-

Posts

342 -

Joined

-

Last visited

AALAWS's Achievements

Advanced Member (3/5)

1.2k

Reputation

-

She's alive! 100kms into bedding in the new rings and she is driving super nice. There's no tinny rattle coming from the loose turbo heat shield and there's even a rattle, that I thought was coming from the front suspension, that's gone so that's a win. WOF and Rego'd, aircon regassed and ready to cruise - but I do feel like a bit of a plonker having to rev it at intersections and not let it flat idle (engine rebuilders recommendation) but oh well. I should be able to get a good drive in this week and chew through some kms. Then when the oil and filter get done I'll put on a new crank pulley (squeaky and delaminating) and a few viscous fan clutch. The rest of the 'to tinker with' list is: Wheel alignment Cut and polish New radiator pipe bracket Fish oil rad support and refit front mudflaps and new bolts/clips for lower fender and inner fender liners Repair drivers seat Repair shrunken vinyl on T-Top trim and in back seat New clock Repair centre console lid Fix rattle from windows Tighten up door latch's - not perfectly flush Repair cracked boot plastic Secure sub When $$ Allows: New Wheels Closed door respray - fitting new windscreen, mouldings, quarter glass and door glass trim and Targa seals.

-

Finally arrived..... Fitted and off to get the donk the hole with a shiny new pink heavy duty clutch

