Leaderboard

Popular Content

Showing content with the highest reputation on 02/26/24 in all areas

-

My next mission... M32 ARV. I wanted one of these years ago but they weren't available. I scratch built one on a welded hull Sherman at the time, it'll be interesting to see how close I got it. Anyway, it's going to be Kiwi spec for Italy in 43/44. Stone & grey camo. It may not be historically accurate regarding specific units, but what hell ? Progress so far...9 points

-

This build was never supposed to make it to a "next page", oh well. ECU mount which will be tucked up behind the glovebox/footwell. Needs some rubber isolating washers and fixings. REVISED, now attached to the back of the glovebox for even more space saving. Its got a nice locking plug but also needs to get the vacuum feed with minimal kinks to the MAP sensor from the vacuum block. Also its nice and close for the wideband as the wideband plugs into the ECU. The plug is bigger than the actual sensor so the cover plate for the gear lever hole will have a wideband sensor sized hole with a grommet. Working on a mild wire tuck, battery all wired up and will be unnoticeable once carpet is in again. Other than that, motivation is at an all time low so updates will be slow. Turns out getting married is quite expensive so not sure if the KP will be driveable this year. The Mini is currently in for a small birthday, new tyres and a once over. Working towards paint. I think a nice orange for both cars eventually would be nice. Inspo:7 points

-

6 points

-

So time to attack the underside so I looked into how to do this. Acid dipping was going to be 1st option a place nearby but that was no longer around and closest place was tauranga with a 6 month wait? Next plan was sand blasting, the entire shell quoted was 3k so out of my budget. I decided to just go cheap and learn along the way. I first got a sandblaster unit from super cheap. For sand I bought a 10kg bag from bunnings. I fired up compressor and it was a fail. Sand would not flow, it was damp... adding water to it was a worse idea it blocked it entirely. I undid hose and blew it out. So wet sand and water was a no go. Dry sand only. Tipped the entire bag out on clean concrete floor to dry, then sifted it into bucket ready for launch. I then made slight increases to the diameter for sand input and the air hole. Since this stuff goes everywhere I put a tarp up and wore a mask and welding helmet for protection. Had the fan blowing dust outside and got cracking into it. These are the 2 sides as a comparison, check out the horrid welds? These are factory or before my time...5 points

-

Seat belt bar arrived so fitted it a few weeks ago with a bit of ratchet strap persuasion Been using it to grab fencing supplies the last few weeks, can fit a 2.4 post in the back, less dodgy when weighed down by a few bags of premix Next job is to replace the gear selector detent springs, sometimes it doesn’t want to deselect gears or it’ll jam in gear, hopefully this fixes it.5 points

-

Saw the remains of, I think, three at a farm clearing sale in Southland about sixteen years ago. Have seen a restored one being driven around at Edendale Crankup at least once also.4 points

-

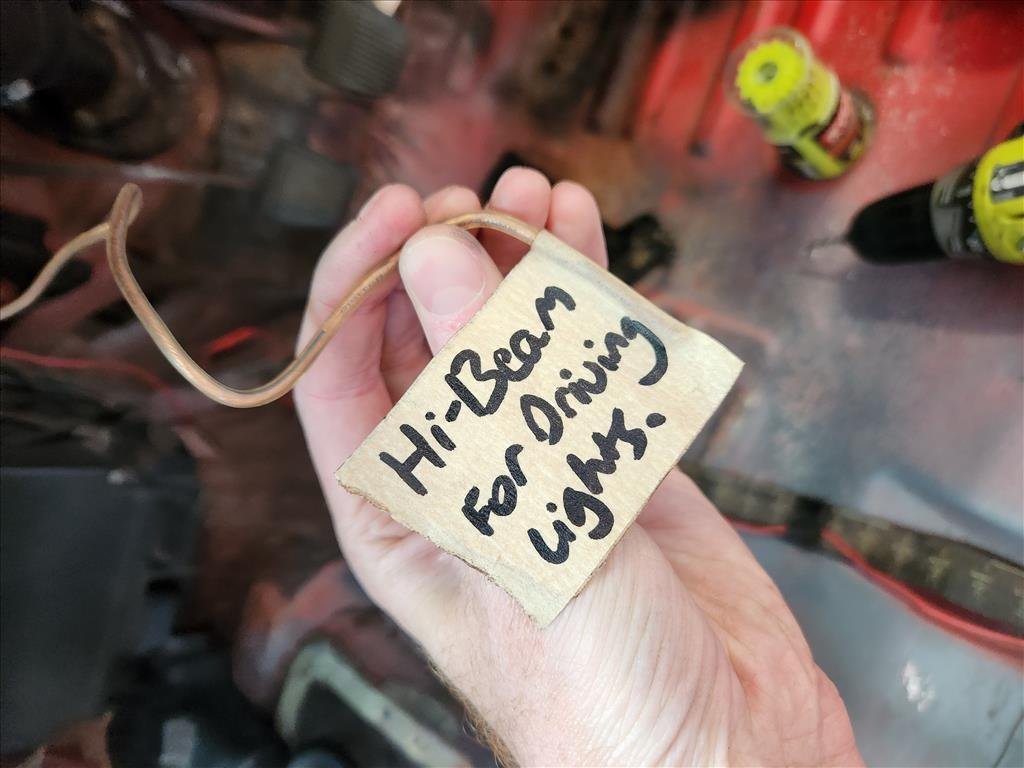

Two tasks planned for today, both failed. First task was to remove the dashboard. Reason for that is so I could check out some wiring behind it and also make sure I could eventually get as much undercoat sprayed up in as many areas as possible. Additionally I didn't want to damage it when trying to grind away the mounting blocks that were put in for the roll cage. After drilling out one broken screw and breaking the surround for the steering column unfortunately I did not get to take the dash out. I was thwarted by the choke cable knob that seemed like it was fused on by the nuclear power. I also didn't want to undo the choke cable from the engine bay and drag it all the way through as by this time my interest in that portion of the project had been depleted so I put it back together as best as I could and had lunch. I did find this gem under there which answers one puzzle about the headlights. After lunch I thought I'd see how I went with grinding away the roll cage boxes at the front. Unfortunately I could only access so much with the grinder and when I got to about here is where I gave up. Talking to some panel beaters the suggested method from a DIY point of view is reciprocating saw to get in as many cuts and angles as possible really and smash/grind out the rest. Just a shit job all around. Oh well, an excuse to get some more tools.4 points

