Leaderboard

Popular Content

Showing content with the highest reputation on 08/09/20 in Posts

-

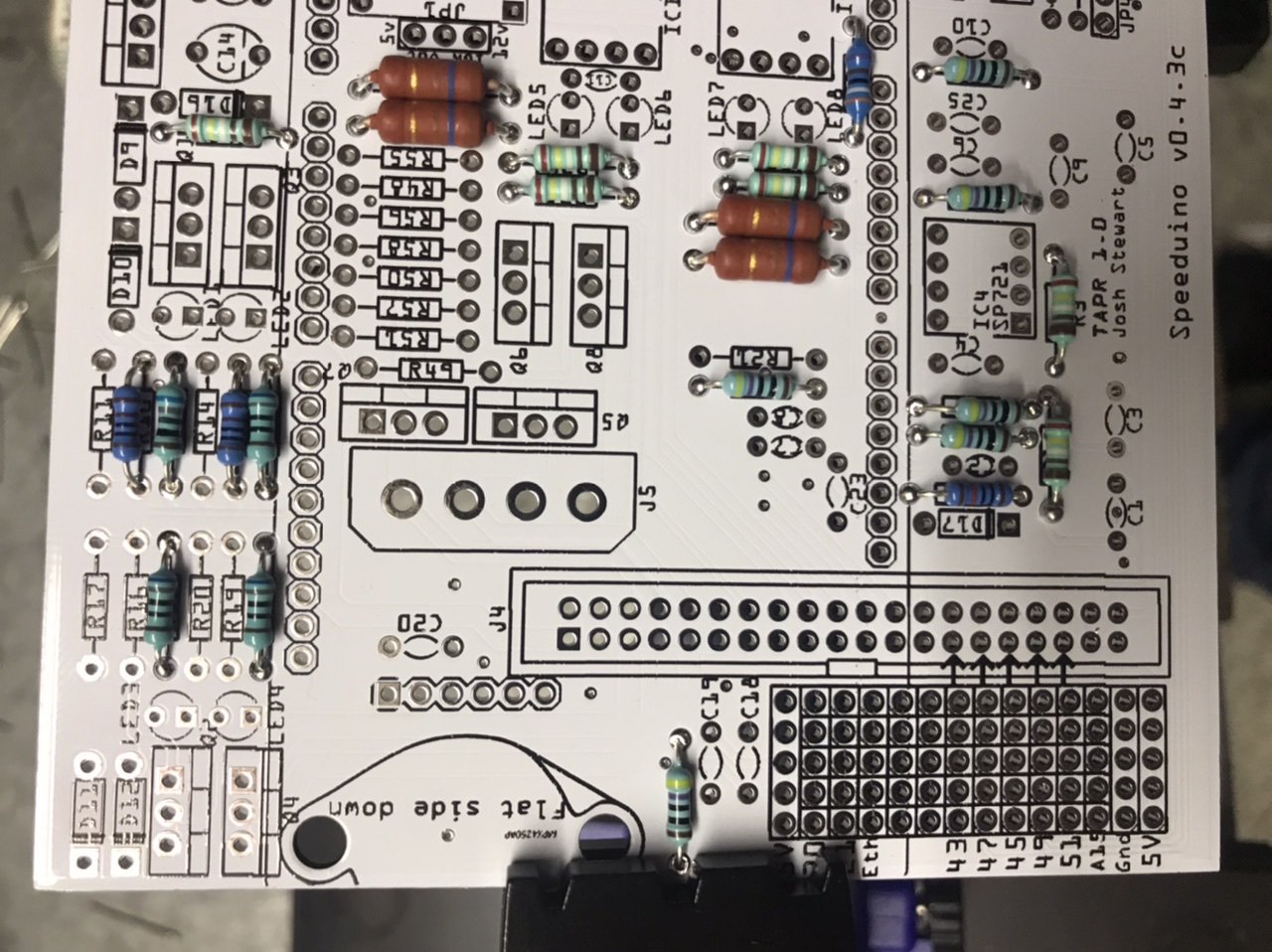

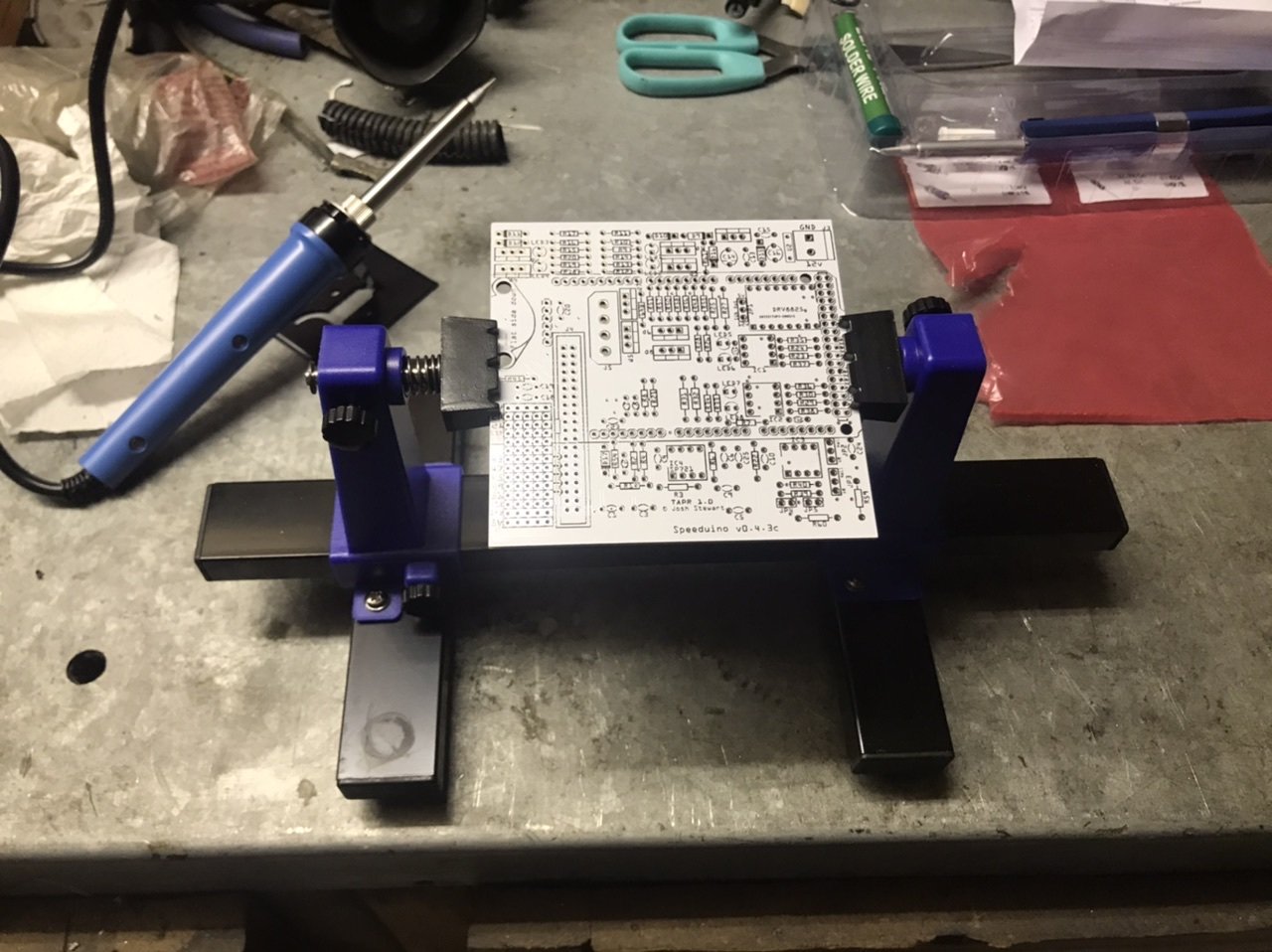

Took the Imp for a hoon on Saturday. Went to visit a mechanic who works from home up a valley not far from us because he has fields of cars and I had spotted some Subaru Leones. Sadly he doesn't have an front wheel drive models because I wanted to nab any gear boxes that I can just as spares in case my decides to detonate. Top bloke though- he knows his scooby stuff having been a mechanic for Subaru NZ. He's given me a contact to try for boxes. So since it was a very lourverly sunny spring day indeed we thought we'd continue our drive further up the valley and check out a load of nice roads we normally cycle on. It was so much fun. I didn't drive super quick. Just enjoyed the nice handling and it feels quick anyway when you sit so low. I took this pic along the way. (some fellow oldschoolers might know the area because it was part of a circuit I lead folks on for a friday cruise on the weekend of the oldschool nats, Marahau 2014. We went to Mapua for lunch and hung out with all the posh people there. Then home via the supermarket to end a nice day out in the Imp. The day before I had picked up some carpet that local lady who makes funky cushions had sorted me out with for cheaps. Proper auto carpet, same as what I had used in my Viva... The workshop is finally a fair bit emptier having smashed out a few other jobs and got them picked up/delivered. One job we just did was build some hefty steel art deco styled gates and a large set of doors for under an outdoor cooking area for a customer in Nelson. We reckon the gates look really neat so I have to share ... Now going back in time to where I had finished off in the last post. The oil pump was now mounted and I had a oil filter mount in place. I had forgotten to take a photo of the inlet/outlet off the mount but picture two tubes coming out of its base and going through the wall of the engine block. I now had to link those two pipes with things. One had to make it way to the oil pump and the other had to work its way to the back of the engine (as positioned in the Imp) and link up to the main oil gallery into the block. I had to have a good think about this. Whatever I do to make it work has to be easy to assemble, through the bottom of the engine with the sump cover removed. Once the engines two clamshells are placed together I don't want to ever separate them again for two main reasons... 1 : Because that involves removing the heads so new gaskets required and that costs money and I dont like spending money. 2 : It also involves a tricky little system to fit three pistons into the bores, from the bottom of the bores, using removable piston ring compressors through a gap of about an inch inside. You'll see more on that later. I am NOT looking forward to that bit. Originally the Honda oil feed system used pipes and sealed everything with O rings. It works well and makes sense. I could work with that. I did entertain using lots of AN fittings and hose etc. However there was a few reasons why not. They are a bit pricey. They were not easily available locally, especially during lockdown. It is not at all easy to swing spanners inside this engine block. Did I mention they are pricey ? Ultimately if money was not really an issue for me I would dry sump the engine and run a external pump. But ugly, expensive, external oil tank in the way somewhere, driving the pump off a currently non existent belt drive pulley (not even got to that point yet for an alternator but I have an idea) So keep it simple with stuff I have to hand! With that I rummaged through the pile of alloy stock I had and found a few bits that would work... But O rings were going to be a bit trickier. The size used by Honda didn't match anything I had nor anything I could find on my suppliers website. They were odd. I looked through a Honda parts diagram online and found the Honda part number along with the exact size of the O rings. Nice