Leaderboard

Popular Content

Showing content with the highest reputation on 12/12/24 in all areas

-

Needed to fix a thread on the old vw but couldn't fit the usual tap handle, You can buy these but I have a lathe and the steel was free, took a while to figure out how to cut the inside part, then I overshot it a touch, tapped three M4 grubscrews to center it better, just used it and seemed to work well, I now have a bolted down battery in my car for the first time ever!16 points

-

So I have been attempting to get the box back together, but it has taken 3 attempts so far; #1 - all the clusters back together, everything inserted and getting to put 5th gear on when I realised I was so intently following the written writup on Xweb that I had forgotten to put the actual gearshifting mech in because it wasnt part of the writup. Sigh, gently pull it apart and scrape off all the blue gasket poo. #2 - everything back together again but realising the there was some burring in one of the the detent ball holes and the now impossible to get out ball bearing was moving neither forwards nor backwards. Sigh, gently pull it apart, extract the ball and then scrape off all the blue gasket poo. #3 - slowly and methodically reassemble it all again, barely even referring to the writup cos there is now an element of familiarity with the process. I am still waiting for some axle seals, but apart from that its all done. Like the old box it has a tapered drain plug in a straight tapped hole, I think I will make a straight plug up so I dont split the case. Anyway there are very few pics of all this as it required much concentration.12 points

-

9 points

-

7 points

-

6 points

-

4 points

-

4 points

-

Guitar renovation. Last century I used to play a bit, completely hopeless now but wanting to try again I attempted to set up my crappy old acoustic properly, got all enthusiastic and shouted it a new bridge, saddle etc but the truss rod thread stripped just as I was getting it right, so I swore a bit - and have been looking out for a decent'ish used one since. Saw this advertised at a charity shop, Ashton D25, scratched, rusty, 2 strings so grabbed it as a cheap project... [Reviews state the D25 is a 'cheap, nice sounding full-sized beginner/muckaround guitar' so perfect for my needs] I re-strung it to check things and apart from needing some new parts it actually played OK, neck was straight, strings at good playing height etc, so I ordered a bunch of bits from Aliexpress, then stripped it right down and gave it a good clean. Can't do much about the giant scratch on the body but might try to hide it later... The Ali machine heads fitted perfectly, sort of wished I'd got the black option now though for full blackout look, but they look far better than the grotty old ones... And the new bone nut and saddle looked to be well made. The plastic ones were worn out, (nut had actually crumbled at the 6th string and I'd filed a temporary notch to test it) also got some fancy bridge pins... Biggest issue was the cheap in-built tuner, that was missing the battery holder clip. I bodged it up and it still worked but the cover/clips are always going missing and are unobtainable, so bought a combined tuner/equalizer/pickup unit to turn it into an electro-acoustic... This is still on the way, so I gambled that the online templates will match what I actually get, and cut the hole while I had it apart... Hopefully this arrives in the next few days and I can see how things go together, bit of wiring/fettling to do when I get it. It won't be fancy, but I should have a useable geetar for around $100 all up...4 points

