Leaderboard

Popular Content

Showing content with the highest reputation on 03/22/21 in all areas

-

Pulled the bellhousing inner core. Came out ok. I fill the pattern with raw sand first to get an idea of how much I need to mix. Messed up by 1/2 a kg so had to franticly mix more which meant I didnt pack it well enough. Still more than fine to use.26 points

-

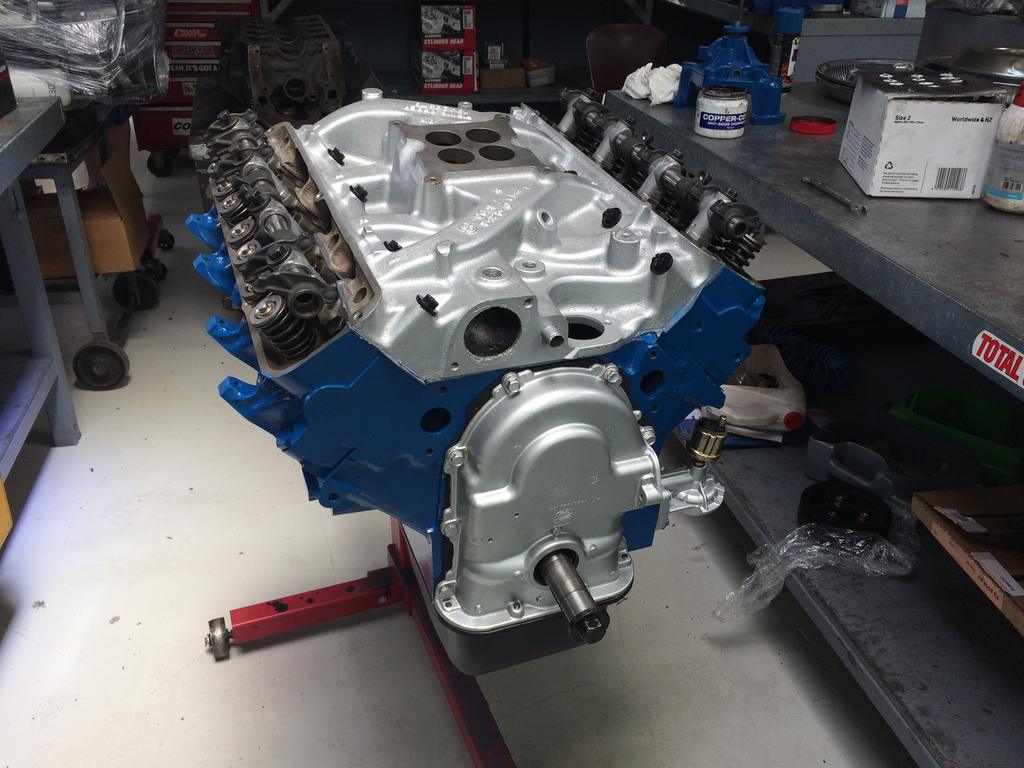

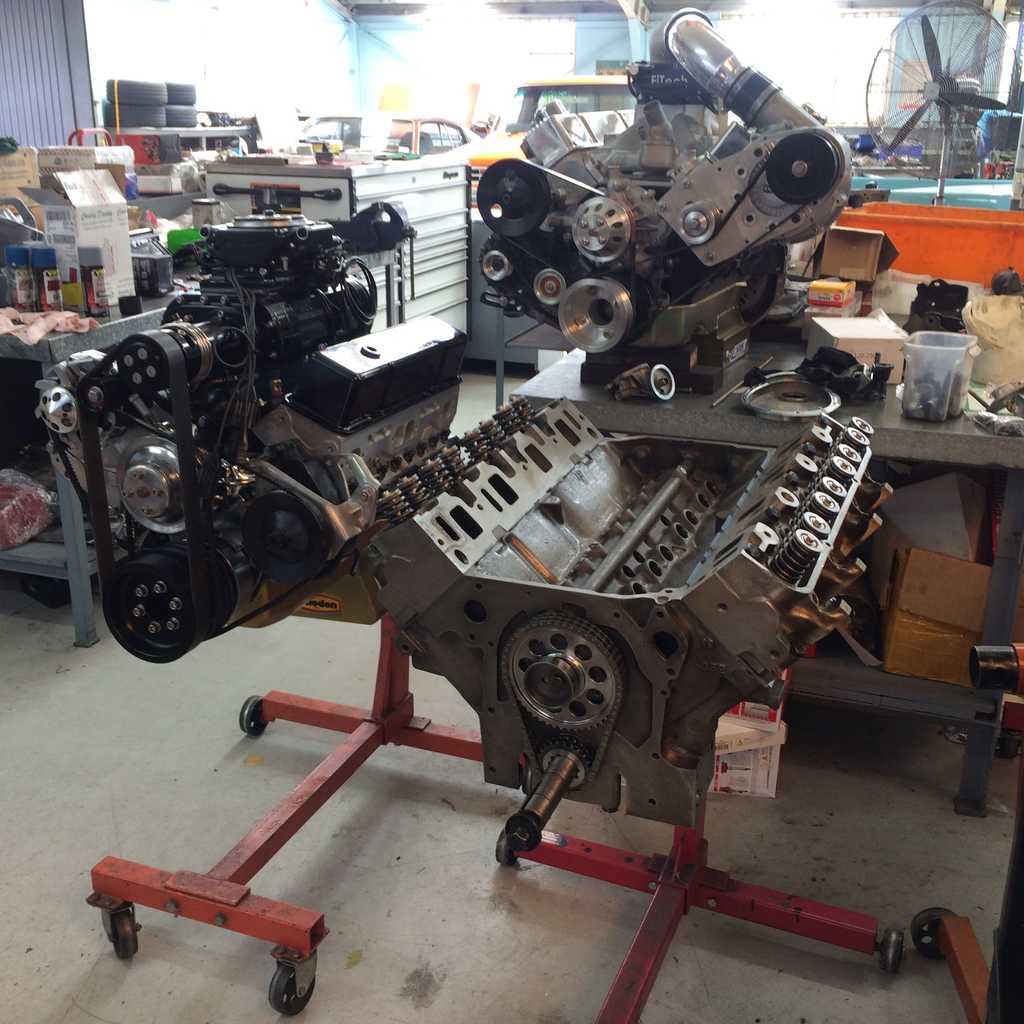

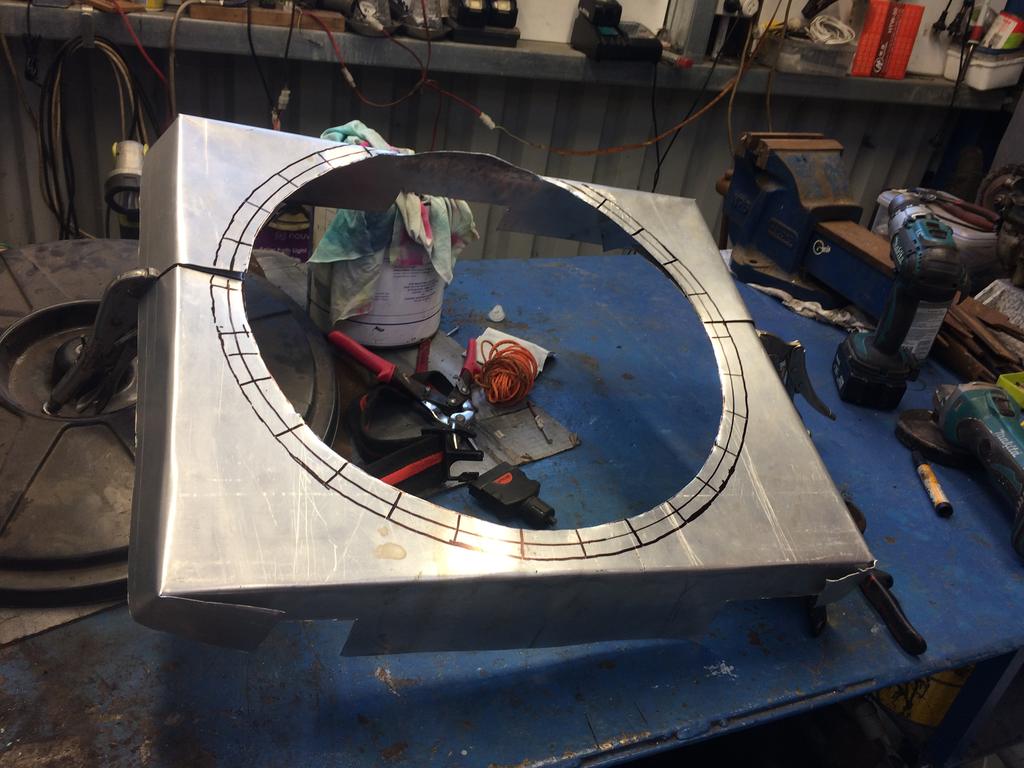

fuck im useless at updating this thread. motor goes and had a few hiccups on the way. Hei dizzy being shit and causing a misfire And me misplacing one pushrod not into the lifter causing one cylinder having no compression and still some overheating problems polished up my rocker shafts and machined the rockers to suit and in the hole. during the engine rebuild i spent some time and made a fan shroud its definitely nothing flash but worked with what i had and my current skills I then loaded it on a trailer to get the cam break in procedure done at work on the dyno. after that i fixed up my old points distributor and got that working as the HEI caused a miss and fitted a new set of ignition leads new cap rotor points and condenser and changed the mechanical fan to one with a better angel which works much better which is actually a chevy one I also got these valve covers as a freebee from work as they required welding as had been broken and customer never came and got them. and sat out the back for years so had them welded and started to polish them up Ive put these on the backburner as spent hours on them and painted one and the paint peeled off and the more polishing i do im still not happy with them as they are not the greatest casting. i