-

I had Lets Get Graphic re-make my side billboards in proper vinyl..much better! Accordingly the duraseal peeled off the adhesive and then they had to thinners off stubborn glue..oops. Took it for its biggest run out to rangiora MCM show.. went great until the needles wiggled and it stumbled then the Amp gauge read drain. Parked it up and left it until the trip home couple days later, it did it again but didnt hinder the journey. Few hundred metres from home it backfired and the needle came back to life and it was charging again! By the time id washed it and drove back in shed it wasnt charging again. Tore it open and spotted a broken field wire so i soldered it back on and not change. Weird. Fucked aroubd with tests and bypassing things, external reg tested ok. Left it with a customer whos a sparky, could tell he wasnt into it but said hed take a look but his test bench wasnt working. Few weeks passed so i went and grabbed it back. He did say the wire sheath looked like it was degrading and it might be earthing. Put my pick under the other field wire to tweak it into open space and there was no pull resistance..broken too. Was a bit awkward but soldered a new wire in between the broken ends and threw it back on, Amp gauge working! Then it stopped. Decided it was the centrifugal forces throwing it out and the wee bare wire patch was touching so dripped epoxy glue in/on to make a protective sheath and its been great since. Will get another Alt cause its pretty fragile and old.4 points

-

If you ever need a new rear door latch cable I have a brand new one here I was to put in ours before it got nicked. The cable in ours would jam up and not latch properly, Rosie took it for a wof up here, the back door opened while he was doing the brake test and a bag of apples fell out.. still passed the wof tho #cuntrylyfe3 points

-

3 points

-

3 points

-

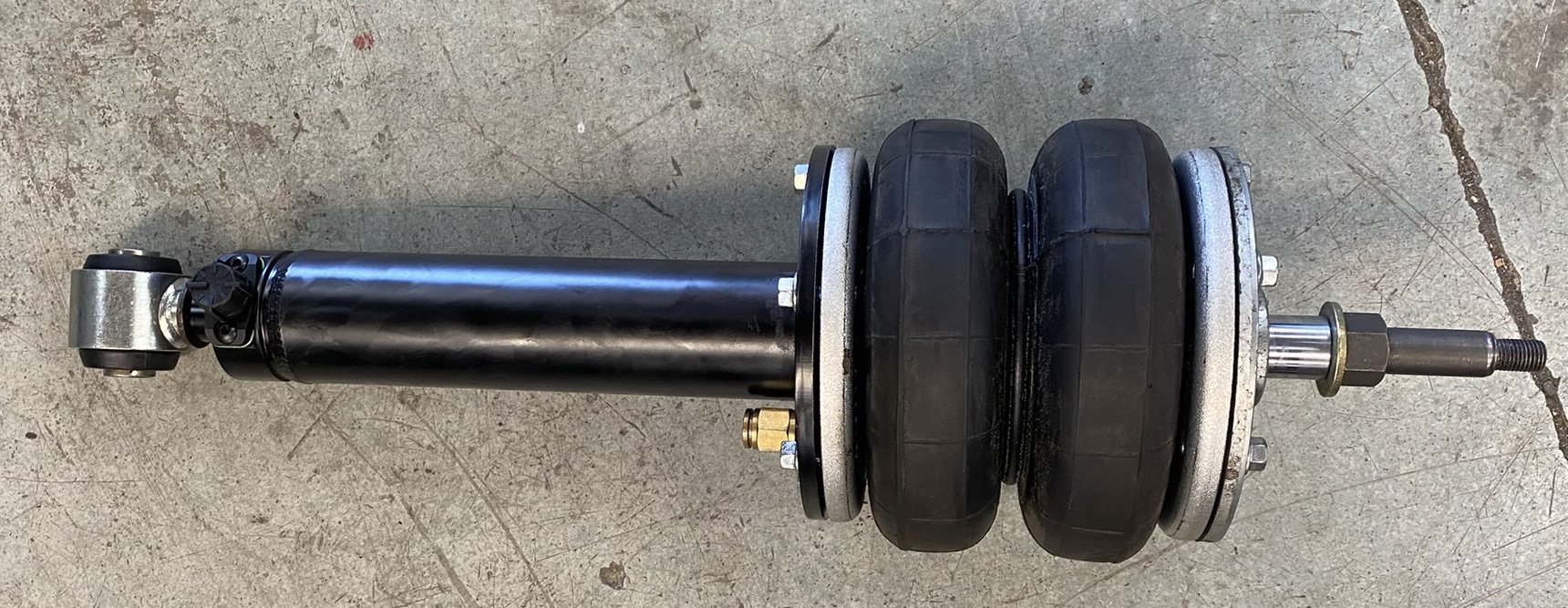

Have being doing a lot of stuff recently to try get this ready for beachop. The doors now open electronically with the small spring loaded knobs next to the window. And lock using the factory lexus Remote. Door Rubbers are all on. Window rubbers are all glued up. Bitumen sound deadening in the doors. Is much more of a pleasure to drive. Even with the door cards off. Reversing Lights added and wired in. Have moved on to version2 of the boss air struts. Such a better product. No welding the bush onto the bottom, they come with a threaded boss on the bottom and a range of Threaded mount options. Also a 1/8 female npt hole for the air supply. Instead of the Hydraulic style male fitting and hose they had before. Made it to the last southwards Cars and Coffee in Kapiti. Excellent morning out with lots of cool cars to see. Matts & mine were easily the lowest cars present. Had forgotten about the 1954 210 inside. Was a nice surprise. Have also put a false floor in the trunk. With a 4 channel amp beneath that. On top of the space saver. Wired into the parcel shelf speakers and ready to wire into the front door speakers this weekend. Have an infinity Bluetooth Amp adapter to wire in, instead of a headunit. (despite costing more than a decent headunit) Also next up is to get some gas struts onto the hood. in place where the springs would of been. As at highway speed the hood likes to lift and float around. And is quite disheartening at 100kmh.3 points