of Honda to do that! Looked up sizes online and it turns out that they are a JIS standard Oring. I never knew of such things. Actually very common among many Japanese cars. Even better - when I searched through my suppliers website they actually had them! But wait - there's more!!! They were cheaper than all the other O rings close in size. Yay! But the shop was shut to public and I couldn't visit it anyway. Boo! Thanks Covid However- the shop was open for supplying engineering places that were considered essential services. It happened that one of the employees lived not far from me. He delivered some and left them in my mail box. Yay! So now I could start what Hannah refers to as the London underground of oil tubes. I worked my way from the oil filter and made various blocks with holes and tubes with grooves. All very carefully measured to fit just right and tight but constructed in a way that it could be taken apart from the sump opening. I was lucky that I happened to have a large drill bit that was spot on for the final pass on the bores to suit the pipes and O rings for exactly the same amount of 'squish' that the Honda factory pipes and fittings have. I made sure that all the bores were as big if not bigger than the Honda setup so not to increase restriction on the oil paths. You'll see later that I will be over driving the pump in speed by a notch but that's another story. I must add that the job of planning, measuring and machining up all these little bits was a super fun way of spending time during lockdown (in between going for heaps of bike rides on super quiet roads!) Here's some pics of my subway tube network. These are the two blocks that seal onto the in and out pipes for the oil filter... The closest hole will feed a pipe heading back to link to the oil gallery. The further most block has a hole that takes a connecting pipe from the pump. Here's a view from the side... Lets zoom out a bit so you can see where they are in relation to the pump... You can also see how the pump is bolted to an adaptor plate which is bolted to the inside of the block. My connecting pipe that goes between pump station and filter station is in two parts so it can be fitted easily from below... Together its like this (lighter for scale... because all the cool kids measure the dish of their hand machined oil pump pipes with lighters like this)... Then fitted in place... Connections man! So I had the pump to filter sorted. The filter to main gallery looks like this... That pipe sticks out through a hole that was originally for the shifter mechanism ( I think. But whatever... thanks Honda for your convenient hole) You can see the oil gallery below. I will make a bolt on block with oil ways to connect them. I will also design it so I have the potential to take off from there and add an oil cooler. I would rather run the engine without one. It never had one as a bike but the engine did have more air flow over the engine though. But my engine will have a well finned sump cover to pull off heat plus be free to radiate heat better than on the bike. I shall run it and see. Its not a race car so I suspect that with really good synthetic oil I'll be fine. Its a pretty understressed engine anyway. Maybe I can add an oil temp sender to my filter block and run that through the ECU so I can have it show up on Tunerstudio for evaluation? Hmmmm - I like little things like that. But either way- keeping it as an option is good. I have yet to make the cover plate (some alloy plate is under my bench for it) that will go over that end. All simple stuff that. Once that's in place I can make a union block to suit the pipes. That cover plate will also have the oil filler and possibly a centre engine mount to suit a cross member but I have not yet decided on that. Moving around to the flywheel end of the engine you can see where the oil pump drive shaft hangs out, waving about like an unsupported shaft with no attachments... That shaft needs some motorvation and that is going to be part of the next exciting instalment. It involves Shimano....13 points

