Leaderboard

Popular Content

Showing content with the highest reputation on 05/11/21 in all areas

-

So, I still own this It got used for a daily for about a year or so, and I made a few more changes to it - t3 knuckles and modified the tension arms for more caster. And changed out the rear end to an 4.11 F code center from an mx73, with an Altezza torsen. Here's a terrible, old, cellphone picture of it about then; A little later while I was taking a short break from possessing a license I pulled the windscreen(s) out to fix up the rust that was coming along nicely in the lower corners of the rear screen frame, but didn't actually get around to actually doing that for a long time The 4a was getting pretty tired too - at some point i'd lost one of the filter socks and gave in and just ran nothing at all - so a life of hard work and then that, it was starting to experience pretty heroic levels of blowby. So was looking at doing a rebuild on that, but then I happened to be at Zebra looking for something unrelated, and found this in one of them mental WiLL VS doodads; A 2zz. No real idea what condition it was in but being zebra, it was cheap enough to get to just stuff around with Id actually already bought a j160 to put on the 4a - had a look at that, and the way a few key things on the 2zz were arranged (simple steel sump/pickup, easy waterlines etc) it actually looked pretty straightforward to make work in a rear wheel drive arrangement. Did a very rough 'adapter plate' to the j160, for a sort of proof of concept and threw it in the engine bay, it all fit a little too well I figured they already make 190hp standard, is all aluminium, has vvtli, gain 200cc, so why not really This is going back a little while now, and progress has been glacial (had a kid/wasting my time with other projects) but it looks something like this at the moment; Ignore the 20v throttles propped up with a bit of wood for artistic purposes but yeah it's mounted, the headers are now done, the j160 is more or less adapted, and the rust is fixed too I'll put up some more detail on that stuff soon discussion\tell me how stupid i am22 points

-

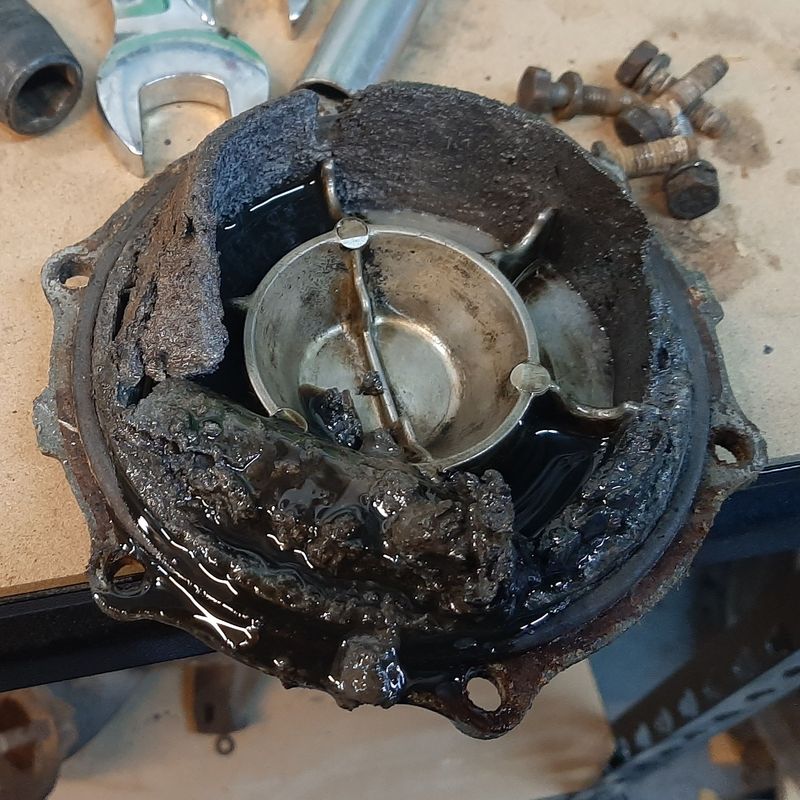

I Zebra'd a new engine mount and also put the factory exhaust manifold back on, as the other one was leaking horrifically from everywhere. Then did a bunch of other things and got it fired up! Pretty chuffed with that, it's a nice feeling to not have it all blow up immediately. I reckon it's gonna be pretty rowdy with these cams haha. I then mucked around for ages and bodged together water and heater lines, filled it up with coolant, then.... fucked up. Despite my previous efforts I managed to wire the waterpump backwards and I think I let the smoke out. I fixed the wiring but now it doesnt work. Will be lame if I have to buy a new one, as they cost as much as this bloody engine did haha. Depending on the motor type I might just be able to bodge this one to bypass the variable speed and just run it full speed full time. Dunno. Aside from this. I really need to pull the wiring loom apart a bit, because currently the alternator wiring is baked into the loom up top, but it needs to move down lower. Also because the block is taller, my trumpets hit the bonnet now. So will need to make some new ones. However will all 3 of the polyurethane mounts in, it's now super rigidly mounted. So I can hopefully push it close to the available space without issues. But it was awesome to get it fired up anyway. I'm still a few tasks away from being able to drive it, if the water pump isnt fixable it'll be next month that I can buy a replacement.11 points

-

Yeah.. He is retired tho right? No dependants/mortgage? Gets a pension.. The opposite of my situation, I'd be doing what he's doing in a heartbeat if I was able.8 points

-

Took some more shots since it was out of the shed. She’s now at the blasters. Cancery upskirt6 points

