Leaderboard

Popular Content

Showing content with the highest reputation on 05/04/21 in Posts

-

oh, hi!! so yea things have been great with this car. except the output bushing on the gearbox is flopping around and subsequently the output seal is leaking and flinging oil all over the exhaust. this is shit. the gearbox has only done a couple thousand Ks since it was brand new from Toyota. apparently this is fairly common on the new R154s which fucks me off even more. I've fucked around with changing the seal multiple times and all the other usual checks but it just keeps on leaking. cool. so to fix it i have to take the motor and box out because of the whole massive drive train/small car thing so out the motor comes. its fairly depressing taking a motor, that you have worked very hard on to make as new and shiny as you can, out of a car and seeing all the road grime and shit on it, as well as all the crap that goes everywhere when you start taking things apart. well, its what has to be done so away we go. not sure what else ill do while the motor is out. im not 100% happy with the clutch i put in it. its juddery and grabby at take off which sucks so that may change. fuck knows.............. anywho, first step, jack up your car. 2021-05-04_05-59-44 by sheepers, on Flickr17 points

-

11 points

-

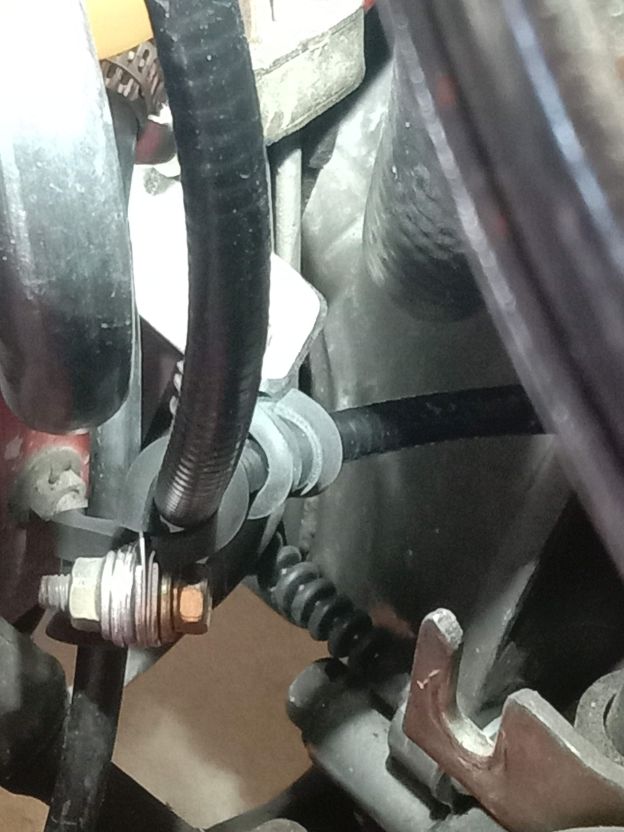

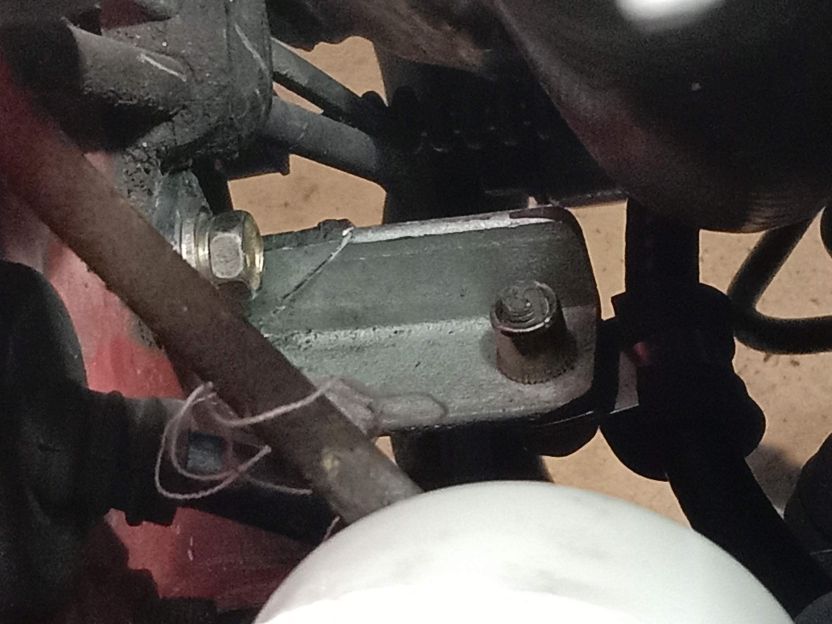

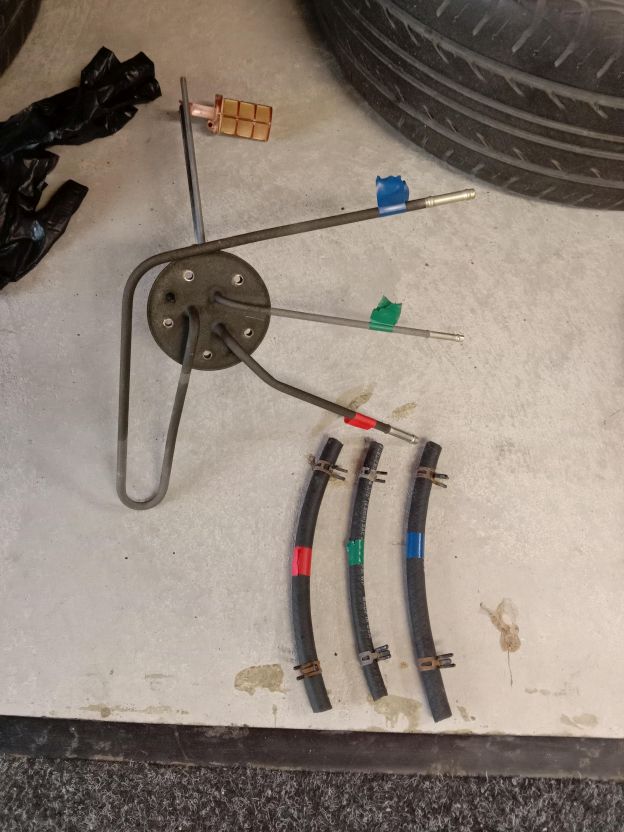

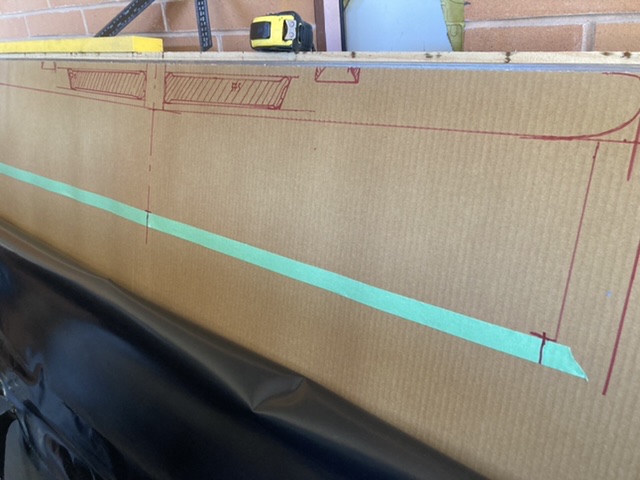

Still chipping away, have had a few jobs that held up other jobs, so progress hasn't been as quick as i'd like. Couldn't put brake master cylinder in till I sorted the clutch and couldn't put fuel tank back in till i'd sorted the brakes... Anyway, a quick run down below. Tried to start it the other week to make sure it still runs, it doesn't. Figured it was probably fuel as it will have been sitting for a while. So I dropped the fuel tank out to find the tube pretty blocked, so that hopefully answers that. Drained the fuel tank, turns out I put quite a bit more fuel in over time than I thought, fill the mower container and any lose containers I had. Took the worst to the dump eco area. Dropped the tank in to Hornby Radiators and they gave it a good clean inside. I grabbed some new hose while that was being done. Got fuel tank back and gave it a quick paint on the top half, only surface rust, but some was a bit pitted so worthwhile doing. Fuel tank. Hoses labelled for future reference, also labelled on car. After getting the insides cleaned. quick tickle up Then a coat of whatever rust paint was lying around. Was blowing a gale, can't beat a brush on product sometimes. Engine fuel supply pipe with some meths in it, sloshed it around a bit and left it overnight. Grabbed some pipe cleaners and it's good as now. Getting a new intank filter thing was too hard