Leaderboard

Popular Content

Showing content with the highest reputation on 19/09/20 in all areas

-

4 points

-

4 points

-

I've started collecting and making parts for this POS, to convert the rear to independent suspension, upgrade the front to the braked hubs, and get long travel shocks all round. Bits for the spool/centre drive thing, new taper lock sprocket, front disc off a CB250, and a flex plate and starter from a MAZDA 3. Also a 30mm shaft and bearings for it to live on, I got some MX5 axles and hubs too. The axles are quite small and light, and have a flanged end, so perfect for this, The chunk of hollow bar is to make new hubs, as the MX5 hubs are too big to fit in the quad bike rims. So I machined up some hubs that use the MX5 bearings, and will make doofers to connect to the suspension arms. I also made some adapters to go from the MX5 4x100 pcd to Yamahas ATV 115x4 pcd. I found some I had started making (can't remember what for?) out of 6mm plate, so hopefully they are strong enough, I also got a few 16 and 20mm rod ends for the front end, as that's how the barracuda hubs attach, Still lots to do, but slowly chipping away at it.4 points

-

3 points

-

I've brushed it quite a bit on repairs. Less cleanup that using a spray gun.2 points

-

You can roll it on with a nook and cranny roller using the fine felt or sponge cartridges. Got a mate who's in the industry and they do it that way sometimes (when someone else's in the both) comes out pretty good apparently..2 points

-

Yeah, sorry, I wasn't paying enough attention. I saw etch but I was actually thinking epoxy in my head. Derped it up.2 points

-

I got some in. Here's how these ones actuate the handbrake mechanism ... 1st 2 pics of what they look like with pads fitted. These next 3 pics are taken with pads removed and the handbrake levers showing their movement. Basically each lever presses against the steel backing plate of each pad moving them against the rotor. Might talk to @Taistormsometime about how to go about the handbrake setting up if I can't figure something out myself. But yeah, this is how the Wilwood Powerlite handbrake setup essentially gets it done.2 points

-

Two part filler will react with single stage etch primer and it will fall off in the future, trust me.2 points

-

I mean, I could be wrong but that's the theory I use. Filler can trap and absorb moisture so I figure protect the steel, filler, sand, respray more epoxy if you rub through then sand and filler prime then sand then top coat2 points

-

2 points

-

Another 2 done. Worked well. I think 4 paper weights is enough for now. Time to move on to something big! For reference of where it goes. Houses cam gearing.2 points

-

2 points

-

2 points

-

1 point

-

That's my understanding. 2 pack epoxy on bare steel, sticks like shit to a shovel and seals it, then fillers etc...1 point

-

The market and information is all fucked up for the hobbyist car painter. The professional grade manufacturers really don't want you using their shit, you will most likely use it wrong and its kind of a dangerous good. The parts stores can't really fork out 2 part paint to every retard so they sell cans of paint technology from years ago, there is no system, no real data sheets its crap. Add all that up and you have a toilet of information. Go watch what a body restoration guy will use, all 2 part products that we mention on old school twice a week. You can do everything with 2 part epoxy primer, seal metal, seal your bog (under and over) , you can wet coat it, you can brush it on, it doesn't sand very well but you can block out for a top coat on it if you wish. It doesn't have isocyanates like Urethane paint so its not deadly. It is the staple tool in doing any body work on a car. Etch primer is old as fuck, it doesn't seal anything, you do not bog on it. throw it in the bin.1 point

-

1 point

-

Fuck it's beyond great that this little fucker is running and driving again and so massively upgraded to Richie standards. So. Fucking. Good.1 point

-

You can bog over 2 part epoxy just fine, if you are buying a modern filler like evercoat etc it does not trap moisture and the data sheets say its fine to use on bare metal. Just epoxy prime it after you have done the work don't drag it out and leave metal and filler open to the world for ages. Either filler on bare metal or over epoxy primer, then seal it up with epoxy. If you use any single stage paints I will stab you, rattle cans go in the bin.1 point

-

1 point

-

Etch prime first so there's a barrier from moisture against the steel.1 point

-

1 point

-

Can tell Trev's middle name is Barry by his use of an adverb in front of remember.. Either that or he's a boomer, prob both.1 point

-

1 point

-

I'll park my car right at the end of the drive to keep everyone on the road.1 point

-

1 point

-

1 point

-

1 point

-

And today the bulkhead connector has arrived. So stoked to have this piece of gear.1 point

