Leaderboard

Popular Content

Showing content with the highest reputation on 02/17/19 in all areas

-

10 points

-

6 points

-

Enough backstory, now for the car. As mentioned, I picked it up over the Christmas break from the family home up north, being that it has been used sporadically I put aside a few days to go over every nut and bolt to be sure the trip back to Christchurch would be uneventful. First up, a few small jobs... Sort the petrol smell: The original rubber joiner had given up years ago meaning the tank couldn't be filled past halfway, a crowd in the west island have reproduced them so out with old, in with the new Then came a tune of the engine, I had been nervous about this as i've never touched SU style carbs, turns out they're easy, plus my learning was made faster by having a full set spare to look at. The engine also has a mysterious click from about #2 or 3, I have adjusted the valves but it still doesn't change, oddly it comes and goes, is mildly engine temp dependant and there is good compression on all four, for sure something that will need more digging..... The eagle eyed 510 spotters will notice the brake master setup is not correct, having be swapped out for a different style for race duties. for now I will run with these until I get the original rebuilt and cleaned up. With mechanicals looking ready for a drive I moved onto the interior, how about the stolen dashboard you say? well as luck would have it, a history of writing off Datsuns racing had left my father with just enough bits to kit the car out as required, he even produced a full set of badges that I now have tucked away awaiting some modern technology for reproduction. The carpet was very much in fine race spec consisting of two or three coats of red paint, in order to prevent my girlfriend from running off halfway back I needed something to muffle the road noise, once again the family parts warehouse presented a front carpet in the most delightful shade of poo brown, matched with carefully positioned black mats to cover the tears a more suitable environment to conversation was produced. Yup, white interior, far better suited to summer! With everything packed and a torn bit of envelope to suppress the steering wheel vibration we headed south, we both held our breath over the Cook strait as the Datsun met salt air and stumbled on start up leaving the ferry, incidentally some muppet had forgotten to fully set the distributor after resetting the timing and had come loose, sorting that we drove on to Marahau for a bbq with Alex and Hannah. On stern advice we reluctantly drove over the Takaka hill, well actually I have been fizzing to do this for a long time and boy was it fun, even with 50km speed restrictions and road works its gotta be one of the best drives in the country polished off with an epic view. And that dumps us back home nice and safe. So plans from here? I was planning on a full restoration beginning this winter, the paintwork is pretty rough from being done for the track but i'm just enjoying driving it too much to take it off the road for any considerable time, there are a few things to start with: The engine tick, it may just be me but I want to dig further just in case I have a side draft manifold and throttle bodies, efi was also on the plans, but SU's just drive so nice and the fuel economy is pretty reasonable. Replace a broken shaft spring on the rear carb - this is causing the idle to not fully drop occasionally, no biggie, but sometimes irritating. Complete the CAD models of the badges and get some replicas made, this way I don't have to cry if they fall off/get broken. Get around to picking up a 5 speed or fit the 3.5 diff in the shed, 3500rpm cruise is a tad loud for my increasing age! Repair the split dash, irritates me a bunch looking at it Paint up a few potential rust spots. Actually decide what colour the carpets should be and source new front and rear Polish up the chrome Clean up the wheels Source new window rubbers so the window trims can be installed. While the list is long of potential performance upgrades, I'm not keen on going too far from factory with it and any modifications that can't be reverted to factory are off limits. Long term it really does need a repaint, but the BRE colours are growing on me and the aged look is reflective of why I brought it, for driving!6 points

-

It's the little things like this that make the difference to this food trailer. Not just a traditional caravan shape but style as well. I payed a visit to Boss Powdercoating and dropped my rims off to get cleaned up. Once they were done i headed to The Bling Company and had my white wall tyres fitted. The before and after is unbelievably good. Before after shot ow @Geophy6 points

-

5 points

-

5 points

-

Today's events went really well. Had @Geophy and @flyingbrick over today help out. Pretty excited about the following weeks. Ah yes we have an Instagram page for Greg's ice-creams now as well. this is for the people who cant view Instagram or also don't have it.4 points

-

It's pretty avg. Durepox or similar two part epoxy primer is what you want as said 124 times in this thread before.4 points

-

Didja buy it? I see it's no longer listed, although there's always the newer green one in Northland for $6.5k. The autocar buyers guide has this very "Jag owner" advice: "Check for misfires on the V12 by holding a bank note over the exhaust pipes and watching for uneven fluttering." You might also want to test the cigarette lighter by rolling up a bank note and attempting to smoke it.4 points