suspect these are from the 70s also shows where it got repaired And while i was on a trip in the usa prior to covid i got some needed parts which i still need to fit. also just before i rebuilt the engine i cut off the rear mufflers and straight piped it as was really quiet no v8 rumble at all. then was loud and sounded like a tractor so rewelded them back on. to be continued...12 points

-

So it got picked up this morning, got into the tow truck with minimal fuss. Then over the course of a couple runs the front brakes seized on sticking it in the middle of the road. Gosh that got exciting , after trying a couple things went fuck out and sprayed some Wd-40 on the discs. Success! Then to make it better the wheels fit! Stoked, do now it's too unseize the brakes and give it a clean. Then it can go on a transporter. Yay. Anyway pics Going on And out side Diddys pad. R Monster truck! Imagine that without dropped spindles or a flipped axle. So keen.11 points

-

Spent a couple hours sorting the front brakes. Yeah the pistons are siezed solid, as in i had to bash the caliper off with a mini sledge. tried to free them LOLOLOLOL NOPE. so now the front has no brake pads, PROBLEM SOLVED. so its just a clean and should be GTG PRetty happy tbh . CHeers @Spencer for lending me some tools and space at your pad. will have to get something for AMy as a thank you haha. Oh and the shower, was getting pretty cold after the rain and stopping moving wow so much water. So stoked the rims and tyres fit , and even better I got +6 positive, which actually works out bang on , still inside the gaurd and give more room for wheels vs chassis. but holy moly , the amount of room under those gaurds is insane. even the rears have like 100mm+ on top of the tyre. so im really happy. Might move the front tyres on and get some in a 60 profile as its sitting up at the front now. but thats miles down the track. MUST GET ROAD LEGAL7 points