-

pulled it to bits and got it ready to remove the motor. ive ordered some parts which willtake ages to get here so im in no hurry. i thought id tidy up some stuff while im waiting. water return pipe from the turbo went into the original spigot and the second one was just blanked off. it looked a bit dumb so i pulled the stainless tubes out, welded up the holes and welded a dash 6 nipple on lower down. 2021-05-09_07-04-13 by sheepers, on Flickr 2021-05-09_07-04-05 by sheepers, on Flickr then i thought id make a new, smaller radiator reservoir and windscreen washer bottle because real-estate in that area is real tight and its a pain in the arse to get to anything in that space. not finished yet but getting there. cut some 75mm box section put a pie cut in the bottom to help clear the body work better weld caps on each end sand them up a bit weld the screw caps in still got to put the inlet outlet fittings in and mount the little electric motor for the windscreen washers but that shouldnt be a drama. ill just hide it underneath like i did for the V8 2021-05-11_08-14-23 by sheepers, on Flickr 2021-05-11_08-14-29 by sheepers, on Flickr 2021-05-11_08-14-35 by sheepers, on Flickr 2021-05-11_08-14-41 by sheepers, on Flickr5 points

-

5 points

-

Gidday, me again with the crappy volkswagen. so last time we left off that i got it out side. WAHHOOOO the next thing on the list was tires and to dial in the ride height. i had messaged seedy al a we while back and asked what size tire he ran on the front and i run these also but this time i fired him a message to see what he was running on the back, and yikes it was a small tire compared to what i was running, which was a 205 70 14, i done some tire comparisons online to find something that would give me a smaller tire but nothing to small. I ended up with a 205 60 14. this is 22mm smaller in the side wall, allowing me to go a little lower with out having to ram the tire up into the guard. but since going lower i now have a lot more toe in, now causing the tire to catch on the spring plate adjuster. so i got some shims from bunnings, yes bunnings stock shims for vw kombis (washers). what i needed to do is shim the spring plate out a bit from the arm to help correct the toe in being this is one solid arm with no adjustment. this required a bit of fucking around, with the 1st attempt having to much toe out. so i removed a shim (washer) and put it all back together and it seemed pretty much bang on. So i got my 3 meter straight edge and drew some lines to the front and back and chucked a tape measure over them. i had the wheel alignment 5mm toe in. this measurement was comparing 2 meters behind and 2 meters in front of the wheel. so i thought my 5mm was pretty bang on for something that is not really adjustable. picture of the solid arm which i placed shims on to correct my toe in issue ^^^ this is the rear i placed spacers where the arrow points With that all done i was able to actually drive it out side and down the road a couple of times. was good to finally have it out side. I was using it a bit here and there to see if anything was an issue or i would need to adjust anything a bit more. My biggest issue was i was not able to select gears that well, i was really starting to get pissed off about this. got talking to the guys at v-dub shoppe and they gave me a bush to replace in the gear linkage system close to the gear box. fucked one this little guy was toast, it was ment to be solid and have no movement but it had about one 8th of adjustment in it causing it to no select gears correctly. replaced that and OMG what a change! while i was up there i got this image of it all done. next up i proceeded to loose my drivers side hub cap about 4 times with in 10kms from home, found it each time which was a bonus. next i needed to sort some shocks out for the front, while i was out at @Fuckedifiknows house i was talking about what i needed to do and he passed me these. and then i got some shocks but i was going to need to do something as the shaft was to big for the bush on the shock. well we had @Kimjon pop in and take my vespa for a ride and he suggested he take them home and chuck it in the lathe and take a few mm off it to make things easier. finished result! next up i needed to tap the shock tower so these could go into them. she was a tight squeeze but we made it work. time to make some bump stops for the front and the rear. front ones go a little like this. put some holes in them make sure the holes line up then you get them lazer cut and leave them for 2-3 months back ones go a bit like this remover rubber dog chew toy (way before we started this) Get smaller rubber chew toy make small rubber chew toy screw into metal thing thanks to @Geophy make metal thing that rubber chew toy screws into be one with George the kombi glad i still know how to melt metal together not that well. so paint metal thing black and screw little chew toy in also removed the big cup thing off the rear control arm for more clearance so i have a bit more travel before bump stop hits, this was only held on with 2 little tac welds so i feel like i done good here. now when it touches a good solid peace that wont fall apart. done some other things to make clearance issues not an issue but i wont show those as i didn't take photos....... but here is a photo of it allll done. do you guys like the no hub caps? or with the hub caps? visited my mates out at the v-dub shoppe to show of and thank them heaps for all their help. and our next adventure was to the bay of plenty to see some vdub people and inquire about getting the kombi checked over for a wof. the bay of plenty was great to us. chilled out with beth and tayla before visitng the wof place. re done my wheel bearing while i was at the wof place cause it was making some noise and then headed out to catch up with a vdub mate brought some rego and went to take a comparison photo when i got back home. thats it for now. next time on adventures with the 64valiant family and George the kombi we head to beach hop and vw nationals. stay tuned4 points

-

things are pretty great with this car. just got to sort out the seats and some carpet but thats for another day. i bought some new rear disks for it a while back because the ones i had were turbo fucked. minimum thickness is about 11 mm and one was down to 9. so yea, in they went. not a big job but still. 2021-05-01_12-59-34 by sheepers, on Flickr 2021-05-01_12-59-28 by sheepers, on Flickr4 points

-

Potentially, people should be getting out more for sure but there's many limiting factors some mentioned above. I'd love to be retired so I could drive around constantly though. How good?4 points

