-

Posts

672 -

Joined

-

Last visited

-

Days Won

1

Brennan's Achievements

Post Fiend (4/5)

1.9k

Reputation

-

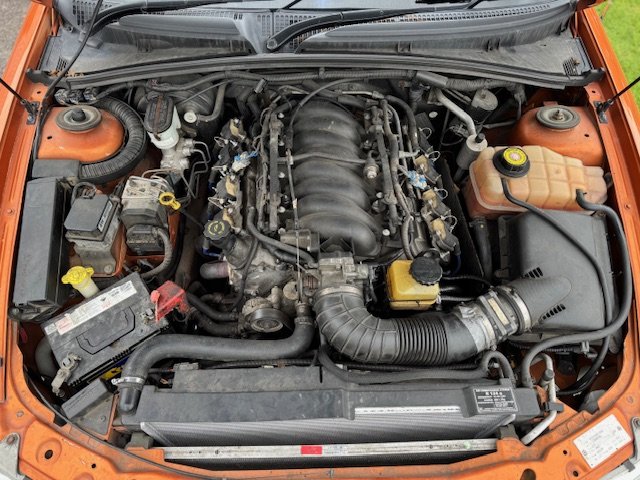

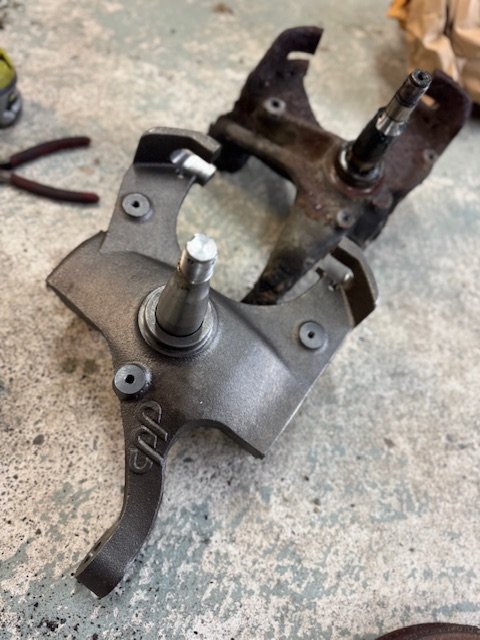

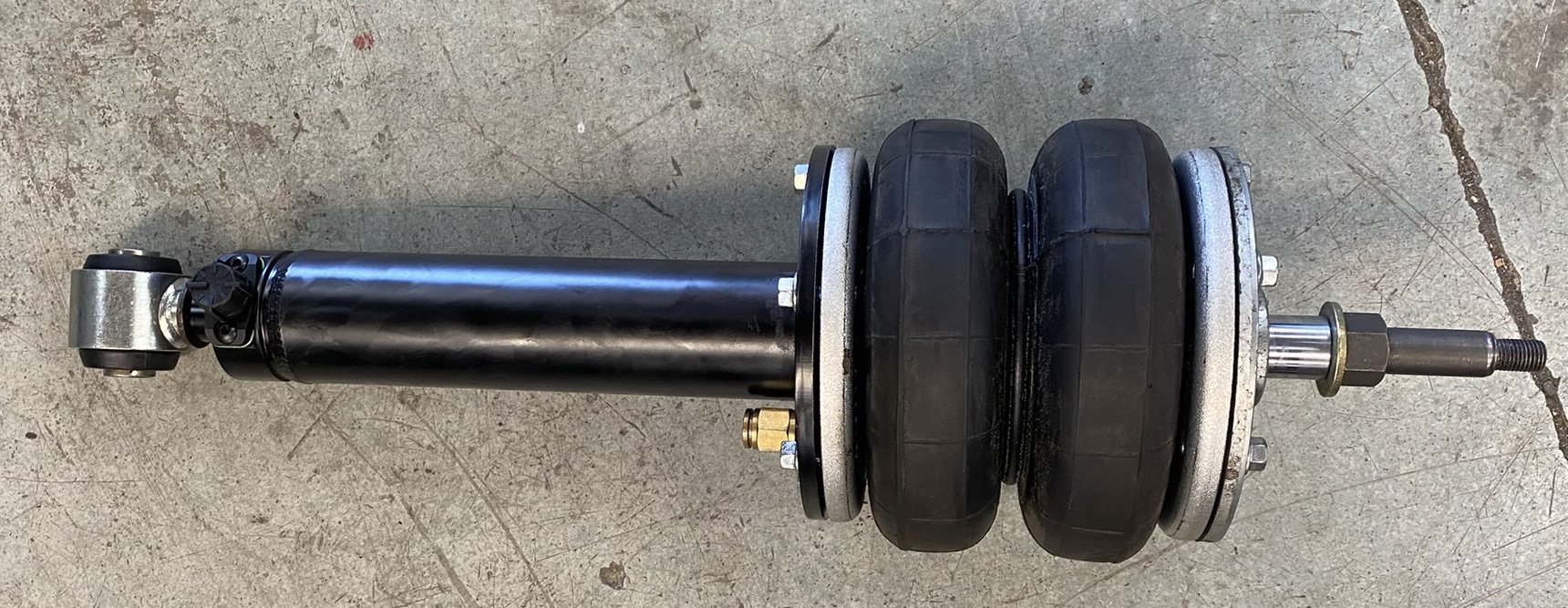

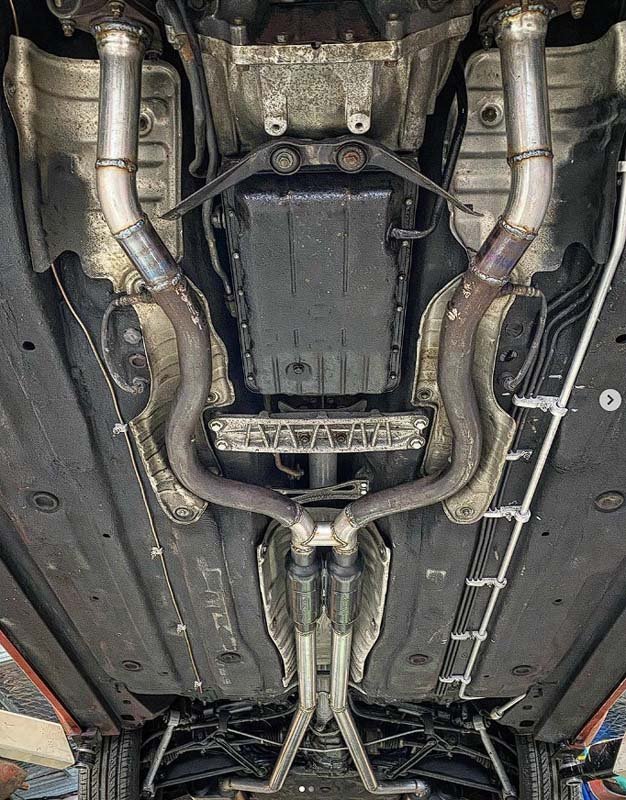

Good progress despite lack of updates. Front lower A arms cupped and top sprint pocket plated over ready for the slam speciality air bags. Rear suspension is mostly together. Have just been told that i need Rose or johnny joints on one end of the 4 links. As this wont pass certification anymore due to the lack of flex/twist in the poly bushes. Have the engine in, with custom engine mounts. All the chassis cross members/braces tacked in and transmission supported. Floor Cut out of the cab for the transmission. Since the front end is lifter 2.5inches. Got the steering back on today. Trimmed the Radiator support panel to fit the Z'd frame. and checked clearances on everything. Everything seems to be working as planned.

