Leaderboard

Popular Content

Showing content with the highest reputation since 04/20/24 in all areas

-

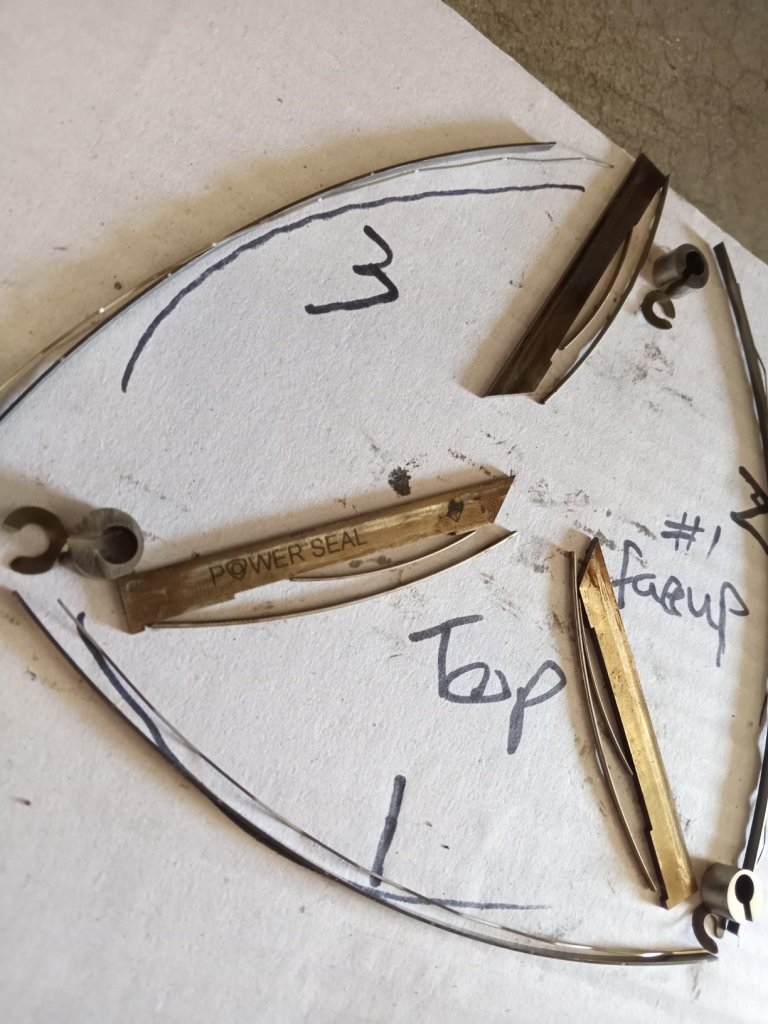

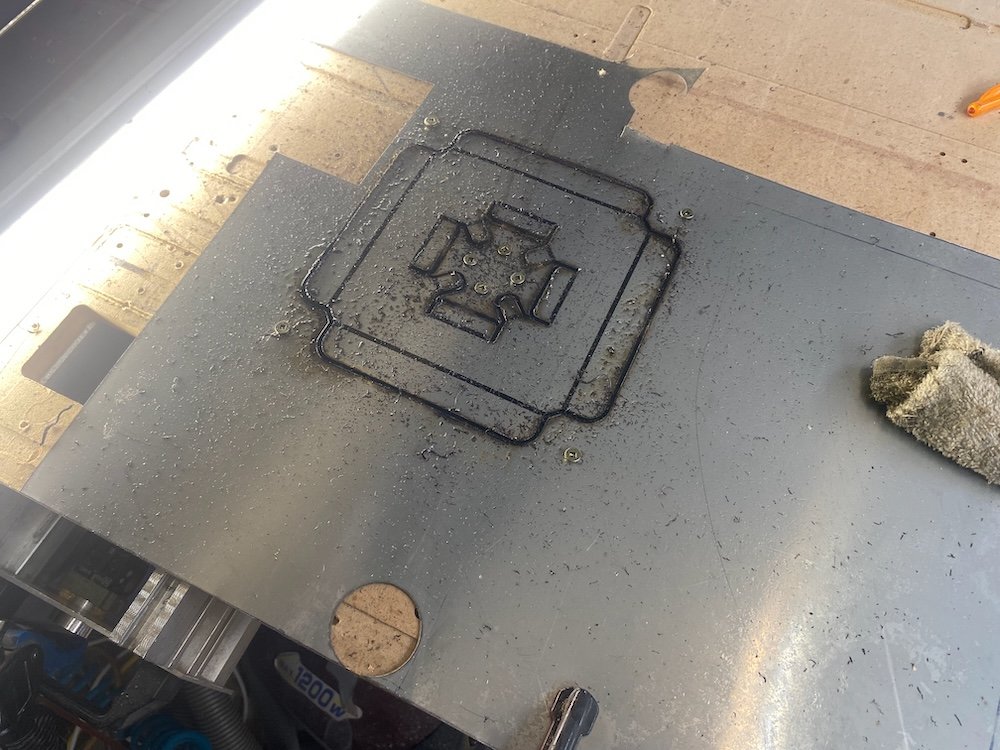

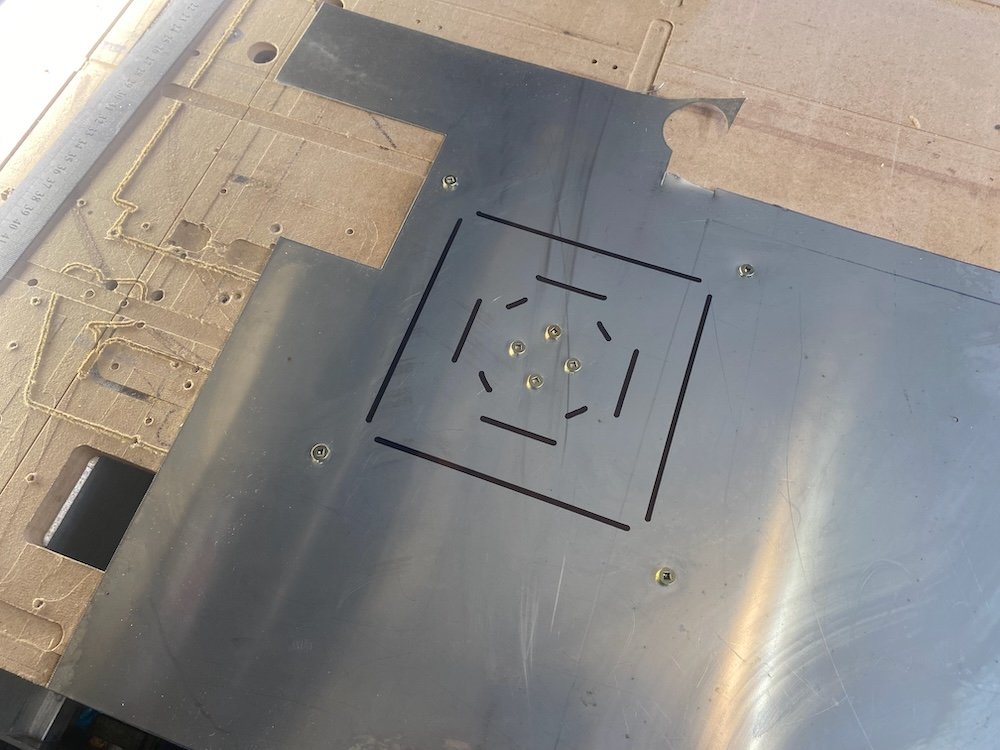

As per the title this next stage of building the exhaust silencer/muffler/back box/ take your pick has taken much more time and effort than I had always expected. I started by taking the blue imp apart. To Woolf valley garage I went.... ..where I removed (rusty mild steel) exhaust, bumper and rear valance.. Popped it onto rusty imp shell... Now I knew exactly how much room I have to play with. Whatever I was going to build had to work with several things. I wanted the box to be mounted higher than the existing one behind the Datsun engine as I was sick of scraping it on steep driveway exits. It had to be built completely of stainless steel, no exceptions. No more corrosion. It had to look tidy and fit within the bumper line, tailpipes excluded. The tailpipes were to be twin centre exit. I had a very specific look in mind and they have to be just right. It had to be quiet enough and yet still sound sporty. This last one is tricky and will most likely need modifications to get right hence the last design point... It has to be modular, easy enough to disassemble and repack with sound deadening (most likely glass fibre) Now I knew the size I could build it to I started by making some flanges. This so I can unbolt the flexible sections between the V clamps and the box. Made to suit the 44mm tube as per the tube off the V clamps. Lifted the big folder we'd made onto the bench top and folded up some 1.2mm stainless. Although heftier than I could have used I've gone with this thickness to helped avoid the tinny sound thin stainless boxes can make. I wanted perforated stainless tube but couldn't find any within NZ. Got some perforated sheet instead - again 1.2... Which I cut strips from and formed up into tubes as such... Welded... Now I had the start of a box and some tube. I could sit down and nut out a design. I have had some basic ideas for ages on how it might look inside but it was really good to sit down and see how it might work. Drew some ideas up.. Nutted out something I think would work well and be easy enough to change if need be. Time to commit. I had to cut some blue steel. First actual act of modification to the imp in my quest to plonk a flat six in it. Now I could double check box sizing and weld the flanges in place. Folded up the second box side.. Complete with captive nuts to suit a lid.. Tail pipe time. I almost went with twin 2" exits but they were just a tad too big. Settled on twin 45mm. Tacked them to yet another stainless pair of flanges to work with the modular design aspect. Happy with the look I then fully welded them on the inside. The flanges will be sealed with a soft copper gasket. Happy I had the look right I cut the centre top from the box, created a recessed bit and carefully welded in the second threaded flange. So now I have inlets and outlets where I want them and just have to connect the dots. Ideally a nice long a route to dampen sound while keeping it as smooth flowing as possible. Plus, as per original brief, it has to allow for easy disassembly and re-packing. There was quite a bit of head scratching with this bit of the build but eventually I sorted a design out. I cut various bit of sheet and put big holes in them with a nice brand new holesaw set. Made little boxes with more big holes... Shaped bits like a heart...(#putmyheartandsoulintoit.....) Welded the ends onto the main box, curved in bit to help with flow and also hide the external bobbin mounts from view a little. Now I had a collection of parts that would come together and form a london underground of tubeways for the exhaust gases to follow. I was pretty happy with the layout for its potential silencing effect. However I now wondered if it might just end up being a touch too quiet and restrictive. Luckily I had come up with an idea early on where I could add some valves. Quite a little bit of extra work involved but the more I'd thought about it the more I was convinced it could work well. With this in mind I had built the middle chamber width to allow for some valves and made sure they could be removed to fit said valves in place. I cut some 44mm holes in the middle chamber lids and made some to valves to suit... Whipped up a little press form to create brackets.. Valves mounted. Underside of lids have the heart halves which help direct flow from one tube back too the next, or up and out through the open valves.. Valve shafts stick out through back of box. Sealing will be by a combination of spring loaded fibre and silicone washers. Now for an exciting point in life that every shed 'Barry' looks forward to. Emptying out those boxes of little random fittings that have