-

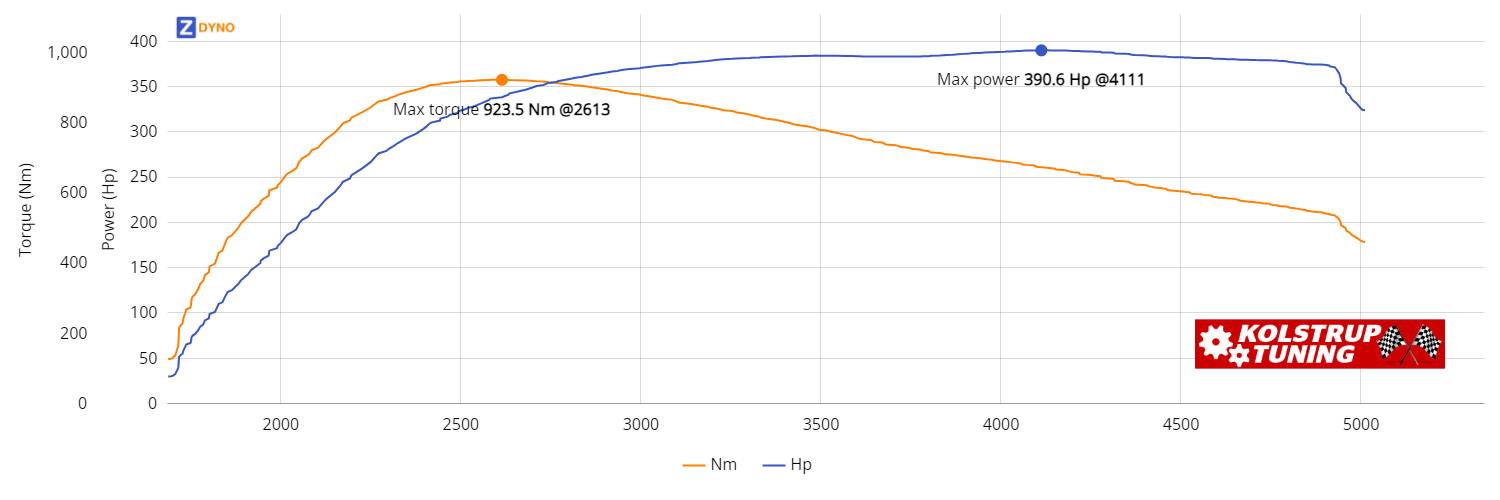

Sorry to everyone that I have blue balled with this project! Over the period of god knows how long it's been so far without any cool stuff happening. I have not yet made good on my promise of doing zillions of rpm with a shitbox wrecker engine. In V6 variant at least. I've been putting in some solid hours to get things finished to try get to the drags. But tonight I've come to see I'm not going to make it. If it was just about getting the car finished enough, might be feasible with some long nights. However it turns out I need an MSNZ license as well as a log book in order to race without wof/reg. I've been going down this road over last few days to try organize it. I paid $70 to join a car club, which is a prerequisite to applying for a license. However it was then was going to be another ~140ish bucks for a license that might not arrive in time. So combined with some extra expenses to get car in a drivable state I'm probably looking at $7-800 I need to pull out of my ass in a hurry. My bank balance got fairly well emptied a week or two ago when the neighbors dog tried to eat our cat. Then the cat crunched my finger when I picked it up. So big vet bill for the cats injuries, and a week on antibiotics and a day or 2 with bandages for me. So as exhausting as it has been pushing hard to get this done. For now I just have a rest. But it's really close to being drivable. Since last post: -Firewall finished -Put crossmember and steering rack back in -fixed gearbox leak (loose bolt) -fixed engine oil leak -finished exhaust manifolds on both sides, down to a finished flange. So they can stay in for good while I make rest of the exhaust. -Got motor and box back in -TA63 booster fitted -Interior started going back in -Started on battery tray -ITBs properly fitted and bolted/sealed up -Exhaust manifolds on properly with gaskets etc, all bolted up properly -Some wiring stuff sorted -2nd wideband wired up -radiator back in -front of car back together -Motor fired up again! My collector flares out to 2.25" or 2.5" (cant remember) but then you can see down where the flange ends up, thats where it flares out to 3". So does this mean it's an F1 car now? haha. The last weld I did on this pipe was the one on the rear of the 3d printed part, and turned out quite nice compared to some earlier efforts. Also, although I'm no welding expert by any means. Holy shit, it feels like cheat mode being able to weld indoors. So much easier when you're not battling a mild breeze on the driveway. haha.3 points

-

Surely a real Barry would have popped down to Woolworths for some weetbix, and made a gasket from the box? I hope it holds for you it's been a bit of a journey.3 points

-

I've given up on the gasket its fucked now anyway and special order from basically anywhere that sells such things so scraped the mating surfaces till they are shiny and am resorting to only grey gasket schmoo. It's on sitting properly and has bolts hand tight I'll nip up in morning and pray to the gods this chapter is closed.3 points

-

3 points

-

PowerThread3000 Also available in 3/4 impact , for those hard to tap threads. Just ask for a PowerThread60003 points

-

I have that same regulator water/oil trap at approx 1ft from the compressor outlet, then 10m line, then I use a disposable filter (the red ones that screw inline) at the gun. I recently changed to rubber line as my old blue one had gone crunchy and full of holes. Rubber line is nicer. Also got a regulator with gauge to go at the gun (I had one without gauge only on my good gun for clear etc) which is also nice Without the filter at the gun I would get water coming through on more humid auckland days (normally I would aim for a nice day, spray in the morning and if I drained the compressor before hand it wasn't an issue) Compressor runs almost full time spraying a whole car, it puts out just slightly more air than I spray. For home job it's fine I think, no real issue I'd like to run some black pipe up and down my back wall of new shed to make multiple water traps (the reg at 1ft is literally.hust because that's how much extra line I had, it should be further) I do probably more painting than an average shed wombler, but less than someone who paints I guess, and current set up has been fine, with room for improvement3 points