-

Tbh he's putting everyone on this forum to shame. We should all be doing this sort of trip more often4 points

-

4 points

-

3 points

-

3 points

-

Installed some Oxford heated grips- the grips and controller/wiring is all quite nice but the included tube of superglue is a complete waste of time as both grips came loose before I'd left the drive. These are not like regular grips and have a hard plastic inner sleeve which does not shrink against the bars like usual. I pulled the grips off again, roughed up the bars and plastic sleeve, then glued in place with a thick smear of liquid nails. Completely the wrong application for that glue but it seems to stick like shit to anything and everything, and the grips sure don't feel like they are ever going to move now. Let's hope the glue doesn't soften with heat.. Lol. The controller has some voltage sensing thing too. Its connected direct to the battery but will not operate unless the motor is running. Guessing they need a minimum of 13v or something to turn on. This is a great feature because I'd say they could drain a battery pretty quick if the motor wasn't going. Check out the huge factory bar end weights which screw into the solid aluminium bars. They entire handlebar plate thing is also rubber isolated-lots of consideration given to comfort and one of the many reasons they are a bit tubby.3 points

-

3 points

-

Got the car back together just in time for CJC Gripfest at Manfeild. I mounted a passenger's seat and took a few people for rides including @Mitch.W and @Snoozin. It's the first casual trackday this car's done since Nats 2013, so was nice to get out there and have fun cutting laps. There were a few cool cars to play with! Scott embarrassed me by passing me in his EP71 Starlet (looks like a regular old EP, but is B18C powered). The front bumper is still a work in progress, but I'm happy with the over all look. Thanks to Emma for the photos and videos .3 points

-

car went to the paint shop to get the runs out of it and get the final cut and polish. i went and picked it up last night and it looks amazing. anywho, today i wanted to fix the exhaust where the flex joint had worn through because its the lowest point and its had a fucking over judder bars and whatnot and subsequently has a hole it in. step 1 - jack up your car. this is where things went wrong. 2021-04-25_02-55-42 by sheepers, on Flickr car slid off the jack on the way up. given what could have happened i got off extremely lightly. it bent the radiator support up and bent the bottom of the radiator real bad. it also bent the bottom of the front bumper. however, the radiator isn't leaking and the crank pulley is unscathed which is a fucking miracle given what happened. i was able to bash the rad support back down and i got most of the bend out of the bumper so it looks fairly normal again. fuck it could have been WAY worse.................. so yea, after dealing with that i moved on to fixing the zorst. cut out the fucked bit, made a new bit, tacked it in place, remove zorst from car and fully weld, add 4mm thick bash plate and put zorst back in car. 2021-04-25_02-55-49 by sheepers, on Flickr 2021-04-25_02-55-55 by sheepers, on Flickr 2021-04-25_02-56-02 by sheepers, on Flickr 2021-04-25_02-56-09 by sheepers, on Flickr 2021-04-25_02-56-21 by sheepers, on Flickr then it was time to wax the newly polished paint. that went well. it looks pretty ace tbh and yea, i cant take a photo that justifies how good it looks. but it looks good. take my word for it. 2021-04-25_05-34-27 by sheepers, on Flickr 2021-04-25_06-18-48 by sheepers, on Flickr 2021-04-25_06-19-23 by sheepers, on Flickr 2021-04-25_06-32-09 by sheepers, on Flickr3 points

-

Yep absolutely! “She’s a 20 footer, and don’t slam the door!” When sourcing parts I kept coming up with ‘repair caps’ that you just zing over your chassis rails. impending doom!2 points

-

In some cases in the land of freedom, that's the repair, lol I have a customer with a first gen camaro that didnt quite look right, he had it blasted and it had double rear panels, the original rusty ones were still there2 points

-

Yeah, I didn't actually mean to offend anyone with the earlier comments. It would be great if we could all get out and do stuff with no commitments2 points

-

I did one similar not that long ago and another similar not long before that along with several other forum members. So ahh.. Not true?2 points