basket with my time frame, so I gave it a good clean and chucked it back on. Oh yeah and the new hose: While that was being done I went down to CBC in town and they made me a new clutch cable. The old one had been resting on the exhaust so the cover was pretty toast. No pics because I just wanted it installed. But it was a pretty sweet cable. I had it made 50mm shorter than the one I had, as I couldn't route the one in the car without it hitting exhaust and steering. So with the new cable made I made a bracket to hold it clear of everything. Factory they have a bracket, but it's NLA so I had to just guess it. Asked on a FB group dedicated to these cars but no one could be bothered taking a photo for me of how it's run factory, boo. Anyway, the bracket, which is part of a realtor sign I chopped up. Gave it another tweak with the rivnut tool after this photo and got it compressed a bit more, shes solid as fuck. Bolted to the firewall and installed a P-clip on it to hold the cable. Bolted two clips together to keep the clutch and speedo cable apart and keeps it off the fuel line on firewall from filter. No idea how much of this junk is legit, but none of it's under pressure, it's just done to keep things apart so nothing can rub through. Seems legit enough to me, guess i'll find out soon enough when it gets checked. Just need it together for now and worry about the details later. For those that don't frequent the spam tech thread, I asked about bleeding my new master cylinder and went with this solution. Which when installed worked like this. Didn't leak bugger all when being bled, and I just clamped the pipes with vice grips when done so brake fluid didn't go everywhere. So then I bled the rest of the car, gave up doing it by myself and installed someone in the car to pump for me. It was after I had done this, I realised I had fucked up... I pulled the pads out as I was getting a bit of fluid leaking while trying to bleed the nipples myself (no euphemism). So I thought rather than potentially fuck the pads i'll remove them. I'm sure you can work out the rest... thankfully the pistons are long enough for this rookie mistake to not be an issue. They pushed back in fine with a nipple released. Was going to rebleed the whole system again tomorrow anyway with new fluid. But that is a must now as i'll have air in one side of each caliper. No biggie. Next time I'll have brake pad shaped bits of wood to install. Quake safe on axle stands with enough junk underneath to stop it being able to fall on me. Next up will be work out why the dash sits too high to where the windscreen will struggle to fit on one side. Then book in a windscreen install. Then do my own alignment to the point I can get the brakes bed in a bit. Then book proper alignment. Then not sure... i'll worry about that another day, getting close.11 points

