-

Posts

13207 -

Joined

-

Last visited

-

Days Won

78

Everything posted by cletus

-

A crisp high 5 to both of you for your rapid progress

-

1000% at least talk to a repair certifier first. I had a customer once who had to spend 13k uncovering repairs , getting it inspected and repainting it back to how it was at the beginning - ie just finished panel and paint.

-

Gang members also have access to the information, you could try your local motorcycle club? ‘Significant breach’: NZTA employee passed on personal details for drugs | The Post VTNZ conducts review after privacy breach by Head Hunters' ghost unit - NZ Herald

-

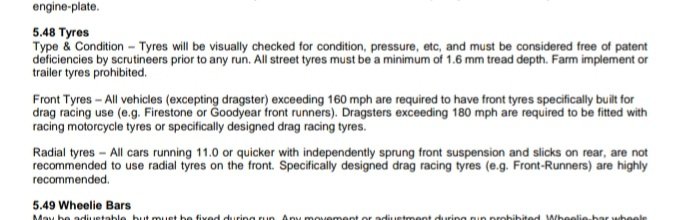

Yeah it's not great to mix radials and bias ply tyres, it can make for some interesting handling Nzdra rule book says

-

Probably should have them, because of bias ply Hoosiers on the back, but when those are worn out I might try some drag radials , so would need a radial on the front

-

Good to see a new project! What happened with the viva? Kinda bummed you didn't finish it, was a cool car

-

Not sure yet, I usually struggle to get there on time after work/traffic/probably overheat in the southern traffic jam

-

Bart, your ute I like.

-

Yeah something like that would work

-

The steel wheels on it are very heavy. When it did its quickest time it had some very light cragar super tricks on the front. They were popular in the 70s but the internet reckons there's not many around these days because they were prone to failure. I bought them ages ago from a guy who took them off his car because they made creaking noises when doing tight turns, they were very cheap. They weigh as much as a bag of chips and are a bit sketchy, also the tyres were right on the limit speed rating and load rating wise. Plus I had to run a 5mm spacer which I did not like. I only did 2x passes with them on and didn't like it So I've had my eye out for a second set of wheels suitable for drag racing Being an impressionable teenager in the 90s who read street machine magazine a lot I've always wanted a set of weld draglites. They don't come up often second hand, I found a set a while ago but they were not wide enough. You can still buy them new but they are pricey Picked these up today, 15x5 and 15x8. Tried them on then got the tyres off, they are very fucked. They need a polish but should tidy up well Anybody know a good polishing place in south auckland?

- 128 replies

-

- 24

-

-

-

Yep. You would likely need to add something back in to make it strong enough/roughly the same strength as it was. Wouldn't need anything complicated

-

It's not particularly difficult It is intended to be used by people modifying cars, to help them with their projects. there is a range of people with different abilities sending applications through and they all get looked at, they are not viewed as wasting anyone's time. Some are hundreds of pages long with cad drawings and FEA paperwork, and some are literally hand sketched drawings. Photos are very helpful in an application You will probably struggle to find someone to teach you how to do your particular project as it's quite different , so there isn't going to be anyone with a recipie for exactly what needs doing. Certifiers can guide you along the way but, time is money, if the certifier is willing to help design the car/mods you're wanting to do, it gets expensive quickly Time is the biggest factor when getting people to help you. It's not uncommon for me to spend 2-3 hours a day on the phone, talking to people about their projects, emailing , looking at parts etc etc. This ends up eating into the time I have to do work I can actually charge out- there has to be a balance and this is why it can be hard to find people who can help you lvvta.org.nz you can download a design approval application from there There are also infosheets on design approval https://lvvta.org.nz/documents/infosheets/LVVTA_Info_11-2012_LVVTA_Approval_Application_Guide.pdf https://lvvta.org.nz/documents/infosheets/LVVTA_Info_01-2016_LVV_Custom_Independent_Front_and_Rear_Suspension_Approval_Application_Guide.pdf

-

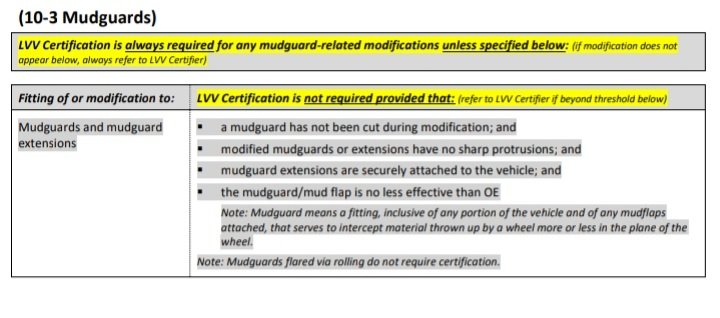

Not required Will need mud flaps though

-

Yes. Fuel and brake lines. I usually recommend running them away from the driveshaft where possible, as a rear loop on a solid axle car is (a) hard (b) looks stupid (c) not particularly effective Not quite as bad on something with IRS

-

Probably fine, by the time there's a weld there it will be pretty much at the bottom

