Leaderboard

Popular Content

Showing content with the highest reputation on 05/11/19 in all areas

-

Long time no post. I got real sick of the internet so I made a hat out of pams aluminium foil and stopped the govt stealing my ideas and kinda backed away from the interwebs for a long time. Anyway since then, in true Seedy Al style, I've had about 20 cars and broken most of them. The one I've had for ages is affectionately known as the BBQ. I bought it as a bog standard E36 328i auto and proceeded to throw 10K at it to make it into a really tidy msport spec car with coilovers and bucket seats. Then the engine caught fire and the lovely folks at Swann gave me the car back and $11k cash. How I bought it How it turned out So.. long story short, on the way is an L98 from a VE commodore, Tr6060 box, and a lot of bleedy knuckles and swearing. Engine due in a week so will get stuck in. Also being a ghey, naturally I got an E46 msport 330i convertible and put the wrong offset wheels on it so it rubs and is twitchy, Great! Photos to come, I forgot how to code. XX Spanners14 points

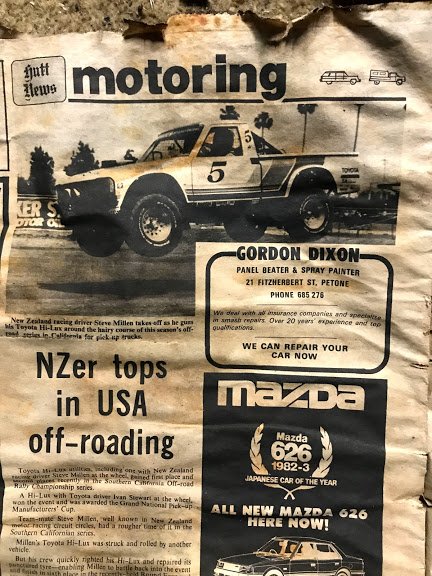

-

I just visited the guy who owns the rotary demonstrator car. He has some very useful body parts that will make this project a million times easier. He has offered me the rotary car and spares but it’s not in a great state. It hasn’t run for a long time and probably needs a rebuild, apparently it’s a 13b but thinking about it now maybe it’s a 12a being late 70’s with a carb. I’m no rotary expert though. It’s using the vw gearbox so ratios are not good for a rotary. The car got wet and has been partially left to the elements. Its really not what I went there for but in the back of my mind it makes some sense..... maybe... fck.5 points

-

Engage safety squints Oxy torch cuts through an 800mm thick slab in single pass5 points