-

10 points

-

7 points

-

So more fails. My understanding was that if you swap the sump over, all of the bolt holes line up to the gearbox. But what it means is "At least the bottom half will line up" because literally nothing lines up to the engine block It looks like the best compromise is to drill the block. This means all of the bolts will work except for that center top one, which I guess is good enough. It's pretty meaty at the places I've drilled it. And yeah I literally just used a drill, thug life Ahhh well, still making progress I guess. Just need to file out one of the holes a little bigger then I'll have it all bolted up as good as it's ever going to get. Luckily the dowels that were in the motor came out super easily, it turns out that there is a position for dowels that's common to both the gearbox and motor. So that puts my mind at ease for making sure the clutch is aligned to the output shaft correctly, even if my bolts situation is yuck.7 points

-

So another couple days of trying to get it running well... this time I actually got it started ran kinda rough as hell but it went. Untill i played with it more now I've gone backwards. Looking at a decent starter and maybe do away with the points. Also found out the guy I got it off didn't transfer the private plates 20 years ago so I've had to track down 2 deceased estates to see if I can keep the plates or just bite the bullet and get gross new ones Also gave it a bit of a clean looked like someone was hotboxing in it the windows were like tar sticky and so were the seats which are original I'm assuming no rips or tears so win. Basically meaningless cosmetic tidying so i didn't feel like i needed to shower by just looking at it. One of my mates is the local panel and paint guy so I've had him look at it. Without doing a showroom fancy job on it thats about maybe 5-6k if im lucky. Also heres a hose someone put on.... basically filled with cheese Also the original brochures and ownership stuff from when the dealer got the vehicle which is kind of cool Heres an idea forgot who has this one but its similar to how I wanted to do one of my escorts. Like a turquoise teal with white.5 points

-

So a year and abit ago I was looking on trade me and someone was trying to sell a ford Sierra project and after looking and wondering I brought it next step was to get to the north island to get it ,so packed up the family and away we went and I got this!!! Its a Ford Sierra xr4i it has a 2.8V6 cologne engine the person I brought it off was going to make it into an RS replica so I’m going to continue with this theme4 points

-

Bort Malcolm fucking Cooper Simpson.4 points

-

Hiding it and fixing it are not the same thing Bort, you menace. bartdat4 points

-

4 points

-

https://www.trademe.co.nz/a/motors/car-parts-accessories/performance/turbos/listing/3080040716?bof=AdygKDSk4 points

-

4 points

-

And that's why you don't buy cars from Christchurch3 points

-

You didn't fix it, by the way.3 points

-

You've got lovely boobs. Not sure I like your girlfriends hairy chest though.3 points

-

Big mission today to get old motor out and get the new motor/box/clutch/etc assembled. I was thinking it would likely be best/easiest to drop the motor out the bottom, like I've done with MR2 in the past. However once the axles are out it's pretty easy to turn the motor 90 deg and pull it straight out the front. Ended up spending about an hour and a half playing Dentist, when the new motor and new box both had the same alignment dowel stuck in them. Took a lot of heat and CRC and filing some flats into it before the bloody thing eventually came loose. Once that was sorted I tried aligning the box onto the motor but it was just too dark and too tired. So will get that sorted tomorrow after work. I CBF with the power steering so I've been keeping an eye out for a manual rack Echo at Pick a Part etc, but havent seen one yet. Then one just popped up on Trademe so bought it. hopefully it isnt missing a UJ or something specific to the manual rack (probably is, and I'm stupid for buying this) "3 points