-

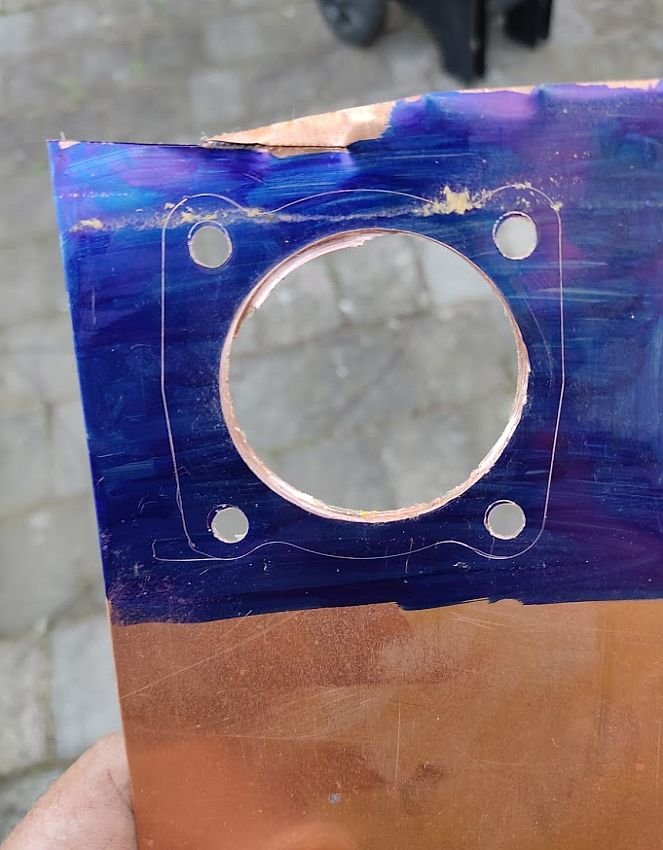

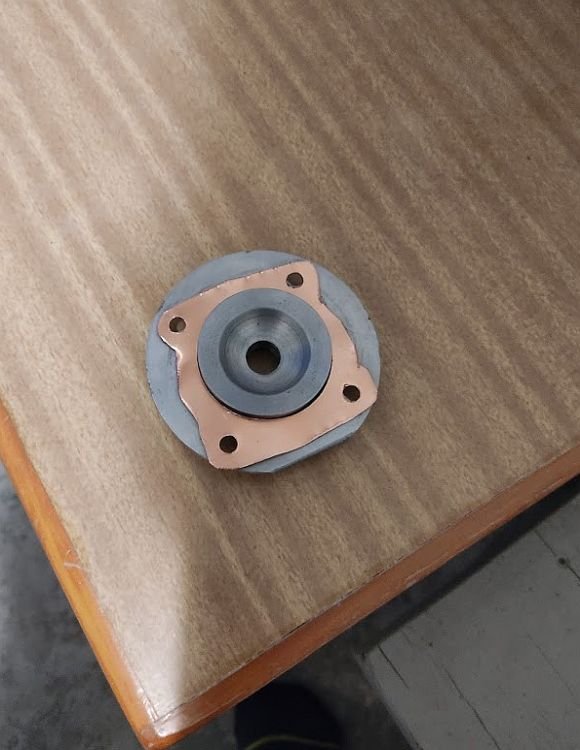

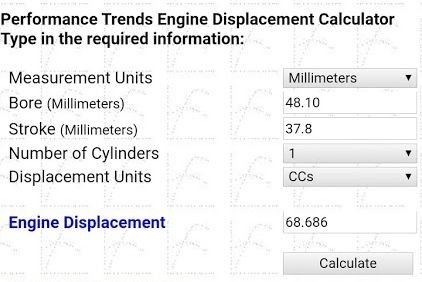

Genuine Suzuki base gasket I removed measured up at bang on .50, found a roll of .40 paper I had kicking about and squashed a bit and got this .50 - .12 = .38, couldn't have gone better if I'd planned it! Cut a gasket, then played with shimming the head to find exactly what thickness I needed gasket wise .75 was indeed about right giving a squish of bang on .65 Scrounged up an off-cut of copper, measures at .76 Spent a while marking out a gasket, took my time trimming it the best I could with snips Then promptly fucked it cutting the inside, attempt 2 or 3 went a lot better, not great but good enough for now. Next time I think I'll just bite the bullet and get one waterjet cut!! Test fit gave a squish of .67, I annealed the gasket with a MAPP torch, wanged it back on and torqued it up, checked squish and got .64, mint! Not so mint was dropping a nut while the head was off and it falling into the cylinder, the piston was at BDC so it went right down the exhaust port and is now in the expansion chamber ha. Oh yeah, and I finally measured up and ran the numbers 68.68cc of fury!1 point