-

5 points

-

4 points

-

Exciting times here at the only Imp workshop in the valley. It runs! But typically there are a few small hiccups. Some actually quite comical. I think we should re-wind back to where we left off last time. So I needed a new ball to see the gear stick through until I can get a decent proper replacement. I had bought a section of nylon/teflon bar. I made a gauge from card to match the curve inside the socket that the ball would rotate. Then I reversed that into a gauge that I could place over the bar as I machined it. Not exactly brain surgery. Which leads me to a little giggle about this bit of comedy gold... https://www.youtube.com/watch?v=THNPmhBl-8I he he. Love it. So yeah.. easy job. I got a pretty match and it came out OK. Works well enough but the reverse lockout plunger spring is a bit too keen and popping the gearstick left into the reverse plane requires quite a sharp movement. Luckily it would be easy enough to sort, except for that removing the engine and box bit.... I might just put up with it. At least I'll never accidentally select reverse when dropping down into second before hurtling around a tight corner feeling the full force of the mighty 68 little Datsun Ponies as they rocket me forwards. But before I got too excited about such F1 levels of performance I thought it might be prudent to protect those little Ponies from breathing in dusty air. I needed an air filter that fitted the space I had (not much area in height available), looked good and was cheap. There was nothing available. So I'll make one. I started with an old but perfectly usable filter from a customers Ford econovan (Mazda really..)... I chopped it up, essentially slicing off a section of the right thickness to suit the height I had. I then grabbed a section of 5mm alloy sheet I had in stock, chopped out two discs with the Jigsaw. Put a hole in one with a holesaw which allowed me to hold it in the lathe to machine it down. Reduced the thickness by 3mm leaving a neat lip around the edge to not only hold the metal filter outer in place but hide and seal the edges... For the lid I welded an old steering wheel boss I had kicking about onto the plate. Then I machined the plate down to suit, like the bottom one and then cut the boss off. Cleaned up the marks and ended up with a filter that fits and looks the part too. I'm very happy with it In place... Note the ugly pipe hanging from the rocker cover breather. I need to sort out something there. The manifold the carb sits on seems to be spot on level since modifying it. Welding castings like this can often be a bit tricky what with porosity and dirty alloy. The datsun item seemed quite clean in this respect... The tiny little Hitachi twin choke carb that sits on top is so dinky. I have no idea exactly what model A series engine its from as I had been given it by a friend who had got it with a job lot of Viva parts. I can only hope that the jetting is correct. I'll soon find out. I might try again with research on the numbers. I had to reconfigure the throttle cable layout to suit its new home. This involved a new pulley to suit the cable pull on offer from the stock Imp throttle pedal... So the filter was sorted, carb in place, cables all hooked up (after buying 3 metres of Shimanos finest brake cable outer to suit the stainles brake inner for a tandem bicycle) and it was all getting a bit exciting. I was starting to get those 'first start, will it start, will it blow up, is the engine actually rooted?' feelings and thoughts. I double checked everything and put some petrol in the tank. No coolant yet- no point if the engine turned out to be a plonker. It would only be one more thing to have to remove. Turned the key as Hannah excitedly watched the engine from the back... Whir, whir, whir, whiiiir, whiiiior, whiiiiiooooouur, whiiiour, whour, wooohour, woooooouur, woor, woor, woo, wo, w....w.. Bugger. Well that battery that charged up ok, seemed ok, was obviously not OK. So we connected the booster pack on. Winding winding winding. Nothing. Hmmm. Has to be spark. Fuel pump, barnd new, was working fine, fuel at carb and at correct level. Fuel smells from exhaust. Spark then. I checked the coil- yep. Power to the coil. I checked it had power when turning over (some ignition switches can fail like this). Yep all good. Checked for spark with spare plug on lead. Nothing. Checked on king lead. Nothing. took cap off and checked rotor. Good. Checked continuity on leads to and from coil to electronic pickup in dizzy. Fine. At this point I was getting a sinking feeling that the pickup module in the dizzy was broke. However I knew that the previous owner had the car running not long before I bought it and there was nothing I'd done that could break it. I checked the polarity on the two wires. It was correct according to the electronic ignition swap thread on Datsun 1200 wiki. i had a look at all the photos I had taken of the wiring before I pulled the car apart. Hmmmmm- the two wires are the other way round. I did some more quick googling and it seems that they should be that way. Tech wiki- you lie. Swapped the two wires and this time we had spark- which my hand can attest to as it had 20,000 volts jolt through it. Reconnected plug lead, tried again and this time something. A muffled backfire. Tried again- same thing. Hmmm- timing is way out. Dizzy timing and it was fine- I had previously very carefully setup TDC using the stick and two marks meathod to double check the marks on the crank pulley because the car has got Toyota 5 rib pulleys on it (previous owner had at one point been running a supercharger on this engine) Everything seemed fine. Then Hannah quipped up and said "maybe its 180 degrees out and its on the exhaust stroke?" She was correct. I had spent all that time checking the tdc but not properly checked if both valves were closed. Oh silly me! So we spun the dizzy round and reset its timing. Jumped in the car and on about the second go it started. Yay!!! It sounded good. Not too noisy. Ran it for half a minute, workshop filling with smoke as all the paints, spilt oils, greasy finger prints burnt off. Decided it was worthy of some coolant and so Hannah filled up the system. It took ages to swallow about 9 litres of coolant, even with the bleed nipples open up front. sadly there was a pinhole on the thermostat housing I'd repaired and the old Smiths temp gauge decided that because its parent company was Lucas it would wasn't going to turn up to work. It was getting late so we called it quits and I removed the housing to seal the pin hole. I swapped the gauge over for another one and went to bed. The next day I thought would be the day of the first drive. I excitedly put the number plates on. I didnt want to fit the rear plate in the usual position on the engine cover. There are no holes there, no light, no light mount and the plate is too wide that it akwardly covers over a section each side of the main centre hole. So I drilled two tiny holes and mounted it below the bumper, with a light on one side. I think that I'm going to change the light though for a neat one hidden in the un used and slightly bent crank handle hole on the bumper. But back to the that drive. ooooooh exciting. So exciting I had to go have a nervous poo. Once back I started the car, with the help of the jumper pack and warmed it up a little. Clutch in. oh. That feels weird?.. let the clutch out eased the car out of the workshp into the sunshine, first time this shell has moved under its own steam for a very very long time. Awesome! Righto- lets go. Then suddenly.. gurgle gurgle splatter splatter. Coolant starts running out of the heater onto the passenger floor. Bugger!!!!! Arrrgggggggghhhhhhh! Righto- thats it. I'm over it. We pushed it back in to the workshop, into the corner of shame. I muttered some more choice words and then said to hannah "fark this...Lets go for a bike ride" So we jumped on our cyclocross bikes and went for a strop in the local mountain bike park. I got to contemplate the problems and felt much better once we got home. Then this happened... I had the heater matrix out and on the bench in about one hour of the Craig Charles funk and soul show. Turns out it had frost damage, from cold Canterbury days sitting out in winter (this heater was from Imp 3, the Christchurch car). Luckily I had a good spare!... Then that clutch. It had over extended itself and when I tried it again once back home it pissed fluid everywhere, having jammed a seal... I have swapped in a spare seal, extended the pushrod so it starts from the very start of the piston travel and will watch it- you can pump it out with quick clutch foot action so something aint right. I suspect its the flexible line has inside kink. I'll look to replace it. In normal use the clutch seems ok. Time will tell. Well that was a wall of text! I hope you all enjoyed my ramblings. Oh and the spare temp gauge I fitted is crap too. I'll buy a new complete setup. I promise the next installment will be full of joyous Imp driving tales4 points