- 2 replies

-

- 23

-

-

-

Started on the C-Notch. Brought a Beststart BTC500XP, Pilot arc & Non-HF plasma off amazon. And hooked it up to a burnt out laser cutter from my work. And wow has it been priceless. And was only about $600 including shipping. Tried to make the Notch big enough to not eat into the bed to much. But also big enough for a decent sized bump stop and lay frame on a 28inch tall tyre. Cut the front clip off. to "Z" the frame. Raised it up 2.5 inches to get the lower A-arms off the ground. And moved it froward 1 inch to correct the wheelbase. Dropped the the front radiator/body mounts down and back the same amounts to get them back where they should be. All plated in 4mm. The new Chassis Height, and started boxing the chassis too. have also picked up a 1999 SS Commodore to part out. Mainly for this. has done just over 200,000kms & seems to be fairly well looked after.

- 2 replies

-

- 26

-

-

yea, custom made, will have quite a bit of room behind the c notch under the raised bed. This is what came out.

-

Yea, This had one diesel tank on the LHS. The RHS tank appears to have been removed at some point. Its available if you want it. I'm going to go with an alloy tank at the back.

-

Yes, just noticed how many of them i was using for inspiration have the front wheels way to far back in the guards. I'm not toooo worried about getting the cab on the ground. chassis rails would be nice though. And it would be amazing to get the lower a arms up off the ground. As I was reading on one forum of a guy that wrote his truck off when the a-arm grabbed a manhole cover. So yea I am thinking ill z the frame vertically 2.5inches and forward 1 inch. or so. Will do some over the top plug welded fish plates. And likely have my brother Matt weld those parts. Since he actually does this for a living. Yup, they are 2piece drop spindles.

-

Yea there seems to be a few more pop up than i was expecting. Looking at the Adventra wagons. Americans on youtube make swapping the tail of the 4l60e from 4wd to rwd look quite easy. And the adventra v8 are so much cheaper than an ss commodore and more looked after, with lower kms??

-

Yea, Dad just got a 50 Merc on the road with bags on lower link bars that ed Jnrs built many years ago on it. Seemed easy enough. all 6mm plate (which seems a little overkill compared to the pressed 3-4mm thick impala lower rear links)

-

Brennan started following Brennan's 84 chevy C10

-

Tell me I'm doing something wrong. Silly for making a truck next to useless. Sell me a Hood safety catch/hook and LS1. tell me to but 20s or 22s with rubber band tyres on it like every other c10 on Instagram.

-

Saw this 1984 C10 Chevrolet on Facebook Marketplace 5 hours away in Tauranga. And had a desire to C notch and bag something. (its actually a 84 GMC High Sierra Classic, diesel) Was priced well with most of it there, pretty much just no engine and trans. The next available weekend, my dad & I shot up and brought it home. Have some Slam Specialties SS7 & Air fittings coming for it. It could do with an LS1 & 4l60e if anyone has one they could let go. Got it stripped down pretty quick to see what I have. Very little rust. Just a decent size hole in the firewall. But that's just an excuse do a shaved firewall. Also missing the hood safety catch/hook if anyone has a spare. Some unused Drop Spindles were on Marketplace in Northland for a bit less than I could get them into the country for. Hard to believe how big and heavy these are. Go them in. The cut springs out. Diff out, and the whole thing a whole lot closer to the ground. C-Notch and a 4 link of some kind to come. I'm think Bags on lower links. Outside of the chassis where the leaf springs were. The front lower A-arms are on the ground. but the Chassis isn't. but a good 40mm?? So it is likely a Frame Z will also be in order to lift the front end up. This could also help in moving the front wheels forward an inch to get them centred in the wheel arches again.

- 2 replies

-

- 25

-

-

made some new Top Hats for the rear. As it went too low and wouldn't raise up high enough. Was a right pain trying to get into driveways without smashing the bumper on the ground. Was a lovely day in Whanganui for their annual show at the high school. Same at Levin's show. Taking a brake from this for a while. We did get a commercial sewing machine, so going to give Upholstery a go. Also needs Painting. But in the mean time ive brought an 84 C10 to try and get just as low. So will just keep driving this.