-

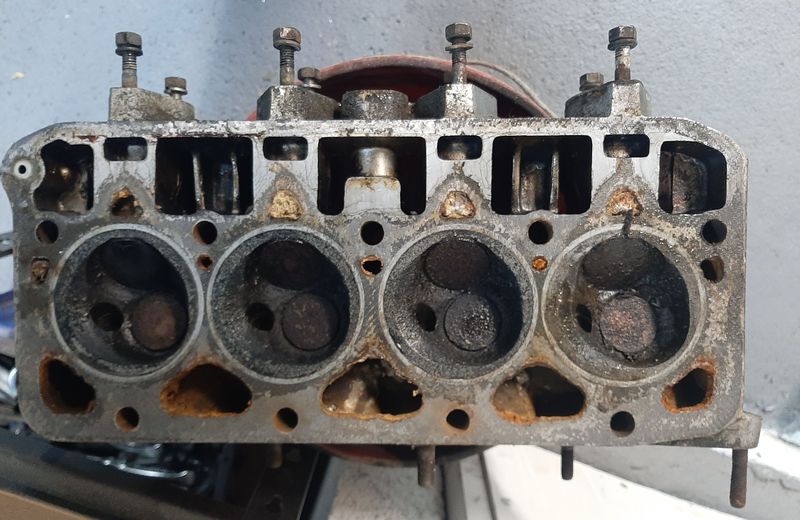

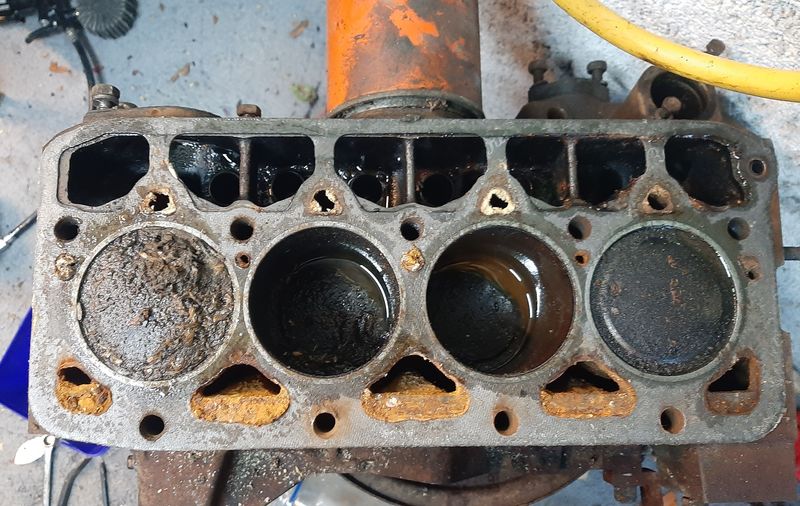

I got a engine crane for my birthday, so i yoinked the spare engine from the boot out and ripped into it. Its a 115.000c engine which was probably from a Fiat 1500 sedan or Crusader based on a Solex carb it has. This would have been the factory engine in my 125P Ute and is also the 2300 engine less two cylinders, so shares a lot of parts and design It only had three spark plugs, no air filter and no oil cap, with grass seed and mouse nests everywhere, and appears to be seized. Perfect. Remaining park plugs out look not bad, not too bad at all, not bad. Hmmm. Valve cover off, well, would you look at that. Bit of crud under the open oil cap, but otherwise clean I guess? Centrifugal oil filter says, well maybe you shouldnt get too excited, just yet... At this point the effort of getting the crank nut loosened the engine shifted. Some more oil down the cylinders and it moved nearly 360 both ways. Couple of the valves were sticking so Head off, Mouses grass seed and fluff so tightly packed in on the inlet valves it was actually stopping the valve from closing again. Ill chuck it in the vinegar for a bit it should clean up i reckon, no damage, just grub Guess which cylinder had a and a mouse living in the spark plug hole! However thats a pretty new head gasket, can still see the writing A bit more brake clean and the pistons look shiny! Bores are a bit surface rusty in a few spots as expected but no scoring, i reckon a hone might be all it needs. This is after some worn out wet and dry and wd40 for about 20 seconds on the worst bit Need some M12 x 1.5 bolts to put it on my engine stand, then ill remove the pan.2 points

-

oh, hi!! so yea things have been great with this car. except the output bushing on the gearbox is flopping around and subsequently the output seal is leaking and flinging oil all over the exhaust. this is shit. the gearbox has only done a couple thousand Ks since it was brand new from Toyota. apparently this is fairly common on the new R154s which fucks me off even more. I've fucked around with changing the seal multiple times and all the other usual checks but it just keeps on leaking. cool. so to fix it i have to take the motor and box out because of the whole massive drive train/small car thing so out the motor comes. its fairly depressing taking a motor, that you have worked very hard on to make as new and shiny as you can, out of a car and seeing all the road grime and shit on it, as well as all the crap that goes everywhere when you start taking things apart. well, its what has to be done so away we go. not sure what else ill do while the motor is out. im not 100% happy with the clutch i put in it. its juddery and grabby at take off which sucks so that may change. fuck knows.............. anywho, first step, jack up your car. 2021-05-04_05-59-44 by sheepers, on Flickr2 points

-

They say the two happiest days of Birtish car ownership are the day you get the car and the day it leaves your life. Well the other day it left my life (at least for now). My dad is taking it on a long road trip. He is taking it to Auckland, via the bottom of the South Island. They're staying at Lake Hawea tonight. I think their trip will be complete by around about the 15th. Hitting the road: Somewhere in Mt Somers I believe: Lindis pass (actually surprised it still ran up there): He insisted on taking the roof rack with it. I bet it uses 25% more fuel now. When it gets up to Auckland my brother will paint it and we will try to track down the few remaining bits that it needs to be complete and then will stick it on the market. I'll keep this updated as the photos from the trip come through. Feel free to add any spotted photos if you see him on the road.2 points

-

1 point

-

I had to liquid nails the grips onto my last bike too to get them to stay. I was glad I sold the bike before ever having to replace the grips...1 point

-

Oh you got some work ahead ! know your pain all too well though pretty much replaced all those rusty panels on the impala but mine didnt look that bad to start off, Hopefully dont get too many nasty suprises after blasting cause i sure did ha!1 point

-

1 point

-

Buy a Hiace without seats in the back, problem solved lol. Are the vans cheaper with seats or something?1 point

-

Somewhere on the dash there will be a button or dial with a label "Vol+" if you increase this setting the problem should go away, if its still there then increase the setting a touch more. Hope this helps1 point

-

This week turned in to week after next week so dropping to blaster tomorrow! kinda been in limbo so not much progress (vinegar soaked and painted some clips + bolts) but today I said fuck it and knocked out the first 2 of MANY patches to come. firewall passengers footwell ..and figured since the blaster is passing over, I’d expose these bulges around the shock towers so it’s nice and clean behind. also blasted the crusty bits on the front valence and made a few holes. I just zapped these up and rust killed.1 point