-

3 points

-

Meant to be damp Sunday night so I got a cabin that can sleep 4, Other 2 nights is under the stars. just throwing it out there2 points

-

2 points

-

Some small car enhancements, as opposed to some small car enhancements: Prius rear-view was vibrating a little on the trapezoid mount on the windscreen. This is a toyerda. We don't need that crap. we have other crap to enjoy. I got a bit of random skanky hose, put a scallop cut in one end to nudge the mirror stem. Boom. I now have crystal clear view of the cops following me who have zero interest in the Prius I'm driving. I'd cut down an window shade for the Dai, but it's missing a sun visor to hold the passenger side, so I hot-gooed some left-over Neodymium magnets to it. Now I don't have to bother fixing the actual problem:2 points

-

Whilst waiting for builder to start the keg build, I been buying a looot of parts. He started the rotors last week (all new side seals need clearancing x12) then he onto stacking. Bought the 'infini' momo centre cap so many years ago..got the wheel to suit now, Infini was the top spec JDM version of the FC but also badged to the BF mazdas of the day? Mazda OEM, Franklin, Aeroflow,Link,Pac,..try my best to use only kiwi sourced stuff, but the US & AU has supplied a few trinkets that only they do...example is 3D printed gauge holder ontop of the gauges, deletes the ashtray flap which has never been used.. Currently in contact with Vinny fab in chch for some bespoke items further on the build. Anyways, pics of stuff from the bin..2 points

-

I just want to make sure I'm not signing up to get stabbed2 points

-

Lost about 1 minute over a week, which is about as new for one of those, certainly pretty great now that it's 75 odd years old. Suits me, Just roll it forwards a minute at church on a sunday1 point

-

1 point

-

I heard that a gn250 with its large tyres soft suspension and cushy seat are the perfect combo for cracked ribs And get some accom1 point

-

I are a pulsterer. I pulled the other two seats apart and have collected the best bits from the 4 to make two good ones. The seat covers weren't super gross but I decided a turn in the washing machine wouldn't hurt them. Tbh they didn't come out looking much different They might get another turn in the washing machine I reckon.1 point

-

Cunty job. Am in the midst of floor skunge removal on the datto. Not fun! Recommend scraping all the under seal off first before blasting, will make the blasting job a bit easier. Good luck!1 point

-

OK the P rating says that P1 is basic P2 is OK and P3 is the best... il check on the web what else is available but yeh thanks for looking out.1 point

-

So I just had a bunch of injectors tested. Most of them came out as expected. However one set was waaay off. A brand new (been sitting for ages) set of seimens deka FI11445 came back significantly lower than expected. (advertised at 750cc) I purchased them back in the day from a reputable supplier and I have no reason to doubt they are China copies. Seems strange to me that even after sitting the flow could so far off. They are low impedance so I'm wondering if the test rig didn't like the low impedance and was packing a sad or some other fuckery is happening. Has anyone else come across this or had a similar thing happen?1 point

-

It’s the real fine dust that is harmful. The dust you see hanging in the air or the dust you can’t see. The filter will tell you if it is suitable for silica. That one doesn’t mention it so it would be best to get the correct filter. Google Silica dust health problems.1 point

-

1 point

-

Love your perseverance man! A lot of love and learnings going on. One tip for the spot putty (pinholes/chips/whatever) is to buy a pack of single sided razor blades, and holding perpendicular to the panel, scrape the excess putty away (once its hard) The less you have to sand the flatter it will be come clear-coat time.1 point

-

1 point

-

New AC system. As previously I bought one of everything from rock auto. Then I installed it. It was quite the job to get the TX valve out but yea whatever. I still have to fit a fan to the condenser, factory they don't have one which doesn't do the rest of the system a lot of good and is the reason why the TX valves shit themselves.1 point