-

2 points

-

2 points

-

I've got a Spice girls sticker on my old one...2 points

-

That scratch is crying out for a sticker to go over it :p2 points

-

I've now done a few cars on 50l compressors, here in Canterbury its pretty dry and you can get away with it, just. I have a large aluminium bodied line filter that does an amazing job at removing moisture, nothing like a refrigerated dryer, but good enough and religiously check it, once it gets warm, its time to go inside for a cuppa. It takes some planning of how you're going to do each coat, during base coats figure out how much time/cycles the compressor tank takes to heat up and cool down so that when it comes time to do the final coats, you know how much you can get done each session. Most 1ph compressors won't do full duty cycle so that also plays into the mix depending on your level of mechanical sympathy. Sucks balls, takes way longer, but its cheaper than rewiring for three phase!2 points

-

I bought this boat 10 years ago and have never put it in the water. It's still is on its original trailer and has the number 59 on it which I am thinking was when it was built, which seems about right. I bought it from Whitianga, and they had bought it from Gisborne. It had a reasonably new outboard fitted to it at the time which is what they were after. Then I picked up a second hand 75 Merc for it from Gisborne of all places. The exterior of the hull has fresh paint on but the interior was in need of a tidy up so I set about redoing the interior. I got most of the construction done but life got too busy so it sat until now. Anyway, we have decided since the engine has been sitting without use and will probably need a fair bit of work, we will buy a new engine. So, I went down to the local marine dealer who sells Honda outboards and have ordered a 4 stroke 75hp for it. They tell me it doesn't take that much to get these small ply boats to get up and go. I will post up more pics as I go.1 point

-

Noticed the master cylinder is leaking a little out the back. I thought I put a seal kit in it, but I guess that was 7+ years ago and it's just been sitting in a box since then. Hawkswood have no stock. I wonder if BNT will have anything... It's usable for now, the brakes just need to work enough to tow it 6 minutes up the road to visit the alignment machine. But that likely won't happen this year.1 point

-

Yes that’s correct and I also forgot to mention set air line pressures - say running 60psi stepped down to 25 at the gun is less ideal than starting with 60 at the compressor, 40 at the in line regulator and 25ish at the gun regulator. I can’t remember exact science but it helps keep air delivery even. Etc1 point

-

7 bucks worth of potato sure buys a lot of motivation1 point

-

I have no experience with iwata guns @lowlancer but probably lots on YouTube about that specific gun if you’re painting a whole car then 50l is suboptimal; you will be running around 20-27psi so you shouldn’t run out of air but the compressor will get hot and you will get moisture in your lines. In between coats drain your water traps. It may get so bad that you have to drain in between panels… it can be done but if budget allows get a second tank to go with… I find rubber hose to be better than the plastic-material hose, and you also want a wall mounted filter and one at the gun end at a minimum. After about 2-3m of line from the compressor fit your filter. I think I use 1/4” line too. I haven’t really liked my SCA filters I got filters from spraygunsdirect.co.uk hose from tool industrial and nitto fittings from SCA.1 point

-

No mine was fine interestingly enough, though I did end up doubling up on the copper washers as my helicoiling wasn't as straight as I'd have liked it (did it on the car which was a fun experience...). I think I did give it a bit of a light blocking down to take off any high spots and raise any gouges that might make sealing trickier.1 point

-

Or projects.. timing is poor. Settling on house next week, shed build imminent. Too many bluddy kids expecting some jolly fat cunt (me) to furnish them with useless shit they will use once and never again. Ugh.1 point

-

I was contacted yesterday and asked to call in and discuss a few things with the boat. The engine is now on. We have decided to go with tote tanks and put them in the bin seats behind the front seats. Originally it had a copper fuel tank which I have but it will be retired. Tote tanks are easy to use and you can just lift them out and use the fuel for something else if you are not using the boat for a while. Another advantage of a 4 stroke engine I would think. The biggest obstacle to getting it in the water by Christmas will be the trailer. The springs are not healthy and would need replacing I would think to get a Wof. I asked them to find a new trailer as even if I fix the original trailer I would still need to do a lot of maintenance on it every winter.1 point

-

Also good for water divining, with a firmware update.1 point

-

Reinstalled the underbits and put it back down. Now I can test the lines for the rear brakes. And need to make mounts for the passenger seat. It could then go on a wheel alignment machine to see if the subframe is mounted straight. Then put it back up. Take everything back off. Weld the subframe mounting studs so they can't move. Finish the welding on the underside of the passenger seat mount. Seam seal. Then some kind of top coat. Put all the bits back on. Put it back down. etc... etc..1 point