-

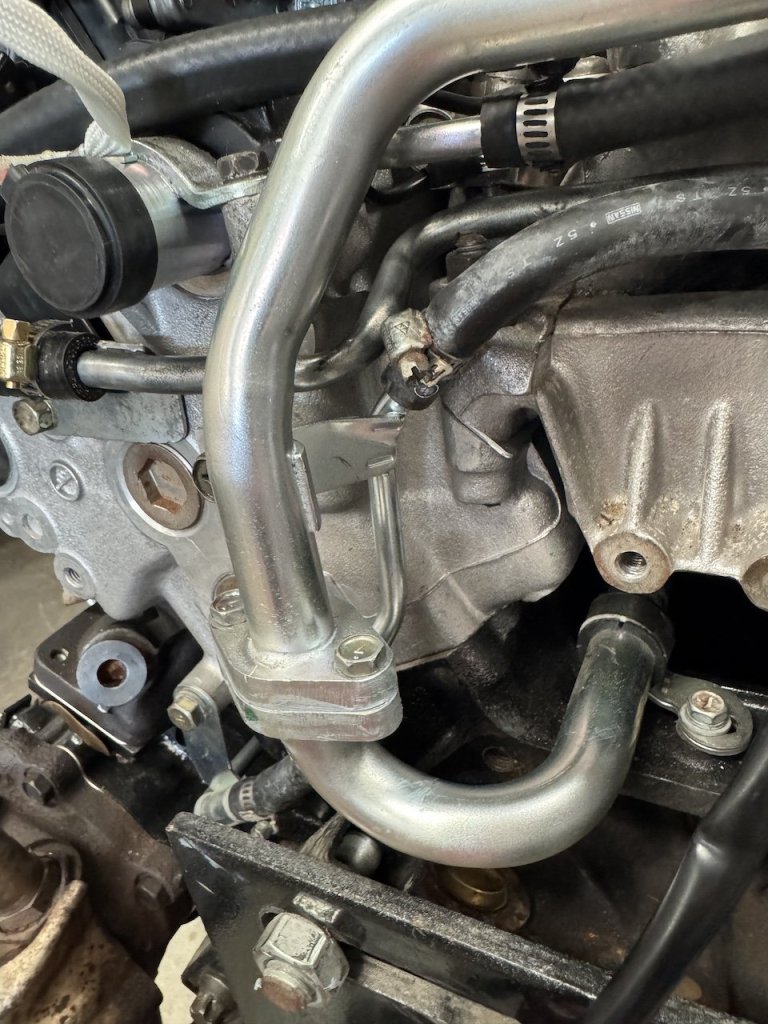

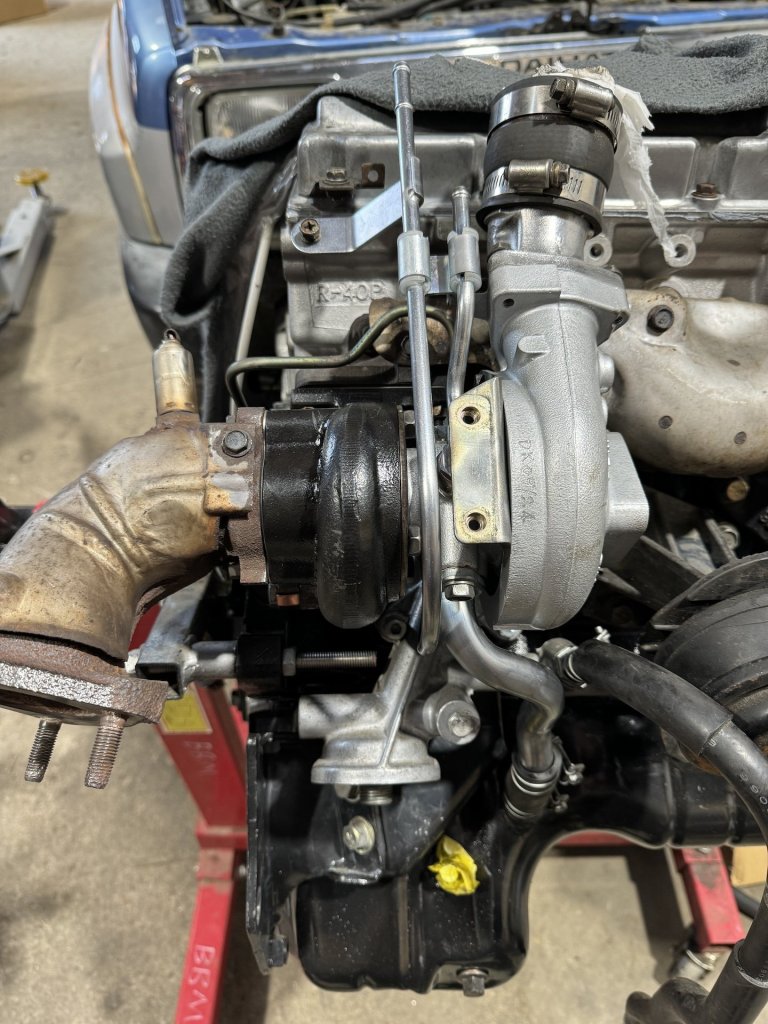

Put on some new studs and got the turbo's bolted on only to discover that there was a gasket missing for the intake - only another delay...but they eventually arrived with a few other little bits and pieces. Got some reconditioned injectors from Oz which saved a few $$ and got them fitted along with some new VTC valves and an EGR delete kit. I also replaced all the fuel hoses and a bunch of water pipes ect at the back of the block. Gave the plenum a clean up and replaced the gaskets for the throttles and AIFF too. looks like at some point someone spilled some resin or epoxy on it but managed to remove most of the visible stains. Now i'm just waiting on one more pipe and she's ready to be refitted back into the car!

-

Turbo's rebuilt and drivers side fitted - only snapped one manifold bolt ha ha.....waiting on a new set for the passenger side

-

Bottom end got a total overhaul with new .5 OS pistons and rings, and the heads got tested, machined and a whole bunch of new bits thrown at them. Timing kit all done and turbo's are off getting tested. Slowly putting her back together in my spare time, replacing bits where I can.

-

Next she was off to the body shop to get a dent out of the sill, the crushed sill joins straightened out and the radiator support replaced. So these are all fixed up and good as new again - the paint is so new it sticks out so might look at a quick closed door respray once it's done.

-

Well it happened sooner than I thought it would but that's life. Back in....holey shit, September 23, I had to pull the engine due to a head gasket failure so it was time to refresh the whole engine. Definitely needs 'more low' with the running gear out Started stopping it down, going through everything to see what was needed and making a list.

-

Car made another trip to a local metal magician to sort out some small dents and panel gaps. The fenders are aftermarket so needed some decent tweaking to allow the headlight surrounds to sit nicely and line up with the bonnet. He went to town with the hammer and file, cut out the inner door frames to get to the skins and pretty much tightened up the whole front end. I had to ask him to stop as it was getting pretty spendy - I have an engine rebuild going on at present on my 300zx too, the rest can get a skim of filler here and there. It's back in the shed, should be getting the final lot of body work and getting the interior and engine bay painted very soon.

- 72 replies

-

- 18

-

-

POST THREE of Three: I got some thicker heavy duty shrink wrap of a sparky mate to be the dust cover on my outer steering column - looks pretty noice. Fitted my new smaller brake booster and master, clutch master. It's pretty dang close to the strut tower, but a little manipulation of the firewall should pull it out a bit more. Fitted the steering column dust seat and the outer column along with the new hydraulic pedal box.......all fits very nice. Once the steering box is in it will be ready to roll/steer and the final panel touch ups/flare fitting can be done before I figure out my plan/$$ for paint.

- 72 replies

-

- 16

-

-

POST TWO of Three: Also gave the dash area and inner firewall a coat of black - having it body colour means potentially having some orange showing through. So like the front headlight panels, having it black makes for a better finish IMO. It was then time to modify/recreate the firewall panel to account for the new hydraulic clutch and brake booster mounting holes. Took the old one and marked out a new one, added a few new holes, a lick of paint, reattached the insulated backing and we're away...

-

POST ONE of Three: I have two steering boxes so i stripped one to get the gist of it, cleaned it up, bought a few new seals etc, gave it a lick of paint and it'll be ready to go once I set the backlash and fill it with oil.

