skidmark

New Members-

Posts

8 -

Joined

-

Last visited

Converted

-

Local Area

Outside NZ

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

skidmark's Achievements

Newbie (1/5)

132

Reputation

-

Rear Springs: My original rear springs are typically Bugatti in format: a forward-cantilevered quarter elliptic multi-leaf array. The springs in my 2 sets were pulled apart, and they showed heavy rust pitting to the extent that they were not going to provide reliable suspension without cracking or breaking. So, we decided to get new springs made. There's a place in countryside Victoria that specialises in re-fabricating new springs for old cars, and when they examined one of my spring-sets as a sample, they went "Yeah, yeah, yeah, nah." It was going to be too much work! A bit of internet research alerted me to a specialist in the wilds of Wales, but he only does work when requested by Tim Dutton, and he was on the verge of retiring. Then I found a chap in Belgium who had just finished making new front springs for a Type 55 - he posted a short video of himself jumping on them and bouncing around - a I figured that we had found the right guy for the job. There was a bit of to-ing and fro-ing involved: the original array for the T49 springs is 1 leaf @ 7mm, 5 @ 5mm, and 10@ 4mm. No-one, anywhere, has access to suitable 7mm thickness spring steel. We got spring engineers and gurus involved, and ended up with a revised recipe for the leaves in our spring array: 2 leaves @ 6mm, 4 @ 5mm, 10 @ 4mm. Same overall depth to the spring array. A Bugatti factory drawing showing the original rear spring array dimensions. This gave us a good specification to work from. The process of fabrication, further machining, bending and tempering took way longer than expected, as a result of lockdowns and a cardiac crisis from the spring-bending consultant, but finally the 2 spring arrays were completed and assembled. In this pic, further radiused bevels are yet to be cut into the nose of each leaf, and then they get curved and tempered to suit the specified load and deflection.

- 5 replies

-

- 34

-

-

Rear Axle Outer Hubs: To secure the fancy alloy wheels onto the stub-axles on the T49, Bugatti designed a rather complex outer hub. In my pile of bits, I had one of these, but not the other. There's a mob in Geelong South who specialise in doing custom CNC jobs for racing cars and V8 Supercars etc, and so I sent them my existing hub which they measured and copied x 2 - I figured it was best to go with the same on both sides, and keep the original as back-up. Lovely shiny new things!

- 5 replies

-

- 15

-

-

Wheels: Bugatti was one of the first manufacturers the employ in-house-designed alloy wheels, used on the 1924 T35 Racing Cars at their somewhat inauspicious debut at the French Grand Prix, Lyons. Bugatti-designed alloy wheels were subsequently employed for GP racing cars, and for also certain touring models, such as the famous T41 Bugatti "Royale". For the Royale, he designed a 1-piece alloy casting resembling a hydraulic turbine wheel. These wheels, at a slightly reduced scale, were offered as options for purchasers of the T49 touring Bugatti, and my pile of bits included 5 of these T49 alloy turbine wheels. The factory-stamped number is visible, as are traces of original paintwork. A friend has a touring T49, amongst his collection of Bugattis, which he keeps in Europe for motoring around the Continent, UK, and North America. He experienced failure of one of his original alloy-wheels, and so had all his wheels tested, discovering that they were all suffering from advanced fatigue and cracking up. The castings are 90+ years old, so it's not surprising that the metal may have become brittle over that time, especially with use. Luckily he managed to secure a replacement set which were the last remaining examples from a series that was cast a couple of decades ago, and has had no trouble since, although the current whereabouts of the patterns is a bit of a mystery. With this information, I determined to get my set of alloys crack-tested and properly checked. I thought it was probably worth getting the aesthetics attended to at the same time, as all 5 were showing oxidation and pitting that needed reversal. This image shows my instructions to the wheel-polishing mob, with a picture of a "Grand Sport" styled T49 that went to auction in France. Can't say I'm disappointed with the outcome - nice work! This one shows a bit of a curb-side divot, so it will be the Prince Harry. Crack-testing of all wheels came up negative - whew!