-

3 points

-

I usually tweak the handbrake so it drags, go for a thrash around the block a couple of times hard on the brakes then tweak again.2 points

-

id rather just weld it instead of a barry fix2 points

-

2 points

-

2 points

-

2 points

-

So I skipped a few picture updates. After lots of cleaning, grinding, filing, and making up a seat stay I tripped this off at the paint shop for sand blasting and a coat of black. I picked it up today, really pleased with it. They used chassis black paint which looks spot on in my opinion. Not to bright not too dull. I got the rims done at the same time so next thing to do is rebuild the wheels.2 points

-

Making slow progress on this whenever I can be bothered. The control panel is covered in leather jacket, and we have volts! I bought a kitset of a motorised chain similar to a tank track, and used it to create a motorised curtain. The curtain grinds its way noisily open and closed, which adds to the cheese factor. It's lit by some Christmas lights: Hopefully the lights in front are sufficient to stop lights behind from being visible through the thin fabric. I discovered that my plasma globe causes my neon bulbs to glow dimly, which is kinda cool. I hope I don't have to ditch the plasma globe because it scrambles electronics in its vicinity. Next up on this project is puzzling out what the rest of the controls should do, and deciding how much effort to put in. I'd quite like a magic eye VU meter.2 points

-

Bit more progress on this, Did some more panel beating of the front end, it had been chinned quite badly on the passenger side especially, and had a sharp bend just below the round bumper mount holes. Now its pretty even and roundedish, way better than before. Once the front bumper is on it will be hidden anyway. Again very finding very little rust holes, there is some, obviously, as well as surface rust, and there are a couple of tears as well, but its held up very well considering. Removed the handbrake mechanism so i could tidy up the handle, and the lower mechanism was scraping on the valance, so that all got removed for a clean paint and grease. its crossmember also got a light sand of the surface rust and a squirt of 'not quite body colour' spray paint as a test, pretty happy with that! Check out the factory cut out for the end of the mechanism, it as all chewed up around the tip of the pivot before Looked good, so did a bit more sanding Its starting to look way less shitty. Still shitty, just less I also got onto the brakes, i needed to pull the fronts to inspect and start parts hunting. 10" Aluminium drums front and rear. Check out the pile of dry dirt and grease i chipped off - its caking everything that pile is just off the backing plate. Ive only done the fronts so far, ended up having to pull the hub off, as the drum had differentially welded itself to the steel hub and the puny M6 spacer plate retainers that get moved to another set of holes were not going to shift it. Got it off in the end and its all clean and dry and no damage. Im glad the drums especially are ok they are simply NLA. Cylinders are rusted stuck tho but they are quite cheap, shoes less so (rears are cheap, fronts are $$$) I bought 16l of vinegar for about $24 and started chucking bits in after i water blasted them, ill check them in the morning. Someone had already taken one of the rear brakes apart already so i have those bits in a shopping cart already. The Brake and clutch master cylinders were already removed too, but praise be, they are not seized. The clutch master and slave is the same as my 2300 wagon, ie Lada stuff can work, so that's good. Im very very happy the brake master cylinder is ok. It is available but not cheap, because its a part that is shared with both Ferrari 330 and Lamborghini Espada, lol https://www.okp.de/xtc2/Ferrari/45-Brakes/Master-cylinders/Brake-master-cylinder-Ferrari-330-1-series-4-holes-flange::19478.html?language=en2 points

-

A whiles back I had a nice FD RX7 , and then I sold it, because of reasons. Always thought it was a silly thing to have done, so I have now un-done that decision... Sort of. FD's are in a bit of a bubble at the moment, with asking prices being sky high. It doesn't seem to me that many are actually selling at these inflated prices though... But, you can't argue that the prices on them are going up. I expect the bubble will burst at some stage and prices will fall to something more reasonable, but more than likely still more than I'd be willing to pay. I managed to do a deal with my former employer, High Performance Academy, (whom I still do work for on occasion, they're awesome guys ), to acquire this: They had purchased it to use for their tuning course, as a worked example on a rotary engine, but it just wasn't tidy enough, and would have taken too long to get there for their timeframe. They ended up purchasing the white FD I owned at the time, which was good to go for their needs. Towed it home (Christchurch) from Queenstown last night behind my 3.0TDI A4. Only a little dodgy... But actually towed with no problems. No scrubbing / scraping, and no weird handling, basically didn't know there was anything behind the car, except for the increased fuel usage and lack of usual grunt. Max slam. Spent this afternoon cleaning. So much dirt, bird shit and sap. The cover had blown off the rear corner, and because it was tucked away, no one noticed. Paint is a bit marked (it's had not completely shit re-spray in the original red), but it'll buff out. Plan for this is to tidy it up, replace the interior (most of it is thrashed), and get it going again on some factory(ish) twin turbos. I love the quirkyness of the sequential twins, and I know them inside and out (literally) from my time with my white car, so keeping those is a must. Most of the parts to put it back together are with the car. I'll be doing some hunting and scrounging for sure though. The wiring is roooooooted, but luckily I know a guy. This will probably take priority over the Starion, as it needs much less work, will be good to get it to a nice driver state. HMU if you've got a stash of parts! ;-).1 point