-

For some reason my wife hasn't murdered me. So here's another project. It popped up on the Facebook market place, which is about the only thing it's good for in my mind. Long story short, the seller had it among several other assorted wrecks on a big off the grid property, the cars were already on the land when he bought it so there is zero history. I wrote out a receipt stating this so I have a way of proving ownership. There is no police history for the plates or chassis number. The plate and chassis are not on Carjam, or NZTA where I spoke to a few people including a supervisor who was very helpful but basically it came down to the fact its not on their records because it must have been deregistered before they moved to a new system in 1994/5. Paper records were kept for 7 years then destroyed....fck. So here I am knowingly buying a unregistered car with no history, no windscreen (unique to the car) and has been left outside for who knows how long. But the metal floor pan is solid. WTF am I getting myself into:3 points

-

Back to the dyno today after sorting the fuel system. Made 355whp @26psi. It's safe to say an 11sec pass is coming up3 points

-

So probably should update this.. a few things have happened lately. I put the car into Automania (a car show in Auckland for those not familiar), or more Matt (the organiser) asked if they could use it in the Nissan stand, looked all good. Probably the cleanest it's ever been actually. One of the conditions was they had to clean/detail it and Grant from Final Touch took care of that. Turns out I won a prize too, so now that car has won two prizes I haven't claimed LOL The second condition was I would exploit their free transport by having them send the car to Strange Workshop to get a whole bunch of stuff taken care of and start the road to road legalness. I asked him to do a fluid change on basically everything that has fluids and he put all these fancy ones inside.. I would've gone to the warehouse bargain bin personally. While doing the oil change he found a crack in the sump (which I knew was there but was hoping it would just fix itself) so I gave the go ahead to do a repair on it. The original plan didn't go quite as we expected as there wasn't really any access from the top side so just made a whole new edge bit. Also the diff was seeping so fixed that. While on the hoist he arranged for some panel guys to come around and check out what we'd be working with rust wise. Unsurprisingly (I also knew about these things) the side sills will need to be cut off and replaced/repaired on both sides. There's probably more stuff too but hard to know until start cutting. So far this area in the rear of each side appears to be the worst. Jon also replaced the rear brake lines and brake cylinders as both sides were flogged. Found some locally but didn't quite fit so he milled down what needed to be done to get em on again. Both of the original brake calipers on the front needed a rebuild but a while ago I bought these Hilux 4 pots which bolt right on, just needed to get new lines done up which Jon took care of as well. He bled the system up and it's all minty. I had replaced the discs a while ago with some slotted ones as you can kind of see. So now it's just sitting there while I drag ass because I want to drive it briefly when I'm back in NZ shortly then will give the go ahead to cut er down and throw all my money in the fire. Discuss -3 points