- 5 replies

-

- 18

-

-

skidmark started following Bugatti Type 49 build-up

-

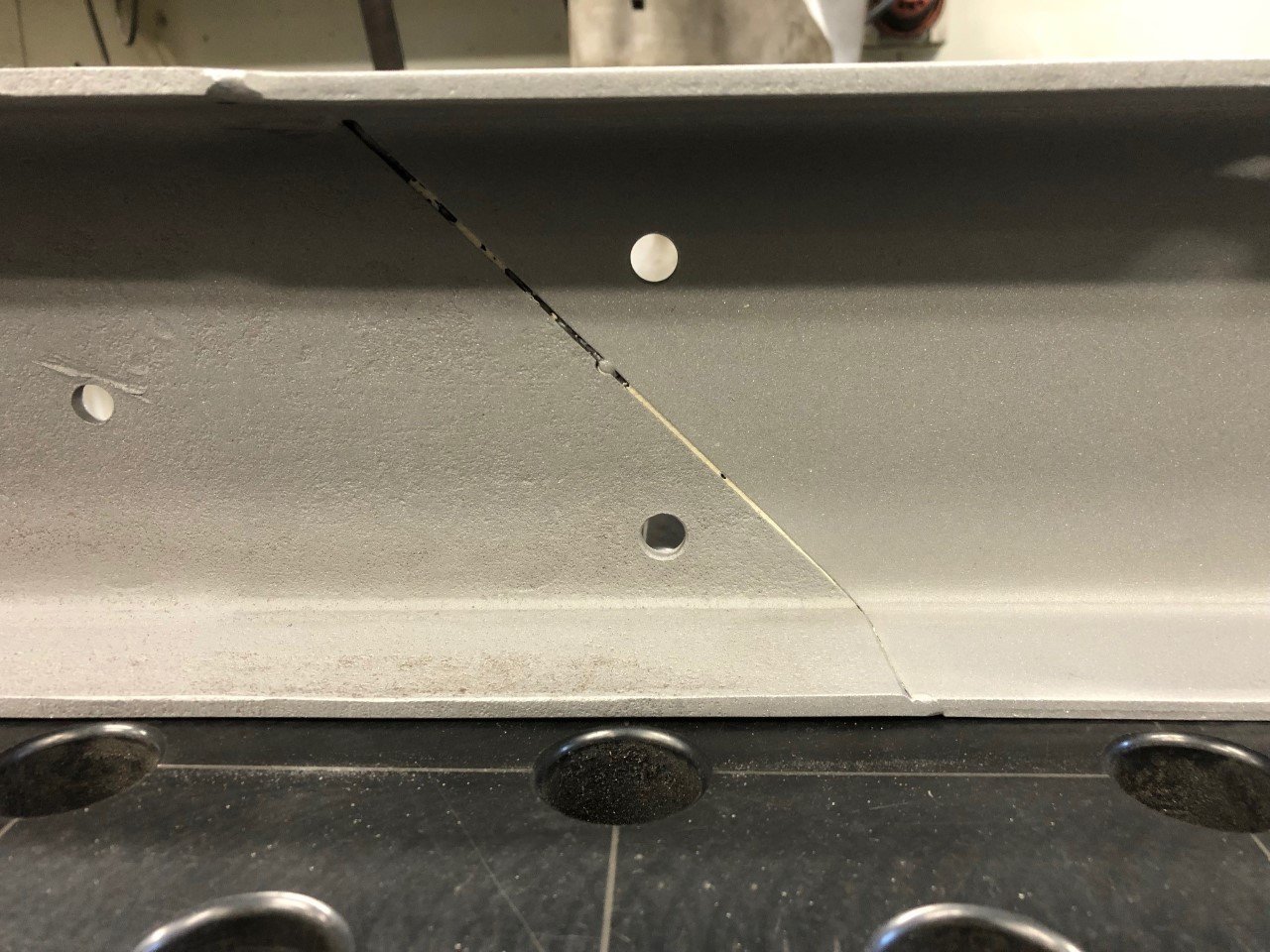

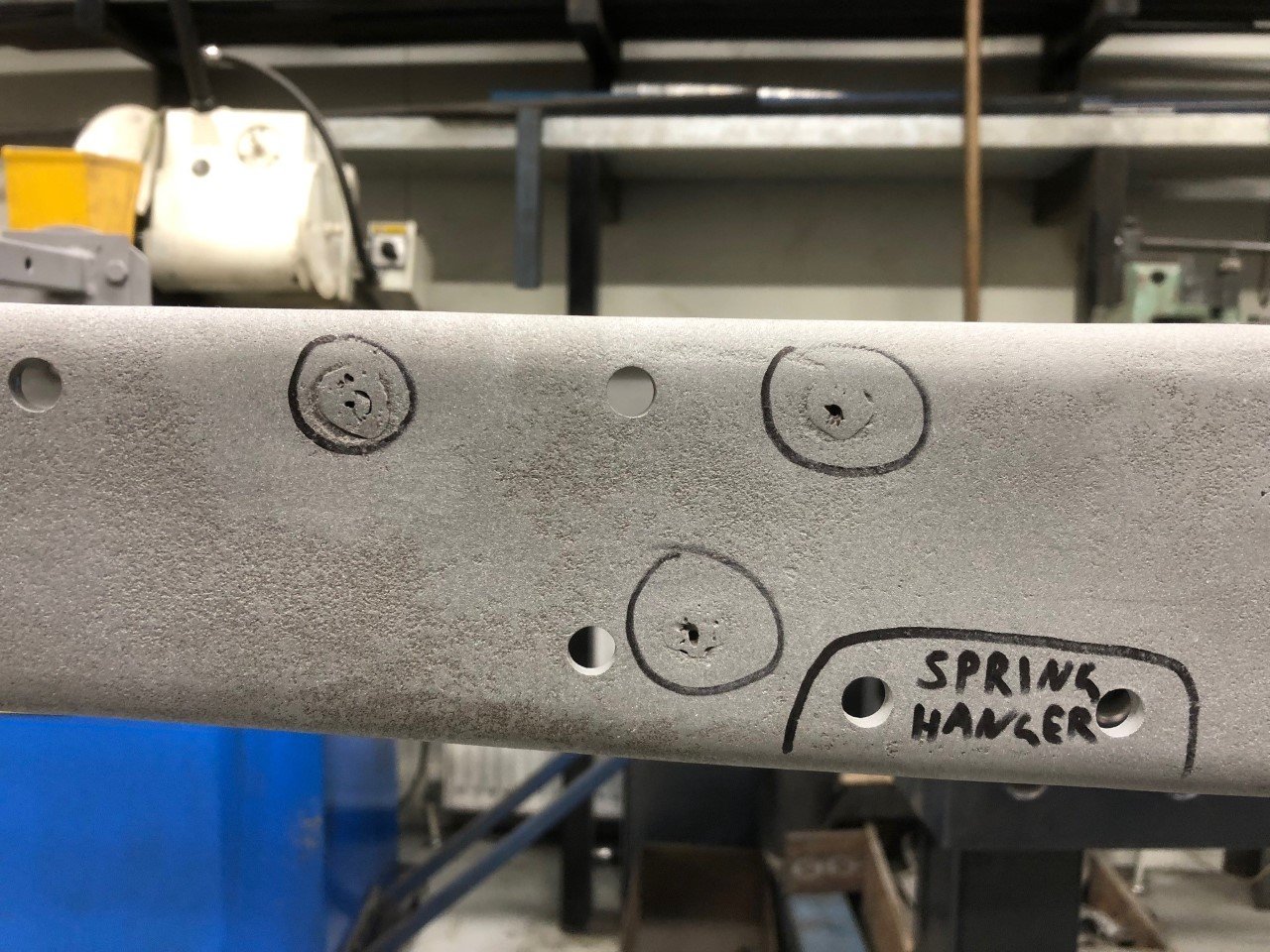

Progress: The chassis-rails were full of holes drilled in incorrect or non-parallel positions. These have been welded-up. There had been addition inserted into the longerons of about 415mm, which corresponds to the difference between a Type 40 chassis length and that of a T44 or (short) T49. We found poorly-welded-over holes that would have exactly corresponded to the positions of Type 40 engine mounting bolts, so it appears highly likely that my chassis started life under a Type 40, painted a red-oxide colour. The chassis inserts were made from non-matching steel profiles, of incorrect thickness, and had been welded only across their upper & lower webs, then bogged-up and painted over. They were fundamentally cosmetic and would not have performed a structural role beyond the first serious pot-hole. These have been removed, and replaced by correctly dimensioned and properly welded inserts. Horribly wrong chassis insert hidden beneath the paint & bog. Since removed and replaced properly. Texta markings show original holes for engine-mounting bolts, matching with dimensions for a Type 40 Bugatti - a friend with a T40 sent me photos and a template to double-check!

- 5 replies

-

- 12

-

-