-

Need a ute to carry moulds for the engine project. So I got a 67 El Camino. Picked it up in Tucson and drove it back to CA without too much stress. Has the original 327 with camel hump heads and a modern (/80s) 700r4 trans. Ton of things to sort to make it a daily. Like it doesnt run very well! Timing feels off or vac advance isnt working. Carb seems way too big. It looks good from a distance but dont let the fool you!1 point

-

1 point

-

1 point

-

90s wingroad so same bloodline1 point

-

New engine is home so finally got a chance to look it over...... its fucking filthy! Power steering hoses must of leaked forever and they just topped it up. Cool stuff though after a casual poke around. Billet mace engineering oil cap cheesy but cool, A mace modular blower pulley setup has been fitted so its a piece of cake to change sizes/boost Egr delete has been done on head fully gone! New looking water pump, belts and rear main seal have been done recently. It came with the pcm bcm and ignition key so i could potentially just slam it in if its compatible with my cars body loom. The Meh stuff. Doesn't have the flexplate as it was a manual. theyre balanced different to the ecotec I'll ask around i may be able to get my ecotec one balanced to suit i will be using an ecotec transmission anyway. Not end of world. Loom has some twist and tape joins on the trans section of loom easily reversed but the pcm will have to have had some reflash to allow the manual to work. The exhaust manifolds have lots of snapped bolts..... it obviously had headers which they kept.1 point

-

I'd you wanted to make it from scratch you would really want a shrinker stretcher, some wooden mauls, a shot bag and a good assortment of hammers and dolly's. And a bunch of time Here's how I would do it Start with an over sized sheet of steel Put your main bend in it (area below the cut outs) Pin that to my workbench and fold it over a pipe to get the curve for the section with the cut outs Put the upper section bends in So now you have a "2d" copy of the panel with curves only going up and down (no complex curves going in 3 ways yet) Then I would work along the panel and start stretching in here and there by hammering on dolly to give the panel its general curve. But more work with a shot bag for the more bulbous ends. Will also need to shrink the flanges on top and bottom Cut the holes out and hammer and dolly the folded lips. Some might make more sense to weld. Probably just fix it unless it's worse than it looks?1 point

-

1 point

-

Yeah with the Carina, even swapping from a height adjustable column to one that isnt, absolutely bloody everything was different haha. It was also weird that my new gearbox had no speedo drive, just a blanking plate for it. But then thankfully it still had the nylon gear inside the box, so just plonked the other speedo drive in. It would have been a right bastard if that nylon inner gear wasnt there haha. It must run the speedo signal from the ABS unit on the NCP13 model. Maybe because with the big block 1500 motor you're doing too many hectic skids all of the time to rely on the front wheel speed as being accurate.1 point

-

1 point

-

1 point

-

They say the two happiest days of Birtish car ownership are the day you get the car and the day it leaves your life. Well the other day it left my life (at least for now). My dad is taking it on a long road trip. He is taking it to Auckland, via the bottom of the South Island. They're staying at Lake Hawea tonight. I think their trip will be complete by around about the 15th. Hitting the road: Somewhere in Mt Somers I believe: Lindis pass (actually surprised it still ran up there): He insisted on taking the roof rack with it. I bet it uses 25% more fuel now. When it gets up to Auckland my brother will paint it and we will try to track down the few remaining bits that it needs to be complete and then will stick it on the market. I'll keep this updated as the photos from the trip come through. Feel free to add any spotted photos if you see him on the road.1 point

-

So much hate in here, I can't even tune a carb, let alone tune an engine with EFI that wasn't setup for it. Go work on your cars, the lot of ya.1 point

-

I just put alloy spool of wire+ matching size tip in normal mig welder+handpiece. has rolls with different knurl for alloy I think/maybe/cant remember. Plus pure argon for shielding. It works acceptably but its suited more for thicker/structual type stuff because you end up with not enough heat to start with, or enough to start with but it gets too hot quickly. so difficult to make a nice job of anything that is only a short weld. Also you are relying on the arc to blast the oxisided layer off, which with mig means wire going so this also is a factor in shitty starts to welds unless you can run higher amps etc. (i.e. thicker materials) The other tip with using it in a regular mig is to keep the torch lead as straight as possible. I never had any issues with brids nests etc. just the aforementioned limitations of the setup1 point