been stashed away 'just in case you might need them'... Such fun! I selected my (stainless!!!) treats and scribbled on some alloy. Made lots of alloy swarf.. Ended up with these levers. Pinch bolted to the shafts along with added grub screws. The short length of threaded rod will be changed for a long length of stainless rod, actuation method from within the car yet undecided. Possibly a 12volt door lock motor etc or maybe mechanically with a bicycle cable. Recessed the backs to allow for seals.. So yeah. Lots of parts! Compulsory photo of thing exploded into many bits... All together now with some arrows. Remember each side is just a mirror of the other side (there is a small cross over hole in the centre plate that separates the sides) Valve closed... Valve open... I think it'll be quite a difference in sound and look forward to hearing it. Valves can be seen in action in this very exciting video... So It's pretty much complete except for the mount points which I'll do once I've got some bobbins from engineering shop along with seals. The lid will be sealed by running a bead of silicone which I'll let set before clamping the lid down. Oh I weighed it too. I was worried it might end up quite hefty but it will be only about 6.4 kg once all the bolts are in/packed with fibreglass.. The box will be painted satin/matt black leaving the tailpipes shiny. Silencer mounted in place... View from above showing plenty of room for the valve linkages in place. I ended up cutting a tiny bit more of the valance away so there's room for a stainless heatshield. I then covered the valance with some masking tape to help prevent it getting too scratched while I put back in some internal strengthening and capping it all off. I'll also be adding mount areas for the bobbins. I'll remove the engine next and add in the big multi-pin connector to the engine loom. Then I'll be seriously very close to removing the Datsun engine and cutting out the under seat area just as I have on this rusty shell. Wow!!55 points

-

However, during the pre purchase inspection I picked up a few things in the engine bay and suspension wise that placed some doubt on how far the mechanical restoration had been taken. Nothing major, but just little signs that some items still needed attention. On getting it home, the first thing that I did was to fit an electronic unit to the existing distributor in the hopes of resolving an intermittent misfire. We then clocked up about 1000km during which time I was almost constantly fiddling about to try and get the timing right. In desperation I eventually pulled the dizzy out for a closer look and discovered excessive play in the shaft, so I ended up ordering a brand-new distributor from MiniSport in Adelaide. The new distributor came with its own set of electronic internals already fitted so the old unit went into the parts bin. This solved the misfire, and we ended up enjoying another 500km of trouble-free motoring until one day the Moke just suddenly cut out and left us stranded at the side of the road. Luckily, we were close to home, so I walked the rest of the way and returned with our Holden ute and a tow rope. After a bit of troubleshooting, I pinpointed a fuelling issue which turned out to be a faulty float valve. Got a new one sent up from MiniSport and we were back in business. Shortly after that the actual carby started playing up - again excessive wear - and we ended up ordering a reconditioned SU from MiniSport. Since then its literally been an annual oil and filter change and the fitting of a new battery and we are now up to around 2400km of travel that we have undertaken since purchase. And that pretty much brings us up to this point in time. In my next update I'll cover some additional maintenance work that has happened over the past few weeks. And no one likes a pictureless update so here is a group photo of our small fleet:29 points

-

I did a thing. First I went to visit @yoeddynz who kindly welded the crack up. I also got a preview of exciting Imp developments.... When I got home I had a look to see what that plug thread was. Interestingly it appeared to be an M22x1.5 parallel thread, which meant a tapered plug made very little sense. And it just so happened that I had an M22x1.5 tap and some threaded rod. So I messed around for a while to get this; I put some pretty mega threadlocker on the insert, so it shouldn't go anywhere. Now the fucked shaft. It was pretty obvious that the broken bit wasnt a new development, and that the box had basically been working ok like that, so I did the obvious thing and just put it back together with the broken bit back in place, retained by the gear and the retaining nut. It feels fine. I figure that worst case I lose 5th at some point, by which time I will have a new box to go in. I will lift an optimistic pint to that notion tonight....26 points