-

1 point

-

1 point

-

1 point

-

Just get good at masking and save the hassle I masked mine up and it came up fine, just spent my time making sure the tape was perfect, and also thin stuff.1 point

-

Correct procedure is to take it to a vtnz or vinz that deals with re registering cars, tell them what you are doing, they will remove the tag, and store it while it's being painted then refit when it's done.1 point

-

I've had a tiny amount of play in my rear wheel bearings so decided to rebuild my whole rear-end New CVs, bearings, aftermarket stub axles & companion flanges to take a 108mm CV. Old vs new stub axles. They have a larger splined diameter and are beefier at the wheel flange. This now shifts the weakest point in the driveline to my r180 diff, but it should be good enough for my engine. I also replaced all diff seals & o-rings so hopefully it stops leaving little puddles on the floor now. I couldn't get a micrometer inside the hubs to confirm, but I've assumed the play was from the bearing spacers getting overtightened and mushrooming slightly. So I cut some 0.05mm shims and torqued the hubs up and things feel right now. The left hub required two shims. Everything seems to measure up correctly and there's no play anymore. Rad! However. At this point I realised I have a problem. Since my new companion flange accepts a 108mm CV directly, I no longer need to run the CV adapter plate I used to use. This means my axles are now 25mm too short. FML. Cars aye!1 point

-

Recently picked up one of those generic 220l freestanding blasting cabinets, so I could set to work blasting/primering/painting the rear suspension/bag mounts etc in several batches. Such a time consuming task but super satisfying seeing once scummy parts come out looking new. Need to replace the window and do an LED light upgrade to the blasting cabinet before I can do anymore (the front suspension bits). Can't see shit in it anymore. Ended up cutting the wheel bearings off the half shalfs so I could paint the drum brake backing plate. Don't have a press so might try the axle in freezer, bearing in oven trick for fitting the new bearings I have before I go door knocking around the neighbourhood trying to find someone with a press I can borrow. Then I can finally get the diff back together in one piece. The whole diff hangs from a rubber bush that sits in the boot floor, I've got a new one of these bushes on its way from Germany as the original is suitably flogged but it seems the replacement one is on the slow boat so who knows when that will get here, but I need it to refit the diff so bit of a stalemate there. Also picked up a 722.6 trans out of an early 2000s W203 that suffered a timing chain failure (like most of them do). these don't bolt up to the M180/M130 family of engines so I need to make up an adapter plate, which is my next job will also need a controller for it but that can wait. I've gone the complicated route of gaining a lock up torque convertor and a 5th gear, but a man wants what a man wants. Until next time.1 point

-

Some updates. Waikumete upholsteres made a carpet for me. 2 pieces, like original, and we found a loop pile in maroon! Which was brilliant, as I really wanted a loop pile for that more premium appearance. 20210321_161234 by Richard Opie, on Flickr 20210321_165710 by Richard Opie, on Flickr I think it turned out pretty well! Did the boot also, but I haven't got a pic of that for some reason. 20210408_210246 by Richard Opie, on Flickr Engine and gearbox came out again. This is minutes before it all lifted out. Very easy. 20210417_114901 by Richard Opie, on Flickr Pulled apart the gearbox with great guidance from Earle McFarlane. 20210417_121227 by Richard Opie, on Flickr Measured all the clearances, then pulled it apart. Selector hubs are a bit pwnt, there is excessive wear in the shift forks, bearings seem all right but they're all being replaced anyway with all those parts in the post above. So now the mainshaft has been assembled (in my absence) and we are just waiting on the forks to come in from Japanland so we can reassemble. 20210330_125040 by Richard Opie, on Flickr Since the motor was coming out anyway I thought it'd be a good time to get the top end sorted, as it's only ever been a stock head and cams, despite the bottom end being built/hi comp. This is a spare smallport head that I spent a while scrubbing in the shed to get clean. 20210330_125016 by Richard Opie, on Flickr I then thought I'd try cold jet/dry ice blasting as a bit of a test case on the cam boxes to remove the baked on sludge and scum. This is the result. Pretty awesome! I'm going to be using this process to clean some of the undercarriage parts in situ on the Honda. 20210331_084622 by Richard Opie, on Flickr I stripped the head myself, once I learned how to remove the collets from the retainers it was all pretty simple. Here's the head, with all the bits catalogued and in containers, with the Kelford 193B cams and Supertech retainers/springs I bought ages ago for it. It's in with Alan Harris at Harris Performance Engineering (previous Lynn Rogers) for porting, some tickles on the combustion chamber and a port match of the ITB manifold. I then got to thinking about what audio this car is going to have, even if you can't hear anything inside it really. Initially, I was going to run a modern Bluetooth head unit in the glovebox, and got as far as buying this pretty rad Sony unit that has 50wrms per channel - from a head deck!!! Enough to power anything, speaker wise. But then Ed sent me a link to a Yahoo auction that changed things. 20210422_172330-01 by Richard Opie, on Flickr 20210422_172308-01 by Richard Opie, on Flickr This is an AD-189T fitting kit/adapter produced by Pioneer in the early 80s. It fits a 'B' type head unit, which is conveniently what the 'component' systems of the early/mid 1980s are. Before the standard DIN size we all know and love today. It replaces an entire middle panel on the dash, replicating the OEM fit where normally there would be a spindle mount head unit (as is the case on my factory dash). I had never, ever seen even a picture of one of these kits before, let alone a NOS one on Yahoo. So I bid on it, because who doesn't love period accessories. And I won it. So then I thought I'd probably better find a head unit to fit. 20210422_172407-01 by Richard Opie, on Flickr I ended up with this Pioneer KP-717G tape deck. Note - it's a tape deck only, there is no AM/FM radio or anything with this, as was the style of the component systems of the time. This one was listed with a clean bill of health, and some remedial work done to ensure it was operational. The auction was backed up with a video to prove it. It's one of the higher end units in this range, with Dolby NR, adjustable tone controls, all the fruit. It doesn't have an amp on board - luckily Ed has one of the Pioneer GM-4 amps for this to plug into, that will find it's way into my car. 20210422_172454-01 by Richard Opie, on Flickr This is how it should look when installed in the car, using the AD-189T kit. Fuckin. Awesome. I reckon. 20210422_172612-01 by Richard Opie, on Flickr 20210422_172638-01 by Richard Opie, on Flickr And this is essentially what the initial system I run will be. Later on I may add some fronts - I have some NOS Pioneer TS167 coaxials, and also dual cones whose code escapes me right now. These TS-X9 are incredible though - I had them wired up to my amp in the house and they produce enough bass you can actually feel it through the floor. How they achieve it, I do not know. Sure it's not sub levels, but it's a beautifully balanced sound that I hope will be loud enough to listen to while pootling along at slow speeds or stuck in traffic. Thank you for coming to my TED talk. Hopefully, next updates will include a rowdy cylinder head, a slick shifting T50 and some Phil Collins tapes in the KP-717G.1 point