-

Oh I forgot to mention a while back that I managed to get my Mum to do a spot of sanding to when she visited. I doubt she would have lasted log though but I think she did like the fact she had a trapped audience to waffle on to while she did sand... However- that was obviously before paint. Now we are right into the fun jobs of piecing back together the big kitset. The trickiest thing is trying not to get too carried away with cleaning things but it always does seem such a shame to put messy, rusty or dirty items onto a clean shell. I think in the future I'll try to stick to ratty cars like the Viva wagon. Saves time when things can be messy So yeah.. cleaning things. First the bumpers. I straightened both as best I could and Hannah then cleaned the backs and painted the surface rust in Por15... I then trial fitted the front but once bolted up it was slightly wonky. I ended up having to whip up a bending tool to straighten out the slightly bent mounting points... All straightened I mounted the bumper and stood back to admire the first bit of bling... We then hauled in the other two Imps and went over them like a team of car stripping Piranhas and removed all the last morsels of useful bits... With bits removed they then needed cleaning. Hannah quite enjoys these jobs and did a stirling job of making things all shiny again... I filled the roofline and inner wings over the rear arches with cavity wax. Much more enjoyable this time round then the first time I ever used some back in Blighty on my Rx3, in winter on a very cold day. This time round it flowed perfectly... Together we fitted the head lining we removed from Imp 3- the one rescued from Christchurch. Its a bit discoloured around the edges where the contact adhesive that the original factory worker had brushed in place has stained it right through. Not much we could do with that. But its rip free, pulled up nice and tight and looks better then nothing. Its in keeping with a 54 year old car... I then made a engine cover stay. Because the cover is fiberglass and had no mounting points for a stay I had added some before painting along with a suitable point on the car with them further apart then the standard imp placement to take away extra leverage over a flexible f/glass lid. Now to connect the dots. I had a rough Idea of what I was going to make when I added the mounts and just went with it. I had a piece of stainless the right size and used a plastic knob from an old broken cafetiere I had stashed in my bin of 'might be useful one day' bits. I bent the stainless rod in such a way that when the lid is opened it slides up and drops over a stainless bolt then cant go further. To drop the lid you have to lift the knob slightly- this way a gust of wind cant lift it and make it drop. It works sweet as!... Next big job was to get the wee car back on its wheels because I had some work coming in that required the hoist. I refitted all the suspension and luckily had collected 4 decent shock absorbers with good shafts. However the springs were going to be too long. I'd happily pay the $200 for some Montie Carlo springs. For those not aware they are the popular lowering spring set for Imps that most people fit. However the freight costs for a set to NZ is too much for me to cope with and anyway- I have 3 full sets of springs I can play with for free. I like free. So out with the Makita... After doing a heck of a lot of web browsing I deduced that one coil off the front and half off the back would be a good starting point. Totally aware that I'd be raising the effective spring rate I reckoned this would still be OK. The car is going to be a touch heavier all round anyway but too much extra stiffness to the coils without adding extra damping would be no good. I definitely cant afford new posh dampers at this point so I played it safe... I then heated the cut ends up with the Tig in several zones, flattening the coil as I did. This worked well- the heat didn't travel very far. Its not optimum. Optimum was what I used to do back in the day when I spent 3 months of my apprenticeship working for a Blacksmith resetting leaf springs and shortening coils etc. But I dont have big furnace at my disposal nowadays so Makita it is Then cut the ends flat and they came up sweet. It will be really interesting to see how it sits on these and this I wont know until the car is fully built up to full weight. I reassembled the struts and finally I was able to fit the minilight wheels from the racecar on and lower the Imp to the ground. Ooooooohhhhh. I dont know when this car was last rolling but I suspect it was a very long time ago! It felt so good to roll it away from the hoist, stand back and admire it. Plenty of premium positive camber to come out as the weight piles on. I'll soon be ordering some better sized new tyres and getting them onto the rims. While the car is off the hoist Hannah can continue assembling interior bits and I'll be attending to some work on other peoples cars.4 points