-

I mentioned in my last post that I had new shocks on the way, well, they arrived, so let's get them fitted. I began by jacking the rear of the car up, putting it on stands and removing the rear wheels. This gave me access to the shocks and springs. Both the yellow stripe and the part number on the shock indicate that it was a poverty spec shock from a low spec (not Works) Alto. Note the missing lower rear spring pads, the spring shouldn't be sitting on the metal like that. The spring also had the incorrect colour code, yellow and white, not blue and white like the Works spring has. Other than the paint mark they look visually the same, I don't know if the Works has a higher spring rate or anything. Removal is really easy. On my car the side boot trims have been cut, I believe for the damper adjusters for the adjustable rear shocks the car used to have. This gives me perfect access to the nut that holds the top of the shock in place. Because I didn't care about the old shocks, I used a rattle gun to zip the nuts off. Before completely removing the nut I supported the rear beam with a jack under the spring, so the force of the spring wouldn't ping the arm downwards With the top nut removed, I removed the lower bolt on the shock and removed it. This one was very dead. Because they have gas in them, once compressed by hand they should extend to their full length again. This one had no resistance to compressing it and made no efforts to extend. The other side was only marginally better, where if you left it for about 5 minutes it would have extended in full (it should extend to full in a matter of seconds). The new shock has the correct KYB sticker and P/N on it, but it appears the new replacements don't get paint codes like factory-fitted ones do; the factory paint code for a Works is purple and green. I ordered these from the parts book to Works part numbers, so I know they're correct. With the shock removed, I could push down on the hub by hand and pull the spring out. I then fitted the new lower spring pad, in the correct orientation based on the service manual I then replaced the old upper spring pad and fit the spring The new shock slips into place next The top mount on the shocks is interesting to me. The top of the shock has a captive rubber mount and steel sleeve. There is then a top bush and metal washer that sandwiches the shock tower into place. On the underside of the shock tower there is a metal cup that locates the captive bush Even the top bush is weird, the shoulder goes face-up The washer sits on top of it and the nut is placed on top As the nut is tightened, the bush squishes and flattens out under the washer I guess compressing the bush like that creates a fair bit of tension, so the shock won't be rattling around in a hurry. Other than jacking the hub up to ride height and torquing the lower shock bolt, that was one side done. I copy pasta'd the other side. and then onto the ground it went. With the combo of fresh new zero km un-saggy springs and the lower spring pads being fitted, the rear ride height has increased a touch. It's only a couple of mm higher and should settle a little as the springs bed in. I know why they put the KYB sticker where they did now The Suzuki lineup at work the other day Looking clean sans tow hook now too So, how does it drive now? Well, the blown shocks explain a lot! I thought it was just lame povo spec shocks, but even that wouldn't have been as bad. On the road at low speeds the rear feels firmer, but there is a huge difference in how the car feels on the open road, the rear is much more planted and doesn't pitch and dive so much. In the corners, it's a lot more controllable and the rear doesn't feel like wobbly jelly. I still think it needs the extra stiffening of the rear swaybar to balance it, but cornering speeds can be higher than they were beforehand and the rear follows the front wheels like it should. I reckon it'll be good for a second or two off my laps at Manfield next time, particularly if I can get it to rotate as the Jazz did (no hope for trying to do that when I was lacking any confidence in the rear end). Some more (boring) bits should be with me soon to tidy the interior up further, and other than that I'll just keep driving the pants off it. Should hit a milestone soon too...1 point

-

@a.craw4d, @yoeddynz , @locost_bryan, & @everyone. thank you for your appreciation. So buzzed up on it, started another. We're off to Italy in late '43. There may be some GC's about. / pic of 15 minutes in... Also, @Indiana_Jones, Stug ?1 point

-

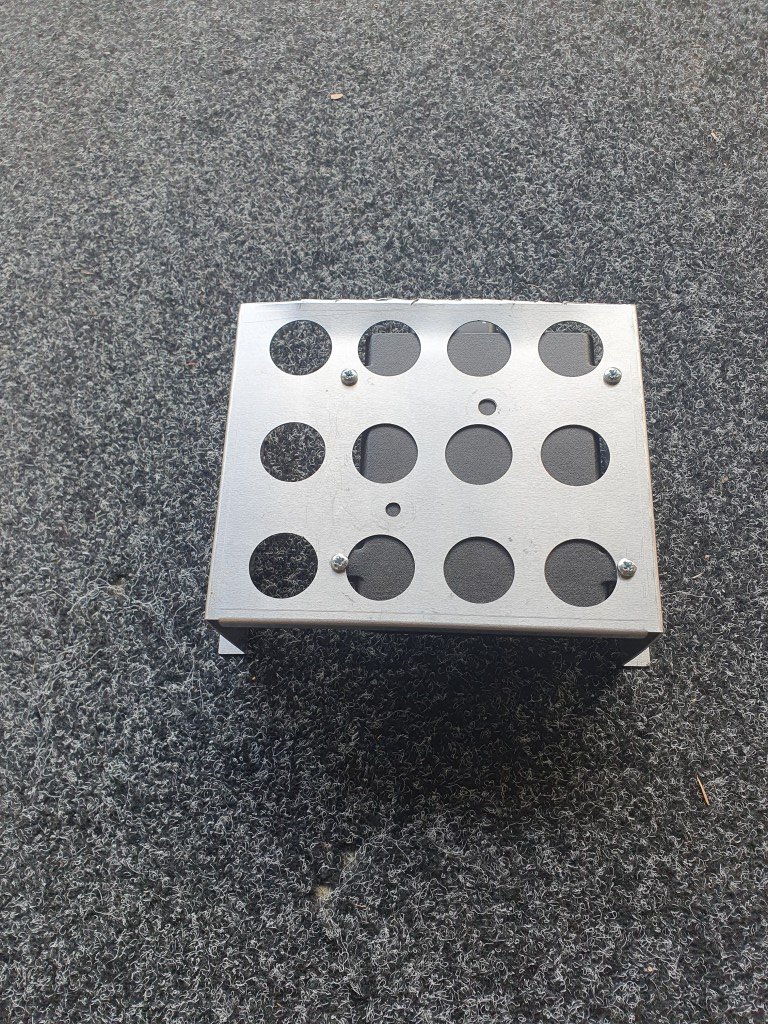

Battery box with breaker mount. Need better fixings for the battery mount but works for now. I managed to get the breaker JUST to fit on the top bracket, probably a couple of threads welded on would be best to hold it down. Currently the dome head fastener has a slight protrusion into the battery zone which I don't like. The bracket I got with the battery has been repurposed to mount the ECU. This one was a lucky find for cheap off marketplace. PC680 sized mounts WILL fit a Vertex battery easily. Note, there is a thick rubber gasket layer between the battery and battery bracket.1 point