-

A little bit of detail on the engine, its a 711M block and L3 head which should make it a 1600 sport. But it has extractors and a 42 DCOE 8 Weber. I wonder if its standard internals and cam? I haven't tried turning it over yet. The coil was removed and inside the car, either its dead or was a way of immobilizing it. The fabricated radiator pipes are steel and rusty inside, no water in it due to dried and cracked bottom hose (I assume). It does have oil in it.3 points

-

Before I bought it I did look into whether you can still get a windscreen. First lead was that he seller said a "guy who does certifications in Lower Hutt also has one". So I rang who I thought it was and turns out he has a Rotary powered one and some spares, but no windscreen. He did say it used to be possible to buy them in Australia but had no contacts. So I joined a FB group for Australian Purvis Eureka owners and trawled through that looking for any mention of windscreens. Ended up posting and asking and got a lead for Moran Motor Glass in Queensland, AU. So I googled them and called, the guy was very helpful and said they can be made to order but the shipping would be bad so said a company they work with in Hamilton should be able to order one. So I rang Windscreens Direct Hamilton and spoke to Dean. He said there are two type so it needs to be measured. But it can be done, they are made in Vietnam and there is a 10 week wait. Cool. A windscreen is possible. The fibreglass windscreen frame is damaged so that needs looking at before ordering one. I figured out that I had the later slightly higher roof line version, this is like GT40 height, or pretty close to it.3 points

-

3 points

-

16 in the clip and one in the hole, ktrips about to make some bodies turn cold Now they yelling their hybrid hate, but with climate change, ktrips had to conservate2 points

-

2 points

-

Imagine how much their bottle rental from BOC would cost!2 points

-

Poor old Mitch must be wondering what the fucks going on with his drift trike. Sadly not much, as my parts from Ebay never arrived. First time I've been let down by Ebay... but it's been 4 months...no parts! So I decided to do what I could with what I had: I adapted a brake caliper to fit the rear, just needed a narrower bracket to hold it. Recycled an old brake line that I found at a swap meet (completely packed full of shit). Blew it out with air, then a generous spray of brake cleaner...repeat... Then set up a lever I got of trademe for $20, and bled the system. Took a bit of bleeding, to the point I was wondering if the caliper was frozen in place...then pop! All is good in da hood, and brakes now working perfectly. I'll buy a clutch off trademe for triple the Ebay price and finish this thing next weekend.2 points

-

2 points

-

A single SU would be good. feeding into a turbocharger2 points

-

So following on with my 1 step forward and 2 steps back theme, I pulled this apart again... I was mulling over the engine and its unknown history so decided to do some preventative maintenance before slamming it back in the hole. So the box and fly came off again, the engine got slammed on the stand and its front and pants taken off. Had a bit of a look at the bottom end , all looked very clean - almost suspiciously clean, but looks relatively stock I think. There's a metal head gasket on it and the ports have definitely been played with but who know to what extent. Its got some HKS cams apparently but haven't pulled the top covers off to look yet. Anyway, put the new oil pump on, glooped the windage tray and sump back on, dummy fitted some new Toda cam wheels and a fancy belt. Ive got a new idler pulley for it but need to drop in to Toyota for the new water pump so will fit that next time. Fly, clutch and gearbox went back on then dropped it in the hole. Headers fitted and some other bits and pieces. The clutch hard line was a bit fucked up so made a new one from braid and bled that up. Making progress very slowly. Yes the cams are not aligned, the belt is just sitting there poser spec. All has to come off again so I can fit the hall effect sensors. Will have a CAS for sale shortly if anyone needs one. Fuck theres a long way to go. Anyone know where to buy new passivated bolts for this turd? I can't bring myself to put the old shit ones back in - especially as most are missing.2 points