-

So that was last weekend but then this week a hardtop had popped up on TM locally for too much. I managed to get it slightly cheaper but still, not that cheap... I think I'll still try and get some out of Japan to sell at some point given how much they go for nowadays. Crazy. I took the old Gloria out to collect it. The guy selling it had an FD3S as well which he showed me, it was fucking slick. Super tidy. It turned out that he was originally from Auckland but was now living in Nightcaps of all places. Hilarious. Anyway we got to yarning about the 90's/00's Auckland car scene and it was a good wee chat before I bumbled off. Then when I got home (in between rain showers again) I started to fit it up. Mine has apparently never had an hardtop before as the plastic trim pieces were all in one piece and covered up the mounting fixtures. This one came with all the parts so I used those and my eyechrometer to mark and holesaw then grind clearance into the plastic to fit up the catches. THe end result was as follows: Obviously black looks fucking stupid so I will be painting it white when I get a chance and removing the soft-top from underneath when I refit it once painted. That's all for now.11 points

-

So when I finished the last post I said to myself that the next one should be less wordy and just let the pictures do the talking. Now bear those good intentions in mind as you read the following. I did say that I might need to go to Palmside for the repair panel for this one, which means I am all the more proud of what I was able to pull off. Considering I only have the bench and a couple of hammers and dollies to work with, it came out pretty close. When you see the photos side by side it looks like the rear sloping section is slightly further forward than the original, especially compared to the shackle bolt access hole, but I'm planning to run an early Mondeo space saver or something so I'm not too worried. My cheviots wouldn't fit in there originally anyway so no biggie. Looks pretty good in the hole too. I left the front edge unfinished for now until I figure out what I want to do with the wheel tub and how to connect the two together. You might have noticed I also reused the original strap bracket thing too so, um, neat? So with the inside panel sorted I started on the outside. I started by stripping the paint back, along with the bog. So much bog. Ain't she purty? After setting to with the bench, hammers, and dollies again, I got this whipped up. It looked pretty good and I was preparing to tack it in but as I cleaned up the inside of the rear little corner piece I was finding more and more pitting so I figured I might as well do the whole job proper. Believe it or not, this was roughly formed with a rubber mallet on the grass on the back lawn before I did the final fettling the normal way. If it works it ain't stupid right? And so next began what I can honestly say is my most successful panel welding so far. All told it was about two hours to get to this point, welding 10-15mm each time and hammering on each weld to keep the warping to a minimum. I left the front little bit untouched for now because I'm planning on replacing the wheel arch at some point so I'll finish it off when I get that finalised. Some more panel beating and a quick coat of primer later, I got this: Lighting it from a very oblique angle exaggerates the imperfections but it gives a good idea of what I'm dealing with. I've since spent more time sorting that out as best I can and made some good progress. I don't think I'll be able to get it mirror straight with my abilities but it's pretty close now and a couple of coats of high build primer should get it there. It's a damn sight better than it was in any case. The last panel I wanted to play with in this area was the lower part of the door surround/quarter panel attachment point. This bit. As you can see it's pretty lacy and I wanted to change how the panel fitting worked so I make a replacement up that was slightly different. It's the top one here obviously; the bottom being the now installed quarter patch. You can see the flange where it used to sandwich between the quarter and valence has been folded over and an extra flange added to sit flush with it. From the inside: This is going to let me plug weld the valence directly to that flange and remove the protruding section that they all have from factory. It obviously worked fine for Ford and made it very easy to manufacture but I don't like how it looks and it's always been my plan to remove it. I realise it'll be hidden behind the bumper in the end and no one will ever notice but that's no reason not to waste a few hours on it for me. The finishing touch for this area was to add in the dimple for the bung that covers the shackle bolt access hole in the inner wheel well panel. I could have just left the panel straight, but then anyone who saw it might begin to suspect that the car wasn't a completely standard, unmolested example of a 77 Escort Estate. Obviously that's not something I'm willing to risk. All you need is a lovely wee die like this and you too can keep all the anoraks fooled. I'll take the hole out to final diameter at some point. Don't rush me. I just spent something like three hours hack sawing through this so I'm a bit tired actually. Over the course of making up these panels I did a few plug welds with the TIG. I was quickly convinced I should get myself a MIG before doing many more. So until then, the panels are going to sit nicely in the corner, ready to go when called upon. In the meantime, I've opened another can of worms. The driver's side quarter has similar rust problems, though not as severe. I figured I might as well crack into it while the techniques are still fresh in my mind and I can't progress on the other side. I started by stripping the paint again. And the bog. Even more this time. I'm reminded again how thankful I am to whomever bodged the shit out of this car didn't just scrap it. Cause judging by their skill level, they really should have saved themselves the effort. And then where would I be? This patch it going to need some considerable beating around so I'm definitely going to need access to the inside of the panel. Which means this has to come out. And this. . It's a weird, almost double skin design, but not really, with a decently voluminous inaccessible cavity between the quarter panel and this inner one. With no drain holes either. Of course. So any dirt or water or bolts or bread ties or bookmarks or whatever that falls down there is gonna stay there. Until it rusts itself a nice access hole anyway. But it comes out easy enough in the end. I love spot weld drills. I have some plans for this area. It'll mostly be back to standard with new steel and better drainage, but I also have an idea for the back-most section that I'll reveal later on, assuming it works. Soviet space program style. In the meantime I'll get myself a welder sorted out and keep chasing my wheel arch lead. I'm not sure I stuck to the plan with being less wordy but hopefully it's been entertaining nonetheless. Thanks for reading.8 points

-

8 points

-

So a week ago I did actually manage to find some time to get stuck into the replacing of parts on this thing. First thing I did was in between rain showers, change the brake discs and pads. This was a bit different than I was used to with the rears but actually super easy once I looked up why the fuck the piston wasn't retracting.. (there's a bolt at the back of the caliper with a hex head screw in it that needs rotated to pull the piston back) Fronts were typical push back spec, nothing too exciting.7 points

