-

Posts

1,607 -

Joined

-

Last visited

Everything posted by ~Slideways~

-

I've driven it for around 2.5hrs total now. First drive was almost an hour and no misfire (fuck-yeah-mother-fucker-fuckyou-you-goddamn-intermittent-fucking-bastard-get-fucked, etc etc). So I'm quite happy about that. Took my kids for a drive each (only 2 seater) both loved it and their first experience in something properly fast. 10y/o boy said he couldn't stop shaking with excitement and didn't want to go home and 7yo girl shrieked with glee and giggling, said it was like a roller coaster (she went on the big 'adult' roller coaster at Rainbows End 10 times). Of course I drove it just enough to give them some excitement without being silly. Man it's responsive, even 3rd gear at 30kph it makes boost instantly. I wonder how long it'll be before I want more power. Definitely the fastest I've ever driven, more than my old 220kw at wheels ae92 and that was only 900kg. Getting used to it again, drove to work and found it bottoms out on the stupid gate rail which sucks. Might make some wooden ramps haha

- 419 replies

-

- 13

-

-

-

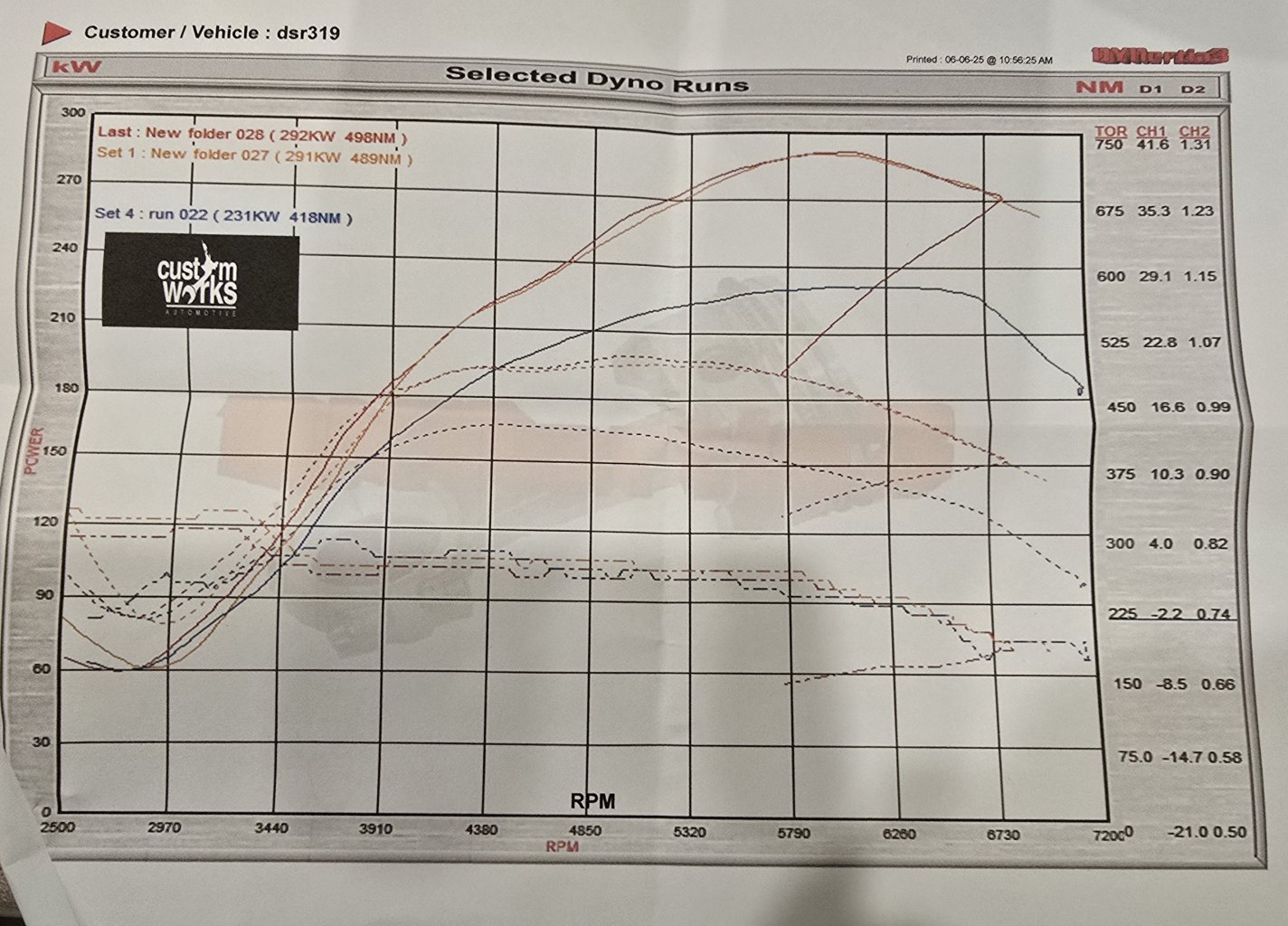

Got it all sorted and back on the dyno to run in and see what it can do. I drove it around the block to test for leaks etc and had no misfire. So put on trailer ready for dyno. Sounds like it behaved on the dyno which is a relief after so much work. Had an arbitrary goal of a responsive 300kw at the wheels, made 290kw @ 18psi around 6k, so plenty of revs left, seems to be limited by the turbo. Looking at the graph it trails off earlier with more boost. So probably exhaust wheel/housing (12cm twin scroll). Maybe the 25nb runners, but that doesn't explain it trailing off earlier with higher boost (well maybe but the