-

The roof is the door and it is damaged, it lifts up via hydraulics which looks like it was disconnected at some stage. There is a big switch in the drivers side, on the other side of the panel inside the body there is this: Which leads to this blurry ram jobby: And at the back on the car by the engine is this pump, with disconnected hose:2 points

-

2 points

-

And the next morning I got a reply!? The Hospital HR manager said he doesn't know the car/owner but he happens to be the editor for the Constructors Car Club (kits cars, homebuilt etc) and he would pass it on to their Historian who might be able to help. The historian has been an amazing help, he wrote an article about the history of the Purvis Eureka in NZ. Two accountants in NZ got the rights from Alan Purvis of Australia, who owned the rights there after getting the rights from Richard Oakes who designed it in the UK in '71 (ish). The article was very interesting but in summary, they cost too much to make and they only made 7. They had the plan of offering them with either a Rotary or a Ford Crossflow Kent 1600, instead of the most common (in Australia and UK) VW Beetle engine, since they are based on a Beetle floor pan. These were built by Tony Lynch of Lynchbuilt in Auckland. So it looks as though mine is 1 of 5 built with Ford x/flow power. I was given Tony's email address, and I emailed asking if this car was one that he built and if he had any records. To my surprise he replied and again, very helpfully confirmed that he did build them (the final assembly and fabrication) but the body panels, engines, wheels etc were supplied by the guy running the project (with the rights in NZ). So Tony suggested trying to track him down, he unfortunately hasn't been in contact for many years so wasn't able to help there. So I looked up the name and the word accountant which lead to one possible option, which kind of fit. An address is all I have to go on so I've just printed out a letter with some photos, in the small chance it is the same guy. If it isn't they might get a bit of entertainment out of it I guess. No harm in trying.2 points

-

Next was trying to find any details on the registration. The plates are black and look to be issued in 1978 which. Google tells me, in very little detail that from '77 to '79 someone made them under licence in Auckland. No records of how many were made or by who. I searched the car for anything, no windscreen for reg or wof, nothing on the number plates but they look like they have been on there since 1978 at least. Then I found a sticker inside the drivers lexan window, which is very very sun damaged so can't see from outside. "Wellington Hospital Parking 1980-1983" A lead! A stupid one, but SOMETHING. So I emailed Wellington hospital via their employee records info request thing. Worth a try right? Maybe someone remembers the car or who owned it almost 40 years ago...long shot.2 points

-

Hey All, Finally bought a project for my son and I. Want to return it to original, it's pretty good, hasn't been modded, still has factory exhaust!! Found it in a shed 2 years ago, went back last week with a pile of cash and picked it up. It hasn't been on the road since 2003, and hasn't run for at least 5+ years, the owner said it had a computer issue. Was rebuilt before parking up, and was told it had new genuine housings installed. Looking around I think thats correct, it also has new cap and rotor, brand new starter motor, the oil is spotless. It hasn't been crashed and repaired, and the body is as good as a 35 year car can be expected. Haven't seen any major rust at all, underneath looks really good. The fuel tank is completely shot, but after clean the lines, filling the engine with 2 stroke oil to lube it up, then spinning it over with no plugs to get oil pressure up, all seems good. We fired it up last night and it run pretty well for 2 mins, then stopped and we couldn't start it again.2 points