-

We have owned this little Moke for about 4 years now and since I'm starting to do a bit of work on it, I figured I'd start a thread as it might be of interest to others. So, first up a bit of background. When we lived in NZ, Mrs Flash owned one of those newish 1275cc SPI Rover Minis. It was a Jap import that someone had done quite a bit of back dating on. A lot of the changes were fairly subtle, but the most notable things were the fitting of 10-inch Watanabe rims to replace the original 13-inch units and the removal of the modern dashboard that was replaced with a classic centre mount speedo. The car was a little rocket and super fun to drive. Sadly, we made the decision to sell it before heading off on our Australian adventure and last I heard it was somewhere in Christchurch. So fast forward a few years and we are now permanently OZ based and looking to get back into some classics. We often thought back to the fun that we had with that little Mini and decided that owning another little Leyland would be good. The climate over in tropical Queensland lends itself to something a little more open and so we set our sights on a Moke. After checking out a few we ended up pulling the trigger on a fully restored 1100cc powered 1974 Californian look alike that was going for reasonable money. When I say reasonable I really mean that after doing my own sums I concluded that I couldn't have restored a clunker to this level for the money that was being asked. So, after swapping a few calls with the current owner together with the studying of some detailed photos a "deal in principle" was struck pending final inspection. We grabbed a hire trailer and headed south down to Noosa hoping to be returning with a loaded trailer. Gave it the once over, took it for a quick drive, some cash changed hands, and this happened: In my next update I'll talk about the maintenance undertaken to date and then a little bit about the current work being done. Thanks for looking.23 points

-

I got it all back together and has all of its gears so I'm calling that a win. It also does not appear to be leaking any transmission fluid, another win. So then I looked to the wheel bearing situation, and smashed that out. There is a dedicated X1/9 forum, Xweb, which has a lot of excellent info and how to's. I found a great pictorial run through of the process and set to. I did need to make a special tool to remove a locking ring but that was no drama. Octagonal lock ring fuckery. Special tool made by a special tool. That and the engine going in meant Sunday was quite a big day, so I left the tie rod end for tonight. On the basis of this minor last task I booked the car in for its recheck and a wheel alignment. After work I went down to sort it, only to find that the rod end is the wrong one, and about 50mm too short, GAHhhh! It took two weeks for the last one to arrive, I am so disappointed. Anyway. Previously to this weekends shenanigans I had done some messing with the jetting, and drilled the mains out to 130 from 125. So I took it out for a short run so I could bleed the cooling system properly and check the AFRs which were much improved, as was the idle to main circuit transition, so that at least was good.23 points

-

Old guy next door who loaned me that big van, died a couple of years ago, and his daughter isn't really coping with home ownership. She's been away ~3 months looking after an ex who was having heart surgery. So I had a bit of time to think as I wombled around doing this, and concluded doing something for a neighbour was pretty appropriate for Anzac day.21 points

-

This is kind of random project thread worthy. So I’ve owned this old single axle car transporter for over 20 years (apart from a short period where a mate owned it, then I bought it back). In about 2005 I gave it a rough wire brush and painted it tractor red and put a new timber deck on it (necessitated by a mates Fiat 131R almost falling through the rotten old deck). I’ve been meaning to give it a refurb for ages, but it kept passing wofs and just looked like shit. It progressively got worse until @azzurro borrowed it and it had some structural failures where the spare wheel mounted (coincidentally while also towing a Fiat on it). He kindly patched it up before returning it but it needed attention. After moving back up north I decided it was time to tackle it and strip it right down and give it a birthday. Fix a few bad welds. Paint, new electrics, new deck etc. Anyway. After a few solid weekends of work it’s just like a new one. P.S. if you want to buy it, hit me up. It’s only small (suit Viva, 1200, Escort, Starlet etc).21 points

-

20 points

-

One outer headlight (dip/high beam) gave up the ghost during Beach Hop. I installed these when the car came to NZ in 2003, so last 21 years, fair I suppose. The working one looked a bit sad too so I though I'd replace both. The centre high beam set are the ones it had in Indiana and seem fine. Took them out and cleaned up the buckets (I ended up doing all 4) followed by a squirt of Black Zinc. I did the same for the small aluminium trim pieces that go in where the masking tape is, and the blacked-out areas behind the grille that were a bit scruffy. It turns out that modern Hella lights (stocked at BNT) are all semi-sealed and don't have the nice domed shape so I got a couple of 5 3/4 sealed peams from PartsSelect on TM Let there be light! Also picked up some used PP from Trademe.20 points

-

Not too long ago around Xmas I had heard that there was developing interest in my Auntys beetle and so in oldschool fashion I acquired another OS machine to add to my collection. To fill in some blanks we need to go back to 2007, I had a brush with the law lost my license and moved to Surfers for a few months for a cool off period.During my time there I got the use of this thing to commute around I had 2 jobs over there one a part time job at a tyre shop and another washing dishes up in Sanctuary cove at a high end seafood restaurant. The Lil bug was great and I only had issues with fuel delivery when it got too hot. I'd push it over to the side of the road between surfers and Miami and wait a while for it to chill... once I got fed up with part time work I managed to get a fleet job with Baurepairs down in west burleigh. First day on the job being kiwi got the general hazing from the lads and they got it back in equal amounts, they all enjoyed commies and falcons as long as it had a v8, so here we are with the Lil herby puttin about with a raspy exhaust note. Couple weeks later one of the lads had car issues and broke down and was resorting to the bus. I offered a lift as it was on the way home. Needless to say he was reluctant. Oh well suit yourself. Next day I offered again and he decided ok sure. We cruised along and headed up the coast towards his stop. At one of the lights I was waiting to turn right and this guy was beside himself, next to us was a beach blonde in her own bug waving at us. I wasn't paying attention and so I finally had a look and she was alright to look at. I played it down, so the next day he gets to work telling the crew about the ordeal and the bug is now dubbed a pussy wagon. The crew then insisted we do a Roady to Byron Bay via nimbin. It was a great time had by all and a few yarns about nimbin could be told. Better to not sharn on about that too much... back to the main yarn. A few years later... and a few more to be exact Since then it was exported to NZ about many years ago where it got parked in an old hanger and left to gather dust. I developed a curiosity about will it go and maybe putting it back into operation. At xmas last year I headed down to drag it out and see if it was still in one piece. Someone had wired fuel pump on backwards as I heard it bubbling into the tank so seemed like someone had borrowed the fp and then put it back. Got a fresh battery and a while later it barked into life. Dry rotted and coozed tyres were next on the list. 60 bux later we had a set of roadworthy treads the fronts were bad but they held out. 5 Hours later rolled into the 09 and parked her up. The was a mean mission. It's been parked up for the last month just waiting for garage space to accommodate this so we can begin stripping and assessing in conjunction with the viva18 points

-

Believe it or not i worked on this today. I went over to mums to sell a valiant diff to a rooster off marketplace. While i was there i set about refitting the copper radiator. With a view to giving the block a good flush before fitting the purdy new rad. I got that in. But decided there wasnt enough day left for the actual flush. (We spent ages digging through my pile of diffs, turns out i have three spare VG diffs) I went to start the old bitch up, cos i havent heard it run for ages. But the fuel pump didnt seem to be able to fill the fuel filter. So i gave up on that too. Ill take an electric pump over some time, and finish what i started today. Pic of the pile of diffs for thread.18 points