-

I'm having a go at making a (double) rustic sliding barn door. I had a look a at few options to buy one ready made and it was going to be a couple grand. So, off to bunnings... $200 in rough sawn timber later. Which was then run over my buzzer to bring it into shape and unify thickness etc. I'm trying to keep some character in this, so not looking to make it perfect, just a little nicer than the shit timber I picked up...but not as perfect as framing timber either. I was so absorbed in making this today I didn't remember to take photos along the way. But this is it all glued up on the floor. The diagonal and corners are just temporarily screwed on to hold it square while the glue dries. I'll call the above "stage 1". Next up is to make my own hardware, finish the door and hang it. Though those steps may be spread across a few more weeks to come.3 points

-

Starting on a new mould for some 4AGE ITB trumpets but learning from some previous mistakes. Problems from the past are that I've had too little draft angle on some parts that are quite long. Also that some of the excess untrimmed parts end up folding over something and locking the part in place. Also trying to use only 2 pieces when theres no reason not to use more if it makes life easier. Annndddd I think it will be a good idea to add some tabs so I can twist the halves relative to each other to try get the part free. Previously I've damaged the moulds by needing to smash a screwdriver in (or whatever) to get the halves apart. Hopefully this will help! I'm hoping I can make at least four, or even eight from the one set of moulds. I'll also try drill some little holes in the moulds, fill them with wax and then so afterwards I can use some compressed air to blow the halves apart hopefully if they are stuck. The center part of the bell shape still needs to be dissolved out, but cant think how else to get that sweet sweet return angle on it. Worth it... Fingers crossed! Fingers crossed!3 points

-

2 points

-

Friday update. Dropped car off at certifier the day before Waitangi day. The car only got pulled up on the way the rear brake hoses were run. (I guessed it would fail on this). Everything else was sweet. The certifier was so happy with the way it was done he brought forward the Compliance check which was done last Friday. Compliance guy had a slightly bigger list but nothing major. - Align headlights - RH wheel rubbing (center steering rack) - Bride seat fouling on seatbelt stalk (there is some adjustment to clear this) - Repair gouge on inside of LF wheel So in short nothing major! Seeing as I'm back in full swing at work I gave the guys at the cert place the go ahead to remedy everything but the wheel. I dropped this off to a trusted repairer yesterday and should get it back next week. So depending on how long it takes for the cert plate to arrive the car should be all legal within the next couple of weeks, happy days! Goal of making Toyotafest this year is looking good.2 points

-

You mean XJ-S, this one here? https://www.trademe.co.nz/motors/used-cars/jaguar/auction-1935049799.htm A British racing green coupe with tan leather and a V12 for under $4k. In a couple of hours you could have it looking a lot nicer (from a distance) than in the photos. That pre-HE V12 is meant to be the thirstiest engine in the world, but you can fix that for more than $4k with manual conversion kits or Chev V8 conversion kits depending on what shape the V12 is in. You should absolutely purchase that rough, underused V12 XJ-S which has no history, no WOF and no reg, and then you should bring it to oldschool Nats. This would make you the grandmaster lunatic.2 points

-

This car has been a long time in the making acquiring, but being the descendant of an original Datsun foamer, it could be said it was my destiny..... The car being a 1972 Datsun 1600sss, the back story? well, take a seat..... 20 years ago the car in question was owned by a young man in Palmerston North, being an easy target it was stolen and taken on a joyride, thankfully once they had had their thrills it was abandoned to be recovered by the boys in blue, but the good luck didn't last, while in impound some scrots jumped the fence and stripped her of all the fancy sss interior, with the badges, steering wheel and dash board gone, there was not much left to identify it as the performance upgrade intended by the factory. Being the Datsun man he is, when my father got word of it being up for grabs he beelined for the impound yard for a nosey, even though the interior had been stripped, the body was in fairly good shape and for a price that we'd all love to pay now, he loaded it onto a trailer and tucked it up under a tarp in the back lawn. At this stage he had a standard 1600 set up as a track car for competing in classic classes at Manfield & car club sprints, but with a teenage family, i'm sure restoration of the sss was still a long way off. Here's a younger me in the 1600 race car in the early 2000s during a carclub motorkhana, most likely the first time I drove a 1600 too! Somewhere in the mid 2000s the race car got close and personal with the tyre wall at the end of the back straight at Manfield, coming out very much second best a donor shell was required, with the sss being in pretty good shape it was quickly fitted out with all the bits and went on to serve race duties for a number of years, thankfully my father realised that sss body shells were getting hard to find and so when a standard shell popped up cheap, he brought that to convert to a more modern safety standard and the sss was reunited with standard parts and retired to weekend road duties. As all this unfolded, I left home, traveled the world, invested heavily in Ladas, eventually to settle in the Datsun capital of NZ, Christchurch. Two years ago the stars aligned on a SAR training exercise and while stocking up on pies in Fairlie, I spotted this wee beaut Sparking a deep down affection I followed it around the corner to where it stopped and of course I started chatting with the owner, turned out its been in their family for quite some time, and the lovely lady informed me that there was a Datsun club and that they had nationals on in Ohakune, even better was that year's theme, 50 years of the 510! Looking at dates they lined up and before I knew it I was hitching a ride north with our very own Datsun barry Runamuck to meet my father and other 510 foamers from around NZ. After a weekend driving around the central plateau I was convinced I needed a 1600 in my life and a plan was struck to purchase a dereg but complete vehicle that was tucked away, sadly after discussion with panelbeaters over the required rust work for re-vin the costs looked a bit daunting for my current plans. A few months later my father slipped up and offered the road legal sss to me, I rapidly agreed before he could back down, only downside was I had no leave left and a work schedule needing much attention, this meant I had to wait until Christmas break to pick up the car! For now it's late, but I shall dig out some more pics and tell more about the car itself and the mini and major plans ahead. Discussion thread here:1 point