-

So I flicked the 944. It wasn't something I was intending to do, but a fella on the Porsche Transaxle NZ Facebook page popped up a 'WTB' post and I responded. With a high price. He initially declined, I didn't budge an inch and then a few days late the wife had mysteriously allowed him to purchase the car. He drove across from Tauranga, was rapt with it, and drove it home. Am I upset? No not really, I didn't get especially attached to that one since it burnt me (and my wallet) a lot during my near 2-years of ownership. Decided I wanted another DC2R, some of you might remember my 96-spec I had about 2007-8 and came along to a couple of NZH NIMM's in etc etc way back then. I put the word out that I wanted another one, and happened to meet Tim Bell (unsure if he's on the forum yet?) around this time through some of the other Hamilton fellas and a group chat. Tim being both an excellent human and the owner of a minty fresh DC2R put the word out among of his Type R friends, and turned up this car. DC2R Phone (1)-Edit by Richard Opie, on Flickr It's a 2000 Integra Type R-X. The 'X' is basically the final run of these cars, from late '99 through to mid 2000. You all know what a 98-spec car had over a 96-spec. But the R-X added to the list with a few more luxury mod cons. Power folding mirrors, 6-speaker audio, blue-tinged faux carbon trim, privacy glass, bla bla bla. Basically the best spec they came in, unless you reckon no options at all is the best. Which is kind of is. But anyway. It took a little bit of negotiation. The seller got semi-cold feet about the whole thing, had a change of heart, then another, and I ended up buying it for a fairly premium price. But it's clean and tidy, with absolutely minimal molestation. When I first viewed it, the car was on TE37, had a Recaro SPG on a fixed rail, was running a Neptune-chipped ECU via adaptor harness (yay no splices etc) but I was happy enough to not bother with all of that as I wanted as close to stock as possible. As it stands, the car has a Mugen Gen 1 exhaust (cat delete via welded in stainless pipe), and Ohlins adjustable coilovers as it's only mods. Which is fine. Oh and a very terribad Japan-spec hodgepodge stereo of shitness. DC2R Phone (2)-Edit by Richard Opie, on Flickr But the good! It's clean, straight, has new rotors, Endless pads, 160000km on the odo, a VERY clean engine inside and out, great even compressions, the suspension has $1700 worth of recent rebuild receipts, excellent black Recaros, tidy dash and is the perfect base for what I want. Actually I need to speak to @64valiant about replacing the bolster on one side of the drivers Recaro. DC2R Phone (4)-Edit by Richard Opie, on Flickr My plans? Chuck some nice fresh audio at it - I've bought a stack of Focal speakers, have a nice Image Dynamics amp and an Alpine bluetooth headunit for it. Tidy up the alarm/install a new one, refurbish the tired OEM wheels, go through all of the tarnish fasteners beneath the bonnet and replace with nice fresh ones. You get the idea. DC2R Phone (5)-Edit by Richard Opie, on Flickr I'll leave you with these phone shots for now - once I have the wheels done and dusted I'll be heading out for some proper shots with my big boy camera at some stage. Nice to be back though. Forgot how addictive these wee engines really are. And how rattly and generally shitty they are/racecar.1 point

-

Hopefully it isn't going to be too much of a hassle to get it re-vinned and back on the road. Good luck with it.1 point

-

I love this project. Such a weird car, and so ambitious considering its state. Most would've run a mile! I was tempted to buy the pair that were on the tards for ages but never had the balls.1 point

-

I love what you have done with my old Z650 awesome look, glad you posted your work, usually when you sell a bike you never see it again. Is it still going ok?1 point

-

1 point

-

I'm a member of the datsun FB group so yeah - I can try. But actually it'll be more fun and satisfying to make my own and then it can suit the spot perfectly. I have a feeling that the Datsun item will still be too tall. Must do sidedrafts.....1 point

-

1 point

-

Duct it through a grille in the rear hatch like a Fronte1 point

-

1 point

-

1 point

-

1 point

-

Awesome I need an excuse to try out one of my junkers!!! I think I might check out my alternator thoroughly this time1 point

-

My '05 hilux was transplanted with a '97 350 chebby (LT1) and was certed as such. I bought it that way so prolly also need to see a psychiatrist and certainly felt like I needed therapy after driving it for a while as was depressing what a horrible pig it was. Sounded good but1 point