-

Dipstick. I didn't have one with the engine parts and I had to move the location. The 7M Dipstick location is right where the 4M engine mount goes so I had to drill another hole in the block. No drama the boss is cast into the block, just had to drill it. Then I set about modifying a jz Dipstick tube to work. I drilled the hole to big for the jz tube so I had to weld it to build it up then machine it to size. I fluked the size and got it perfect, its a good tap in fit. I cut the stick to length and used the 4m in the crown to get the oil level marks right. Then I put the sump on, probably not for the final time but it's on.18 points

-

So point of having it stop is to have it driving is so it can be moved around. Driving a project is a good motivator too Point of being able to stop is to drive it outside to give it a good clean underneath, mainly so we can see whats under there and dont get filthy while working on it This car was driven a lot on wet gravel roads. There was a LOT of dirt underneath Quick tidy of the 14x7 and 14x8 Cheviots while they are off with some fine scotchbrite to get the worst of the oxidising off Some blue springs and matching blue ADJUSTABLE RIDE MONROE GAS shocks in the rear. Pretty sure both he springs and the shocks are completely shagged from carrying around the LPG tank but interesting to see. Didnt spot any lines coming out of them either. This thing is an absolute whale compared to the rest of the fleet Gave it a wipe down with a waxy towel Swept out and tidied up stuff And shuffled everything back to bed17 points

-

When we purchased the little Moke it had only travelled 1614km since being restored born witness by the odometer reading on the brand new Speedo. The story goes that a father restored the Moke for his disabled son. The son was wheelchair bound and old mate had even fitted 12 volt rams to the rear hinged fibreglass roof so that he could get the youngster in and out of the passenger seat. Problem was that the youngster didn't have much upper body control either and nearly fell out of the Moke on the first outing. The family got such a scare that the Moke got parked up for a while before they sold it on to a young fella from Noosa. I think that the new owner fell in love with the idea of owning an old classic without realising that it isn't like driving a modern hatchback with all the mod cons. He was also not mechanically minded so he ended up farming the maintenance out to a local mechanic and after receiving a few repair bills the novelty of owning the Moke wore off. And its at this point that Mrs Flash and I stepped in to take over the reins. So, both inwardly and outwardly the Moke looked absolutely immaculate as borne out by the below photos that I saved from the original advertisment:17 points

-

1000km post run in oil change time. Then I took it in for some surgery on the exhaust. I got sick of playing around with it so like a coward I farmed it out to a zorst wizard. There was much choppy chop and a quieter centre muffler was grafted in. Still sounds good but is now bearable to drive. Wizard made multiple angle adjustments to clear the diff and brake bias valve and torque arm. One problem to report: Whiff of antifreeze when the heater is on. GROOOAAAN!! Looks like dash out in my future.17 points

-

Today went pretty smoothly, managed to solo tow the old girl off the lawn and onto the driveway and waterblast 2 years worth of lichen off. Found lots of cancer had spread but not as bad as it could be. 15 yard test is still a pass. Also found lost of lifting bog from its life before me, will make for interesting times ahead. Had to use the quad with a bare tire on the front to push it into shed as the brakes were binding on, got wife to steer it and it went slowly rolling into the jack, axlestands and compressor. She hops out 'i tried using the brake but it didn't work, its not my fault!!' Calmed her down with 'if i told you it had no brakes would you have hopped in it?' Prolly no dinner for me tonight lol.17 points

-

We decided to remove the front clip to tidy it up and make it easier to get to the suspension and enginey bits as well. Check out the custom radiator shims - the Torana must have a shorter engine bay. We got $50 of random 202 bits of FBMP and amongst a couple other handy bits that included a near new water pump, a much better thermostat housing and the extended fan thing. Nose cone off Note the blue inner on the drivers fender i think this was replaced post restoration as the paint is overall much worse than any other panel and seems to have been painted only once bolted on - the passenger side is also a replacement (originally a pale yellow/mustard) but was fairly obviously repainted with much more prep and attention while off the car. Other than the fender rust behind the front wheels where water and mud collects, the front clip panels are entirely rust free which is nice Fenders out Pulled everthing to bits, cleaned it, derusted, and painted Pretty pleased with that, pressed a couple of dents out with the press and it seems to sit nicer too Going through the front indicators to make at least 2 ok ones inner fenders tidied up rad support seperated from the nosecone and all bits including the lamps all cleaned, derusted, unbent, painted, threads tapped and reassembled. Nose cone has similar treatment but just knocking the cracked paint off on the outside and primed it. Looks worse at first glance, but its straight, rust free and ready to bolt back on, or for body work at some future point. Need to sort the rust at the base of fenders but all that stuff is ready to bolt back on. Because my big sheet of 0.8mm is for baby cars, I picked up some 1.0, 1.2 and 1.4mm panel steel offcuts today for $15 + GST ( https://rietveld.co.nz/ - what a treasure of a place - a true barry paradise!) so ill probably make a start on patching the bottom of the easier of the two fenders next to start to ease into it.16 points