-

1 point

-

It must just be UV that it doesnt like.. but if you have the choice between good primer and average primer...? Durepox wont budge no matter what you do . Short of blow torch.1 point

-

Yup. I used pa10 on something i left outside and after not long iy had cracked and started curling up off the surface1 point

-

They come in different strengths. This changes the speed at which the piston rises and drops so can prevent fluttering and alter throttle response1 point

-

I was lucky enough to get a pool table. It's a childhood dream come true and despite not really having a big enough house to put it in, we do have a spare lounge that has no real purpose...so that's now my pool room (let's call it "a work in progress") Now there's one end of the table where the wall is a tad too close. Solution ...cut the cues down, or build a bigger house??? Okay, for now I think I'll just cut the cues down. Cue loaded in lathe. Boring a hole to stick the weight back into the butt of the cue. And there we have it. 2x shorties, 3x tall timber. Next on list is to make a pool cue rack and a sexy pool table light box thingy like the pubs have hanging above the tables.1 point

-

One at work got failed for no sleeve in the hole as it went inside the draw bar also another ones line is run along the front of the axle to the other brake and it was failed for being all rusty (from stones flicking up etc) they replaced it with new line still along the front1 point

-

1 point

-

1 point

-

It's a trailer, no one gives a fuck tbh. Just shove it inside the rails.1 point

-

Thanks guys, years of working on it is coming to the finale. Car still needs some minor panel work and and new paint job in the future but for now I'm just going to drive it for a bit and enjoy some Touge.1 point

-

1 point

-

1 point

-

Lol China factor. Might as well chuck some higher ratio rockers in for a bit more grunt while your at it1 point

-

I went back to it and noticed the pushrod guide is worn out. Possibly because the stud on that side was a tiny bit bent, I dunno. Anyway I've splashed out $9 on a new guide plate, pushrods, rockers, studs and nuts from eBay. Hopefully that'll sort it.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

oh hello. long time no posting we finally got the profile of the caravan cnc bent. borrowed old bad pennys work horse to get it done. pretty excited about the weeks to come now. just need reunion to be over with and get this thing rolling again. EXCITED!1 point

-

I just couldn't help myself but take this photo... Having fun stripping remaining bits from the other two Imps, cleaning and painting bits and generally playing about with what is a big model car. Proper update soon.1 point

-

You're a lunatic of the highest order and for that I commend you! And now I'm looking at that xj in gisborne on trademe longingly...1 point