-

Wheels on and looks ok proportion-wise... Will try to get chain on today for a hoon.1 point

-

gaw blimey, the frame and gubbins are back from the painters, was stoked on the three working day turn around. even more stoked on the finish! potato poor light pics dont do it justice, the finish is grouse. I went for a sandblast and then an epoxy chassis/industrial paint, its a decent coat and has a real nice gloss to it. cant wait to get it all greasy and yuck reassembling. If anyone was interested; frame, swing arm, brakestay arm, triple clamps, side stand kick stand to sandblast and paint was $200. Can thoroughly recommend Comac Industries here in Napier, good dudes who pine over classic bikes and have some rad solo speedway bike memorabilia around the office. Carb kit has arrived, waiting for my yambits package then she'll go off like a long tailed cat in a rocking chair factory1 point

-

Using the A/C and the loud pedal I averaged 12l/100km thats not bad.... my 2.6 datto is about the same economy.1 point

-

Awesome, thanks. Looks doable...just need to see my physiology now to talk about the voices in my head telling me to do bad things to a new car.1 point

-

I'm just looking forward to seeing a Leaf with a Flathead Ford V8.1 point

-

There are emissions rules to consider to some extent, but I think that is more based on the running gear than the chassis.1 point

-

Long time no update.. Not a lot has happened since "16, been to nats banks peninsula, won the grasskhana and didn't miss a beat the whole trip (not that it was a long way) failed a warrant before hand on no horn which took me a while to figure out, turns out there was no earth strap on the rubber coupler to steering box.. Fuck knows how the horn had been going otherwise, And also the hand brake cable on these is mounted via two of these rubber bobbin mounts, they are in fact one of the things I thought would fail the re-vin on but somehow they made it all the way through 6 wofs.. *edit, also failed on the rear muffler which @RUNAMUCK kindly donated.. Multiple hanmeats, the last of which ended up with a fair distance on a potholed gravel road up the back of Hanmer in the snow and rain, the one bonus of the potholes is that my heater fan randomly started working which was terrific as every time it rains the car fogs up like a bitch.. Problem solved. That was 8 months ago..... Decided I should really give her a clean for the next wof.. My little girl was dead keen and came around the corner holding a trade spec scrubbing brush and a wire brush gagging to help, I let her do the wheels, sans wire brush of course.. In the end I did the wheels while she spayed them and me with the hose.. Came up ok, As per the story of my life nothing else on the turbo/injection front has continued because of a lack of working space and the house.. all good tho I guess, she purrs along and is out of the shit brotown weather so I'll just keep driving her as is for now..1 point

-

Nope. Go for your life. As long as you meet cert requirements you're good to go.1 point