-

Yesterday, I put the intake. There were no tears, copious swearing and ALMOST one snapped bolt. But not quite. 2000 Honda Integra Type RX-955-Edit by Richard Opie, on Flickr The garage is only wee, so this is a door-up jobby. Yay for a break in the weather. 2000 Honda Integra Type RX-957-Edit by Richard Opie, on Flickr Car goes up, bumper comes off. More stuff needed to come off, too. How easy is it taking off a modern car bumper. This appears to be attached with 2 self tapping screws, 3 push-in clip things and a 10mm bolt. And maybe a hearty splurge of hopes and dreams. 2000 Honda Integra Type RX-962-Edit by Richard Opie, on Flickr The old intake arrangement consisted of this piece of convoluted hose feeding the original airbox. In the interests of total originality, I still have the big resonator that sits up in the guard and all the pieces required to reinstate to OEM will be kept. 2000 Honda Integra Type RX-963-Edit by Richard Opie, on Flickr The airbox has to come out. Along with the radiator overflow bottle and it's bracket. And the support bracket for the airbox. And you also need to undo a stay that connects the clutch flexible hose to the hard line. This becomes evident later in the swear-fest, after Richy says "surely I don't actually need to remove that part." 2000 Honda Integra Type RX-976-Edit by Richard Opie, on Flickr Next, we attach this wee stainless bracket to the bellmouth part of the kit. 2000 Honda Integra Type RX-981-Edit by Richard Opie, on Flickr Then, you slide the bellmouth into the OEM intake arm. You'll see there's a wee spring on the end that goes around the circumference of the arm. This keeps enough tension on the joint to prevent slippage, in lieu of some ghastly looking hose clamp. 2000 Honda Integra Type RX-985-Edit by Richard Opie, on Flickr THEN, oh boy, what a humdinger of a step... the wee bracket bolts onto the mounting tab vacated by one of the three bolts that secured the original airbox. MAGIC. But yeah nah, it located perfectly. 2000 Honda Integra Type RX-991-Edit by Richard Opie, on Flickr The filter - a K&N item made specifically for the kit - then slips onto the bellmouth. It's a pretty tight fit, so it stays put. For now at least. Until the next step. When it seems to be a real sausage in a hallway situation right when you don't want it to be. 2000 Honda Integra Type RX-994-Edit by Richard Opie, on Flickr Unfortunately, I had to use all 7 of my hands to complete this step, so couldn't document the in-progress part. That's a big V-band clamp at the wide end of the airbox. After you have successfully managed to spend most of your life maneuvering the airbox into general position - I took the headlight out also to help - you then have to deal with clamping the bellmouth, filter, and airbox together with this big clamp. Now, the filter loses any conviction whatsoever to retain its interference fit to the bellmouth flange at this stage. This results in MUCH fumbling, and I'm pretty sure one of the instructions in the manual was "say FUCK a lot," but I don't read Japanese so I'm unable to confirm. So yeah, it's quite a challenge to ensure the clamp, er, clamps all three of the components. Often times you'd be like "YUS GREAT SUCCESS" only to realise the bottom (which is totally inaccessible) wasn't properly clamping. 2000 Honda Integra Type RX-995-Edit by Richard Opie, on Flickr Anyway, after saying 'fuck' about 589 times, it paid off and I got it all clamped up. I also added the trumpet to the bottom (fixed in place with aluminised tape) and fixed the bottom snorkel part with the supplied bracket. No pics, cos it was dark and I was mainly fumbling about trying to finish it off. 2000 Honda Integra Type RX-1018-Edit by Richard Opie, on Flickr The next day, the all important task of fitting the sticker was on the agenda. I struggle to attach a WOF sticker without it being 78% air bubble, so trying to place this no doubt expensive adhesive thing was slightly stressful. But we got there. 2000 Honda Integra Type RX-1009-Edit by Richard Opie, on Flickr Final step! Stand back and admire the view. Took it for a test doort round to sheepers place, seems to have fattened up the midrange noticeably in conjunction with the headers. And there's heaps of noise, so this unequivocally means it is faster. Thanks for looking.6 points

-

Dad's been round and after inspection said to run new cog as original is stuffed... Turn cog upside down and fit onto shaft. Now matches with original jackshaft position Bore new hole... Fit roll pin. Ready to go.... In position. It is known that on some of these you need to have dizzy in place before manifold is on. Its not a stockcar motor which have a tenancy to snap the rotor tag off so this is of no concern.... NO more computer saying 6000rpm is too much. No more injection saying Nope. My old EL 4.0l in stockcar used to run 8000rpm all raceday. Did that for 3 years until catastrophic failure6 points

-

Nah nah nah, paint the windscreen frame black to match for a seedyal special5 points

-

Managed to get the left hand side upper engine mount carved today. Then drilled all of the mounting holes and bolted everything together. Next step is to carve some gussets out of 8 mm plate for the upper mounts and I can then glue everything together. Until the welding is done the engine weight is still supported by a wooden spacer between the front beam and the 4Y sump so the rubber mounts should compress a bit once I remove the spacer. For those wondering the bit poking through the center of the one vertical plate is the dip stick tube. Thanks for reading.5 points

-

5 points

-

5 points

-

5 points

-

No relevant pictures. But I fixed the rust in the floor the other weekend. It's a fair bit quieter to drive with no holes in the floor. Have used it to move firewood around and dump some green waste for my nan4 points

-

4 points

-

4 points

-

Long story short @- i5oogt - @azzar and myself were in takaka to buy yet another mk2 Mirage . The car was in the impound yard at Orange mechanical also in takaka. We went for a wander around their yard and in their , to be crushed pile was this cream nissan 720 no wheels. No bumper or plates. On closer inspection it had two rego labels........ It failed a wof on rust in the floor. The owner not wanting to spend the money getting it fixed. Decided it was the end of the road for the little ute. Strange since hed owned it for nearly 20years and had never taken it out of the valley. After contacting the owner a deal was struck and plates and wheels were obtained from his possession. The wheels having 4 near new maxxis commercial tyres. First hurdle was the takaka hill..... in a sd23 powered ute Not to be scoffed at the little ute chugged up the hill in 4th gear most of the way. (Had to find 3rd for the real tight corners). The sd23 was quickly proving itself as a force to be reckond with A quick stop in motueka to wash the moss and lichen off using @Slacker_Sam. Car care kit. And off we set to Christchurch. Register but no wof. Made it to murchison for a meal at the pub before dark. But after that was all nigh running. The sd23 was more than happy cruising along at 100km and seemed to be a set and forget in 5th gear up hill and down dale 5th gear did it all. 6hrs on the road from takaka to chc and over half at night. And over 450km in a ute destined for the crusher. Better yet it didnt use a drop of oil or coolant on the drive back3 points

-

Good reminding, who hasn't had their creative ability smothered by the toils of daily life yet? Do we need a sticker etc?3 points

