-

Could be useful if the dipstick is hard to get to when installed in the Thames?2 points

-

Got the plug out, was a bit worried as thought it was going to be a cunt. Also found some dodgy/damaged wiring for the alternator so pulled that out (need a few bits to repair it). Looks like some suspect oil lines as well (diesel life so vacuum pump on back of alternator) so think I'll replace those. Oil return on turbo is also clearly leaking and making a fucking mess so I'll pull that off as well and will be good to replace a few bits there. Hopefully this will limit the horrid oil leaks this thing has. Obviously can't do much till the world returns to normal, but no drama, will be nice to sort these little things out once and for all.2 points

-

More updates... Laid some paint this afternoon ready to go back in the car. Also, forgot I never posted the guard resurrection. In December last year I spent some time repairing rust, filling and sanding. Got some paint matched, its not perfect but pretty close considering the lime/yellow/milky colour. The paint tin is back at the shop and they are having another go at it. So back to the diff, aiming to have the exhaust sorted on Saturday and the diff in on Sunday. Might go for a hoon up the road on Sunday night2 points

-

So from here I made a basic jig to mount the faces of both diffs on. And please remember, this is the first attempt I’ve had at anything like this so I wasn’t really sure how to tackle it. just used basic angle iron and welded it to the bench and bolted all the suspension components to it. Cut them off, and sat the 1600 diff on the jig and rolled the mounts o to the new housing.2 points

-

decided to have a play with something other than rust /welding/cutting/making.......turns out pulling a 44 year old front end isn't as easy as undoing some nuts. the front end most of the bolts had to be cut and studs pressed out..most of the bushes were none existent .(i have a set of bolts front another front end ) all stripped down after a couple of days with wire wheels on my drill press and some de greaser and a wipe down and coated in POR15. i bought a full bush kit last year and found 2 good condition steering boots in my parts shelfs and all rebuilt with what i have ...still need to get some new tie rod ends upper and lower ball joints and decide on discs and what calipers to use......and some split pins and thats the front end completely done.........once the world returns to normal. and the crap left over.2 points

-

fizzed it all up today, been stripping out all wires/ all non essential wires/cables off of the bike and routing through tubes where possible to clean up the look gonna have a go at fibreglassing the seat base tomorrow which should be interesting2 points

-

Another thing I did a while ago, someone might like to copy to amuse them selves/kids. Bottle rocket launcher, pretty simple just some PVC pipe, a ball valve and a collar to catch the bottle. Goes pretty well off the compressor. Shallow groove that holds an O ring to seal the inside of the bottle neck The O ring sits under the collar. I got a bit carried away using a lathe to make this. The pin holds the bottle on with the small ridge under the cap. We find that about 1/3 water and as much air as the compressor can supply gives best results, It mounts on a bike rack so it has a nice solid base to sit on. @scooters2 points

-

Anyone on here who's ever used a hot water blaster knows how much better they clean than than a standard cold water blaster. I have a little Karcher water blaster at home, it goes ok but with cold water but is a bit meh. I've heard of people plumbing them into the hot tap to make a DIY hot water blaster. Taking the hose into the house sounds like a recipe for disaster, makes the place look like a meth lab, and my garage is a long way from the house. Solution. Take the hot water to the garage 20l at a time. The water blaster doesn't use much water, I was surprised at how well it worked, and for how long. It took 3 fill ups to clean up the bike frame and parts I was tinkering with today. I probably wouldn't recommend it for degreasing the 440 out of your Grandads motor home, but for small jobs B+ out of 10.2 points

-

1 point

-

i got quite alot of indication. but shit does it look good in the sun1 point

-

Yeah runs are just part of painting. We call the paint depth indicators at work, they're so you know you've got enough paint on1 point

-

currently watching this much longer video about the same trick/more info. he did say on flatter areas hed stick with the razor. he does a good job about making me not feel so shit about getting runs though, "if you dont get a run every now and then, your not trying hard enough or your not putting it on wet enough"1 point

-

1 point

-

Yeah you can save it, watch some youtube videos if needed of how pros tackle fixing clear. I have made a mess of clear in the past and wet sanded it back and put more clear down a few days later, its not ideal but its not a sin. I mean really all the hard work is done getting it flat and in paint, whats a few more days of work in lock down to get it super slick.1 point