exh ports match that size and I've seen 25nb runners on a 1jz make more). Peak at around 6k so maybe later I'll try a bigger turbo. Either a Holset with a known exhaust wheel/bigger housing or a Pulsar something or other, but I don't really want to have to change plumbing etc. I really just want to drive it and finally confirm if the intermittent misfire is gone. I can't really be happy until I've done that since it had been fighting me for so many years. But two explanations for the misfire and melted piston. One injector became unhappy and flowed less and the major was finding a factory fitted solder blob on the Link. So suuuuuurely after all of this, including a full rebuild I can enjoy the car now right? Come on car gods, don't fuck me up again lol Next up wof, then actually test drive it more than onto a trailer.

-

Yeah I reckon this is the one, old stuff now but plenty still around and heaps of support. My old ae92 had 220kw at the wheels with a basic viscous lsd e58 and with good tires it was great for a fwd. I'm sure you know, but this is some pretty big scope creep and direction changes, it could take 10 years to finish and in that time K swaps will be also 'old'. If it was me I'd continue with the awd path but go back to good old 4age. Use a blacktop head, 4agze bottom end (8.9:1 stock pistons, stock rods, twin scroll manifold and aim for relatively conservative 250kw at the wheels. Maybe use the ae95 gearbox if you can figure out the ratios since they have a live rear axle of 2.9:1

-

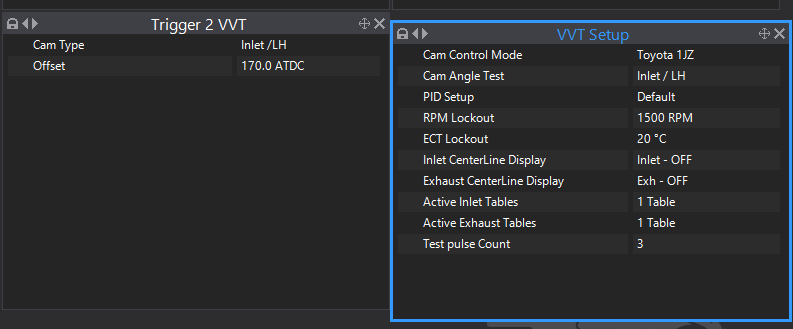

I've increased for the crank trigger but no cam, so will give this a go. Thanks for the advice, I'll try increasing the number reported in the cam angle test. Will double check the cam timing again. Thanks for the input guys.