-

So yeah I don't really update this at all, not much has happened since my last post in 2017. Had to use Google to find this build thread because OS search sucks. For the first time in over 5 years this is now living in the same house where I live. Amazing. I might even use it over summer. It doesn't fit down my driveway though so I'll have to make a small ramp to avoid it getting bellied. Was a three plank job to get it down today when it arrived. I might do some stuff to it as well. Check back in 2023.1 point

-

I finally got the spindle running, as expected it was me being a dumbass about the VFD setup parameters. Although for some reason it is only getting speed control from the potentiometer on the VFD. I am ok with this though as it will allow me to experiment with speeds and feeds. I also trammed the spindle to cut straight and flat, good enough to be able to face the table anyways. I also did a hard out calibration of the X and Y axis so it would cut accurately. I also made up a longer control cable for the big servo, that was stressful. This means everything is nicely tucked away in the cable trays now. Next is to buy a cutter and face that table... Then I'll design a vac table and make it. After that it's all cash money.1 point

-

1 point

-

1 point

-

1 point

-

Speedy fast progress! Just run the spindle manually? Had similar problems setting up mates router that was our fix until figuring out the configuration/communication.1 point

-

Supercharger kit arrived a couple weeks back so I started to pull apart a running car. Took a shit tonne of paint off the strut tower trying to side it all on in one go. Figured out its best to take supercharger off the intake manifold. Manifold fouls on fuel rail with the tvis butterfly plate left there so had to remove then try again. Now the intake head studs were fouling on manifold due to being to long so have removed them all successfully and awaiting new studs. Did mock up with some bolts for now Need to track down a 1st gen throttle body and iscv1 point

-

A bit of a win today. I have been looking for bits of MDF at least 3m x 1.4m so I can have a bed with no joins in it, this was proving difficult and/or stupidly expensive. Then I remembered a place next to where I got some electroplating done that had stacks of random MDF sheets lying around. I rocked up yesterday and told the the man what I was doing and what I wanted, he was super interested and said he would sort it out. I got a call today saying the sheet was ready, so I swung by to pick it up. He had cut 2 sheets of 18mm to the exact dimensions I wanted and sold them to me for only $50, what a GC. I just slammed one on now, looks sweet. I have also been setting up some cable routing and the prox switches, just the Z axis to go;1 point

-

shed night last night = begin general re-assembly. It’s slower than stripping the bike. Applying never-seize. Applying loctite. Taking care no to scratch my new powdercoated frame! I am enjoying the process though, I don’t think I’ve ever put anything back together like this? Typically when I’ve stripped stuff.... it was terminal. Got the swing arm mounted and the forks. The polished triple clamps look grouse but my castaway style improvised steering head bearing setup and the need to shim around the forks where the triple clamps bite, made it particularly slow going. On last years ride I punched the forks up through my homemade clamps fording a stream at speed and I’m hoping to avoid that experience in future. I also ordered some tyres this week from our main man @MopedNZ and I’m super excited to receive them (Despite bucket Barry routinely advising me that They’ll make a bike which is already difficult to ride, MORE difficuilt-er).1 point