-

Minty! Didn’t like how the generic Tridon ones went so rock auto came through again, for less coin! I sent the old booster to a shop to assess its state and they came back at $700 in parts alone x USA in a month. It is a bit of an oddball, but no thanks. I figured it was fucked cause it had been full of brake fluid but a customer I didn’t know had the tech came in and saw it, said he can clean it up and reassemble it and that if the diaphragms we’re going to react badly to fluid contamination then it would happen pretty quickly, that mine was salvageable. I mean it’s junk totally disassembled in a box so may as well sling it back together! He’ll sleeve the master too. Just prior to this, I brought new booster off a chap on Facebook for cheap, he didn’t end up using it. It’s not ideal but was going to make it work.. it’s a couple inches smaller than my original unit but I figured all it does is assist. I could deal with a slightly heavier pedal. me preference is original..1 point

-

Hi. lets go back a few steps. I had just received my beam from Sean at kune re. I put a few layers of brunox on it and painted it black. and stashed it away. the next stage was to fill some holes and touch up some rusty peaces and i was waiting on a mate for a hand with this part but i ended up getting a bit impatient and smashing them out with the mig welder and cleaning them up with a grinder cause im clearly not a welder and while i was at it i went over a bunch of my old welding peaces and ground them up and cleaned them up. a few late nights and got the job done. next up i wanted to cover the underneath with brunox and get a few layers in to convert the small amount of surface rust it had and set a good base. with that done i went around and chucked a bunch of seem sealer on crap to clean it up and make sure aint no water getting passed my dodgy welding techniques. once that was done i dusted the under body with some underseal. end result was pretty much brand new. next job was to get the beam in the bus, i needed to put the steering arm and the torsion arms on. this also meant i needed to shorten my leaves to now match the narrowed beam. to have them narrowed i visited a mate who helped me cut them and he welded the ends together to make the leaves go into the ends easy. here we cut. here we weld then i kinda rounded the edges to help it find its own way into the hole and re drilled my locating hole for my arms to bolt into. next up the torsion and steering arm on the beam next job to put the beam in, and jesus i am lucky to have a hoist. me and @flyingbrick lowered the kombi down over the beam and bit by bit we went up and down with a peace of wood between the beam and the ground as the fitment was so bang on with my underseal on it she was binding up going in, definitely should have used lube. but we got there in the end beam in, the brakes went on the front, new rotors new bearings, new calipers, the only 2nd hand part here is the drop spindle and the retaining nut which was robbed of a bus rotting away. this wasnt an easy job. i ended up using a strop and tightening the bottom arm and kinda fitting the drop spindle in the middle now with that all done i installed my gear linkage. i replaced the bush at the front while it was out before i went and installed this next up was the rear. for some reason i was doing this all to fast and didnt really get many photos of assembly. but the new stepped spring plates are a breeze. actually after that i had to put the rear arms in, which i had replaced the bushes in quite some time ago and they were ready to go. so also installed them after the spring plates. next was the rear hub, i actually drilled my old one out to fit different bolts in for the horse shoes i tried to fit just before covid last year. so i got some second hand ones and headed to evans place to use his sand blaster and clean them up. before: note the long noes pliers as circlip pliers during after and new bearings fot the rear hub section. now with this all done i can put the axel in and put the rear brakes on and continue doing small jobs. next up was new brakes lines, hard and soft ones all the way through the bus. also my last slave cylinder was just left sitting out, kinda rusted and also never really worked correctly when installed on the bus. so got a new one of those but the cups where a different size than the last one, so got some small adapters to make it work also i had replaces both hand brake cables, accelerator cable, clutch cable and complete full axels and cv's some where along the line. This where i ended up in the last post. made it on the ground and drove it for the 1st time in over a year. Great success. one Greg for scale i just checked dates on this and i started grinding the under body and doing rust on the 12th of feb and she was on the ground out side on the 23rd of feb at 830pm.1 point