-

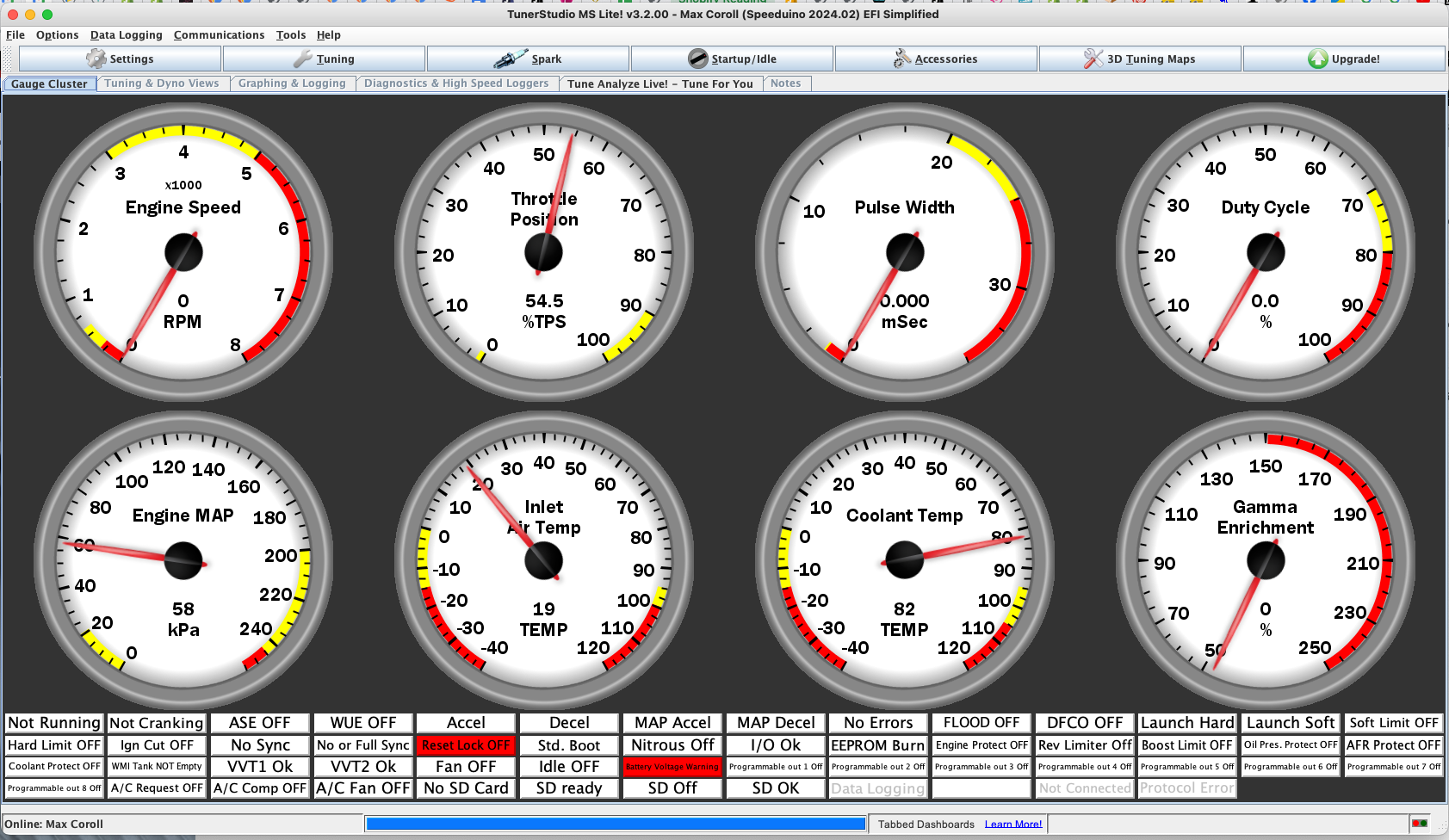

I ended up pulling the whole loom out to check things on the bench. It took a few hours to figure things out, I had made a few mistakes. Since I have pullup resistors on all of the cam angle sensors, the 5v supply on that loom plug splits 4 ways and joins to the signals. However I'd swapped the 5v supply wire with one of the 5v/DI signals on one half of the plug. So looking with a multimeter it still showed the correct amount of resistance on that DI, but, it was the wrong way around. Then I also found a broken wire at the plug end of one of the other DIs. Then I also found one of the pins in one of the plug halves was pushing back out when you put the plug together. So replaced the plug. I've got all of them responding on/off when holding steel against the sensors. While I was there I also changed the supply to 8v instead, hopefully less chance of trigger errors. Hopefully it'll all work okay now.16 points

-

16 points

-

Triggers for the ecu. I couldn't use the stock 5M dizzy because it sits exactly where number 1 throttle needs to be. So after a bit of indecision and fucking around I decided to run a crank angle sensor off the front pulley. I machined the inside of the pulley to an accurate size then I made a boss to press into the pulley. The pulley is cast so I can't weld anything to it. She's a fucking tight fit in the pulley so it ain't going no place. By pressing this hub into the inside is not affected by the rubber isolation layer which can cause erratic triggering. I'll laser cut a trigger wheel and use it to accurately drill 4 mounting holes. Then all I have to do is mount the sensor off the front of the motor somehow.15 points

-

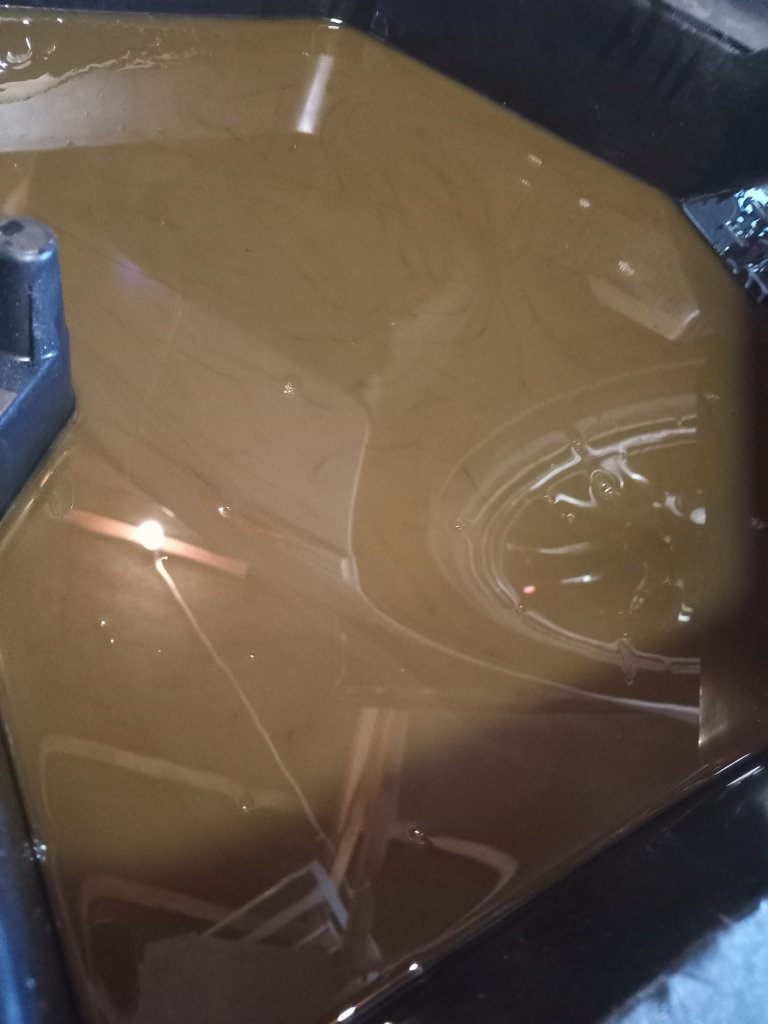

Well this ran with a misfire upon entering boost since i got it, now its really started being undriveable, i checked tps, coils, all the things that could cause that miss and came up with nothing definitive, it always smoked a bit but i thought this was as a result of being rotary and then i noticed the oil looked cloudy on the dipstick, changed it for fresh oil and filter.. The oil looked like this after 10min run time and smells kinda like coolant, time to rebuild, im guessing a water seal let go or something... I should be sad about this or something but im actually looking forward how a rotary engine looks inside, especially a 'worked' one.15 points

-

Since day one of ownership the Moke has always whiffed of fuel when parked in our garage. At first I attributed the issue to the cork gasket on the fuel cap which was badly shagged. I ordered a new one from Minisport but it made no difference. I began to notice that the smell was particularly bad when the tank was anyithing above about half full. We lived with the problem for a good while until one day I decided it was time to do something about it. Crawled underneath and removed the under tank cover plate for a quick look see. Sure enough there were signs of old fuel drips on the inside of the cover plate. At this stage I suspected the problem to be the sender unit rubber seal that sits on the side of the tank. So out came the tank and I removed the sender unit and replaced the seal. Sadly still no luck. In desperation I decided to drop the tank one more time, then filled it up with fuel to just past the sender unit to see what would happen. And .... a slow leak from one of the spot welds that hold the tank sender locating collar in place. I ended up chucking some JB Weld over the spot and that solved the issue.14 points

-

14 points

-

Panel Barry is a stickler for door gaps. Suppose he wouldn't be panel Barry if he wasn't a gap commander. These dogleg panels (his words) which cover the front portion of the rear arch were not lined up well with the doors and it was throwing off some other things. These little panels have always been messed up since I got it, probably since 30 years ago to be fair. So out comes the cutting and welding tools again. The doors also weren't perfect so fixed that up on both sides. I'm happy to hear, and his words "This is the end of the real time consuming type of repairs". We'll see about that I suppose as he works the front.14 points