-

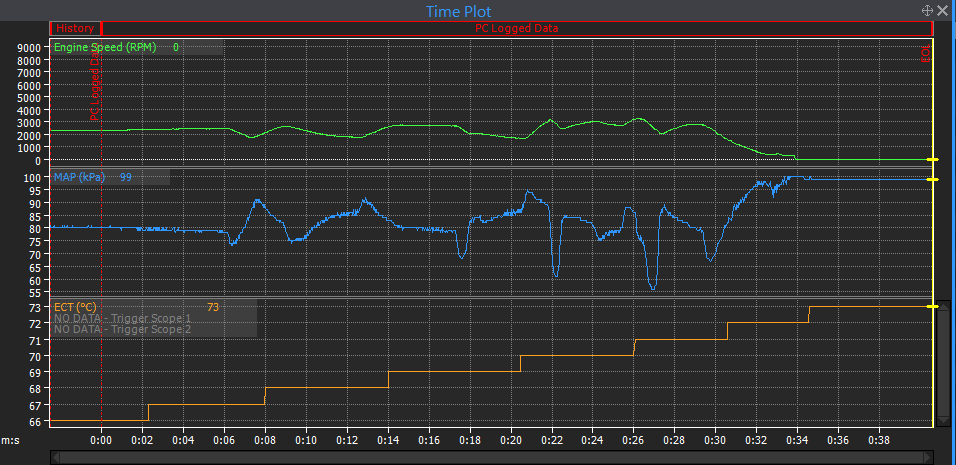

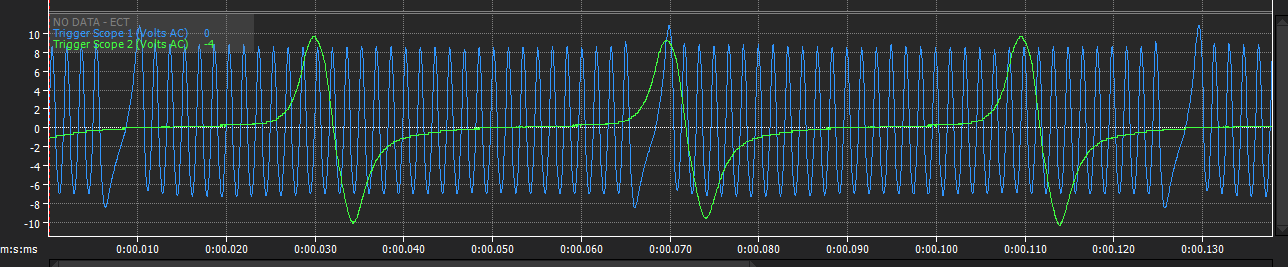

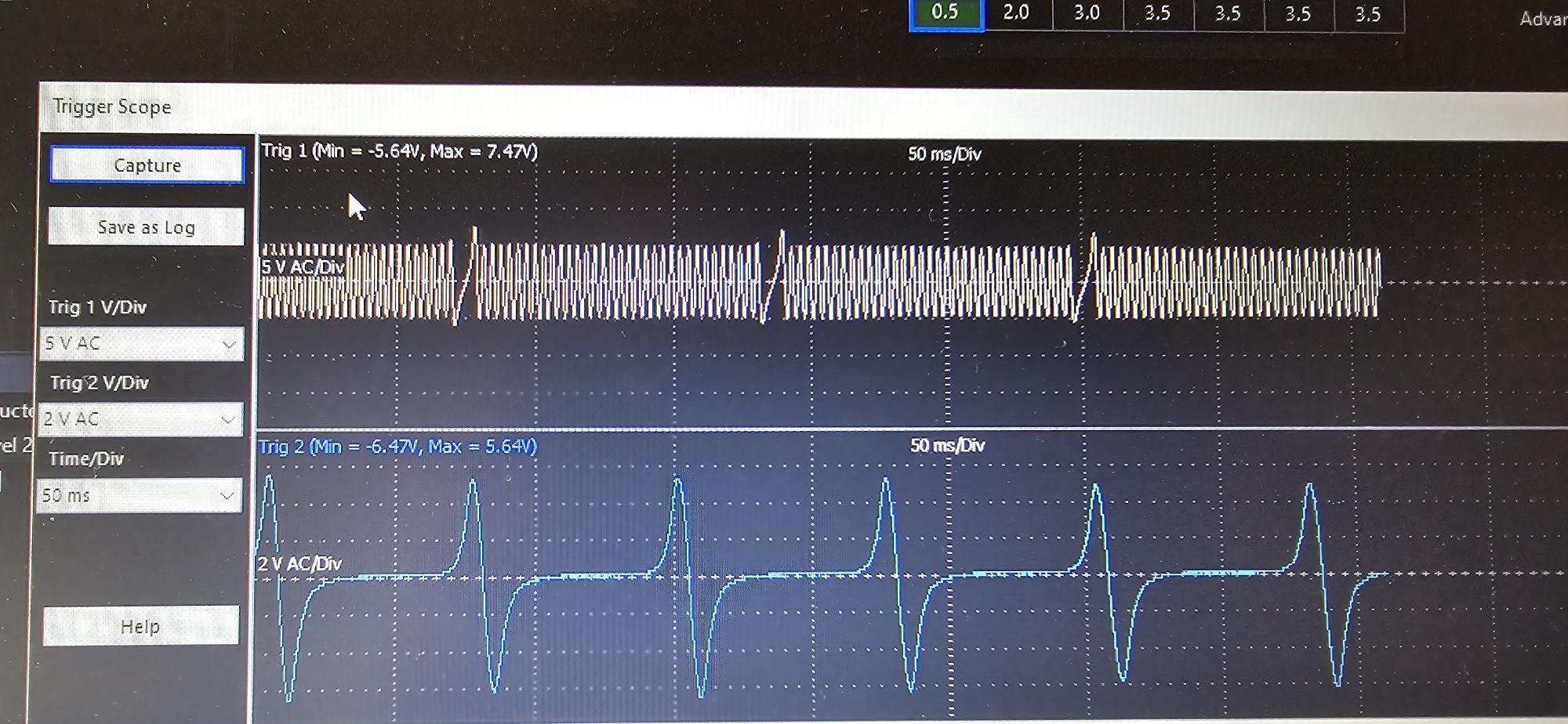

Here is a trigger scope around 2000rpm. Is the cam signal just on or just after the crank gap a problem? Map sensor is doing map things:

-

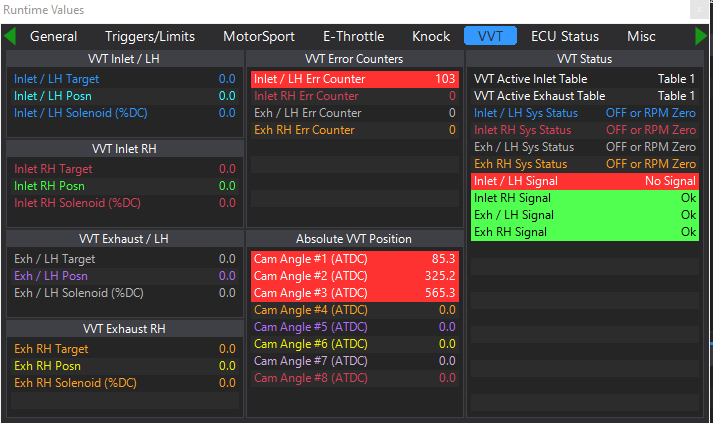

OK bit of progress, the RPM limit was happening when the Cam trigger 2 offset was set to 85 which is the lowest number I get in the cam angle test. I was reading somewhere that this can happen if it is too close to the timing of the missing teeth on the crank. Causing it to think the crank has 'jumped' 360deg So if I set it to 170 which doesn't match any of the reported cam angles, it runs OK and does not RPM limit and revs ok but still has a constant trigger error counting up. Here is the Cam Angle Test runtime screen, the most telling thing is that while running it says 'Error Cannot Sync' next to Inlet/ LH Signal (where the below screenshot shows 'no signal') So it really seems like a cam timing and/or signal issue. But why?

-

Maybe I need to increase the trigger arming threshold, possibly too low?

-

Its a reluctor sensor reading 3 teeth on the cam. It is giving me 3 consistent readings on the cam angle test so I think it's ok. But the actual reading/position may be wrong, this is where the Link help file for this engine suggests the cam offset should be 170 but you use the Cam Angle Test to find the correct number. Mine gives me 85, 325 and 565 and I'm not sure why and if that is an issue.

-