-

Hopefully everyone was thinking I was engine swapping the logo. If you have seen anything that I've worked on in the past you will know my skill set is make something pretty before actually working. Then worry about the driving/functioning later. The logo has fallen somewhere in the middle. (Currently) at this stage we are on track for the drags next weekend. Here are some photos from the past few weeks Thanks for looking1 point

-

1 point

-

Put all new bushes in the rear. Trailing arms, panhard and swaybar. I think it's already been done once before, the rubber bushes came out fairly easily and they had no outer steel sleeve I had to fight with so I'm assuming not factory. Anywho they were a bit fucked and I changed them. Does feel better in the bum now.1 point

-

Bottom end is mint, bearings are perfect still and without the pistons in the crank spins freely. Ill take the head to Mean Machine tomorrow to get it looked over, see what they have to say.1 point

-

1 point

-

A mate of mine custom made an old style engine cover for his modern engine with period correct old style paint and graphics. At first glance you think cool old engine, but then on second look you realise the truth.1 point

-

hey, also it should be made very clear that i have no idea what I'm doing. I'm literally just doing whatever looks good, there is no science in anything here, diameter of the throttle? - fuck knows, whatever will kind of match up with the head and still be big so it looks cool. length of the runner? - 80ish mm because that the number that i pulled out of my arse. angle of the throttles in relation to the motor? - 15 degrees because i have no idea why. if there's something that seems fucky please speak up, like i say these is no science in this at all it should also be noted that this engine isn't really destined for great horsepowers, its a fucking 5m, if i wanted max powerz i wouldn't have started out with such a turd. any input would be appreciated, unless your a shitposting dickhead, then its not.1 point

-

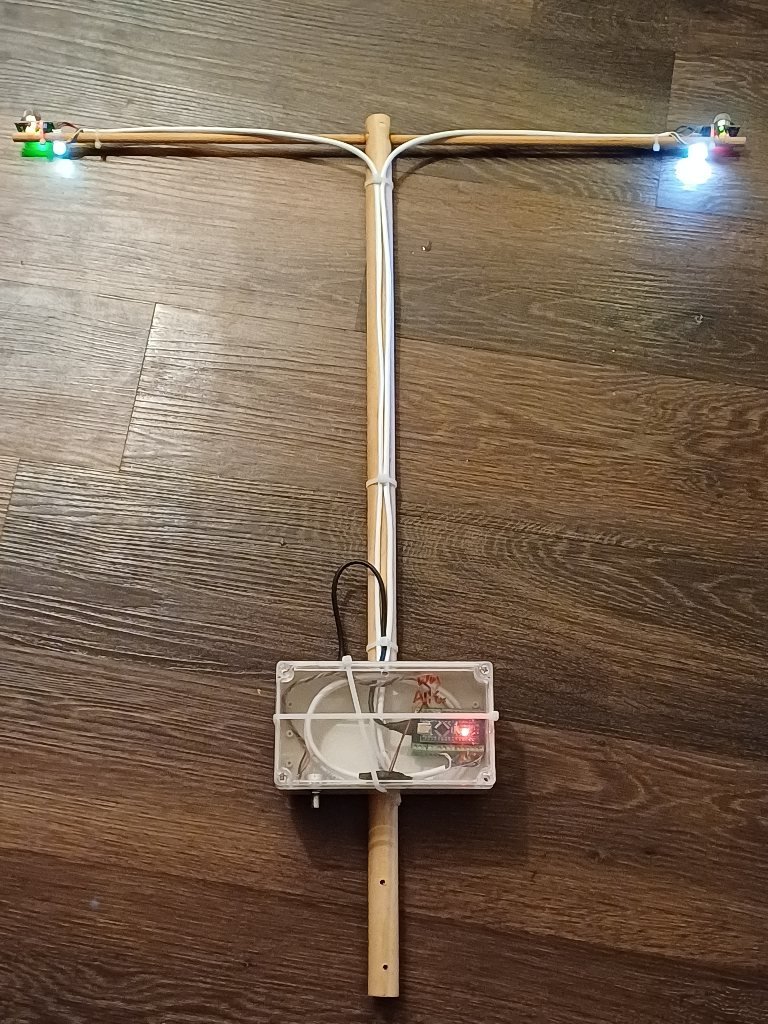

Gas dowser. It blinks, it beeps. What more does a man need? Led at each end changes colour as each gas level rises, and the highest side blinks. It beeps a tone depending on average gas level, (warmer, cooler) to help localize source. I've realised the LPG sensor can be swapped out for ammonia, etc in the same footprint1 point