-

Ha. So pretty much the day after I had cleaned up that old alternator up and got it running on the engine the second hand replacement for my original unit turned up in the post. It came with a 3 month warranty so I'd better check it works before stripping the engine of its ecu etc. Started to fit it and oh.. Poos. It wont fit. So I took it apart, along with the original.. Discovered its just the front housing that's different and I can swap them across.. So while its apart it would be rude not to clean all the parts up and polish it all (tempting fate just a bit...) Fitted to the engine and started it up. Yay - it works and it looks great, which is really quite important given its right there, in the middle on display. I'll keep the other one in storage just in case I need it one day. Now I could strip the engine back down, removing all the cooling, wiring and fuel lines that I had installed just for bench testing. Then I removed the transmission and put the engine back onto the engine stand 2000, stashing it away because its gearbox tinkering time. This Leone transmission has a few little issues that need sorting out in order for it to run in reverse rotation and not potentially turn itself into an expensive insinkerator or coffee grinder. I could probably get away without doing these modifications because the box is overbuilt for the application but I wanted peace of mind. Remember I had acquired the two gearboxes, 1600 and 1800 items, before getting the engine. Ages ago, in fact 4 years ago I think!!! I had wanted to know if it was feasible to run these boxes in reverse. This pic I posted up way back then gives a good idea on what's going on inside... I had already worked out some of the issues back then and knew what I was up for. With more study I found a couple of other areas that need addressing. Here's another bit of wonderful scribbling I did this evening.. The pink arrows show the new axial forces that are being imparted onto the main (driver) shaft and pinion (driven) shaft. The circles are areas that I think needed attention to make sure it doesn't throw it toys from the cot. 1 : the blue circle. Under high torque loads this area could possibly create the sound of nashing teeth but with much messier consequences. The top left one being the third gear driver wants to move to the right and clip the teeth on the bottom right second gear. In normal rotation they would move apart. There's 1mm of clearance there which is probably enough tbh. But I wanted a bit more and had already worked out how I could get it with no other issues and just a bit of tool making. Which is fun. 2 : The yellow circle. This ring was no going to take thrust loading. It is a strong ring and has a deep groove but I wanted to make sure there was no way it could ever shift. 3 : the green circle. In this area there is a thrust bearing that also acts as a neat little oil pump and squeezes oil through the gear hubs/bushes. Under the new loading the thrust aspect is removed but I still wanted to it pump oil and it was going to be the wrong shape to do so in reverse rotation. So I set to work and checked off each job. I made a bolt holder for ease of reassembly - several different sizes and lengths. Once apart I started with the gear side clearance. First off I needed to split the mainshaft assembly down. 4 years ago I had out of interest tried using a puller on the spare 1600 box, which shares the same layout and design but with smaller parts in many cases. The puller didn't work. But this time round I have the rather handy workshop press I made. I just needed some extra tooling to do this job. Starting with some press plates... Allowing me to carefully press the shaft out... Because I'm not posh (or rich) enough to own a surface grinder I needed to make one. Yes its a bit basic but it will work. I made this... Which allowed me to do this.... I ended up with this gear having the 0.5mm more clearance I wanted. Super happy with the result. Now onto number 3 - the little oil pumpy thingee. I went to my friendly engineering workshop in town and got a big lump of 4140 steel. I drilled it out... Machined out a ring which had to be an exact width. Just in case it needed finishing after the hardening process I made an abor to take it.. I carefully machined it to the right profile, cut the sides down and filed the shapes in, just like the original but in reverse. Happy it was going to work I heat treated it. I have not done any heat treating for over 25 years since I spent a fair bit of time in the blacksmith department while doing my apprenticeship. But it wasn't a super loaded critical component and just had to have a durable hard surface. I didn't take any photos. Hannah was there helping as I carefully heated it up with the oxycet to the austenitic stage and agitated it in some lovely rice bran oil (because I can be posh sometimes) then slapped it in the oven to temper it... Following morning I polished it. It came up sweet and the old file test showed it to be as hard as the oem item. You can see the reversed design here... Here's a little vid I took showing it in action... While stripping the mainshaft down I was also pleasantly surprised to discover that this 1800 box has needle bearings in all of the gear hubs unlike the 1600 box which uses bushes on the mainshaft. So oil starvation would not have been as much of an issue but I'm still really happy I did this modification. Last issue to sort was number two - that ring on the bearing. It would hold fine I'm sure but if could make it bulletproof then why not - it's just a bit of extra machining. I started with another lump of high tensile steel and machined out a ring to suit... This fits over the other ring and then the main thrust plate that sits over the bearing was machined out to suit my reinforcement ring. Its all held in place by the end housing which I have yet to fit. All the potential issues covered I set to cleaning out the casing and then started reassembly. In doing so I discovered that the original axle seals are sided on these boxes. They have those helical lines on the lip surfaces which aid in pulling/pumping oil back into the oil side of the lip ( the lip does not actually touch the steel when the axle is moving and in fact runs on a tiny bed of oil) which I had not realised before I'd bought plain lip seals from an engineering supplies. This pumping capacity is shown to be twice as high in helixed seals. Subaru fit left and right handed items. But I'm running mine in reverse. Luckily the originals were in excellent condition anyway so I machined up a stepped tool, popped them out and swapped them to the other side. The diff axle seal surfaces came up good after a clean. Cute little diff.. I'm now about ready to put some 3 bond gloop on the case half and drop the other side in place. Its looking all very nice, clean and shiny in there...1 point