-

1 point

-

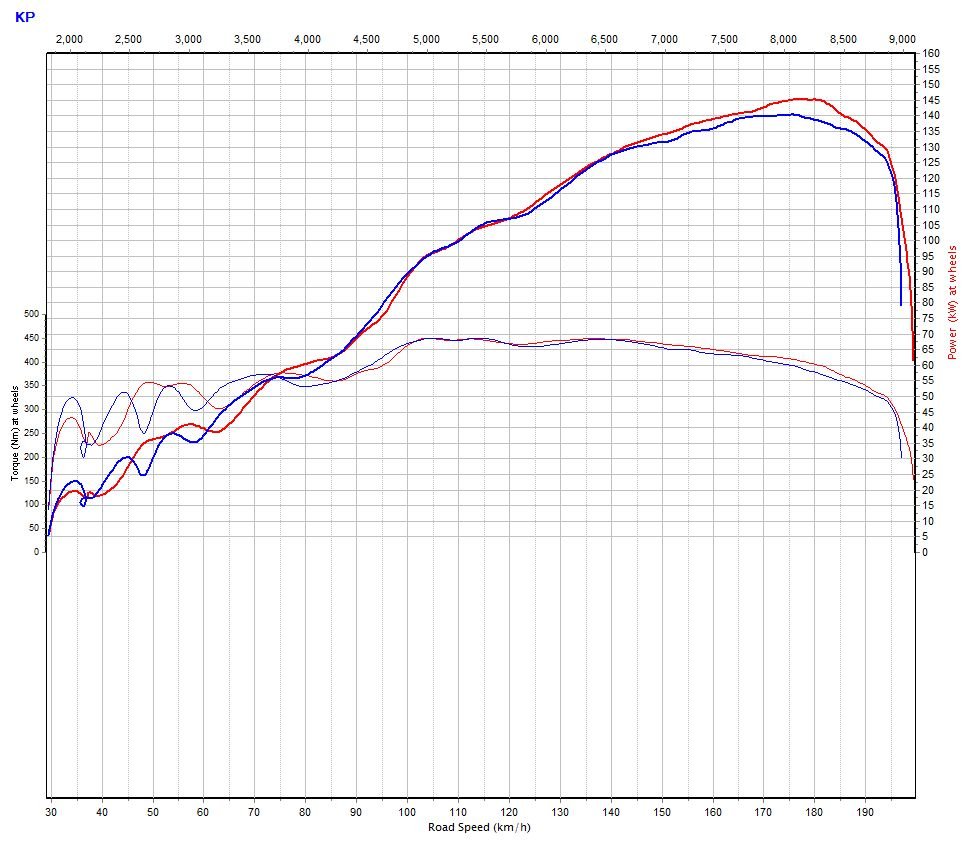

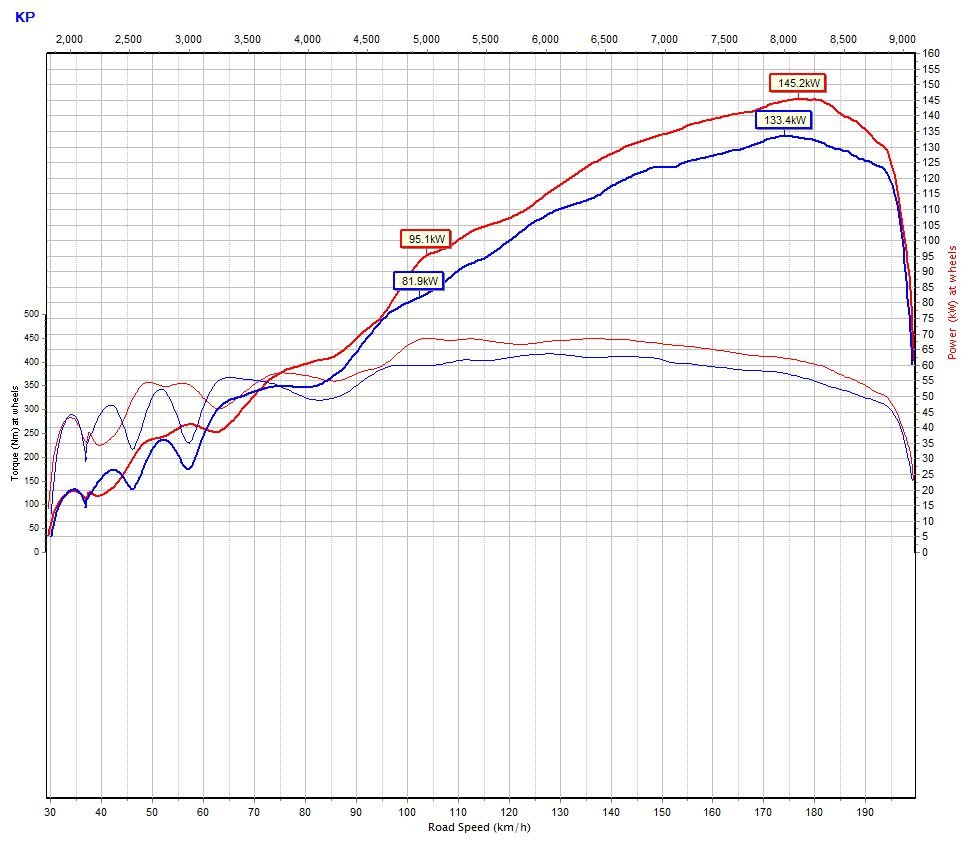

more dyno stuff.... Had to finish the tune after swapping to the small headers. Tried a few things while it was on there. First up; some time ago read something on the internet, that throttles may flow better/make more power just under 100% open rather than 100% open. Yeh nar; blue: 96% open, tried 98% as well same deal just a bit closer to red (100%) line. Maybe it needs even bigger throttles? they are 47mm Next is with the trumpets removed. the below removed all together was expecting some big losses, but not quite like this! over 10kw through the whole powerband.1 point

-

Rad! Similar construction to something small we made to give my dad's ashes a 'viking' send-off. Went a little overboard with accelerant, obviously1 point

-

retail price is $580 for a basic cert inspection, plus hoist hire at a workshop if necessary extra set of wheels- there isn't a set price for that, stuff like that I base on how long it takes and how helpful the owner is. Ie if theres another set of wheels in the boot and I have to swap them over myself, then it would cost more, than if the owner swaps them while im doing the paperwork1 point

-

day four. i had cut these lengths last night but i came in and laid them out on the floor, draw some straight line on the floor and then tacked these cross bars so they wouldn't move i had a left over length and it was going to be pretty good for the front part of the draw bar so i cut another one. measured between the front and drew a long line square up the front which i then made my two draw bar section go out to. cut the angle i needed and cleaned it up ready for welding welding some more welding, but this time the back brace welded one of the spring things backwards as @Shakotom pointed out when he arrived so well yea cut that off and put it on the correct way and proceed to do the other side i didn't quite have the drill side i needed so i used @Beavers favorite tool of my shop, the step trill followed up with the dremel as the step drill wasn't quite long enough. assembled most of it and made it roll!!!!!!! put the floor on it! here i am happy as that i had made this so far and its gone pretty darn well also @flyingbrick drew this up while he was at my place while i was working fuck yes1 point

