-

Posts

1,170 -

Joined

-

Last visited

-

Days Won

1

Sunbeam last won the day on January 22 2024

Sunbeam had the most liked content!

Profile Information

-

Gender

Male

Converted

-

Local Area

Christchurch

Sunbeam's Achievements

Committed (5/5)

4.5k

Reputation

-

-

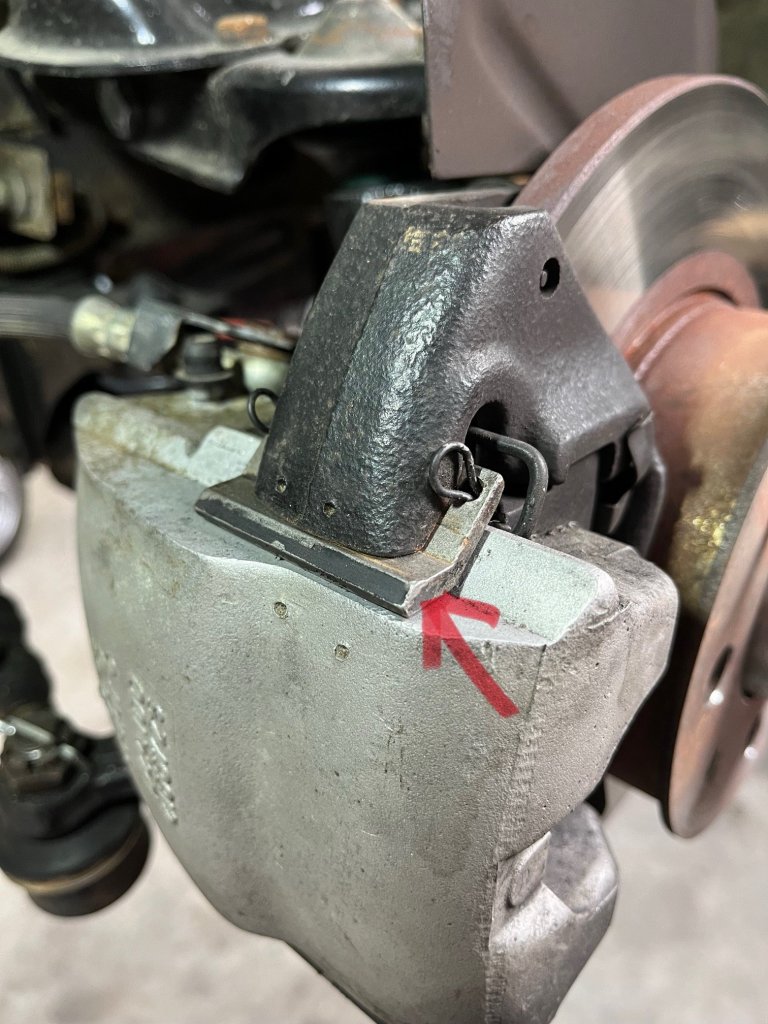

I found your problem ^ Happy to give more tech tips anytime.

- 16 replies

-

- 11

-

-

-

-

Easy pad changes though…

-

Been pulling to one side under braking and a lot of brake dust appearing on the right front wheel so I pulled the calipers to clean these wedgy things. those are what pass for a caliper slide on these old things. I had made the mistake of lightly greasing them when fitting them up 2 years ago and thus there was all sorts of crud glued in there. The Fiat Barries assure me they should be clean and DRY. Next, I wanted to adjust the front camber. The old factory data has the tech dial in a smidge of positive camber. That’s well and good for 175 R13s from half a century ago with bus spec ride height. Mine’s lowered to a well laden height and fully laden camber spec is a smidge negative. So I pulled some shims and my rig and trig tells me I’m now about 0.5 degrees negative camber. Eldest passed her full license test so I told her she was now allowed to drive the Fiat under supervision. She was fizzing hard.

- 143 replies

-

- 19

-

-

-

Change of plan. Starting work late afternoon now, so quickly went for hoon, no leaks! Reassembled interior and a quick wash. I’ll drive it to work and hopefully when I finish at 2am on Sunday there will be no drama. Boy, it looks yellow in photos.

- 143 replies

-

- 18

-

-

Remember this? Time to print a retraction. It was not the fault of the aftermarket, but a brain fart by the supplier who swiftly rectified the error. In the following picture, upper is correct, lower incorrect. With some limited shed time after dinner, I risked further spinal injury to refit the heater. Firstly I wanted to remove the steel heater return pipe so that I could fit a new hose. It’s not possible for me to do this in situ. This however required removal of the alternator and extraction from underneath the car. Et voila refitted in reverse, and then assembled the heater box with my flash new core. What a prick to refit. It goes in ok but if it’s not lined up millimetre perfect, the fresh air flap won’t open. Now I have a new heater core and all new hoses associated with the heater. I refilled the coolant for what seems like the 50th time in the last 6 months and ran it up to temp in the workshop. Wow, what heat and fast! No leaks yet, but I need to top up the system post cooldown and then go for a hoon and get it properly hot and up to pressure. If it oasses that test I can refit the ductwork and reassemble the lower dash. I probably won’t get around to that until next week because I’m a grownup apparently, with a job.

- 143 replies

-

- 11

-

-

- 143 replies

-

- 12

-

-

My wheels were supplied with the correct bolts.

-

Every lady needs more shoes in her wardrobe, ask Imelda Marcos. Performance Challenger 14x6, FB marketscourge score. Anybody want the tyres? 185/55/14, never touched a road, manufactured late 2024, the finest Linlongs. 195/60 is what I need.

-

- 143 replies

-

- 17

-

-

I hadn’t considered that because the outlet spigot has to be just so to line up with a hole in the firewall and everything is packed very tightly. I’m pinning my hopes on my new Italian amigo.

-

More self-inflicted spinal injury today. Heater out, bypassed, heater removed from parts car… hopes aren’t high for this one. Next pic is the good side. Face that the tap attaches to is corroded away, and the fins are jam packed full of birds nest, and there is evidence of seepage. I am in contact with an Italian geezer via ebay who has a nos heater core. Looks like it will be cheaper than a recore if he doesn’t fleece me on the shipping.

-

This was to be a triumphant post about getting the dash back together and happy cruising. Got everything in, and then went for a test drive before refitting the lower dash parcel shelf thingy. The heat was cranking yesssss! Then the heater fan made a fluttering noise as I was pulling back into the shed. Apparently that’s what they sound like when water drips on the blades. Sigh. Pretty substantial rupture. Back to the drawing board, heater out again. I’ll probably bypass it and keep driving. Any good ideas for getting antifreeze out of carpet?

-

Tapered drain plugs can eat shit and die. Every one on my Fiat drips a bit, and they’re all new too.

-

I got quoted a shade over $400 to have the heater re-cored so 690 for an actual radiator is sounding pretty good.

.thumb.jpeg.b39a639a8ff8a614681c3c9dca730a70.jpeg)