-

Back in the country means back in to work on the ol' 86. Firstly, the time has come to get the front bumper repaired. So, off it came and off it went. The plan is just to make it structurally sound again, I think there are too many hairline cracks to warrant a full resto on it. If it's structurally sound and painted, i'm a happy man. The bro's cracked in to it! When i've previously removed the dash, i found it not possible to take out the dash clock surround without breaking it into 30 pieces. This has been an eye sore for years and luckily toyota still make them new Next was to install the JSP coolant overflow/oil catch can combo unit. 10x better than the previous solution. I will hook it back up to breathing back to the engine, I just need to acquire a -10 120 Degree fitting so that it can point down to the ground a bit more as using a 90 degree will make it hit the bonnet Turbo water lines installed. I need to order another -6 90 degree bend fitting as I didn't order enough, luckily I had a -4 premade hose sitting about which works fine, but it's 90 Degree to straight end hence the U bend to where it connects to the back of the head. This will be resolved shortly! Tidied up the NASA heat shield for the overflow bottle, I will get a beanie at some point for the turbo but hopefully this is sufficient for the interim. I've also misplaced some U Channel moulding I was going to install around the folded edge of it so that it wouldn't be possible to cut into the rubber line to the windscreen jets. it'll turn up.. Clean! Gave the interior a clean, still need to address the small rip on the drivers side seat.. I've always wondered where the handbrake light loom was situated in the car, I assumed that it was just that I was missing the wires and it never had them. Turned out in my spares box I had the spare loom, plugged it in and we now have a light. something that isn't that helpful just good small win For 10 years i've put up with using a wooden stick to hold the hatch up. FLOS.ie have new gas struts so in they went. much satisfaction TODO: - Replace oil pump. I'm having lower oil pressure at higher RPM's than I'd like (with a rebuilt bottom end), so i've got a spare oil pump which has the SQEngineering pressure up spring unit to hopefully address that. If that doesn't resolve the issue i'll be getting plasti gage out to measure the cam cap tolerances as I can't think where else I would be losing pressure the way that it is. - Recheck pinion angle since the 15" rims and slight height differences to bring back to 1.5 degrees both sides - Pull out gearbox to replace the output shaft speedometer worm drive. The plastic gear for on the speedo output is stripped, and without knowing what the worm drive it suits, better to pull it apart and replace it with the correct stuff which I now have. - Maybe try cert?1 point

-

1 point

-

Got her down for a wof and it went reasonably well. There was some bubbling in the sill and around the wheel arch he wasn't happy with so I went home and sorted it out. Wasn't anything major. There were only 3 patches needing welding and the rest were just rust treated and painted over. I'll see how it looks at next wof if I have to take it more serious or not.1 point

-

After that it sat for a while and I ignored it in the back of my mind I needed to keep going even if it was just a small thing to contribute. I went to pick a part found a Silvertop engine and got it stripped out for bits I needed. The rest of the engine could be used for a rainy day such as fitting a 20v to my 4af spacio but I digress. I saw a panel beater guy down the road who I wanted to farm the work to, he had someone's shell outside with the tarp half hanging off so didn't think much of that place. Another guy came to my place and yarned for 2 hours about what we could do but he's on the shore and I ain't keen to ship it that far. We basically decided I would do the work and it went from me farming the work out to me committing to proceed myself. Dang. Shit. OK. Supercheap had deals on engine stands so grabbed 2 of them. I bought some 50 x50 3mm wall and decided to make a rotisserie. The carnage follows.1 point

-

The original tank had a small hose for fuel delivery and a fuel guage made by everyone's favorite Lucas. The bones of the guage ie variable resistor and the float rod etc were attached to the new sender. I was In 2 minds whether it would be worth using the older Lucas one and was thinking to modify the dash cluster to use a toyota guage and decided no harm in trying to use original dash guages. I had to ensure the float could get a full sweep from e to f and would not foul on the edges of the tank where the recess was. Few bends and changing the orientation of the floats rod had this working a treat. I didn't chuck any gas in it but tied a string and pulled it up once it was in its place. On the other end I mucked about with the dash cluster and bench tested with a battery and the fuel guage came alive. That shiney paint on the tank was the rad shops default and falls off when petrol gets near, for now il just leave it there but will need to sort one day soon. So with that in mind I was keen to then get gas to the front and start the engine that way I would have motivation to excel to be the envy of my former self who sits in garage looking at the thing and fixes dailys while it weeps in silence. So anyways here we are 2 x 3/8 fuel lines haggerdly bolted into chassis rail... crusty brittle fuel line and the underside looking like the hull of an old fisherman's boat. Yeh that won't do. This is where I went into the spiral of thoughts... you haven't gapped the rings yet soon as they expand your pistons are toast, you still haven't got Silvertop rods and that needs to be done... shit... OK engine out box out. Fuel lines out.. might as well attack the underside make it pretty for future me and have not doubt about how the paintwork is or how fuel lines are attached.1 point

-

Our new oven came with a huge waste of space under it so I drew up a drawer with wheels on the corners and I got it cut and folded. Then I welded it together. Its designed so the wheel brackets slot into the sides and base but it doesn't need welding, that way I can change the wheels if I ever need to.1 point