-

Coffeepot only just fits on the gas cooktop and disasters have struck, a few solutions have been tried but didn't really work, a stainless sheetmetal idea has been floating around in my head that holds the pot up and directs the heat to the pot but with only basic cutting tools I never managed to get far, having just managed to get my cnc router running on sheetmetal, this was a golden time to put a brew on. As @ajg193 asked about my process, I've taken a few photos along the way. First up draw a sheetmetal part and create toolpaths in Fusion, I also make the stock as a seperate body so the machine can place workholding holes in useful places: The idea of this design is the smaller tabs project off the cooktop grill to support the pot while the skirt and larger tabs direct the heat. First machine op, g clamp 0.55mm sheet to the bed and drill 4mm holes: Second op draw fold lines: And finally cut out: This was bit of a disaster, personally I hate working with stainless but I also want coffee, now! Knowing plenty of coolant was compulsory, I got ready with a can of crc, of course this turned into a flame thrower after 50mm of cutting and by the time I hit stop the cutter was toast, I gave it more cutting depth to shift to undamaged flutes and went back to the messy option of heaps of cutting oil, the mdf spoil board was getting pretty smokey by the end of the cut but we got through. Clean off the burnt mdf, add some folds and done: Test run confirms the idea works, but I think improvements are possible. Turns out the tabs didn't quite like the weight once the heat came on and I think a change to the wider tabs could maximise the surface area for heat transfer....... Well, at least the pot won't fall over so easy now14 points

-

13 points

-

Following Kelvin's success with his lowering rails, and girlface's "well it's a quality of life improvement, not a performance upgrade" concession, I nabbed some as well. I wanted to get some adequate before and after's but I was on my own so... we'll start with me failing to fit an upright Suica card above my head. I started with the passenger side - also using Kelvin's patented "do it in the back seat" approach (hmm phrasing) - and I had a couple of brain scratchies around the belt buckle that took things later than I wanted but figured it out eventually. A tricky driver's side before and passenger's side after the next day. Riveting On to the driver's side... and well, there's not much more than to show some before and after's. There's more than a whole Suica card's height now! I kept the driver's seat in the same angle while upgrading it to try and keep these two eye-level shots as close as I could. I can actually adjust the wheel down! You can see my hair! As Kelvin said, "it really does feel like you're IN the car now", as opposed to riding on it. It no longer feels like I have a vertical blinder on. I can more easily see under the front-view mirror. My hair doesn't scrape the head liner, regardless of seat incline. I don't have to recline the back slightly past where I'd prefer it to be anymore. And at the other end my butt's position in the car feels more planted and nestled. Overall 10/10 upgrade. I can't wait to drive it again.13 points

-

12 points

-

Uncle Neemia has been working away at this, one more bulkhead to go in, then it will be “flowcoated” with gel coat to make it smooth, and then the floor can go down, the flooring plywood will be encapsulated both sides with fiberglass, as much as I dislike wood, I couldn’t justify solid composite (coosaboard) material and I didn’t want soft foam core flooring.12 points

-

last month or so Kirsty and I have been poking away at this Got the interior back together, the Torana seats look pretty cool in brown, but there is no reclining function, they only bolt to two of the HQ factory holes and there are bits of wood under the two feet, so some factory or better seats are on the list now too. Seatbelts as well. Got it running off a boat tank off the key reliably, and next task is to make it stop so at least it can move it self around relatively safely. I like having projects be drivable, I like that they can do their main function, lots me think they are pretty much done apart from some petty technicalities. Started bleeding from the master as the pedal felt like the piston was stuck. No fluid exiting from the front port (rear brakes), rear port (front brakes) seemed fine. (Notes for later reference: PBR alloy master, cast iron front callipers, drum rear) Yep - was stuck down and full of schmoo. Got it professionally line bored Assembled it with lots of rubber grease and 'rebuilt' the brake booster Tidied up the engine bay a bit more as well Aaaaand now it leaks fluid into the booster when the pedal is pumped.. I may have assembled it wrong but i suspect one of the seals is blown/nicked or the bore is pitted somewhere (looked fine). Will need all new brakes at some point anyway so ill try to find a kit for cheap, or a new master even (seems they are around $300 from the usual places)11 points

-

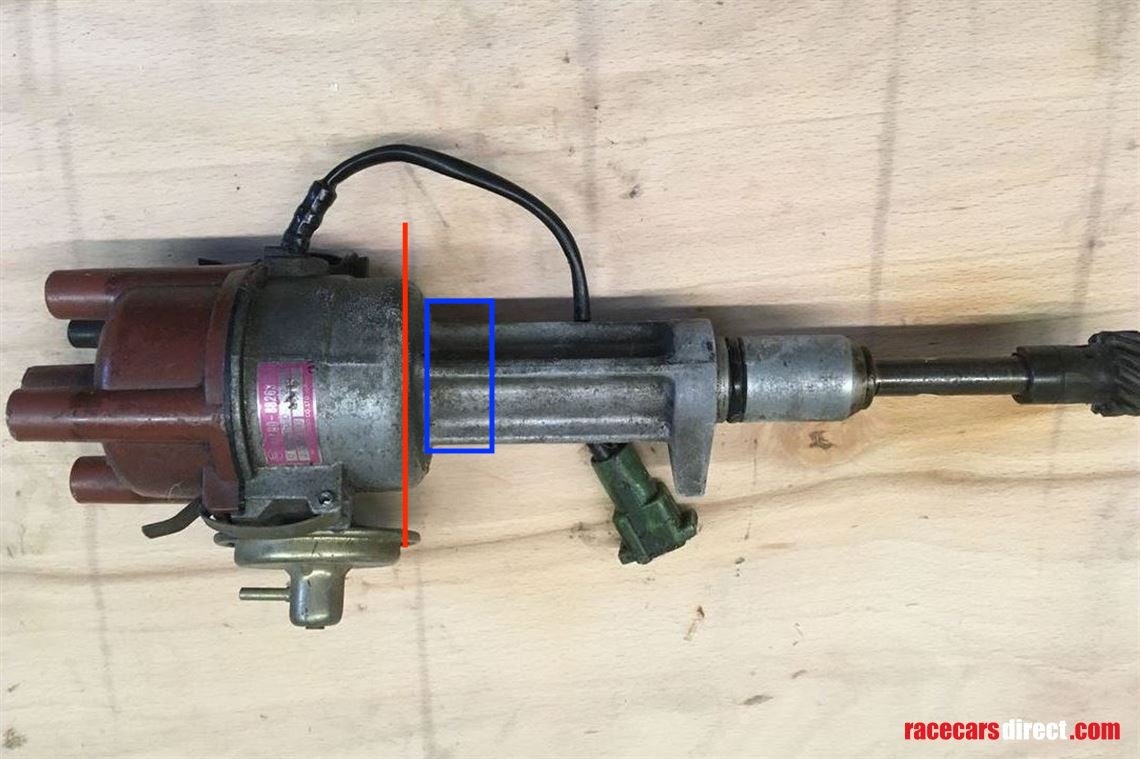

The ECU has arrived, consider me impressed. The micro USB is a bit janky, but that's neither here nor there. It's been fitted with a VR conditioner and configured to suit the Toyota 24+1 trigger setup. It connects to TunerStudio which I'm quite happy to see has Mac support. Now I just need to resuscitate a laptop, as I don't think my Mac Mini will work very well in the car. I went and saw Max on Sunday and we stood and stared at the two disassembled dizzies for a while. The guts of the 4AGE dizzy are too big to fit in the 2TG dizzy, so it sounds like there is going to be some sort of choppy choppy sleevey sleevey action going on. We're looking at potentially cutting the 2TG dizzy off at the red line, turning the blue section down and turning the base of the 4age dizzy down to be joined with a sleeve and joining the two dizzy shafts somewhere in the mix. Max also pointed out the oil port on the side of the 4age dizzy for lubrication and told me he was gonna lie awake at night designing something in his head. I guess my next step is to start stripping the 2TG loom down and working out what I'm keeping, what I'm removing and what I'm adding, along with what is already in there that can be reused. I'm already planning to run the map sensor and IAT sensor off the AFM wiring having done this previously on a Silvertop to Blacktop 4age swap, and I know I'm gonna need some more injector and ignition wires.11 points