-

That’s a balls-deep sorta list. And a good way to spend 4k NZ ive done plenty of little stuff on the car. I spent ages blowing all the crap out of the scuttle/plenum. Was all nice and dry and came out entirely with the long nozzle air gun. Lots of ancient blue tarpaulin strands.. I then poured a heap of rust converter down the grates and what dribbled out the drains got collected and sent back down the top! Que the air gun again and it got maximum coverage. I’ll send some cavity wax down when I do the rest of the car. the current state of the bay. I’ll blast and etch this too. I chucked on my flash looking top arms with new camber bolts then discovered the car was too light with no donk and I couldn’t raise the hub to meet the ball joint lol. Also welded the wee pinholes (went really well) wire wheeled the gas tank and painted in converter.. got home tonight and gave it some hammerite ignore the patches of old sound deadener, gets a new sheet to protect it against the future boot floor then never seen again.7 points

-

7 points

-

First thing I did when I got home was pulled the speedo cable out and cleaned it. Now the speedo doesn't jump around any more. Second thing I did was drop one of the screws holding that mirror onto the door into the door frame, never to be seen again. Third thing I did was lose the keys and then successfully use the Starlet's key on it. (I found the keys again, but left them at home after) Then I went to the fuel station and found the Starlet key doesn't work in the fuel cap. So I'll fill it up tomorrow.6 points