-

1 point

-

1 point

-

Some nice things arrived before everything turned to custard The water passage looks like a shocked face :O Repco is also delivering at the moment - I ordered a gasket set with the cylinder head but it was a bit bent and some of the sealing material had come away, so ordered another head gasket locally. Also painted the water pump pulley a stupid colour because why not. Fitting tomorrow - what's the opinion on copper gasket spray on head gaskets? New one is a generic permaseal. Cheers1 point

-

1 point

-

Cool truck! love the wheels :-). Only the later Starion stuff (5 stud) with the bigger 8" CW will fit, the earlier 4 stud stuff (more common in NZ) is the smaller 7.25" CW. Finding 3.9 gears for the 8" stuff is a might tricky. Early L200 sport models had them. I put 3.5's (from a widebody starion out of the states) and a 2nd gen LSD head in mine though as I wanted better highway cruising. The 3.9's that were in mine were pretty worn out and noisy. With the smaller tyres on it putting the taller diff in it has corrected the speedo which is excellent :-).1 point

-

Oh, remember that time I bought a welder 2.5 years ago? Thanks to Covid lockdown I found some time to set it up and found some balls to start cutting.1 point

-

Got it all fired up and running, it sounds amazing. XR292r cam Lift 0.621 / 0.627 in, Duration 292 / 298, it has vic jr heads i have played around with, a super vic intake and an 850 pro systems carb. Ive got a moroso 7q pan and a melling hv pump in it. In the second photo you can see a clear line heading into the drivers door, this is connected to the trans and used to set up the line pressure for the AOD trans. I spent a good amount of time running it in, and have only in the last week changed that oil for some fresh stuff. It runs really well, but i need a new valvebody for the trans, as the shift pattern is 1 D OD meaning i cant hold second gear. With a 3.25 rear end it sits at 100km @ 2100RPM in overdrive haha, im thinking of going to a 3.9 ratio. From take off it has a bit of a flat spot, i dont have an AFR gauge so dont want to play around with it too much, if anyone knows a good dyno tuner/carb guy in chch please let me know in the discussion thread! Would be much appreciated. God i would love a sprintcar style air cleaner on it aswell, the single stack is only on there because its all ive got I also installed an oil cooler as temps were getting too high, its quite a small one and has given me an interesting problem. At cold idle it has 40psi, and at hot idle as its able to flow through it better, it has 50 psi i think ill have to get a bigger one anyway as temps climb too quick after a decent pull, ive heard shorter plates but more of are better than a few long plates for flow. of oil. Such a shame, i managed to get her all ready for the wedding to be cancelled, makes me a bit bummed that i rushed a lot of stuff together and now have to re do things, but i can definitely say, without the motivation the wedding gave me, the car would probably still be sitting in primer right now1 point

-

Yeah wasn't happy with a single washer so pulled the spokes and built it again, loosely assembled here with 2 washers on each spoke... And after truing it up this happened... Took it for a blat up the street with no brakes, actually rides really well. Gotta take another couple of links out of the chain yet, surprised to find a new chain, hoarding pays off again... Then once I sort brake cables and see if I can get the gears working it should be a decent old bike. Could even get motoring this week...1 point

-

I'll save the long story and go straight to the money shot (this is me squeezing on the radiator hose) So yeh, that's pretty obvious whats gone wrong. This is all in behind the cambelt, that's the bottom pulley/gear at the bottom of shot. Would be an easy fix if anything was open.....1 point

-

Sat in the sun and laced up rear wheel today. Used spoke washers as the old Sturmey Archer hub has thin flanges, and new spokes have too big a bend radius... Threw it in the wheel stand and bearings were adjusted so loose it wobbled all over the show, so cleaned, greased and adjusted them... And all set up on the home office desk to tinker with... Quite theraputic doing this when stressed, wonder if I could get away with it at work... [Edit] might need 2 washers on each spoke to fit right. Dang, lucky I have time...1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.384ff72c8d2b0ee0d34a7bdedb55bdcf.jpeg)

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)

.jpg.aeebd4c5e00d6ce3fdc3ee36654f7f5e.jpg)

.jpg.230dae5cdd9c40a53cd705f61e1bf477.jpg)