-

11 points

-

Over the last few weeks, I've noticed a steadily increasing stiffer steering and during last night's burger cruise it felt particularly bad. Figured I'd do a bit of fault finding today. First step was to remove the intermediate steering shaft to determine whether the issue was on the steering rack end or the column end. With the intermediate shaft out I fired up the engine and waited the few seconds for the Astra pump to come online. What a relief it was to find out that the issue is not on the rack/pump side of things. So turned my attention to the angled steering gearbox and the steering shaft itself. Pulled out the angled gearbox for a closer look. Popped the cover off to check the lubricant level. Turns out it uses grease - or at least mine is filled with grease. I'm hoping that is factory and not some previous owner's bodge job. Anyone know ? Anyway, I neglected to take a photo, but it looked like some of the grease had shifted leaving the top half of one of the gears dry. The grease looked to be clean and still in good condition, so I just topped up the level and fitted the cover plate back on. At the same time I spent a bit of time fine tuning the little adjusting thingy till I got the mechanism turning smoothly: While I had the angle box out, I pulled off the steering wheel and dropped the shaft so that I could grease the upper and lower bushes. They were pretty dry. With the steering wheel off I figured I'd tackle another annoying little issue. For a good while the indicator self cancelling feature on left turns hasn't been working. Works perfect on right turns though. Really aggravating as I keep forgetting to manually cancel the flashers and also pretty unsafe. Anyhoo, I took a closer look at the mechanism and it was visibly okay. There are two little "ears" on a spring steel collar that press fits over the inner steering shaft. Looks like so: Each little "ear" engages with a double ended lever attached to the indicator mechanism. One of the "ears" isn't visible due to the angle of my photo, but I've marked up where it is supposed to be. With a visible inspection not showing anything untoward I enlisted Mr's Flash's help to watch what was going on while I turned the steering shaft from below. Turns out the little "ear" on left turns was not triggering the self-cancelling lever. Pulled it out the collar for a closer look. Both "ears" are showing signs of wear with noticeably more wear on the left one. Thought I'd try and give it a tweak, so clamped the offending "ear" in my vice: Chucked an appropriately sized punch down the centre of the collar to maintain its shape: Then gave it a little bit of loving with a hammer. Popped it back on the column for another test and ... success! With the self-cancelling issue sorted I reassembled the steering and dropped the van back on its front wheels for a quick steering test. Nice and light once again. Loaded up my ratchet with the appropriately sized socket and headed out for a road test and also to re-centralise the steering wheel. It took a few goes until I got the steering wheel perfect, but I'm happy that things are now back to normal. Thanks for looking.11 points

-

10 points

-

Yeah the machinist lapped the valves in the head and did leak tests on each one Thanks for checking. Crap... I think that's an action shot, but god damn it now I have to go back and check lol. Fortunately I have photographic evidence. Yep it's an action shot. Phew9 points

-

Removing the mud and giving the old girl a good bath made it look better, but also made it easier to see a fair few issues. I think this has been restored once before and there are a few rust bubbles starting and a fair bit of paint adhesion and filler cracking in all the 'usual' spots. I shouldn't have but i started to pick. The Premier sill garnish that had been riveted on this lowly Belmonts sills was holding a lot of mud so i drilled (some) of the rivets. Sucks teeth Ill think ill just put that back up there and pretend we didnt see that With the seal definitely broken i dug into all the suspect areas to see how many repair panels to put on the list . This deep crease explains the thick filler on the upper half of this quarter panel, the filler probably made the rust on the lower half worse. Removing the deep filler means the door shut looks 100x better than it did Good 5mm of filler of this too, and much the same on the other side, except that side has braze as well There were signs of lots of filler on this quarter too. It has also been (previously?) brazed some of the filler was 10mm thick Took most of it off with a heat gun, much less messy than with a whirlywoo. The panel looked like this underneath it, from a prang in the rear Spent a bit of time with some hammers and dollies and a bit of extra heat trying to shrink some spots and it is quite a lot better. Like the other side, removing the filler also significantly improved the fit of the doors to the body! So yeah, some bits are pretty much as i expected (doors) some are much much better than i feared (quarter panels, cowls) , but some i didnt even suspect, like the sills, are quite bad indeed. We will need every patch panel you can buy, which basically means its got bitten in all the usual places, but that is a nice change from not being able to buy any panels at all!9 points

-

MX5's can fit car engines np! Such a practical car.9 points

-

How it started ^^^ vs how it's going So I mentioned to Dad that we needed to get the leg off to see if the driveshaft was rusted. I didn't mean now. Dad decided now was a great time. So we've spent however long it's been between that post and this post pulling it apart. We've split the top of one flat head machine screw, broken a bolt, scooped out a couple of cups of this weird shell/grease mix, poured the driveshaft out as a fine powder of iron oxide, and now we're trying to work out how to remove the machine screw with the broken head to release what I'm gonna call the pinion gear.9 points

-

I'm all good with the current safety inspection of older cars, one thing I though.... I think there should be slightly more leniency for the testing of brake imbalance on old historic /classic.. I want the convenience of going to a vtnz, but I don't want the ballsache of having to get a 50 year old braking system to be as accurate and repeatable as a modern day equivalent when the car weighs under 700kg and probably couldn't do a 17 second 1/4 mile..8 points

-

Unpopular opinions (and wall of text from a non-expert) incoming. As a workshop that does a lot of newer stuff - the 3 year first WOF works pretty well for 99% of people. The average driver round here does about 10-15,000km per year. By the third year, it's time for tyres... The majority of those cars are inspected annually for servicing anyways so a cut tyre, puncture or crappy wiper blades gets picked up then. Hardly ever do bulbs or anything else within the first 3 years. If someone does really high mileage and kills their tyres quick - an annual WOF check would pass them, then they'd be bald within 6 months because the time between 1.5mm of tread and a bald tyre isn't very long for a high mileage driver. My argument for keeping 6 month WOFs on the older stuff is that things seem to go from OK to broken much quicker. A wheel cylinder starts leaking, brake caliper seizes up or a rubber bush splits or something starts dropping oil onto the exhaust. It's not that the cars are inherently less safe, they're just at that age where things fail from time more than mileage. So I'd put a 20 year sliding scale on 6 monthly inspections. The current most dangerous cars on the road (that we frequently fail) are the 2002-2012 high mileage shitters that get little maintenance and zero fucks given by the owners. They roll in with cords hanging out the tyres, one headlight out, valve covers pouring oil onto the manifold, ball joints knocking, smeary windscreens you can't see out of....and do you know what - they all passed the last WOF a year ago. The WOF requirement is really there to force people to at least get the car checked by a professional. It makes absolutely no implications that your car is safe to drive at any point other than the 45mins the WOF inspector looks at it. It's hopefully checked to a standard that most things would last to the next mandated check. We currently can't expect drivers to be responsible for knowing if their car is safe to drive because people are idiots and there's very little accountability. I'm pretty sure in blighty, if you got pulled over with 4 bald tyres - that's enough points for loss of licence? So whats the solution. It's fucking complicated. I don't know how much a slightly chafed seatbelt webbing, non functioning tail lamp or a stonechipped windscreen actually contributes to the accident rate and I don't trust the government to know or tell us the truth either. Perhaps we can continue fine tuning the inspection process to focus on the items that really make a difference to safety and spend less time failing cars for 34% tints or a slightly crusty rubber bush or a tiny bit of scabby surface rust on a subframe. TLDR: Tyres, brakes and lights should absolutely be checked often. Maybe other things don't need to be?8 points