-

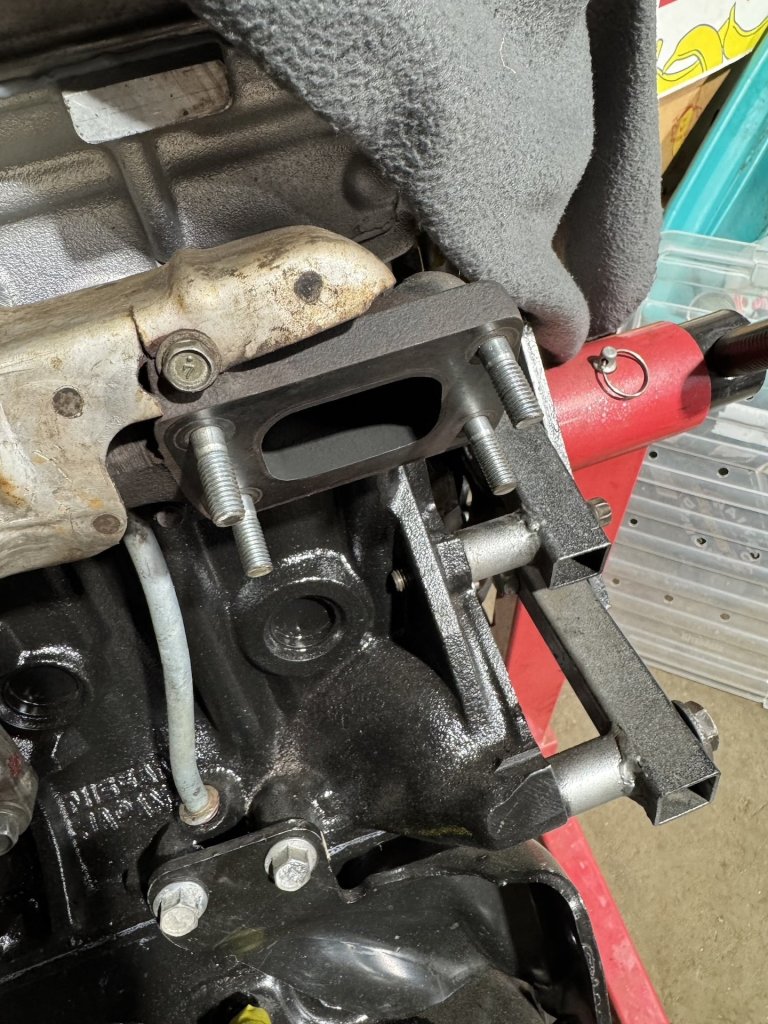

Now to list ALL the things I have done to this in the last 6 months......not much. I've struggled for motivation due to many things, but am starting again with a little by little approach. I've wasted too much time trying to figure out the perfect plan and what to do next, then second guess myself and think "oh this needs to happen before I can do that, but then I'll actually need to do this first" and so on and so on around in circles. I've avoided doing stuff because I don't want to do things twice, or keep taking bits on and off, but today I just said stuff it - just do some stuff, little by little and get moving. Today I simply fitted my doors and fenders and made a plan for a few other things. over the last few months I have achieved this: 1) Turns out the crossmember I purchased years ago with the modified mounts for a 4age were actually completely wrong! My reconditioned AE86 engine mounts and brand new cusco mounts will now be up for sale....so I cleaned up a factory crossmember I had and fitted it with the KE Conversions kit. 2) tyres kept going flat, fitted some inner tubes 3) cleaned up and primed the inside of my doors 4) bought a parts gearbox to swap the tail section onto my T50 - this is to maintain my factory shifter position and centre console. 5) cleaned up and painted a petrol tank 6) cleaned up some fuel lines next, I'll order my flares, get my steering box rebuilt and then start fitting the dummy engine etc to see what firewall holes/brackets are needing modified deleted etc.

- 72 replies

-

- 17

-

-

Gave it it's first real shakedown a month or so back. Drove it fairly hard out to the coast, could have been harder but was wanting to be a bit conservative with her....... I got to 10 mins out of Kawhia and she spat all her water....bah!! Found some water and nursed her into town and then eventually back home. Diagnosis was a loose hose, not one I had touched previously, and a possible crack in the overflow tank which turned out to be nothing. On to the good stuff - picked up these mufflers cheap. A local oil rep had them for years and wanted rid of them - he bought a crashed Z to turn into a stock car and the previous owner had only just fitted them so score! Gave them a polish and fitted them - nice change to the sound right away, got that nice burble when you come off the gas. More Gran Turismo goodness.... Also fixed my rattles in the cabin......kind off.....decent stereo and speakers to drown them out. Out with the old. and in with the new Just need to figure out how to keep the sub from moving without doing any obvious damage.... Velcro doesn't get a decent grip/work on the carpet and the targa straps don't work......any solutions fellas?

-

I get a bit of this with the high idle when cruising through town and it feels like it drives a bit by itself...

-

This is how it sits at the back of the engine - I'm assuming air flow is from right to left so would you remove the hose between the air regulator and the IAA unit or bypass the everything from before the air regulator? The throttle cables across the plenum seem pretty good - the throttles were closing up nicely when disengaged if that's what you mean?