Injectors: Sequential. Fuel Pressure: 43psi on the FPR gauge while cranking. I haven't watched it while running (have to hold pedal). Map: I can watch the fuel table trace moving around with a little vacuum or pressure but will try logging it. IGN: OK will try adding 10 deg. I did try using the ign table from my old map as well as a base map. Trig errors: I can seeing it counting up in single digits while cranking, then after a few seconds of rough running it's up to 60+. I don't know what is 'acceptable' but something is very wrong for the rpm signal to spike for a split second from idle to over 7500rpm and immediately applying the rpm limit cut, every time I slightly press the pedal. This is only in the logging graph, not physically revving that high. It triggers the RPM limit warning, it didn't do this at first so I will have to go through everything again.

-

Yep confirmed with timing light. It's Coil on Plug, had to use a extension to be able to use the timing light but it worked fine and was adjusted in the link to match 10deg. As far as I can tell off the top of my head, getting TPS (calibrated), MAP (calibrated), 2 x Trigger (crank and cam), Water temp, Air temp, Wideband isn't actually wired into the Link, it's an Innovate MTX-L which I don't really trust the readings of anyway. They don't have the best reputation unfortunately. I have been tempted to take it all apart and recheck the vvt pulley and cam belt but hoping there is something I've missed which will avoid doing all that again. I haven't done a compression test no, this is the first time running since rebuild so rings won't even be bedded in etc. But since I am getting Trigger errors, it's the most likely thing to start with. Just not sure why really. The Crank sensor is new too, well maybe a few 100km old.