-

So I decided "right, I've had enough of that really slow leak from the sump gasket. I'll whip off the gearbox, pull the sump from the engine and sort that stuff out" Upon removing the sump I found some cake that looked like bearing material. Connecting rod #1 bearing didn't look the most flash so I decided "out with the engine" Upon removing the engine, most of the bearings weren't too bad but definitely worn. Next task was pulling the pistons Two of the pistons are cracked. A little googling indicates this is a pretty common thing on 4Ks. So the plan now is for the following: -port match intakes on head to manifold/gasket -drop cam and lifters off for a grind, something pretty mild -drop block off for a hone (maybe bore, but the bores look pretty good), new rings and pistons, block may potentially need to be decked if using aftermarket pistons -???? -profit* *probably huge loss, but maybe a gain in power The stupid thing is the car was running absolutely perfectly. I probably shouldn't have opened the can of worms, but I'm kind of glad I did. After this is all done I should hopefully be earning enough money/retired by the next time it needs to be done that I can just pay someone else.3 points

-

THISSS.... Is a very expensive and difficult to get piece of discontinued Mugen equipment for a DC2R 2000 Honda Integra Type RX-932 by Richard Opie, on Flickr Why did I get it? Because I'm a stupid fucking magpie, that's why. I also have a Mugen exhaust and a recently restored header (which for some reason I never updated but OK), and wanted to finished off the intake, header and exhaust (I/H/E) holy trinity with a matching piece. So a friend of a friend found a wee shop in Hong Kong who had this. He subsequently bought it on my behalf, I sent him money, he sent me a large box, I dealt with the hassle that is customs, and voila. Here it is. 2000 Honda Integra Type RX-945 by Richard Opie, on Flickr I am going to read this manual, and figure out how it installs. There's a lot of parts. 2000 Honda Integra Type RX-953 by Richard Opie, on Flickr This is the airbox, and the velocity stack that locates inside the inner gaurd. Vs the stock arrangement, it has a HUGE volume. I'm going to assume there is some kind of science involved in the shape, and volume of it. Because well, justifying it. 2000 Honda Integra Type RX-940 by Richard Opie, on Flickr The airbox attaches to this bellmouth with the biggest V-band clamp I've ever seen. Apparently this particular part is quite responsible for the Mugen setup producing some better numbers than most other units on the market. I'm not a surgeon, so I can't comment with any real conviction. Really nicely made piece of kit however! 2000 Honda Integra Type RX-947 by Richard Opie, on Flickr This thing stops all the nasties getting in, and claggin up my 'tec. It's really important that you keep fine particles away from your VTEC. K&N make this. So you can just do washing and oiling like you do with all the other K&N things and it'll last forever. Or at least for a few thousand KM this gets driven every year. 2000 Honda Integra Type RX-950 by Richard Opie, on Flickr It is REALLY important to have a sticker. So here is the sticker, that usually goes on the shiny top part of the airbox. I'm gonna scan it, so I can get replacements made when I inevitably wreck the other one while I'm doing my best impression of an apprentice signwriter whom hasn't yet read the dictionary definition of "self adhesive." The shiny stuff is sticky tape. In true Japanese tuner fashion, you use that to stick the trumpet onto the end of the airbox. No lies. Join me next time, for the part where I swear, scratch my new parts, cross thread some bolts and take some nice photos of it so it all appears super mint and well installed.3 points

-

Another wet day today. Hunkered down under the carport to keep dry and entertained the neighbors with the soothing tones of my grinder. Managed to complete the two lower engine mounts and most of the right hand side upper mount. Just got to tidy up a few rough edges and drill the mounting holes in the upper mount and then I can test fit this side.2 points

-

My brown seat covers arrived in record time. They're just sitting on top loosely in this pic. For now I'll just keep the black ones on, but if I decide to go ahead and repaint it another colour I'll put them on. Im still not totally sure what I'm actually trying to achieve with this scooter? But man am I having fun riding it. Any excuse to ride to town to get something I'm there. I'm thinking of taking up smoking just so I'll have to do more regular trips to a dairy or gas station.2 points

-

Finished up those flares tonight, the back ones are surprisingly hard to get a pic of in the shed light. I am pretty pleased with them, there were a lot of constraints to work within, but they came up good. I have also sorted the wiper mech, reassembled the dash and fixed the clutch hose. Tomorrow I'll get some more stuff to remake the mud flaps and have yet another go at stopping the power steering pump from leaking. Again. It's really minimal but the wof guy mentioned that it should be sorted.2 points

-

Well here it is ! After working away since picking this up in December last year in a bit of a state here's my version 1 of the Mazda. Car was a mess when I got it so we've been busy in the shed with the deadline of Chrome Expression Session this weekend. Couldn't have done it without a heap of mates an legendary business's! Steve at The Shed Rust Repairs for the rust work Tony for the panel and paint Hayden at Jokers Wild Kustoms for hijacking the car and getting it running while i was away at MCM Marc at RE- Wires NZ for fitting it in for coil repairs ASAP after dyno V1 Mark at Revolution Engine Services for locking me in a last minute dyno tune tomorrow Toby for polishing the wheels and trim Andy Duffin at 3 Rotor Racing for sorting a new spoiler last minute before paint Grant at Cooper Tyres Waihi Beach for heaps of tyre fitment swaps and a last minute pre chrome alignment Jimmy T for painting the dash topper and gauge surrounds @64valiant at Midnight Upholstery for retrimming the dash topper Gav at Precision Workz for redrilling the wheels and fab work Super stoked on the finished result2 points

-

Busy weekend. 2nd half worked well. Little removable corner inserts look clean. Next I need to make a new inner core and figure out where to put some risers. Should be close to going to the foundry!2 points

-

LHS all done, so on to the RHS. It is much worse, but we were kind of expecting that! Some bodgy repairs done it it, probably in the 1970's. Looks like it had taken a hit in the RHS just behind the door, and extending rearwards. Bash the dents out a bit and fill it full of filler seems to have been the order of the day! We will replace the wheel arch with a repair panel that Ralph supplied, which will deal with a lot of the ugly. A new panel is being folded up to replace the whole panel behind the door, to delete the window https://oldschool.co.nz/index.php?/topic/45289-browndogs-1972-v8-transit/page/4/2 points

-

2 points

-

2 points

-

Back to the dyno today after sorting the fuel system. Made 355whp @26psi. It's safe to say an 11sec pass is coming up2 points