-

What's a good running K24 worth? I had a look on trademe but there's none on there at the moment I'll likely have access to one soon, and it's in a handy take home package

-

I remember reading about them as a kid and being "whoa" at 2l turbo 4wd in a hatch Never had much to do with them apart from fixing one for a tight arse car dealer customer we had, it was a fill in job for when work was slow so it ended up taking 4 or 5 months , it broke a ring land so the car dealer supplied 1x second hand piston. Did it with the engine in place, getting the head/intake manifold off counts as one of the worst jobs I ever did Also due to the fact it took so long just doing bits here and there, when I started it I'd forgotten I'd removed the oil filter. It was on the hoist, fired up, pissed oil everywhere, I reached in the window to turn the key off but it had a turbo timer down by the console so I had to do a panic dive in the window to turn it off, the boss thought that was quite funny seeing me with my legs sticking out the window

- 27 replies

-

- 10

-

-

-

Modification threshold specifies guard rolling as not needing cert. That fb lvv unofficial questions page is full of misinformation and people who will do anything but read what the rules are

- 8977 replies

-

- 11

-

-

-

i cant see a problem with that if its all factory parts, and the work is done well, welding is good, sealed and painted etc

-

Does it need the clutch on the s/c? Looks like minusing that would give you a bit more real estate?

-

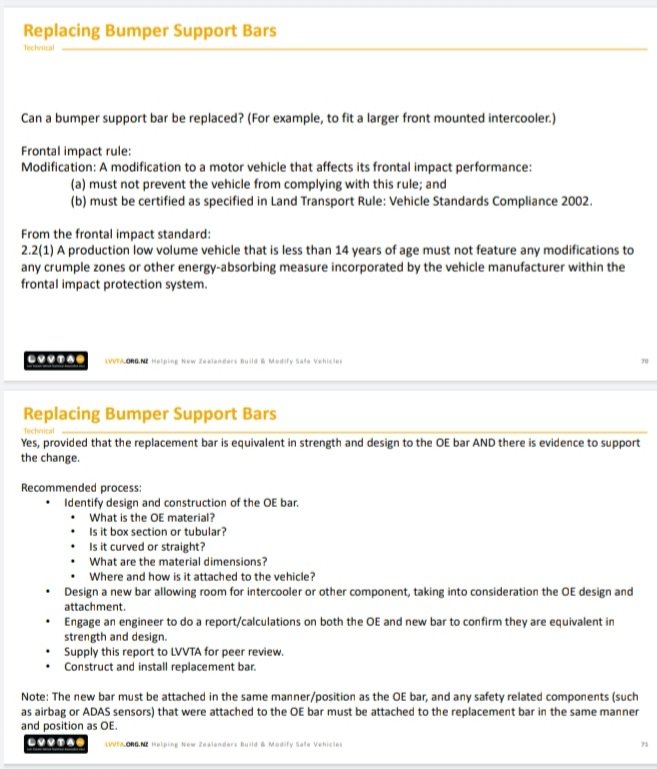

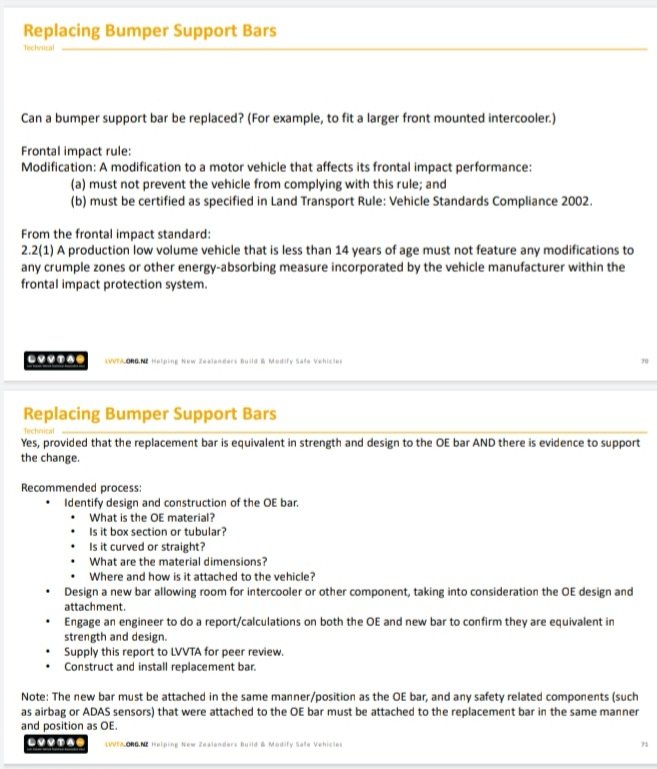

As far as I'm aware, it can be applied to all vehicles, whether 14+ years or not

-

-

-

Can still do holes in single skin panels, that's fine. Lvvta have recently said that you can make a new front beam , but it requires finite element analysis, and approval from lvvta, to prove it is exactly the same strength as original I have not heard of anyone doing that yet though as it's obviously not easy or cheap

-

Cert= can't cut that bumper beam unfortunately