-

Posts

355 -

Joined

-

Last visited

About 1963 AP5

- Birthday 19/07/1978

Profile Information

-

Gender

Male

Converted

-

Local Area

BOP/Central

Recent Profile Visitors

2,884 profile views

1963 AP5's Achievements

Advanced Member (3/5)

1.3k

Reputation

-

I ran the standard 210 secondary jet and the AFR was pretty good. 210 seems like a really big jet but the secondary venturi on a weber 34 is much larger than the primary so you may not get a large pressure drop in the venturi. I think that's why Ford used such a large jet to get the fuelling correct. I'd give it a go with the standard jet, and you can always play around with it later if you need to.

-

Hi there, sorry it seems I haven't caught up on this thread for a while. I removed the 2-stage idle jet, and you used to be able to buy a larger jet holder from Weber Performance in Australia that would fit in its place but unfortunately, I don't think they are available anymore. I think the large jets are still available, but I think you would need to make a jet holder to suit. I used the standard primary and secondary jet, and it ran very well. Pay close attention to the power valve port and operation of the power valve as this is one of the reasons that these carbs run rich when installed on an adaptor plate.

-

Looks like the large jet holder is still available overseas Primary Idle Jet Holder for Weber 32/36 DGAV, Large Size - Pegasus Auto Racing Supplies 52570.011 - Jet Holder LARGE fits Weber 32/36 DGEV DGV DGAV DFEV DGES (carburetion.com) and Weber Performance in Australia still sell the larger jets to suit the 34ADM. DGAV DGAS ADM Weber Carburettor Idle Jet (larger primary) Weber Performance Carburettors Have a look down the carb barrels on a 34ADM, you will notice that even though both have 34mm butterflies the venturi sizes are very different between the primary and secondary. Insufficient air velocity through that big secondary venturi can be a problem on small engines unless they are fairly heavily modified and screaming. The carb is really designed for larger capacity engines (4.1L Falcon) but was a popular swap for modified engines with smaller displacement simply because they were cheap and plentiful back in the day. Mine works great on a 3.3L Holden 6. I have never tried one on anything smaller but I have heard of people having success with them on modified 4 cylinder engines.

-

You are correct, not all 34ADM's have the 2-stage jet, only the ones that were equipped with emission control gear. The 34ADM has a very large secondary venturi and I think that is why it uses a very large secondary jet. Some small engines struggle with the Weber 34 because they simply can’t get enough airflow through the secondary venturi to make it work properly. For this reason, the 32/36 is often a better option for engines under 3.0L. I believe the secondary venturi is actually smaller on a 32/36. I have never actually worked out the fuel economy on the Holden, but I expect it is similar to the original Rochester carb (certainly no worse). I think the Weber is more responsive than the original carb but to be fair the original wasn’t working properly and that’s why I replaced it with the Weber. I simply couldn’t get a kit to overhaul the original carb so the Weber conversion was a good option. It’s been running trouble free with the Weber on for around 5 years now.

-

Thanks for your kind words. The second link was for a special large jet holder that fits in place of the original 2 stage low speed jet solenoid assembly. They used to be available off the shelf but maybe there isn't enough demand anymore to keep making/selling them. It is possible to make a suitable jet holder if you measure up carefully and have acess to a lathe.

-

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

1963 AP5 replied to tomble's topic in Project Discussion

Here is an example of a transmission with the Starion extension housing fitted. Between the N/A transmission that you already have and the wide block turbo version you should have everything you need to make it happen. -

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

1963 AP5 replied to tomble's topic in Project Discussion

A few pictures for you, looks to be in reasonable order You will need to swap over the extension housing from your N/A transmission to get the shifter position correct for the Starion. -

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

1963 AP5 replied to tomble's topic in Project Discussion

Nice, it's all yours. If you don't have a use for the N/A narrow block flywheel and clutch, I can give it a good home. I have a feeling @MaxPower may have the flywheel that you need for your wide block turbo engine. He has a fine stash of Mitsubishi goodies so it might be worth touching base with him. -

