J4m13

Members-

Posts

181 -

Joined

-

Last visited

Converted

-

Local Area

Outside NZ

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

J4m13's Achievements

Advanced Member (3/5)

637

Reputation

-

search his number plate mate on the google machine....

-

super charged 13B?!?!?!?!

-

WHY?!?!?!?!?!

-

I seen you have multi stud discs.... Are they from the factory or drilled external I.E an engineer/diy etc??

-

Good sir!! A good trick to having as little shit in your paint as possible it to spray the floor with your hose and surrounding areas. Walls etc. Just not the roof. Dust likes to settle in all the nooks n crannies so a good hose out prior will work wonders Spray the floor in between coats too...just not so heavy you have some water bounce off the floor onto your paint job

-

Throw us up some pics mate!!

-

J4m13 started following Old cast alloy welding

-

I have a wee predicament. I have an old stationary motor that I recently broke the intake runner on. The motor itself is circa 60's, built in Germany and appears to be old cast alloy. My welding skills are poor at best and I am in need of having it repaired. Is this possible?? and what type of tradesman/specialist welder would be best to approach? My initial thoughts are those who specialise in repairing motorcycle casings and the likes. That being said, my experience in this sort of stuff are pretty limited so i'm hoping to have some ideas from folk far more knowledgable than myself. Any help or suggestions would be greatly accepted.

-

Discuss here about Yoeddynz's little Imp project...

J4m13 replied to yoeddynz's topic in Project Discussion

Why cant I view photos sir?? -

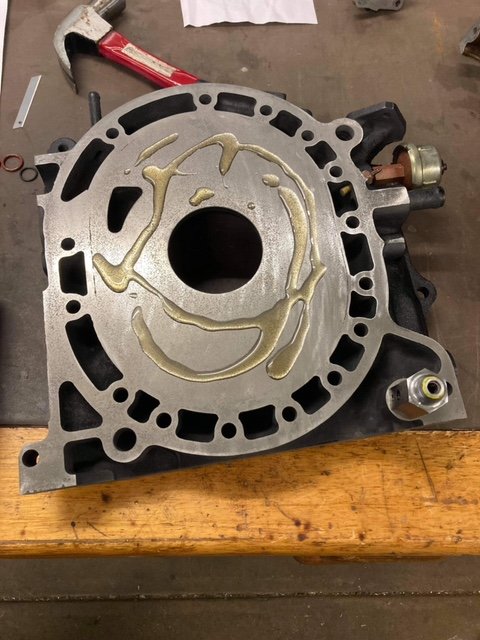

Thanks mate!!! there’s lots of tricks and personal preference. A lot of secret info in the rotary world… im not really sure why as I’m certain most of it can be found online if you have a bit of time and desire to find it. The stuff I know and learnt was from back in early-mid 2000’s so no doubt things have certainly progressed from what I experienced. as for the failure. Most of the examples of gears like this are from over revving and lack of oil. And you’re assumption is pretty good. I was told of the same thing, wipe the bearings creating excessive bearing clearances and movement etc. In turn straining, chipping and or cracking gear teeth, that continue to rip through the rest causing catastrophic failure. hence I went for the hardened gear to eliminate this weak point, as well as upgrade the pressure reg from a 60-70 psi regulator upto around 100psi. also did the multi window bearing for extra lubrication There are plenty of other oil mods that can be performed but for a standard engine, that only boosts 6psi I didn’t really see the point. I guess I can count myself lucky it ruined only rotor gear and stationary gear.

-

Now I have the relief knowing that ive got a fresh engine and gearbox and a few miles of happy cruising ahead of me.... Any hints, questions or abuse. Fire away on the discussion page

-

Anyways…. Cut a long story short…. k drove it as is to get a road worthy from the local mechanic, then went on my merry way to get a set of plates and license it. turned out the orings the injector place I had overhaul my injectors supplied me were too small and I had a severe vacuum leak. Changed them, readjusted my secondary butterfly because it was off seated at idle and the old girl hasn’t missed a beat yet. 750ks, a couple of tanks of gas and lots of smiles has been had so far. almost time for oil change and a few more revs!!!

- 20 replies

-

- 21

-

-

-

From there….. It was drop the old girl back in the hole, connect everything up, bleed the oil system, fuel system and coolant system. yelled out to the wife and had her sit in the seat and crank. got her to wind it until oil pressure gauge moved…. Check!!! connected plug leads and warned her it will more thank likely spin and smell of fuel, possibly cough n fart and blow a bit of smoke. as she held her breath… I could see her nervously about to the the key and I had a chuckle to myself. No sooner had the engine rolled over once it roared into life and my wife and some shit now impregnated in her undies. only the down pipe from the turbo made for a noisey block but with the shit in her undies she didn’t give it a bit of gas so died after about 10-15 seconds. after she calmed down from yelling and calling me a prick I let her k ow to give it a small bit of gas when it catches so I can check for leaks and ensure all was well….. needless to say we had a winner!!! No dramas and once it was warm it settled a bit but idling was pretty shit, hunting and erratic. Anyways…. Some more pics

-

-