-

Yeah make a jig so i can trim each side accurately. Will be enclosed in an airbox eventually. Gonna make a flowbench so i can test a few different schemes.1 point

-

He'd buy the V12, run straight pipes, paint it in camouflage and imagine he was in a military tank.1 point

-

Success! Edges need trimming but you get the idea. Pva glue over plaster was the good combo. Then a little wax for good measure. Carbon sleeve is the best! The inside is super smooth and tgecoutside feels like crocodile skin or something. The biaxial weave is really cool. Gonna order a bunch of different sizes I think. This one is probably a tad flimsy with only one layer of sleeve but two will be sweet with a 6k weave I think. Or maybe just go 12k single. But it's probably lighter than the bolts that would hold it in place. Only about 25 more prototypes and I'll have a usable part haha1 point

-

I've watched a few of those vids of that CF 240z. It's a bit of a balls up how all he is doing is laying carbon over the factory panel to make the new panel, then removing the original panel to attach the new CF panel. The whole car is going to end up fractionally larger that it should be, curious to see how it affects panel gaps and things like tail light fitment. Also the nice smooth finish ends up being on the inside of the panel, which you don't see...1 point

-

So nearly four years after mentioning it and well over four years after coming up with the idea. Here it is! FINISHED! I took it for a quick ride up the road, it feels awesome, taught, light, and responsive. I'll take some better photos of it in the sun over the weekend. *Pine*1 point

-

iv just wire wheeled and brushed all the K frame / arms and rails of my 260C with PA10 It wasn't that bad to do but i'll spew if I have to do it again in the next 5 years.0 points

-

Sadly not! The guy coming to look at my Renault never showed, and I don't have space/finances/a patient enough partner to have more than one toy car at a time!0 points

-

I found you a T bone steak you may enjoy https://www.manheim.co.nz/damaged-vehicles/000000000005446486/1986-jaguar-xjs-coupe-3-6-coupé?referringPage=AuctionListing Link may not work but it goes to auction tomorrow in auckland, probably very cheep eg $100 + fees0 points

This leaderboard is set to Auckland/GMT+12:00

.jpg.f987d0351014b1d90f87d960f0793792.jpg)