-

Things are progressing slowly in the background, Have had my new PP'd housings and front cover over at Toby to get the maddog polish, Shit they came up so good. Plates are getting the casting marks smoothed on them currently and then painted ready for the engine to be assembled. Iv been trying to work out how the jigsaw of the dash/heater/glovebox etc etc all goes back together from a box of a million screws and bolts and a whole lot of parts. Taking its time but getting there. want to make sure anything missing or broken is acquired before final assembly.1 point

-

spent all day fitting some door belt line seals. it goes without saying that i cant buy any seals for the crown so i had to make do with what i could find. i found some generic lengths of belt rubber on "better auto rubber" out of auz which were close enough and i coupled them with some generic felt bump things that are for american cars or something which i got at an american car importer out by the airport. so, now we have some rubber bits, we have to make them stay on the car. i recesses the screw heads into the felt bit by just cutting away the felt part where the screws are. works well and the glass cant touch the head of the screw. drill holes in the door, screw the two rubber bits and the stainless trim on to the door. WAY harder than it sounds but got there in the end. i also put some sound dead material onto the doors while its apart. might get some more tomorrow and chuck some more in the doors. 2021-04-02_04-06-33 by sheepers, on Flickr 2021-04-02_04-06-24 by sheepers, on Flickr 2021-04-02_04-06-16 by sheepers, on Flickr 2021-04-02_04-06-08 by sheepers, on Flickr 2021-04-02_04-06-01 by sheepers, on Flickr 2021-04-02_04-05-52 by sheepers, on Flickr1 point

-

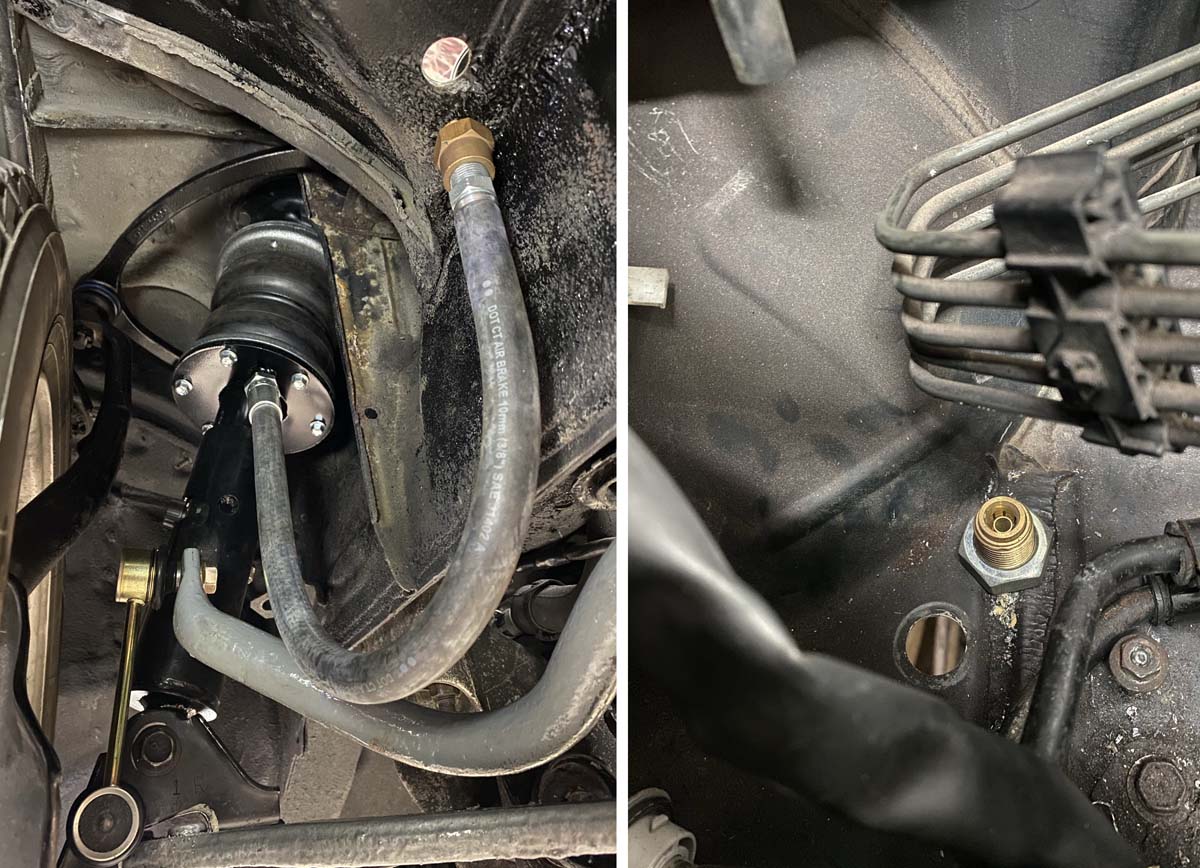

Didn’t have the factory headlight buckets. So brought some Narva plastic universal buckets. They were a little small to fit the screw holes in the guards. And also didn’t accommodate mounting the trim rings. So I 3d printed a couple of adaptors in PLA. Worked well enough for v1. 80s lavender eyeliner trims on. The radiator and hoses are coming together. Seems like it will work. Just a little tight for space. Beneath we relocated the outlet to the side. I Cut a hole in the Grill support bracket, and welded on a "c" shaped tube. So the large lexus loom could be cable tied up behind, and be hidden by the grill. The boss airbags came with some huge 3/8" airbrake hose, with pre crimped ends. They are WAY to long. Almost Twice the length they need to be. So I cut them down. And will add a new barb on the cut end, or a screw on brass air brake fitting, or have a new end crimped on. Unsure yet. This is the Left hand side. Going forward and up through a bulkhead DOT push connect fitting. And this is the Right hand side coming forward and up through the bulkhead. (yes 2nd attempt at position, due to touching tyre.) You may notice the air line passes behind the strut on the left hand side. This is because Boss Suspension decided to make all the struts the same. Not in pairs. Not stoked on this fact. My OCD likes symmetry.1 point

