-

Posts

1,638 -

Joined

-

Last visited

Converted

-

Local Area

BOP/Central

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

MRWEST's Achievements

Committed (5/5)

3.8k

Reputation

-

Well shes been all bloody go round here! Progressing along real nice getting alot of finishing touches off Got a ton of stuff powder coated, subframe, lower arms, gearbox xmember, radiator, oil cooler, catch can, over flow, all the dash brackets, a ton of brackets made for the loom etc. Came up bloody mint! Also got a few engine bits and gearbox adaptor etc anodized black. And RKM polished my housings, front cover, intake manifold, water pump adaptor, EWP etc. Came up bloody mint And the shell has been back at my painter for about 4 weeks. All go, Blocked in 80g and 140g and about to hit it with the 240g before final prime. Body lines, gaps etc are coming up mint! Photo before the journey to painter, looking alot different now!

- 56 replies

-

- 28

-

-

-

Mines a UN series diff so i think that makes it limited options. Can get proceed/marvie 4.7 gears to fit otherwise its the factory 4.1 or 4.4 i think. Dont want to change gearbox as already got a new Tremac TKX so yeah thats out haha. Hmmm good tyres should get me enough grip, being NA the power band will be reasonably linear and high end being PP.

-

Can get lower than 4.7 but seems to be the consensus that NA rotary guys run high 4s low 5s usually. Yes injected!

-

225km-250km depending on the gear. thats plenty in the tin can haha. Predominantly street car but will do chrome type events, odd drag day etc. But will actually get driven on the road as a road car not garage or trailer queen Currently a bounty/courier diff late 90s/early 2000s but limited on options there so looking at others at the minute.

-

Not a honda as the thread seems to have turned into haha but relavent to the title. Contemplating redoing my diff for the rx3 . 20BPP, Tremac TKX with 0.81 final gear, have options of diff ratios of 4.7, 4.875 and 5.3. 100km speed revs are 3425rpm, 3550 and 3860rpm respectively with those gearing options and that final drive in the box. Obviously its going to be causing a hua of a racket at 3860 so am i going to hate my life, or in reality is the difference between 3425rpm and 3860 going to be negligible in punishmnet that ill be happy with the gains from the 5.3?

-

Hey mate, Photos below of what we did with diff head and rear chassis rails notch the bottom photo the rails basically went straight across at the base so weve notched it up for diff tube clearance.

-

Kelvin still does stuff and sells parts to do them as a mate just did a 3UZ surf on 2wd chassis last year and got a heap of stuff from kelvin like mounts/sump/wiring loom etc so would be worht talking to

-

Well wasnt expecting this when i opened the thread, not sure how i missed it till now also. Very cool! Good to see shes getting a tidy up before motor gets in , will be ace!

-

Yep as per all of the above. Fat plate is same as housing and had it out for other reasons. Yes to get the angles right for the box and motor, i believe it fits fine with 13b without cutting but cause 20b is longer and motor sitting further back the angles werent right. So once we raised that and clearenced for the diff head which we had to do anyway figured we might as well notch the rear rails and mod the tubs so can lower it a bit more so worked out well in the end.

-

Been busy busy. Was good to get the car fully dummied up, wiring, fab, plumbing etc all done. Car has been fully stripped, a mountain of stuff sent off to be powdercoated, a heap of engine bits to the polisher, some stuff to anodizing, diff off to be regeared and rebuilt. Getting all my parts together and sorted ready to go an engine builder. Once painters ready to go the bodys off to get some more prep and paint.

- 56 replies

-

- 29

-

-

Well shits been happening. Ryan at OCD Performance in Te K banged out a full new loom with all the bits and pieces i was after. Was after a clean hidden loom in the engine bay which he bloody nailed i reckon basically cant see anything once the airbox is back on. Cars home now to strip down and send body to the painter and then sort someone to build the engine.

- 56 replies

-

- 34

-

-

-

Are you in my neck of the woods now by the looks of it?

-

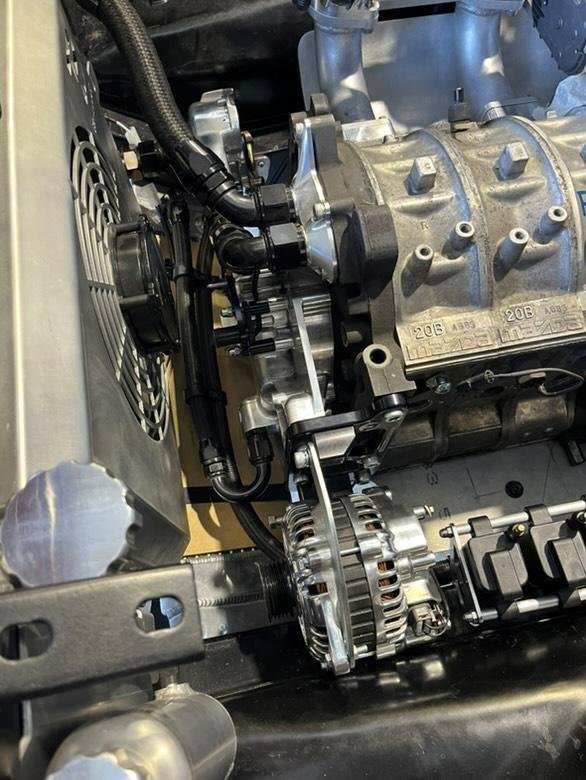

Back into 2025 and on the missions to get this done this year. Car went back to Rocket after new years to finish off a few minor bits. Mainly plumbing, brake, fuel, oil, water all done. Fitted 12a savannah lip, made the rear exhaust cut out in lower valance larger to suit the exhaust tip. Im short on time with 2 young kids and work so figured get them to finish so it can keep moving forward. Cars basically fully dummied up in terms of fab/plumbing etc now. Have dropped off for wiring on Friday and hopefully about a month and will come back all wired up. Running Haltech Nexus R3, PD16, WB2 (3 widebands/1 per runner), IC7 dash and then all the usual safety features, fuel/water/oil pressures/temps etc. Ill get it home tear it down to a bare shell and get it back to the painter

- 56 replies

-

- 36

-

-

Nice work man ,big push, she looked awesome in person on sat, love the colour! Very cool

-

Well picked up the car yesterday from Rocket. Dan and the team have done a killer job. Ended up being quite a list of stuff to do: - Modify gearbox mount to suit Tremac TKX gearbox which required raising the tunnel 50mm to get angles right - Raised driveshaft tunnel 50mm to get clearance -Modify driveshaft to suit TKX tailshaft -Raise under rear seat area an behind fuel tank for diff head clearancing -Make intake manifold, with custom DBW mount -Mount airbox and modify intake feed to line up with airbox -Mount pedal box and reservoirs remotely in windscreen cowl -Modify diff and rear shock mounts -Modify exhaust to tuck it more - Few other minor bits and pieces Because we had raised the tunnel and diff head area there wasn't much extra work to allow the car to be a heap lower. So we ended up notching the rear rails, notching the inside edge of the rear tubs, modifying the rear tubs (Factory half the tub is flat and half tapers down approx 3 inch from the centre to the outer guard lip) so its flat across the top. Now have heaps of clearance at the height its at and nothing rubs which is awesome. Really happy with the outcome, car looks a heap better at the height and starting to come together real nice. Few bits and pieces to do over the holidays then back into it next year!

- 56 replies

-

- 41

-