-

OK this thing is fighting me, I've got it running but badly. Starting but very reluctant, rough at idle (have to hold pedal open) and runs like arse. At first it was very rich due to going back to the 1000cc injectors, updated dead times. Changed the master fuel to 7ms and lowered the fuel table until it wanted to run (much lower than the Link 1jz vvti base maps I could find - one for 1600cc inj and one is stock). But still terribly. I did find that once at around 3000rpm it would rev cleanly which is positive (maybe indicating cam timing issue?) Timing: Timing marks all line up. Timing light showing 10deg with Link on the timing config screen. I have it set to 196 offset, while recommended is around 200 but this is probably from a shaved head and block. Fuel: Emptied tank and put fresh 98 in. Checked the fuel filter, fine but changed anyway. Tested the injectors with Link and can hear clicking. Removed injectors and tested with some pressure from carb cleaner spray can and tapping terminals with 12v. All seems fine. Spark: Tested all 6 coils for spark and all seems fine. Triggers: Trigger scope looks ok as far as getting a clean signal I think, maybe there is an issue with the cam tooth overlapping with the crank missing teeth position? A while ago I realised that the crank trigger polarity was wrong according to a few Link forum posts stating that the missing tooth gap on the graph should be rising not falling. So I swapped it, but with all of the running issues it didn't seem to make a difference. From what I understand, it will work either way with reluctor sensors but can cause it to read the missing tooth gap as an actual tooth, due to being a 'fall' in the gap and miss read the crank position. Maybe I should test it both ways but getting my head around it seems like the below photo is correct. Excuse the phone photo's, it was late... Cam timing (trigger 2) offset: The other issue is that the Link help file suggests the Trigger 2 (cam) offset should be around 170. But if I run the Cam Angle test I get 85 / 325 / 565 (ish) and the Link forum suggests you should use the lowest number, so I used 85. There are 3 teeth on the cam, none are anywhere near 170, so is this my problem? I thought maybe the intake cam was 'stuck' within the VVTi pulley since I took it apart to replace the o-ring ages ago. So I took the cam cover off and moved the cam with a spanner (non interface so should be fine but I also loosened the oil feed to release any pressure), it moved fine and about 30deg or so while the vvt pulley/cambelt stays in position. I THINK it shouldn't matter where it is before starting since it is non-interference the 'slack' should be taken up when the cambelt turns the pulley and the VVT solenoid should not be applying any oil pressure to the pulley internals. Trigger thresholds: I tried lowering the Voltage thresholds but made no difference. VVTi solenoid: I also took out the VVT solenoid and tested it with 12v to see if it is moving. Movement seems to be working fine. Also ran the Link PWM test at different settings and all seem to be ok. After all of this I am now worse off, it is now getting trigger errors and it is getting RPM spikes with a tiny amount of throttle which trigger the RPM limiter. I can see it spike from around 1000 rpm to over 7500rpm and lots of triggers errors. I only have time to do this late at night so its a small gap of testing a few things then the battery dies and it's too late to wake everyone up anyway. So maybe I have forgotten a change I made since I was previously able to get it to rev cleanly around 3k. All I can think of is that the cam timing is out or the polarity is actually wrong now, I remember being meticulous with putting the vvti pulley back together but I am now second guessing myself. Cars man.

-

Thanks reckon it's been done enough times to know it'll work. Except maybe the valve to piston clearance with the mivec head. Good to know about the 3sgte studs, I saw that mentioned somewhere I wonder if it'll work with the Mivec head too.

-

Haha is a sharpy the new banana-for-scale?

-

Far too many people killed them on 12psi and a stock TD04, so I'd be risking a Mivec head getting mangled with piston bits... Hopefully I can get this Nissan/Toyota/Mitsi hybrid thing to work.

-

-

Hmm yeah could be an option, although most aftermarket stuff always seems to be single scroll and thin stainless, but worth keeping an eye out for something suitable.

-

Really good info thanks, didn't realise the X turbo was mounted on the rear (due to new engine I guess). I'll keep an eye out for some TD05 options. The one I saw for reasonably cheap is a TD05HA 152G6-12T, advertised as an evo X turbo but was on some home made looking manifold. I read quite a few reports of boost trailing off after 6000rpm-ish in X's which wouldn't be good for a 4g92 Mivec head since it should be wanting lots of flow above 6k.