-

I drained all the coolant out, took the radiator and pipework off and flushed the whole lot through until only clean water flowed. Let it sit in the sun while I did other jobs and gave the engine a couple of short 30 second runs to help dry it right out. I left it at that and decided to sort out the idle control valve that wont shut completely. I started by removing it and putting it somewhere it'll probably just collect dust for a few months and then maybe get sold/thrown in a bin. I then took Hannah on another exciting date to the local wreckers where we looked under many bonnets to find a suitable replacement. 'Automotive foraging' I like to call it. Here I am in the wilds of the wreckers... I took home a couple of throttle bodies with valves attached. One from a Mazda 3 and the other from a Mazda 626. They had almost identical iacvs but one had an adjustment. I cut a section of alloy out of a big block.. Milled it flat and square.. Throttle bodies.. tested them with some pipe and the earlier 626 item has a similar fail safe to my now removed Bosch item, whereby it still lets air through when 'off'. So that just wont do and I have decided the keeper... Mazda 3 unit wins this competition and gets to stay in the workshop while the 626 item went in the bin. I did some more machining of the block so turning it into a ported hub the iacv bolts to, with an in and out pipe pressed in place. I made a bracket to suit the starter motor through bolts to which the aicv block bolts onto. In pictures.. Bolts onto starter like so... Ended up being not only more compact and better mounted than the old Bosch unit but with better pipe routing too. I ran the valve through some tests on tuner studio and it works really well, shuts properly and is also much much quieter , partly due to it running at a much higher frequency than the Bosch unit. The next thing I thought I'd check was the headbolts out of curiosity to see if they were still torqued up fine. I first laid out some neat material that was absorbent, but waterproof. My sister, a surgery nurse at Wellington hospital, gave it to me and said its handy stuff to have about. Certainly is!... Bolts were all fine and I saw no point in giving them anything extra beyond what Mr Honda specifies, so possibly risking deformation of the heads etc. Next thing was to sort out the electric water pump placement. Where I had mounted it turned out to make it a pig to bleed of air due to the outlet pointing downhill and I knew it could be better. See here... I removed the mounting bracket I'd made for it... Unplugged the ecu etc etc and slid the whole engine/transmission onto the the 'engine stand 2000'. This process is super easy as it can be adjusted to the same height as the big table or workshop bench and the engine slides really nicely on the ribbed sump. Then I slung it into the spare imp and tried out the water pump for size in the new location I had in mind... Cooling pipework serving the Datsun engine exit the bodyshell roughly about here... Much better position. Not only will the pump almost self bleed, being at about the lowest point in the cooling system, but I will also clear up the area of uglyness where it used to be. It also gives me full easy access to the transmission filler/dipstick. I removed the engine, put it back on the table and set to work marking out for a mounting bracket... Then fabricated this bracket.. Which mounts the pump here... New improved temporary cooling setup which filled up sweet and bleed of air easily.. Quality touches.. With the cooling system now filled with just water I ran the engine up to temp. The new iacv was working well and I was more confident in running the engine for as long as my lunchbox fuel can would allow. I kept checking for any leaks and found nothing. The cooling system was working well, the fan kicking on and off, the temp staying around the 95- 97 degrees range I had set on the water pump controller (which also controls the fan relay) and I was finally able to set the idle properly with the idle bleed screw on the throttle body - something I was not able to do with the Bosch iacv which was letting in too much air. Still no leaks. I ran it several times, let it cool down, checked it the following morning and the level was spot on. Touch wood but I think the extra heat and lack of slippery coolant has allowed the head gaskets to 'set'. Either that or maybe there wasn't a leak at all and it was just residue coolant from spillage when I had removed the top pipes to pressure test them. Anyway.. I was a farking happy bloke! (Hannah was super happy for me too) Now with the coolant system working and it idling nicely etc I had the confidence to finally give the engine a decent rev up and see what it sounds like at 6000 rpm. Hannah took a vid... I just love that sound. The overrun rasp that flat sixes make. It revs up so quick and clean (and there's no acceleration enrichment setup on the tune yet until I sort the main fuel table later on so it can bog if you snap the throttle open too quickly) Another vid I took showing the hand throttle... So far the little Mandalorians have managed to keep all their limbs in place. In fact the plenum chamber stays quite cool with the constant stream of cool air flowing into it. Their spaceship has aircon? Anyway. I was happy. The only issue was that the whole time I have been running it without any alternator so meaning the ecu is having to use the voltage compensation tables and its not really an ideal situation having everything running at 2-3 volts less than it should. I took my alternator apart again and ran through as many checks I could, following a very handy NZ auto electrical school tutor video about alternator testing online. I suspect the rectifier is kaput and I couldn't locate a cheap replacement. I managed to locate a second hand alternator, pretty much the same unit and have bought it - now just waiting on the seller to sort their sh1t out. In the meantime I got another similar alternator, this time a nippon denso unit from a Honda prelude that actually has a bit more clearance out back, but with an ugly grey painted steel cover. I ran some pigtail connections and bolted it up, started the engine and now have charging! Yay. With things running at full voltage I tweaked the engines idle tune and cold start settings and am much happier with where I'm at there. In case the other alternator turns out to not arrive/be a dud etc I decided to give this working unit I do have a bit of a polish and paint. In pics, finishing it off with wrinkle finish paint on the tin end cover. Much better looking. I bolted it back in place and did one final run up to temp with a bit more tuning of the fuel table idle zone. I now have the engine able to idle at 650 and I could almost get a 50cent coin to balance on the plenum lid. The engine is still only sitting on the table, not bolted in place so I cant really expect it to be perfectly smooth. I think it idles a bit nicer at around 750- 800, a zone where its also running leaner at close to 14.7. Lots of time in the future to play with settings. Confident its all a good starter and idler, plus realising I'm stalling on the next stage, I have now started to take the pump controller, cooling system and temporary wiring apart. The next time it will be started will hopefully be in the Imp. Next job is to reassemble the transmission, bolt the lot into the spare shell and sort out the gear shift linkage.1 point

-

Congratulations @j.e.d. ! When I open my youtube apparel store you will be receiving a pair of Yellowhammer logo embroided socks1 point