-

Wow. As the new title suggests. All those little jobs. As all those who have or are undertaking a car project will agree these little jobs certainly do add up. I can skip them or rush them especially as the canvas upon which they attach is so clean and tidy. So is no particular order, due to the fact that some of them I start, then stop when I realise I am missing a vital part which has to wait until the next visit to the big smoke, start on another job in the meantime, go back to last job, forget where I was at with it, then realise I forgot to get the bit even though it was on a list, then start on another bit. While all this happened there was also a fair bit of mini adventures going on because Hannah's brother was over from the UK on holiday. We did some very nice camping, biking, hiking trips with him. Because we all like pretty pictures here's some from a few of the adventures had in a last few weeks... So yeah- working on a car project is tricky when tempted by the outdoors like that Back to the Imp. First big job since the last update was to sort out the wiring. I basically re-wired the whole car. The original layout was not going to work how I wanted it to. There was a fair bit to add for safety, extra features, ease of disassembly, neatness. I bought an extra fuse box as I realised 6 fuses were not enough for what I wanted to do. Photos.. The wiring shop.... I have a fair bit of automotive cable I have collected over the years to use... I mounted the boxes and relays onto a piece of clear lexan. It worked out a very neat way to do it. I also took the instrument cluster apart and cleaned it out 50 years of dust. You can see the amount of connectors that have to be undone to remove the instruments... It just does my head in when I am so used to a couple of plugs, even on the Viva which is the same era. So I added multi pin plugs to the loom. Easy now. Fuses and relays in position... The race car came with an extra gauge pod below the dash. I bought a new electric oil pressure gauge, got given a very neat wee rev counter by my good friend Dean (cheers!!! ) and kept the Smiths temp gauge in place. I didnt like the way the pod was wider then the heater control bracket I was mounting it to. So I made a tapered mount to fit between them.... Gauges and dash etc as it now... Other things added were a neat wee push button switch for an electric washer pump because all the squeezypush type squirty rubber butons had perished. I added extra wires for a stereo, amp, electric water pump, under dash footwell lighting etc. Moving to the back. I re-wired the whole lot. Not much to see because all the wires are now tucked out of the way. I needed an alternator belt tensioning bracket. The datsun item was horrid.. So I made a new one. However I cocked up and soon found out it didnt quite line up. I had to had a bit.... In the end it turned out sweet and I'm very chuffed with it ... Now moving up to the front. The battery. It needed a home so it wouldn't slide about. I made an alloy box from some thin sheet. It bolts in place to some alloys bars attached to the bulkhead so i only need to remove two cap screws and it can be removed if I need to take the tank out etc. In photos... I made a stainless bracket to take a washer bottle, of which I can not remember where I picked up but have had for years waiting to use on a project. Finally a home for it ... Heater tap. I needed one. The Imp one was knackered so I went to the wreckers and got a couple that would work. Picked the best fitting. I think its from a Honda. Really neat item and should last. Would be an idea replacement for a stock Imp setup too. However I am running both hoses, inlet and outlet, from one side now where they tee off from the main lines. Anyway. Photos. I needed to adapt the old brass fitting so I machined it out and soldered in the straight section of the old u angle pipe... Altered the Honda bracket and made it all fit... Played with some hoses... and ended up with this... Clutch time. hannah and I had a hell of a time trying to get it to bleed up. I finally worked out two things. Firstly- the replacement seal that I had been sold by a 'reputable' brake specialist was the wrong one and its heel diameter was slightly too large meaning the piston was struggling to return. It was a friday, no chance get another so I went through all my seal collection and found this... However it was too large and wouldn't fit. I looked again. Next up out of the box was this... Still no good! Bugger. So instead I machined a new piston to suit a seat that was the right OD but had a larger ID... Now the piston returned. But it still would not drag in fresh fluid. I took the master apart for the 14th time and looked at some other diagrams online. I soon realised that there was a teeny tiny spring washer missing behind the rubber inlet washer. Its not visible in the Haynes manual or mentioned that I could see. I made one from a coil of spring and now had a fully working master cylinder. The clutch bleed up pronto and works fine now! Phew. Latest job I did was last night. I removed the exhaust and added a boss I machined from a 18mm nut for an O2 sensor. Then I was mucking about prepping an 18mm bolt to make a plug for the time being and remembered I still had not only a boss but also a stainless plug left over from the Innovate wideband kit I had fitted in the V6 Viva. Sweet. A nice treat. And that is all for now. Its getting very close. Engine has a new oil filter and oil, coolant needs to be added (and I bet some leaks will need fixing....) and then I just need to make an air filter assembly for the carb. Nothing available to fit the space, at a price I like, so I will build my own from one 5th of a Mazda Van filter I also need to machine up some Nylon bar I bought to make a new pivot ball for the gearlever. Big thanks to John875 from Australia who bothered measure one of his balls for me and post a photo online. It looks like this...1 point

-

Didja buy it? I see it's no longer listed, although there's always the newer green one in Northland for $6.5k. The autocar buyers guide has this very "Jag owner" advice: "Check for misfires on the V12 by holding a bank note over the exhaust pipes and watching for uneven fluttering." You might also want to test the cigarette lighter by rolling up a bank note and attempting to smoke it.1 point

-

1 point

-

Fuel system bracket & components Dellow Conversions "Qik Shift" for the W55 Supra gearbox1 point

This leaderboard is set to Auckland/GMT+12:00

.jpg.25882dde1112c229c13042e8439e9795.jpg)