-

Just before lockdown I acquired another project in the shape of a 1979 Mustang GT 'Fox'. This is my fifth or sixth Fox bodied Mustang and, like them or loathe them it's one of my favourite Mustangs. It's been off the road for 18 years, but the plates are (thankfully) still live. One of the previous owners has done a stunning job cleaning and painting the underside and engine bay of the car (in purple!) and there is no rust in the bottom half at all. The owner either ran out of money and/or time as he managed to bare-metal the shell but only put a light coat of primer over to protect it. The result was a fair amount of surface rust. Then came lockdown with 4 weeks of spare time. Interspersed with home improvements and work on my Hot Rod I re-bare metalled the shell, repaired any panels that needed it, dug out all of the filler and re-panelled the damage, and filled the holes for aerial and door mirrors. I'm now at the stage of starting serious modifications: The original puny rear axle has been scrapped and a much stronger one is currently winging it's way from the lower North, the seats have gone and a pair of RX8 leather seats will live in their place. The fuel tank has gone to make way for a larger aluminium racing tank and I've started a few other mods which I'll update at they progress.1 point

-

1 point

-

Hey man, recently had this carried out on my 1300 through choppers auto body shop. Used the wilwood powerlites with the integrated handbrake cable setup. We had an engineer draw up and make a mount for it and they tuck under some 14" modgies.1 point

-

1 point

-

I knew that those indoor fountain things houses have would be useful for something!1 point

-

As you may have noticed I'm a big fan of mocking things up in timber before I start metal carving. Because I'm tighter than a duck's bum its a lot cheaper too as I don't waste any steel or cutting disks and besides I have heaps of plywood off cuts left over from our house reno. So I spent a leisurely morning with my jigsaw and a few wood screws and I ended up with this beauty.1 point

-

But anyway a bit of info, it's a jap import Mirage CX Wagon, so top spec for one of these, plush interior, stainless steel monsoons, colour coded mirrors, twin sunroof with the rear one being electric which still works great and doesn't leak amazingly, has air con which still blows cold, and the worst part of all, a 3spd auto. This is the single biggest letdown about it. It is punishingly slow, not to mention when it's at 100clicks it's doing 3500rpm. Aside from that it's a little honey. Anyway back to the story, got hold of a straight bonnet and already had a mint front bumper lying around, so swapped all the nice bits onto it and gave it a good clean. Managed to get hold of the original hubcaps for it too which are a really neat 80s design. Lowered it about 50mm cause factory heights for chumps. Took it up to Hanmer for the weekend a couple weeks back with my mate who also has the little blue 2 door and performed like a champ which was a relief as I'd only really taken it round the block a couple times. I then saw a lush set of enkei aero wheels on Facebook marketplace so snapped them up, and thanks to @smokin'joe who managed to get them a good portion of the way from dunedin towards chch I picked them up from him. Gave them a quick repaint and polish as they were a bit grotty, and got a set of 195/60r14s fitted up on them. Also fitted a pair of LED lights on the front as the bumper had holes drilled in it already so figured I better utilise the holes. Just some cheapy jaycar things but are bright enough to help at night time as the factory headlights are crap. @azzar also worked his magic on it and installed a digi dash from our stash of parts just to make it that little bit more lush. And I put in some semi decent sounds and gave the interior a really good scrub up and she came up great. Plans, probably not a lot tbh, I'm torn whether to manual swap it as its such a rare commodity to have these wagons with a slushbox and I'd like to keep it as original as possible given how rare they are, but on the flipside, it is so painfully slow its not funny, auto box is healthy though and shifts smooth enough for a crap old 80s unit. In an ideal world I'd love to 4d68t swap it for diesel nangs. But that's a pipedream. Middy has been dailying lately and she's loving it aside from getting told "it's so bloody slow" haha. So this is how it sits now!1 point

-

After cleaning the fuel system it still wouldn't run which led to some head scratching. Tested the electrikery and it was okay. After working from the front back it turns out the lines from the tank were around the wrong way. Bit of a relief. Strangely almost certain it was like this when I got the car. Swapped around and waddayaknow it runs!1 point

-

Discussion: wheels, i still didnt have money but i asked about these and got a PM about a guy that knew a guy that had some. legit. 7jx13 cheviot quattro. Fuck yeah. i had the carbs rebuilt pro-fresh-a-nally and bought a brand new manifold. i legit stared at this on my coffee table for an entire evening. extractors wrapped. here you can see some combustion evidence, i had to pull the motor back out as is had no oil pressure on first start up. turns out i'd forgotten an oil gallery bung behind the timing cover. MOTHeR f***ER! thankfully, no damage. a the day it got its first wof in 4 yrs, dec 2019. so thats the car up to date pretty much. i havent really used it, but thats why i've restarted a thread. i've signed up for the kaikoura hop this yr and i want to smarten it up before then, 6 weeks at time or writing. i bought a rev counter off Karl late last year and cleaned it up but never installed it as i didnt want to loose my combo gauge. i've bought all the correct senders for my gauges now so i'll be doing that. i had the eaxhaust tweaked a few weeks ago to make it bark a bit more. i want to tidy and de clutter the engine bay a bit and also fit a fusebox as they don't have them, shold be easy enough to make a few important circuit run through a fuse or 6. i've also had this stereo for yrs, positive earth and just screwed under the dash for looks, had a modern one in the glovebox but it was just a stupid amount of effort to do anything with it so i didnt use it. i bought a cheap 2 channel amp off aliexpress and tried to wire in the OG potentiometer for max barry points. i failed, but a friend who develops tech for a living took it home as a hobby project and had it working in a few hrs. So legit. the song is supposed to be ironic, incase you were wondering. i will update this a bit more over the coming weeks, as she's all legal now but obv needs all those small jobs tidying and finishing.1 point

-

1 point

-

We disconnected the driveshaft incase it was a transmission issue, nope. Diff? Unlikely. So we tried some innovation. With a bar through the pinion u-bolts, ratchet stropped to a tree with some tension on it, we added some heat and hammering to the drums, and after some heavy persuasion there was movement! A bit more work and we had a roller. The next big question was the most important, is it saveable? There must have been a point not too long after grandad parked it up, where he realised he wasn't going to be able to get it on the road any time soon, legend says it had blown a head-gasket. So he decided he needed to preserve it. What happened next is a testament to his forethought and crazy ideas, he covered the car in waste oil. Yup, used oil from his digger, lots of it. He pulled out the interior and coated inside the doors, every surface he could get at got the treatment. Now over the years he copped a lot of flack for this, everybody thought it was a pretty silly idea. What it did mean, was that when we finally dragged it from its tomb, it was in a hell of a state. So, out with the waterblaster to see what is hidden under 35 years of dirt filled waste oil. We could hardly contain our excitement as we blasted off the muck, revealing a 100% repairable genuine barn find example of our Tom Dixon's 1968 Rambler Rebel. There is rust, as you would expect, some repair work needed around the windscreens, but absolutely no rust in the floors or sills. In places on the sills, the paint just peels off from the oil softening it, and underneath is clean shiny new steel. Another by-product, the hinges are well lubricated so the doors all open and close beautifully! At this point we were running out of time to do much else, so we loaded the big old girl into the trailer and shifted her home to the stables where she can await restoration in the warm and dry comfort of the fully enclosed and concreted pony shed. It may take a while, but watch this space.1 point