-

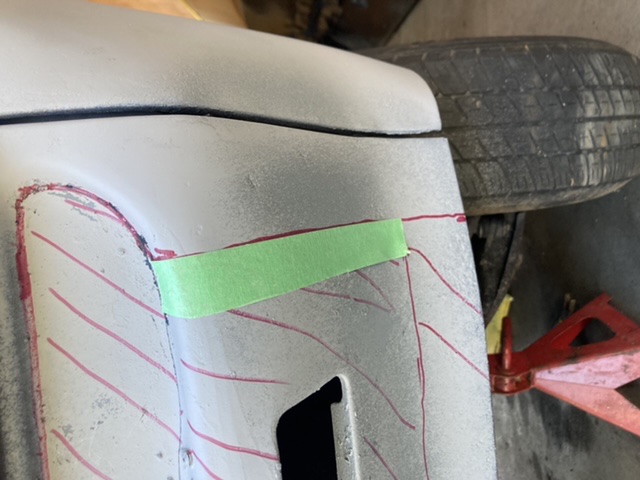

car went to the paint shop to get the runs out of it and get the final cut and polish. i went and picked it up last night and it looks amazing. anywho, today i wanted to fix the exhaust where the flex joint had worn through because its the lowest point and its had a fucking over judder bars and whatnot and subsequently has a hole it in. step 1 - jack up your car. this is where things went wrong. 2021-04-25_02-55-42 by sheepers, on Flickr car slid off the jack on the way up. given what could have happened i got off extremely lightly. it bent the radiator support up and bent the bottom of the radiator real bad. it also bent the bottom of the front bumper. however, the radiator isn't leaking and the crank pulley is unscathed which is a fucking miracle given what happened. i was able to bash the rad support back down and i got most of the bend out of the bumper so it looks fairly normal again. fuck it could have been WAY worse.................. so yea, after dealing with that i moved on to fixing the zorst. cut out the fucked bit, made a new bit, tacked it in place, remove zorst from car and fully weld, add 4mm thick bash plate and put zorst back in car. 2021-04-25_02-55-49 by sheepers, on Flickr 2021-04-25_02-55-55 by sheepers, on Flickr 2021-04-25_02-56-02 by sheepers, on Flickr 2021-04-25_02-56-09 by sheepers, on Flickr 2021-04-25_02-56-21 by sheepers, on Flickr then it was time to wax the newly polished paint. that went well. it looks pretty ace tbh and yea, i cant take a photo that justifies how good it looks. but it looks good. take my word for it. 2021-04-25_05-34-27 by sheepers, on Flickr 2021-04-25_06-18-48 by sheepers, on Flickr 2021-04-25_06-19-23 by sheepers, on Flickr 2021-04-25_06-32-09 by sheepers, on Flickr1 point