-

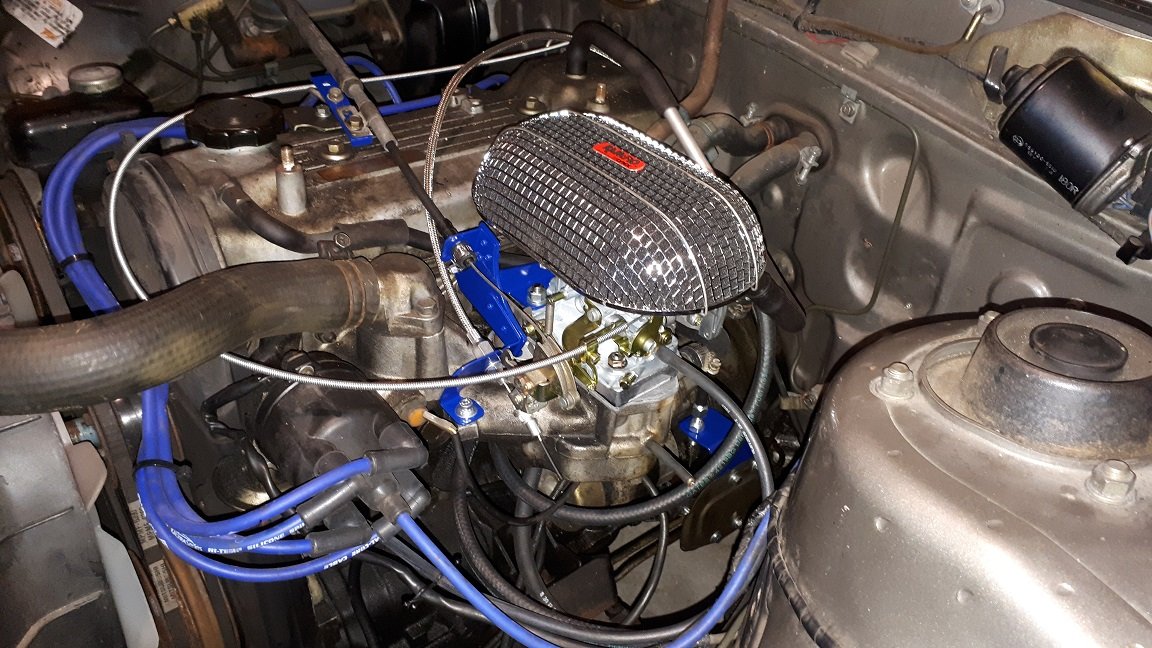

Here she is, my 1987 Ford Falcon XF GL. 250 Crossflow engine. She's an EFI model but running a 350 Holley on a redline intake manifold. 3 speed Borg Warner box that goes alright for now. Mods already done: -Factory wheels swapped with some 12 slotters running 225s up the front and 245s out the back. -Bull bar removed, nicely might I add, so all mounts are intact if I want to sell or put em back on. -Mounted an AFR gauge that I had lying round under the steering wheel. Here's mods list for short term: - New lowering springs front and rear, not super lows - New shocks to suit springs - New wheel bearings - New disk rotors - New ball joints - New Nolethane bushes all round (too stiff and noisy, thoughts???) - New tie rods and ends - Eb V8 rear diff 3.27 ratio LSD (wider by 10mm but should be sweet) - EF/EL sedan tailshaft Here's the longer term mods: - BF Barra N/A - Matched 4 speed btr - Tailshaft to suit - Engine and box mounts (Thoughts on Tuff Mounts, Rod Shop or another brand???) - Front sway bar to clear barra sump. Most likely buy new - Loom to suit - Standalone ecu or reflash stock Barra (not sure yet) - Manualized shift kit - B&M ratchet shifter - Get it engineered (this is where the list will get bigger) - Rust remove and respray If you've made it this far, maybe you'd like to pick any of this rough plan apart! Any criticism welcomed. Cheers.1 point

-

1 point

-

And fuck it, let's add the Z axis. Also I spent some hours learning how to set up the vfd/spindle. This should be good to go as soon as I find some four core cable for it.1 point

-

Thought I would get cheeky and get it to follow a path. Z axis is not hooked up as the cable to the stepper is too short and I was scared it might zoom off somewhere before I hit the e stop. Also I set it up for very small movements because I have no limit switches setup yet. Still, much excitement.1 point

-

Been chunking away at this, tidied up a whole lot of little stuff like making the belts run true etc. Also I fudged together two different types of cable chain that came in the rando servo kit to make a run long enough for the long (X?) axis. Not super pretty but it will work. I will still need to buy some more for the short (Y?) axis Today I made a table for the screen etc and mounted the estop to it, looks sweet and mostly swings out of the way when not being used. I have ordered many proximity switches, apparently you can series the switches on only one input and LinuxCNC has a procedure that will home it automatically with that setup, for a while I thought I would be using all of my inputs for homing sensors. This is good, I will have 3 spare for.... things.1 point

-

1 point

-

1 point

-

Why thank you sir. The panels do stop a fair bit of sand getting into your undies. And no, i've not really checked it for bump steer. I think my bro in law worked it all out, but I couldn't understand his workings/instructions and just welded the knuckles on in the spot where everything seemed the least shit/cleared everything. When I redo the front suspension for the braked hubs, i'll try copy the Barracuda front end as best I can, as I have the plans, and they worked all that shit out.1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.9d5826010dcfae51cb2b51423adc23b3.jpg)

.thumb.jpg.f5853bfcf462ac7cf03fc05082c0bed1.jpg)

.thumb.jpg.aebcfa1d8e44f1e451686cfb31b8bab1.jpg)

.thumb.jpg.008c374b73b85477eef63390e77a89f4.jpg)

.thumb.jpg.586741b5799d459309278c9f2c9c22d2.jpg)

_sedan_(23230030334)(1).thumb.jpg.34d765361d66c78db614bae6ea2c156a.jpg)