-

1 point

-

Lol aren't you then swapping in the scrap engine which made it cheap in the first place? I've been looking into ITB's a bunch and the more I read the more it seems like there is little to no gain except the cool noise, maybe a little more top end and even less bottom end torque. So logic tells me I should do it anyway.1 point

-

1 point

-

1 point

-

Gearbox time. As mentioned in the last post I was pretty set on using a Subaru Transaxle. I could also have entertained an Audi unit or perhaps a Renault 21 item but they are harder to find and more expensive. Subarus are everywhere! So way before I had found a engine to buy I started looking. Now initially it was a Legacy front wheel drive trans that I was looking for but when I realised that early Leones also came out as front wheel drive with a smaller lighter 5 speed Transaxle they got added to the list. Not as easy to find though! Then one day a leone boot lid popped up local to me on my Trade me favourite search. I contacted the seller on the off chance that he might have a box. He did. In fact he had two. A early 1600 item and a later 1600/1800 unit. So we went for a drive and paid him a visit and what a thoroughly top fella he turned out to be. A mechanic by trade, ran a local garage before retiring and now works from home on locals cars. However its what he does in his past time that was really interesting. He has been building small hover craft for years and became well known for building one with wings that could fly.... https://www.youtube.com/watch?v=xhGN4gFYPLk But I digress. He had some boxes because he had been using subaru engines for his hovercraft. So I bought a couple of boxes (one which came with a 1600cc subaru engine attached) , two starter motors, an 1800 ring gear. All for bugger all because I think he just liked the nuttiness of my plans for the Imp. So here is a box. The earlier 1600 in the small casing. about 4 kgs lighter with a smaller diff and takes a smaller flywheel.. This next one is the one I'll use... Its a later Leone 1600 T71G which shares the same slightly bigger stronger casing as the 1800cc. Ratios are 1st 3.636 2nd 2.157 3rd 1.266 4th .885 5th .725, Rev 3.583 - these coupled with a 3.9 final drive ratio should suit the Imp pretty well on its 13" 175/60 wheels. Here it is again next to the stock Imp box. Its not too far off but the gear selector is higher and points up at an angle. The box is also taller at the rear so the tunnel will need to be raised and the removable cross member chopped about. At 35kg its about 9kg heavier than the Imp box. I can take that. An interesting and very handy fact is that the box selector rod works in exactly the same way as the imp item, even the movements in are pretty much the same in travel both in rotation and back and forth ! So that is nice. Now as discussed previously there is the fact that the Honda will be rotating this boxes input shaft in a direction opposite to the norm. It has been done successfully with Audo boxes and I know of a fella who has run a box backwards behind a 440ci engine with no dramas. I'd also had the discussion about the new thrust loadings with a fella in the UK who's into Goldwings. Came to the conclusion that being a Japanese box from a much heavier car, optionally with a Turbo. So its not been to much of a worry however more people have questioned it and now I was really curious. I decided to strip the spare 1600 box down (same internal structure but a smaller diff and different casing) I got as far has the last bearing and syncro hub to remove and my puller broke. I'll use friends press but even so I am now happy that it will be fine. 5th gear is the one with the least thrust area when run opposite direction but that wont be so loaded up. Here's some pics I took... A beautifully done bit of technical description in this one showing original (green) and new rotation thrust bearing positions. (My Samsung note phone needs a new stylus!) On a side note- it has to be the easiest gearbox I have ever taken apart (ignoring the fact I need a press to remove some bits from the shaft) so I will take the box I'll be using apart and rejoin the casings for mocking up purposes later on. Much easier on my back. So lets put the box away in the corner and get back to the fun bit. The flat six. I was really looking forward to seeing how much lighter it was gonna get as I removed all the un-needed bits from inside. With the alternator, starter, inlet manifold and coolant pipes removed I weighed the engine. It came up at 105kg. Diet time! I removed the rear clutch cover that has the slave cylinder built in. Removed the clutch unit. Took off the drive gear housing. Ohhhhhh. Clean and shiny. Neato. I was told that this engine was possibly a low mileage unit but I was not to know until I began to strip it. I was fearing sludge or bad staining inside the castings but its super clean. Here's a shot with a few of the spur gears missing and showing the various bits... Clutch unit added back but without the main rear casing on so you can see what it looks like.. This was fun. I like learning new engine layouts. Here's the front of the engine which will now be facing backwards. Cambelt covers removed and you can spot not one but two VR sensors for the Honda CGI ignition setup. It has a 12 tooth trigger wheel which with a tooth removed could be used as a crank angle sensor for the EFI I have planned. More likely I'll make a 36-1 wheel the same size for better resolution. There is also plenty of room for a cam angle sensor to be fitted- Ideally I would rather run this engine on full sequential injection if ("if !?.... hahahaha" they laugh..." he said if " ) I use ITBS. Cam covers off. One of them had some welding. I suspect that the reason is that the bike was crashed and one cover got hit. Fella who originally had this engine for his project had bought a complete bike. You can see the nifty hydraulic valve lash adjusters.. I removed the cams then the heads. Carefully stashed all the bits in order on a shelf I had cleared. All the bolts and bits were being placed in organiser trays I had bought for the project. I knew full well that this project could well drag on for a long time given life etc. With the help of Hannah we split the crank case and revealed all the gubbins inside... Lots of heavy stuff in there to weigh in! Yay. All this stuff I didn't need went in this box... and that box went on the scales... 35kg Sweeeeeeeeet! That's more like it. A little bit more to lose when I start hacking the crankcase apart. Now I'm aware that I'll be adding some weight back with a flywheel and clutch but hey- this is a good place to start. Its now a 70 kg flat six. Next thing to do was sit it next to the box and line some things up... You can see where I'll have to fabricate a bellhousing to fill that 40mm gap. The Imp was at this point in time 'up on blocks' as I had the Datsun engine out to replace the rear main seal and ring gear. How handy then because I wanted to see how the engine sat in place! I bolted the heads back on loosely and slung the lot up under the imp. I lined the transaxles outputs with the driveshafts so positioning the engine front to back. I took a few photos, took some measurements and noted some stuff. I then removed the transaxle from the equation so I could lower the car down so the engine would sit roughy where it will end up. I stood back and admired it. Wow! It just looked so bloody spot on in there! Man - if my juices weren't fizzing with excitement previously as I stripped the engine down they certainly were now. I'll let these last photos I snapped end this update1 point