-

SOme more things have been done, including all-new loop pile carpet and a nice alloy sealed battery box in the boot but that's not even important. What is important, is the gearbox, which sucks. Downshifting is impossible without a big ol' rev match and double clutch to get it from 4th to 3rd, then from 3rd to 2nd. As the car makes a little bit of a racket, it's quite obnoxious. So I sat down with Earle McFarlane (he's had many many experience with T50s and rebuilding them) and ordered a whole load of parts from Japan. They came in this box. This struck me as odd. Amayama orders are sent to an NZ warehouse then dispatched from there, so I'm guessing this happened locally. 20210325_180028 by Richard Opie, on Flickr And this is what's in it. 20210325_175701 by Richard Opie, on Flickr We have; Synchros for all gears New selector hub sleeves Gasket/seal set Selector hub shift keys Clippy springy things for above Bearings a go-go (all bearings I could possibly get, we need to get the 2 countershaft bearings locally) Some good low km selector hub centers are en route from South Island. Next, I will rebuild the gearbox - well, Earle will rebuild it and instruct me to do some of the easy bits. Then I can finally aim for some twisties and give it a good drive, assuming it all plays the game. Looking forward to pissing around with brake bias, making all that stuff work etc.1 point

-

got the bumpers back from chroming. these pictures do absolutely no justice to how good it looks IRL. 2021-03-23_06-53-44 by sheepers, on Flickr 2021-03-23_06-53-54 by sheepers, on Flickr 2021-03-23_06-54-02 by sheepers, on Flickr 2021-03-23_06-54-10 by sheepers, on Flickr 2021-03-23_06-54-17 by sheepers, on Flickr 2021-03-23_06-54-24 by sheepers, on Flickr1 point

-

Fixed the Steering clearance issue with some Altezza/crown/jzx parts. All surprisingly similar to ls400. But fit 15inch wheels much better. Fuel Tank is still slowly coming along nicely. Just a bit more welding to go. Rear Bumper back on using factory irons. Cardboard air tank also in place. Alloy version should be ready this week. 8 weeks after ordering. Fitted Grill and Front bumper today. New bumper "iron" made up to work with the lack of room. Time will tell if it was a good idea to weld to the spring steel. haha Almost have most of the air fittings I need. Possibly enough to just mock it up temporarily to be able to push her outside for a proper look at how everything is sitting.1 point

-

1 point

-

Also picked up a childens CRF50 earlier in the year, because fuck it, why not. Bought a big pile of Aliexpress parts then got distracted by, 1988 XL185S. Amusingly similar to the XR200 of my youth. Probably could be considered 'shed-find' condition. WOF expired 1998. Rego on hold. Looks better in photos but might be one of the nicer things I own. Carb seized, I might have been too mongrel un-seizing it, so it has a china carb now. Had the rear shocks tickled up/regassed. Bought a new front guard to replaced the crazed/brittle one. Might try for a WOF next week on the 32 year old, original tyres. Its a bit scabby from sitting in a damp environment, but I'm happy. IMG_20200224_180439 by John Bell, on Flickr IMG_20200310_174637 by John Bell, on Flickr IMG_20200314_124427 by John Bell, on Flickr IMG_20200314_114515 by John Bell, on Flickr IMG_20200314_114525 by John Bell, on Flickr IMG_20200314_125051 by John Bell, on Flickr IMG_20200314_125045 by John Bell, on Flickr IMG_20200314_130507 by John Bell, on Flickr IMG_20200314_130519 by John Bell, on Flickr IMG_20200314_130937 by John Bell, on Flickr1 point

-

After almost 5 years my Max is now fully restored. The mechanical work was finished a while back but this year I got stuck in to the paintwork/bodywork. After some poor attempts at doing it myself a mate helped me do it right. Several months later all dints and surface rust etc removed - the body was repainted in the original Daihatsu yellow. Also, we re-painted/finished the bumpers and grill, and even the air cleaner (back to original blue under the bonnet!). The finish looks great and it is now really like a new car. I have put in new grey carpets and a new set of seatbelts in maroon red, as the old ones were well past it. A final big clean of the insides and it has come up a treat with all those who say Max as the sad and broken little car 5 years back transformed now simply amazed at the difference. Here he is...1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.925b7399b4ecc6c3956fe5efcc387e20.jpg)

.thumb.jpg.111dbc69b948fc346c74a4614c5ea15d.jpg)

.thumb.jpg.844a64bdc725055f1f00fb1f8beb19a9.jpg)

.thumb.jpg.73ac61a498311a7e19aae485c1184915.jpg)

.thumb.jpg.9145a1fc1bbd1c5ed45a557805396d6b.jpg)

.thumb.jpg.b0448f15aed133fb1c2d7e022dd0a706.jpg)

.thumb.jpg.30d3d7a0c8f168c56f6ec3ba6fc82e4f.jpg)

.thumb.jpg.71c0d6e0954268f9941d7cb3f2c8ad5b.jpg)

.thumb.jpg.3b44b76e73220f1a2bef01760a9ebdc7.jpg)