-

8 points

-

8 points

-

So it looks like this is a thing. I have entered and paid. I'll be co-piloting the Sigma down from Tga with @MaxPower. The mighty Sigma is being handed over to its proud new owner at Hamner so We are looking for a ride from Hamner to Chch Airport on Monday morning. I think our flight leaves around mid day. @HighLUX will probably be joining us too. Can anyone help with airport transfers?8 points

-

8 points

-

One of the multitude of reasons this car never gets any closer to be finished is my never ending flow of side projects and half arsed ideas filling up the carshed and not leaving enough room for the car! Rainy boring day so perfect for a shed tidying session. Got sidetracked making one of my kids a wand first up (see never ending projects comment above), but got a solid effort in this afternoon so far. Have been putting up with this behemoth being in the way everwhere for years now, never wanted the box anyway so today it got cut up for the burn pile. So much more space efficient now. Lots of things along those lines and now i can see a car sized open floored area again! Will cut open another burning drum tomorrow and get rid of all the scrap timber that has accumulated in the back shed. Then continue the relocation from hoardingsshed 1 to hoardings shed 2..... of 4. Then to tow/push/shunt the car out of its lawn divots!8 points

-

I made the handbrake cable bracket. I can make the cable outer touch the propshaft flange, so I'll make some brackets to hold them away. I'm fairly confident they wouldn't touch by themselves anyway... I must decide how I want to marry the Triumph handbrake lever to the toyota cable so it's still adjustable. The handbrake is offset to the drivers side, so the cable 'just' misses the propshaft.7 points

-

Hi Peter; You mention that you plan to nickel-plate the lovely radiator-shrouding that your Dad has fabricated. My information suggests that Bugatti radiators were customarily finished in an alloy called "German Silver". This may not necessarily apply to the T59, but it may be worth checking out before you get any plating done. The other thing that might be important to understand is that modern nickel-plating is NOT the same as what was used in pre-War Europe (the modern version was invented in the USA, and was only used sparingly there until after WWII). The 'old school' nickel-plating used on Bugattis used a process nowadays known as "electro-less nickel-plating". You should be able to find a workshop in NZ that will still do it. The result is soft and has a satin finish that will buff up quite well, but it is much more durable than the thin, shiny and brittle modern equivalent. You need to specify a minimum coating of 12 microns. The original GP Bugattis didn't have plating on many of their steering and suspension parts, instead leaving the steel in polished form. Die-hard authentic Bugattistes will still opt for this, but you need to devote regular sessions for careful application of moisture resistant coatings to the polished parts, and keep the car in a low-humidity environment. Old school nickel-plating may be a practical option, but - whatever else you may decide - please don't plate your front axle! That would constitute a cardinal sin!!! Your CAD drawing of your proposed steering box appears to differ visually from the T57 steering boxes that I am familiar with - maybe that's the case for T59 steering boxes, but I wouldn't know. The T57 steering box has radial strengthening ribs between the main gear-housing and the attached boss around the drop-arm actuator. I only know this because the steering box in my T49 project is actually off a T57, and it looks quite different to the usual touring Bugatti steering boxes that were fitted to T40, 44, 49 etc., which also look more like your CAD drawing. I'll attach a pic of a T44 and a T57 steering box to show you what I mean. Very excited to see the progress that you're making! Cheers, Michael Anderson7 points

-

Ok soooo, I have a v8 Corolla project that's been off the road since 2010, a Lifan go-kart project, and a couple of later model Corollas sitting in the driveway to tidy up and sell among many other things so I decided that grown-up thing to do would be to buy another project. This one is 2-stroke, something I know a whole lot less about, and as old as my Mum. Dad is a boatbuilder, so it was much easier to get him on board for this project, and he's even let me store it in the woodworking shed. The guy selling it priced it based on what he'd seen a fuel tank listed for on TradeMe. The motor turns over by hand, but the prop doesn't turn, and it sounds like it's a shaft rust issue. I'll dig into it at some stage, but for now creating a thread on here was much more exciting than actually working today. I see the Seagull Barrys race them, so it might be a good chance to buy a silly little boat to put it on.7 points

-

The bits I need for that Wof have arrived, the wheel bearing might be a mission, but we will see. In the meantime I have been hoovering/relearning what I need to know about DCNF carbs and have had some useful and enlightening conversations, some of which can be found in my DCNF thread.. I also decided to replace the expensive oil in the tranny with fresh expensive oil. Mostly cos I drained it all out to put a bit of sealant on the drain plug as it was dripping a tad. When it came out it was kindof murky which I guess is the new oil washing out and interacting with the old. So I did that and it resulted in a pretty significant drip from the drain plug regardless of my sealing efforts. I did a wee bit of investigation, which has had this slightly annoying result; I have a spare box which I stripped enough to get that housing off, pretty much for practice but to see if I could just use that. But unfortunately they are different. This might mean enlisting @yoeddynz in some dirty welding duties if I cant find someone slightly closer. If it welds ok I will tap it out with a parallel thread rather than taper and machine a flat face so it can use a washer for sealing.7 points

-

Ive been making good progress on getting everything wired into the fusebox and controlled by ECU rather than hardwired. I bought 2x 500mm coby hotdog mufflers which are currently just sitting pushed over the ends of the pipes on each bank. Quieter than just open manifolds but should be better once welded. Have wired up ECT, wideband, fuel pressure sensor. The motor was still idling really high (like 4200rpm...) with fully closed throttles, even after setting everything to fully closed. I couldnt figure out why until I noticed that my 2x lower intake manifolds dont quite cover the edge of the circular holes which must be an idle air bypass. It was only by a smidge, so gooed the gap with some silicone and solved that problem. My current issue is that the cam angle triggers arent being picked up properly. This motor uses hall effect sensors on the cam angle sensors, and the voltage they output is too low for this ECU to register correctly. So pullup resistors are needed, which I have wired in. But stilk not working it seems. Some people have suggested wiring them to the 8v power supply rather than 5v supply, and this boosts the output voltage. But this stuffs up my loom a bit, as the 5v supply on that plug branches to a few other things as well as the triggers. So, another annoying problem, but not insurmountable. Just soaking up more time on little bits and pieces than expected. But thats always the way I guess!7 points

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.4c839bcd144e04fd07039dd0a0698b24.jpg)

.thumb.jpg.570970b401ac8d26ce9af7c1bf2bd8cd.jpg)