-

Cheers @Roman I hope so too. Yep they are 4x100 14x6 +38 (with 20mm spacer) Rays gram lights. I look forward to seeing your car at the drags too.1 point

-

Only just saw this thread... love it! Hope it makes it to OS drags, are these 4x100 wheels?1 point

-

1 point

-

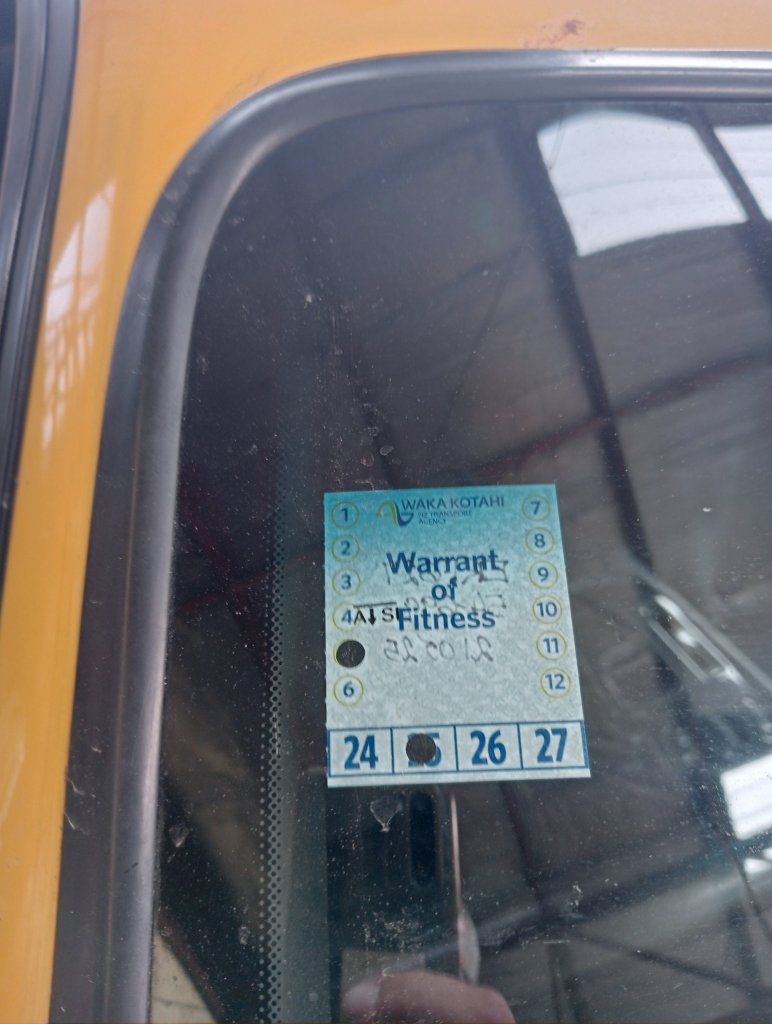

the WOF man actually wanted to stick around for a chat, guess he was a Mazda guy "so what have you got planned for it next?" "I dunno, I guess I'll wait for something else to break" Never had a legal car, this is new territory1 point

-

1 point

-

Finally managed to snag some tail lights out of japan. It was a bit more difficult than I thought to win a good set so I went for a set that looked to be average but with a good centre garnish. There was also a cheap pair of lights closing the same night so I bid on them too. Took a week to arrive from buyee and headlight polish cleaned up the lenses nicely.1 point

-

1 point

-

1 point

-

The Virm has actually been updated recently and made it illegal for Yellow Rx7s to have oem turbos. So only way you will get a wof is if you fit a single BorgWarner 300sxe.1 point

-

I've been working on it a few months now. All of the rear chassis has been cut out and replaced with a RHS 'back-half' section, suitably narrow enough to allow the use of 12" wide wheels under the arches. Engine is in, and turbo's are mounted. It will all have to come out to paint but I'm really pleased with the way it all fits.1 point

-

Our new oven came with a huge waste of space under it so I drew up a drawer with wheels on the corners and I got it cut and folded. Then I welded it together. Its designed so the wheel brackets slot into the sides and base but it doesn't need welding, that way I can change the wheels if I ever need to.1 point

-

1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.570970b401ac8d26ce9af7c1bf2bd8cd.jpg)