-

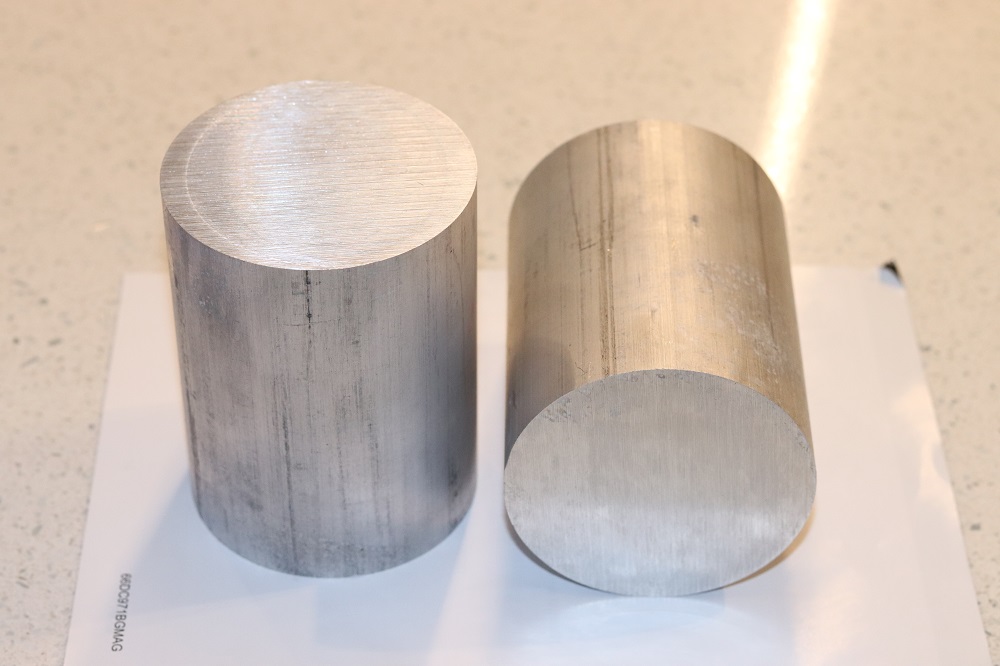

Six months since last update, feels like a year... Spent the last four months with a new member in the family so car time has suffered accordingly. Will keep it brief with a few pics. Have been working my arse off the last week or so to get the car back together. Lots to still do, but I finally have a window of time to get things done, so I have to get it done. Last update ended with lack of clearance between strut and wheel. It was the locking nut to be exact. I spent a long time working out spacer requirements and longer wheel studs needed etc. Problem with spacers is that it shifts the wheel closer to the guard, which I can't afford to do, so I had to come up with another solution. I worked out a design and showed cert man and got the green light. Had a word with Anton @ajg193 and he did a proper drawing of it. He then set about filling his garage with aluminium swarf and made me the parts. I then had them anodised as per @mjrstar's recommendation. The whole design was focused around moving the locking ring further up the strut as due to being angled inward, this would provide the clearance needed without shifting the wheel with spacers. Bottom section has internal thread to match the shock body, Anton did a great job. Installed Gave the rear 1/4 frames another lick of paint or two where the trims will be, to offer a bit more protection. Removed all of the sticky shit off the frame and windows and glued them back in. Then it was time to start putting the interior back in with the new belts. Previous to that though, I spent give or take a day installing all the moving windows in the car, aligning the doors and then adjusting the windows till they operated correctly. I've got them pretty good, but I just don't have the time to get them perfect right now. If they even can be given the seals are all poo and the panels don't line up due to a hit. Happy with the end result though, even if it's not close to waterproof lol. Thursday: Friday Saturday That's where I am at for now. Some up and coming jobs: Install brake master cylinder, make brackets for front hoses, diddle with the handbrake cables, eyecrometer the alignment, organise windscreen install, fit plastics / door cards up front blah blah, too many other things. Thanks for playing.1 point