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

1963 AP5 replied to tomble's topic in Project Discussion

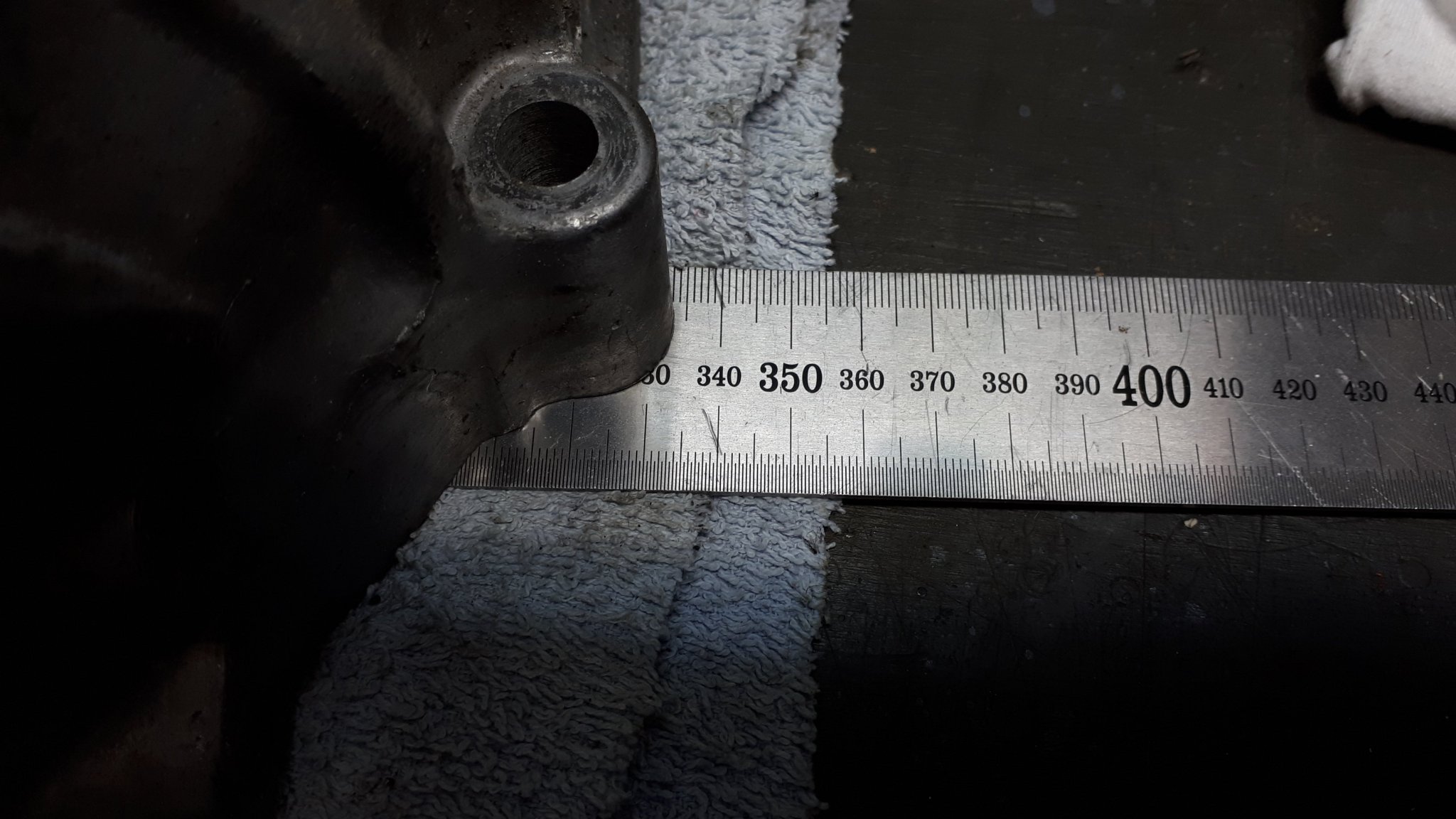

This might be helpful; you can measure across the bellhousing at the lower bolt location to see what you have. The photos below show the difference between the transmission found in a lot of N/A applications and the turbo version. -

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

1963 AP5 replied to tomble's topic in Project Discussion

Hey just a thought and maybe you have already thought of this but your N/A transmission may not work with the turbo engine. I believe that N/A engines are often a narrow block design (but not always) while the turbos are a wide block. The bellhousing may not bolt up to the turbo engine so it might pay to do some measuring to see what you actually have. The gear ratos are also diferent for the turbo engine. I have a transmission under my workbench that I believe is a wide block Turbo Starion item so let me know if you want to grab it. Free to a good home if you are willing to collect or ship it from Matata in the Bay of Plenty. -

Mr.mk1's Mopar or No Car '70 Dodge Coronet

1963 AP5 replied to RUNAMUCK's topic in Project Discussion

When I first started following your build thread I have to admit I thought you were mad and there was no way the car would ever see the road. It seemed like a basket case. It looks like you are well on the way to proving me wrong so well done. This is going to be an awesome car! -

For what it's worth I like the Hotwires, I've never seen a Mustang with Cheviot wheels on it before and it makes me smile. Gives it a down under feel! Loving the car - well done so far!!