In Australia each state has its own regs, and they seem to be under continual evolution. In Victoria, at the moment, built-up "specials" need to conform to numerous new car safety regs i.e. seat belts, collapsible steering column, side-intrusion protection. Provided it is an accurate copy and preferably utilises original components, a built-up "replica" of an existing old car only needs to comply with the regulations that were in force when such cars were originally registered, so my 1930 Bugatti will not need to meet modern requirements when being registered. As 6/7 of its main defined components have original factory stampings from the Molsheim Bugatti Factory, I should be able to obtain a chassis plate from the Bugatti Owners Club (UK) that verifies the authenticity of the finished car, and which gives it a "BOC number" (original Bugatti front axle, diff, gearbox, lower sump, steering box, chassis-frame; new non-Bugatti radiator). In the past, several of the new Argentinian-built Pur Sang Bugatti copies have been imported to Australia and registered as "Bugatti, 1934" or whatever - the authorities seem unable to differentiate between a new build and nicely restored old car... I guess either way they are raking in their horribly exorbitant Luxury Car Tax on top of the cost of the car, so they don't really care about when the vehicle was actually constructed!

-

About 4 years ago I purchased a collection of Bugatti parts from the estate of a chap who had bought them in the early 1980s with the intention of building a Type 49 Bugatti tourer. The previous owner disassembled all the mechanical parts (which evidently had come from a variety of donor-sources) and some deterioration subsequently occurred when vital mechanical components were stored in a room where the roof was leaking. The previous owner also had a very smart "Grand Sport" style body-tub fabricated for the project. This is a close copy of the "Compton" bodies fitted to 3 early T49 Bugattis, a reproduction of which was fabricated for the Southward T49 in NZ. I have been cataloging and cleaning up the parts I have, whilst working out what parts I don't have. Also, I have been scouring internet sources and progressively acquiring missing parts, requiring importations from France, Belgium, Germany, The Netherlands, Canada, and USA. Fellow Bugattistes have been very generous and helpful with information, advice, and spare parts. Recently real work has commenced. The chassis has been sand-blasted and set-up on an engineering table, all of its flaws exposed. We have commenced assembly of a Bugatti that never existed, but one that will be constructed from almost exclusively 1920s and 1930s authentic Bugatti parts, and which will conform to Type 49 specifications in all respects. A photo of the body-tub, nearing completion, in the workshop of Black Arts, C1980s? Sent to me by GregChristogoegl, who built the bodies there.

- 5 replies

-

- 38

-

-