- 70 replies

-

- 25

-

-

The engine felt sluggish down low with the aluminium/silicone intake i had on it. So I managed to squeeze on the factory intake from Matts 1uz Corona on. And went for a quick drive and the power felt better. So decided to make a new larger intake with a Resonator beneath it. Using the same volumes as the factory plastic 1uzfe one. Wasn't quite as good. But is definitely an improvement. 3d printed & had cast in aluminium some finned Lead covers. Used Bennetts Custom co's method on youtube for using oxy action Vanish in hot water to darken/age cast aluminium. Will need to get a photo of the shifter parts and switch extensions installed. Off on the 6 hour drive to Beachhop, in Whangamata. Skyla the dog loved that we could have the windows down the whole way with no horrid drumming noises. Cruise control was lovely too. And the bags rode like a dream over the Hauraki Plain's roads. Also cut out some vinyl pinstripes before leaving. From 3m 3630 Lightbox vinyl for the matte finish. Faux Pinstripes for the Faux old car.

- 70 replies

-

- 15

-

-

Installed the infinity Bluetooth only "headunit" Its alright. Connects fairly reliably. Auto plays at a default volume which can be a pain. No EQ adjustment, so installed a equalizer in the glovebox. Cost more than a decent Pioneer single din headunit. Probably should of just brought one of those, and installed that in the glovebox... Needed some speakers. so chose this hole. Trimmed it out a bit and added some rivnuts. 3d printed an adapter with a rain hood. Installed some 6.5inch component speakers. Used some Dakota Digital Magnum shooters to transfer the Door popper power and speaker signal through the door jam. Works well. Purchased another 2x of the new Boss Universal Struts. Bit longer than the first pair.

-

Have being doing a lot of stuff recently to try get this ready for beachop. The doors now open electronically with the small spring loaded knobs next to the window. And lock using the factory lexus Remote. Door Rubbers are all on. Window rubbers are all glued up. Bitumen sound deadening in the doors. Is much more of a pleasure to drive. Even with the door cards off. Reversing Lights added and wired in. Have moved on to version2 of the boss air struts. Such a better product. No welding the bush onto the bottom, they come with a threaded boss on the bottom and a range of Threaded mount options. Also a 1/8 female npt hole for the air supply. Instead of the Hydraulic style male fitting and hose they had before. Made it to the last southwards Cars and Coffee in Kapiti. Excellent morning out with lots of cool cars to see. Matts & mine were easily the lowest cars present. Had forgotten about the 1954 210 inside. Was a nice surprise. Have also put a false floor in the trunk. With a 4 channel amp beneath that. On top of the space saver. Wired into the parcel shelf speakers and ready to wire into the front door speakers this weekend. Have an infinity Bluetooth Amp adapter to wire in, instead of a headunit. (despite costing more than a decent headunit) Also next up is to get some gas struts onto the hood. in place where the springs would of been. As at highway speed the hood likes to lift and float around. And is quite disheartening at 100kmh.

- 70 replies

-

- 22

-

-

Few things have been happening over the last year. It now has side windows. So I needed a way to get in. These knobs are pulled up, spring loaded they trigger a switch to open the door. Hopefully eventually hooked into the lexus central locking. A pair of component speakers were fitted to the parcel shelf with a couple of our speaker covers next to the freshly polished high stop light. I Ordered a aluminium, laser 3d printed mirror spacer from pcbway to replace my PLA printed one. Polished up really nice. And the print was super accurate and clean. Had the urge to replace the coils, leads and distributors. So brought the whole lot in NGK from rockauto. Luckily i did as one distributor crumpled in my hands as I removed it. A new dual 2inch exhaust was also fitted. Most of it purchased from STA. So affordable. And sounds more like it should now. Also purchased some very very nice, but rather pricey kuryakyn Headlight visors. So much nicer than the cheap generic ones.

- 70 replies

-

- 27

-

-

Cheers. I’m loving it more now that I’m not stressing over it while spending 16+ hours a week trying to get it on the road. Haha.

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)