-

1 point

-

It's off the rotisserie for now! Needed to sort out the driveshaft which require the engine and gearbox to go back in. Got the axles sent away to be shortened and resplined by 105mm a side. That meant I should make an attempt at swapping the Altezza LSD and the 4.1 CWP into the diff head. No pics because I didn't really know what I was doing. But for those that are interested I ended up using the LSD side bearings and swapped the Estima pinion bearings onto the 4.1 pinion. The Altezza pinion bearings where thicker which made the pinion gear hit the diff case. I couldn't get the wear pattern right because I didn't have any shims other than the two that were already on the pinions. Got it close enough for the time being, will buy some shims or give it to someone else to finish off. Decided to run Coil-on-plugs instead of the dizzy relocation kit, mostly just to keep the engine bay looking simple and clean. Got a set of 1NZ coils, I'm thinking of casting up an adapter plate for them. Got the SQ engineering down-pull throttle linkage installed and got the accelerator cable shortened to suit. Made a vacuum block off plate, since I hope none of that stuff is needed anymore. Also at some stage I filled all the unneeded holes in the front radiator panel. Modded the accelerator pedal so it sits a bit closer to the other pedals, as before it was way off to the right. Two-piece driveshaft all mounted now too! Think I got the angles sorted after spending far too long trying to work it all out. It's an Altezza driveshaft with the front half shortened (yes I know the front section u-joint phasing is 90° out). In this photo you can also notice the sills have been strengthened (somehow missed that update somewhere). Used some 3mm angle and welded it the full length and ground back, so it's now really straight! Then boxed it back up to the floor, to try and stop dirt and moisture getting stuck in behind. Makes lifting the car along there way nicer! This is the centre bearing support mount, much thought was also put into this! Hopefully it's fine being welded to the seatbelt mounts haha. Still needs some doubler plates welded on to the other side of the tunnel.1 point

-

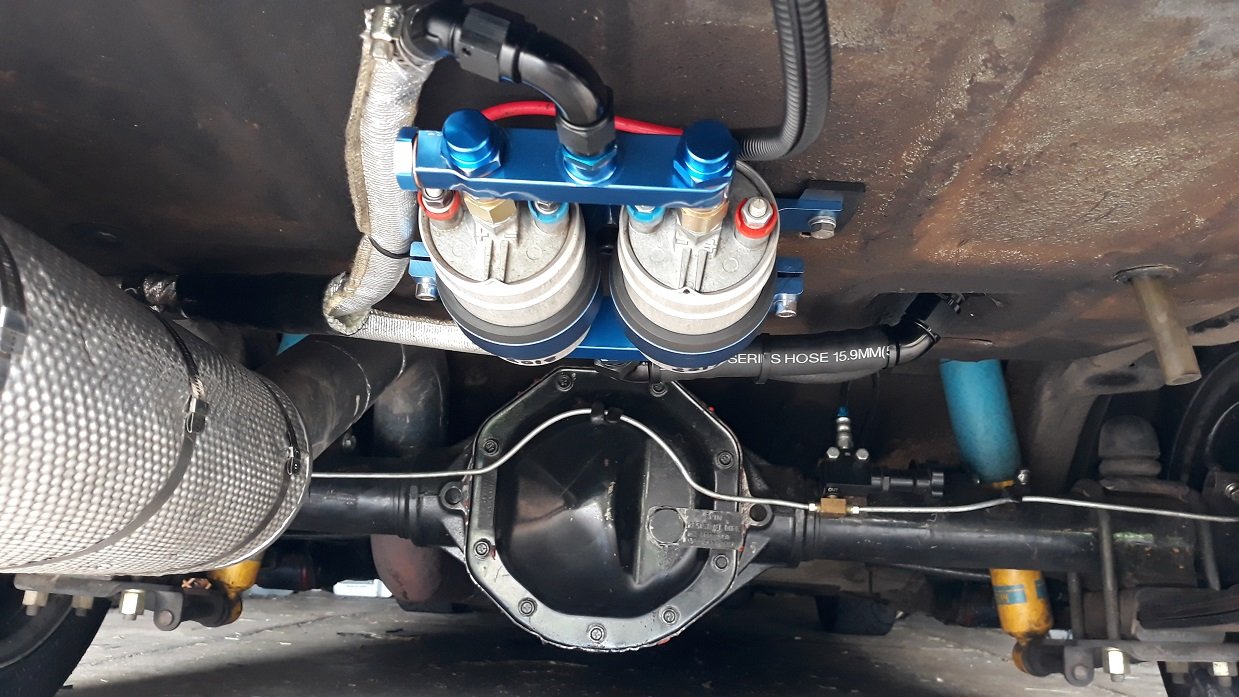

From the very beginning my Bosch 044 pump suffered from cavitation. Sounds like glass beads getting smashed up inside the pump. Well when the fuel pressure fell over on the dyno and it was time to go twin pumps, I emailed GRP4, the tank manufacturer and asked them if the -8AN outlet would flow enough to support two pumps. He was good enough to be honest with me and explain the the pick up pipe inside the tank has a kink in it and would reduce flow. I had no idea it would be this bad! Needless to say this was causing massive flow issues and is a testament to the durability of the mighty Bosch 044 pump. After careful planning and acquiring all the parts to complete the job, I took the tank to Drew at ARE Cooling in Brendale where he cut side of tank open, welded on a -12AN outlet and 1" pick up pipe. -4AN fittings where the fuel sight gauge used to be and tidied up the welds where my fuel sender goes in. The car is back running and the pump is actually QUIET! I will get the second one wired up soon, the ECU will switch it based on manifold pressure, as a guess it will come on around 18psi.1 point

-

Final spec on the motor was Standard bore 2.0L pinto block YB cosworth rods & pistons Ported, big valve 1600 Pinto head (9.1:1CR) MLS head gasket & ARP bolts throughout Custom turbo grind camshaft, HD valve springs, Newman long pad followers YB under piston oil squirters, high volume oil pump & Peterson oil pressure relief valve Custom Go Pipes steam pipe manifold & 3" dump, ceramic coated 3" mandrel bent exhaust GT2860RS turbo Turbosmart 38mm external wastegate, FPR800 and Kompact bypass/BOV Romac harmonic balancer & custom trigger wheel Modified (1 tooth) YB distributor with phase sensor Sierra EFI manifold with 630cc Siemens injectors LS1 coil packs Haltech PS1000 ECU Haltech wideband controller1 point

-

I finally assembled my Capri/ RS struts tonight after having the bearing and seal kits installed by a local mechanic. These are the same set up as the struts I had in my MK1. HSD 51mm 5kg coilover kit, Koni 86-1835SPORT inserts and some Noltec adjustable tops this time around which should get the front a little lower. I put one king leaf spring in the back to see how it looks with my JBW minilites. No point in doing both sides as the diff is coming out soon to swap for R31. Not too bad but needs some 1.5" blocks to get it looking just right ;D1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)