-

Yeah I've been thinking the same, if I make a manifold there isn't much reason to limit myself to the TD05 flange. Except of course that sometimes a cheap one comes up. I saw an evo x turbo cheap but I know they flow less than the 9 from what I've read. I've been super impressed with the spool of the HX35 twin scroll on my 1JZ, that's a 12cm housing (Holset sizing doesn't match TD05 cm sizing) and can get a 10cm housing and heaps of other options reasonably cheap. Twin scroll is meant to work well on inline 4's and unlike 4g63's the 4g93 never got the advantage of twin scroll manifolds. Alternatively a modern turbo like a G25-550, there are so many versions now. Even a turbobits.co.nz branded one.

-

That's definitely an interesting one! Hadn't heard of that idea. @Adoom has some spare CA18 rods and a mill so I'm going to try one and see how it looks. I'll try find a used 81mm 8.9:1 4agze piston to test for valve clearance and see how much needs to be removed from the skirt etc. I reckon this combo should be a good fix for the known rod weakness, without going overboard. Maybe aim for a responsive 220-250kw atw, with a twin scroll TD05 (stretching it) or a twin scroll HX35 10cm since I'll have to make a manifold anyway. If that's too much for the gearbox, I'll have a spare.

-

Ca18det's are actually getting harder to find now surprisingly, unlike the SR20 and RB stuff. @Adoom maybe? Forged 4G93T rods are the typical h-beam type, all the same measurements including the 19m small end but as far as I can tell they all have to be used with full floating wrist pins. So yeah, most likely designed to be used with aftermarket forged pistons. Spool rods come with CP pistons and they have c-clip pins. 4agze pistons have c-clips but they are 20mm pin, which is why I'd have to use CA18 rods.

-

I also came across the Honda B16 eagle rod option (maybe b18?), slightly shorter but then that was made up with what ever piston they used. Good point re: valve clearance with the mivec head.

-

Realised a small snag with the idea of using the 4g93 T pistons with forged rods (maxpee'ing / spool type thing $700ish), the problem is that the factory wrist pins are press fit and all aftermarket rods are designed for floating. So the gsr pistons don't have c-clips to hold the pins in. I want this project to be a parts bin low budget type thing and fix the main issue of rod strength. The idea is far more interesting than just throwing money at it, else it would make more sense to just start with an Evo. Plus I really want to see what a Mivec head can do with some forced induction. Which means I need to use the 4g93 1.8 block and matching gearbox. So I have some options: 1. Use stock rods and pistons and keep the boost low to 10psi. Cheap, but risky and not really taking advantage of the Mivec head. 2. Forged rods (4g93 has 19mm wrist pin) and machine c-clip grooves into the gsr pistons. Probably not worth the hassle and cost. 3. Ca18det factory rods (20mm pin), these apparently fit with some machining (think its thickness of big end) then use 4agze 8.9:1 pistons (20mm pin and known strength for about $100 per piston). These need a small amount taken out of the skirt to clear the crank. 4. Forged ca18 rods for the 20mm pin as above, still need machining. 5. Forged rods and forged pistons. Easiest and strongest. But about $2k pistons and $700 rods. Right now, I like the idea of ca18det rods and 4agze pistons. Fits with the parts bin idea and cheaper.

-

Just a fun street car really, I built the 200sx as a semi track car so don't need another. One day I'll get to actually use it haha

-

Yep re GTO calipers fitting, I was considering this: https://freakyparts.co.uk/products/gto-caliper-upgrade-for-fto But maybe I should keep an eye out for a Legnum VR4 at Pick a Part, there was one there a while ago but it's gone now. You Mitsi guys have all the good info

-

I actually assumed they were the same Sumitomo 4 pot design that Nissan and others used but after an image search, they look quite different. I have them on my 200sx and had to shave the Nissan lettering to fit those black wheels above, they fit fine with RPF1 17x9.5 +18 though. I was vaguely thinking of sharing the RPF1's but since then I've been leaning towards making this Lancer a sleeper without cutting the guards, so it's actually appealing to maybe use the 2 pot slide calipers. I assume 294mm rotors need 16's, but I could still make it look sleeper/normal. Not sure 276mm would be enough, but that might fit under 15's. The GTO sumitomo's would be coming from a work mate, rebuilt etc which is why I was considering it. He upgraded to the later GTO brakes from memory. Are there good pads available for those 2 pots?