-

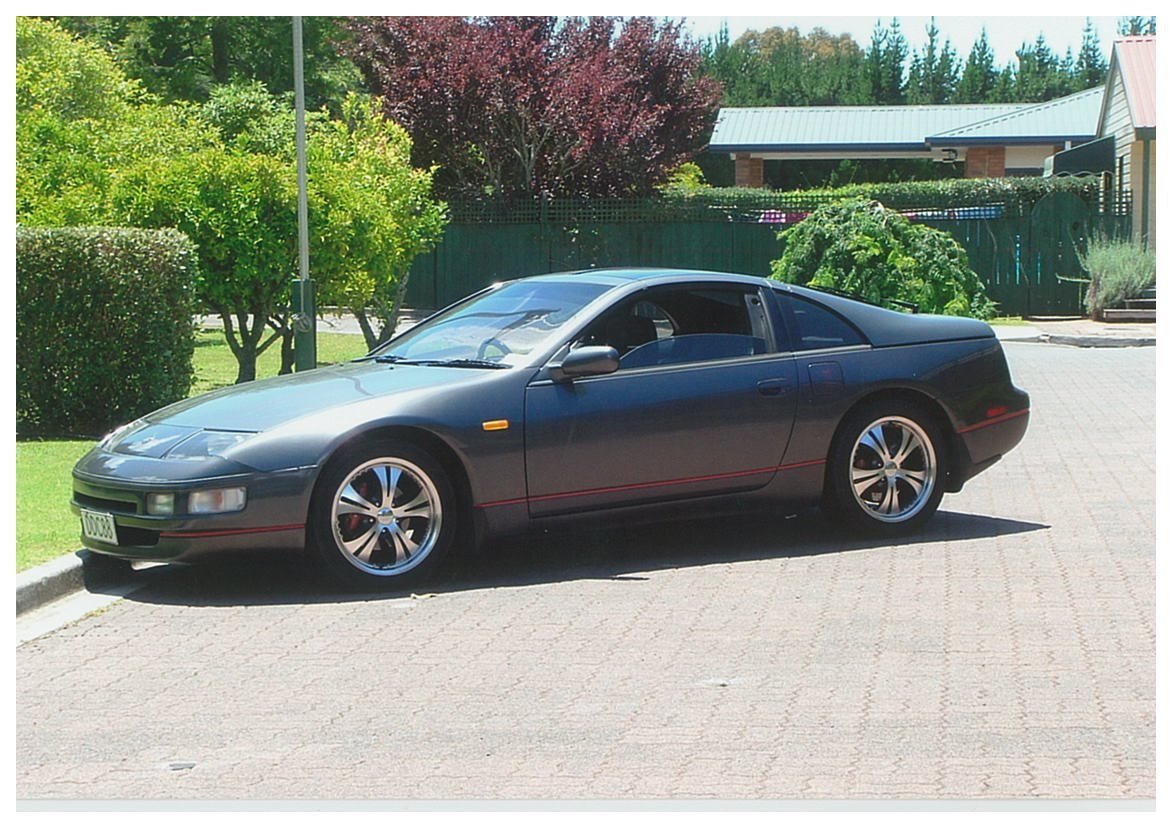

Mate good score! I used to drive a Z32 2+0 T-Top back in the days before kids arrived. I want another and I am pretty sure in my case it is definitely a midlife crisis thing This was my one

-

Yep I have certainly run it at WOT. I have my doubts about the accuracy of the gauge, you can see in the picture below that it doesn’t sit at zero without the engine running so it is probably under reading by a couple of pounds. The real number could easily be closer to 7.

-

Well here it is the first run! I have to say I am impressed with the Holley throttle body fuel injection system, the set up was simple and the engine started first turn of the key. It drives pretty well and I expect it will only get better as the self-tuning software dials everything in. Currently only making about 5 pounds boost but is already a huge improvement over the N/A set up. I will run it for a while on low boost while I get the tune sorted and then install the 15% overdrive pulley to see what happens.

- 30 replies

-

- 22

-