-

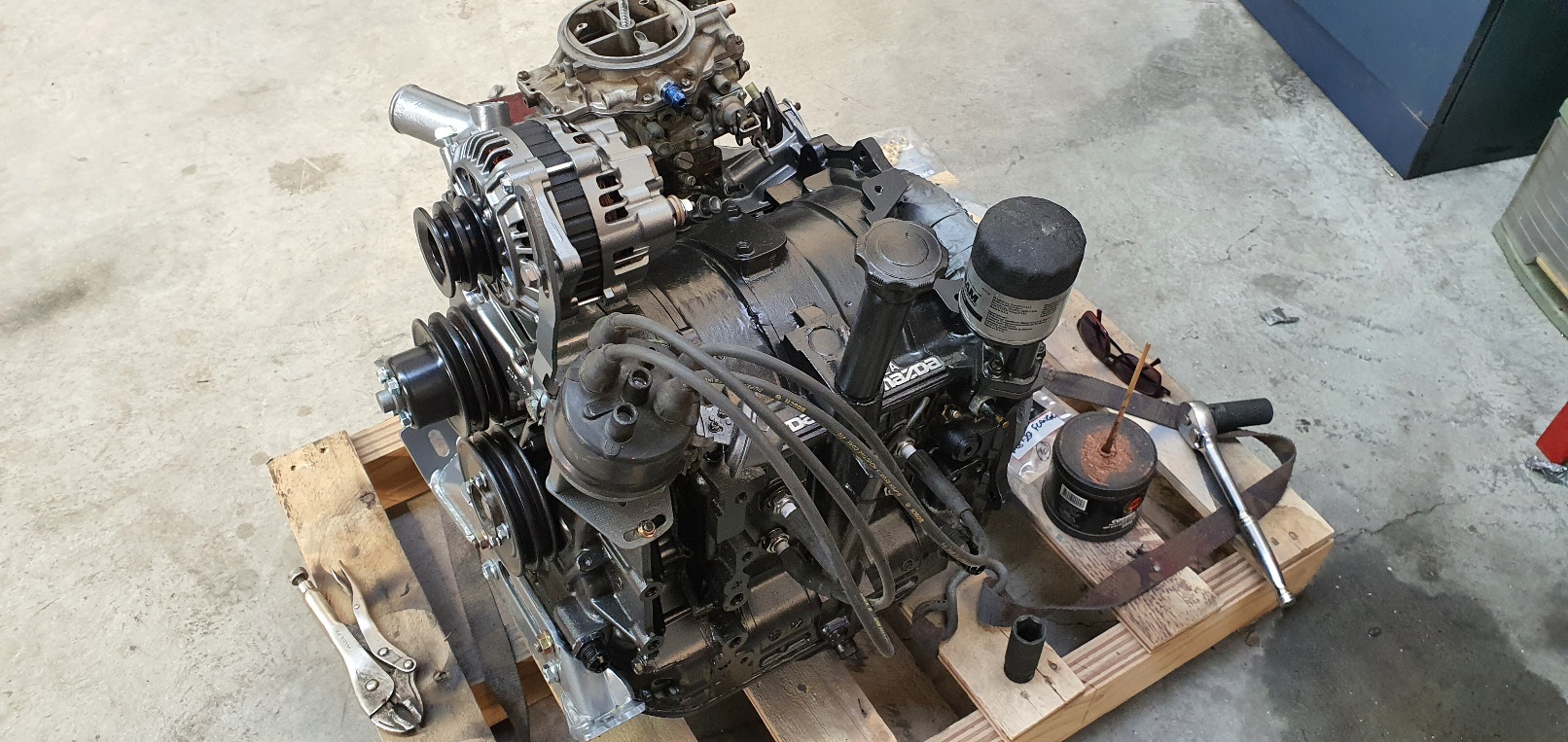

The Sigma has been sitting around a bit. I drive it every so often but it's kind of underpowered compared with my Aussie 6 cylinder stuff and I really wish it wasn't. I have been toying with the idea of repowering it but I thought I might try to liven up the stock engine first. A buddy of mine dropped this off over the weekend. I really have no idea what I am doing but that has never stopped me in the past. What could possibly go wrong?1 point

-

First thing I did when I got home was pulled the speedo cable out and cleaned it. Now the speedo doesn't jump around any more. Second thing I did was drop one of the screws holding that mirror onto the door into the door frame, never to be seen again. Third thing I did was lose the keys and then successfully use the Starlet's key on it. (I found the keys again, but left them at home after) Then I went to the fuel station and found the Starlet key doesn't work in the fuel cap. So I'll fill it up tomorrow.1 point

-

1 point

-

Fast forward half a decade, and not much had changed. I put microswitches into the cupboards so that the lights actually turn off when you shut the doors, and I continued puzzling about what I should put in the radio hole and how I should control it. I decided I wanted a retro-style control panel, so I tried to make one out of a piece of wood covered in the vinyl wrap from the guitar amp case. I got to this point and decided it was rubbish and unable to be saved: One of the problems (besides using wood, the wood being too thick, me not having a drill press to line up the holes etc etc) was trying to sit that modern-style voltmeter behind the panel to hide its age. So I went to Kumeu and bought a voltage gauge from an old car, and started on version 2 of my control panel. The panel was always going to sit in the top of the cabinet somewhere, but I thought it would also be cool if it rose up automatically when you opened the lid, for no good reason. So I bought my first linear actuator, in giant overkill size, without thinking it all through too much. Here is the mock-up of control panel v2 in its raised position. All of the stuff is just sitting in place and is not wired up. I'm gonna cover the panel, most likely in leather, then I'll start deciding what all the switches do and wiring them up. I'm basically an electronics magpie, and over the last few years I've been buying any shiny things for this project that catch my eye. I can't be bothered acquiring the knowledge to create anything too clever with them; I'm just aiming to create a simple retro/steampunk-inspired display that's hopefully not entirely lame. After all, it would be nice if this project actually got finished within a decade of being started....1 point

-

Boring update but will add it for my own records Got drivers window sorted Got headlights working Got seatbelts, rear 1/4 interior pieces and rear seats back in. Spent forever getting the boot popper in and working properly. Probably could have done a engine rebuild in the time it took to get that thing working smoothly. A couple of photos of the boot popper for storytelling appeal. Then I got it out and went for a dodgy, green stickered, no wof, no cert drive around the local industrial area for about 15 minutes to iron out any issues and get a real feel for it rather then 30 seconds up the road and back. Everything went really smoothly. The last noise left seems to be universal joints in the driveshaft. Will dig into those shortly. When I first bought it and put the engine in the brakes were absolutely useless, I couldn't fit in the car, the fan belt slipped and kept throwing itself off, everything mechanical was hitting the body, the handbrake cables were rubbing on the driveshaft, there were no window rubbers, the boot popper only worked occasionally, the steering wheel was so small it was a struggle to turn at slow speeds, the accelerator pedal linkage was a disaster and wouldn't pull secondaries and the trim paintwork was all falling apart. When I remind myself of all this I realize how far I've come in a fairly short time. The car is now really comfortable to drive for an old girl and although far from perfect I'm not scared to drive it. Anyway, enough of this. I'll keep moving forward with things slowly and hope to have it legal for next summer.1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.jpg.ae57da8783184aab564dd3323a1c4541.jpg)

.thumb.jpeg.910c6632f6e66e8cba89476e83b41634.jpeg)

.thumb.jpg.9145a1fc1bbd1c5ed45a557805396d6b.jpg)

.thumb.jpg.b0448f15aed133fb1c2d7e022dd0a706.jpg)

.thumb.jpg.30d3d7a0c8f168c56f6ec3ba6fc82e4f.jpg)

.thumb.jpg.71c0d6e0954268f9941d7cb3f2c8ad5b.jpg)

.thumb.jpg.3b44b76e73220f1a2bef01760a9ebdc7.jpg)