-

1 point

-

56k Warning (hahaha) there's a few photos and a whole lot of carryon in this post! As I mentioned before, this year is interior year for the Celica so the first thing to do is tear it apart. Unfortunately the front seat covers are pretty mangled, rear covers may be salvageable but there's a guy here that does really nice OEM-spec covers for front and rear so might just get a set of those eventually. I will need to get a new rear seat set before I can do that though as it's been bent up and cut for the roll cage that was in there before. This roll cage also means there were mounting blocks around the place like these ones which cause the side trims to be a little messed up at the bottom. I don't think I will be able to cut this one out easily so might just have to live with it. I have to get all new trim panels anyway as you can see these are completely mangled. Thankfully these seem to be available as well. Something else that's mangled is what was behind the trim panel on the rear driver side. This window winder is stripped meaning the handle doesn't work. It looks like sometime in the past they might have tried to think about fixing this by cutting an access hole. It's not fixed so I don't really know what happened there but I would like to try and fix this so I can get sweet pillarless action. After I saw the dramas with getting in here from the Speed Academy videos maybe I'm a little bit happy they decided to do some bush mechanics on this part. Speaking of access panels, thought this was interesting. This car is perfect for running drugs as it turns out. In reality I think this may have been a hole for retractable seat belt? Unsure exactly as the replacement seatbelts mounted to this extra panel that bolts over the top of it, bit odd and probably put in for ADR approval or similar. Seatbelts will need replacement as well but I think I'll just pretend these cars did not have rear seatbelts and do the front only until someone tells me off. The front driver seat was interesting, I can't even blame anyone else for this one as I was the last person to put this seat in. Suppose I did the old "it's future Alex's problem", yeah future Alex isn't super fond of that as it turns out and yet, there is no effort to change habit. Threads are for losers anyway. Another thing to get sorted while things are all apart is the fuel system. Once upon a time an electric fuel pump was wired in, wiring job looks like something I would've rigged up honestly but it needs to be properly done. For one the pump is in the wrong place so that needs to be relocated and it's not on any kind of relay or anything so it runs all the time as soon as you click it over to accessory on the key; I don't think that's correct. I'd like to install a fuel pressure regulator as well to keep it in check. The roof lining has been cactus since I bought the car and probably has been screwed for years before. It's just some cheap fabric that has been kind of glued up there and would've been done when the sunroof was installed; probably in the 80s. I tore it all out and will have to work out a plan to replace that. I won't be coating the roof portion but I wouldn't mind slapping up some squares of sound deadening. Carpet needs replacement as well; I think this was a kit once upon a time but honestly it looks like leftover garage carpet, yuck. Replacement carpets are available in much nicer material these days. Also this white insulation looking stuff under the front got me a little worried. 50/50 on it containing asbestos according to Google images so I masked up with some gloves and tried to tear it out. Frustratingly it's stuck down really well on the passenger side so even with the wire wheel on drill I couldn't get all of the stuff off without spending all my life in there. It's good enough to coat over I reckon. Thankfully driver side was much easier as they were lazy with the application. I plan to remove the dash and everything anyway to get it cleaned up under there as there's a bit of messy wiring as well as the heater core seems a bit locked up (I can't change the heat on the slider) so want to have a look at that, or maybe remove it? Don't need heat if you don't drive it. You'll notice the little boxes in the front as well that I need to cut out which will be a super fun (not) job before I can start coating so that might be one of the next jobs on the line. That brings us to the end where it sits now. Stripped out mostly, vacuumed but not cleaned up yet. I will get the brush and anti-rust spray out for that little surface rust that's kicking around. As for the coating I plan to use bedliner then decide if I want to add additional sound deadening or not; haven't quite decided yet. Bedliner is hardy, it's fairly cheap and it will be covered by carpet anyway so should be fine. I haven't decided exactly how far up I want to go, whether I do all the areas without trim or just the floor areas. This is why I need to get the rear windows working, how sweet is that pillarless life.1 point

-

So @Carsnz123 send me a message November about a pontiac 400 in Hamilton. I promptly sent the seller a message and it turned out to be a 1972 400 with 7k3 heads and the original q-jet ontop. Sparked a deal and then @Beaver did me a solid and picked it up and stored it for a few weeks till john at south island couriers did a north island run and he picked it up and brought it down to chch 2nd week of December rolls around and I've got covid and I get a call from John that he's gonna be in town tommorow. Cunt . Had to call another favor from a workmate to u load it and store it at work till I could come get it in a fortnight . Finally actually saw the motor I'd payed for over a month prior on the 22rd of Dec Got it home and pulled both heads and from best I can tell it's never been opened up till now. Its not up on a stand waiting for some more time to strip it 100%1 point

-

1 point

-

Dredge… decided now I have a garage to put the soft top back on. Repainted the hood sticks over the Christmas break. I’ve ordered a seatbelt bar for it as well so I can take the whole roof off and retain the 3 point retractable seat belts. Currently only bolted through the front hood support until the bar arrives. Had a set of bench seats for it as well so put those back in. Black wheels this year I think. Mostly did this so we can take our new little mate to the beach, off to the dag thread with me1 point

-

Side note: those horrendous looking pullmax dies were a quick slap togethor for a test job that I reshaped for this purpose. I know Pullmax baby Jesus was weeping seeing those pics but they work fine.1 point

-

Got things back together. The gear stick is slightly closer to the driver now which is both helpful but I have also now lost all my reference points Left a car park entrance with a fair bit of speed on, and the drivers door flew open. Not the first time this has occurred so also adjusted the latches, they are pretty well worn however. Slam locks always draw attention as members of the public probably think I'm furious about something. In reality I just want to go home without falling out. Tried to go and find some puddles or things to drive over at the Waimak but access is pretty well blocked off. Found some old photos anyway Moments before this occurred, I believe the driver said, "Watch this!" Which resulted in trying tow the range rover out, which went well... My car did back out of that, but a man with a snatch rope had to come and rescue the range rover. There are computers under the drivers seat for things like the airbag suspension etc. Which were under water... This was a few years ago and I believe it's all fixed now. Keen to try and find some spots around Christchurch for more of the above, Waimak and also Mcleans Island seem like a no go anymore though...1 point

-

Bling'n Billet torque convertor finally turned up from the states, best packed thing I've ever seen foam all cut to shape and not a giant box full of USA air like summit racing, plus a beautiful little envelope with intructions and some more stickers for the shopping list1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)

.thumb.jpg.570970b401ac8d26ce9af7c1bf2bd8cd.jpg)