-

So no further updates on the truck itself , but have been doing a bit of research regarding getting it over to WA and getting it road legal, i should be ok by the looks, only hiccup is if im considered an australian resident, which im pretty sure i am. Also while going through bitsa and bobs there was a weight limit so started looking and remembered that the truck actually came with the handbook. And it had a breakdown of the Vin number. Most of the stuff was obv. it was built in Fremont. And apparently has the Big f44 option which means it has heavier rear suspension and brakes. YAY. iunno if thats good or bad. got a bit caught cause online it says only the c/10 got a 3.4 ratio and the F44 option 3.73. I mean i dont really GAF becaue its not really gonna be hauling all the time. Pretty cool to know though. It should be getting dropped off at Diddy's tomorrow and then the fitment of wheels , a good wash down because WA are nazi's with bio security. then onto the transporter to go to its new home5 points

-

4 points

-

3 points

-

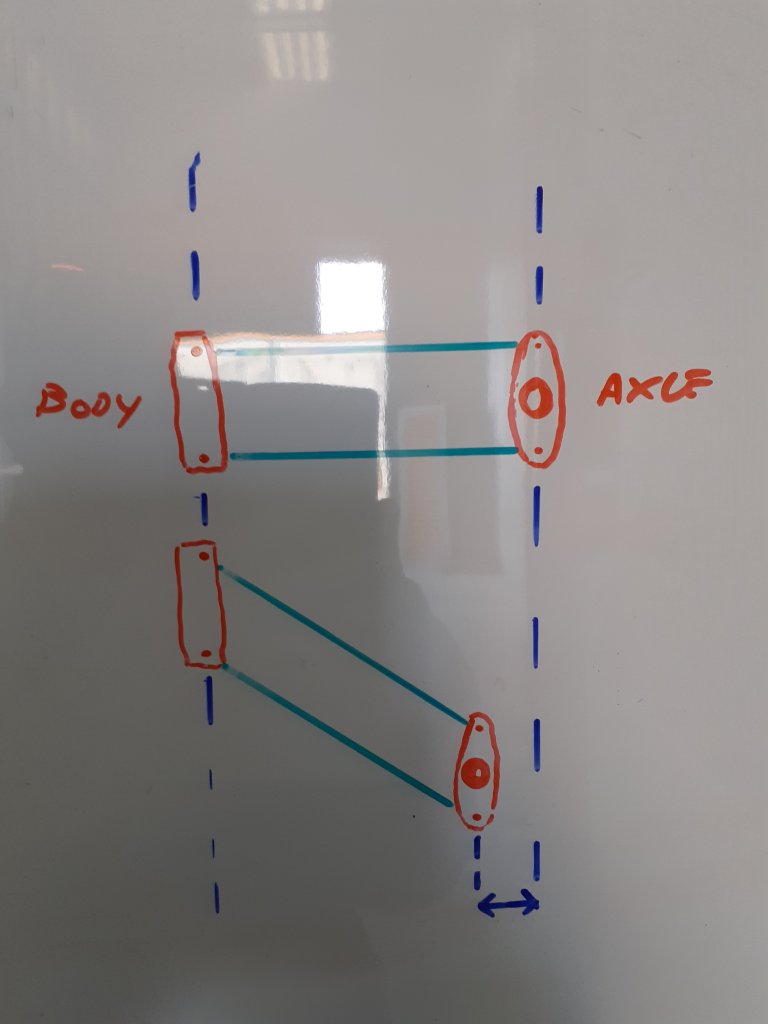

One of the suspension books I read described triangulated 4 links as doing 2 jobs and neither of them well lol.3 points

-

3 points

-

** discussion here - https://oldschool.co.nz/index.php?/topic/74793-helium-elbows-magical-rx-7-fb/ ** Some small progress Racing Beat exhaust now swapped on, deleted the air pump and associated components at the same time to shed about 5kgs and less components engine has to spin. It has definitely opened up the engine somewhat, it feels much less strangled now. There is a small problem of the number 2 rotor 6-port actuation shaft not spinning as freely as the number 1 rotor, so perhaps there is still some more power/drivability with that functioning perfectly. I am hoping to swap to S5 N/A complete injection with inlet manifold, CAS, AFM, coil packs etc as it's just that little bit newer, probably unlock a bit more drivability, power and slightly less fuel consumption. While the wheels were off I noticed the rear trailing arm bushes were pretty toast, and the front bushes aren't the best looking either so did another round of RockAuto shopping for more suspension components. Grabbed some Redline oil for the gearbox and diff too: I picked up a S5 80A alternator along with Banzai Racing double sheath pulley and adjustable alt bracket for some bling, also got a GMB aluminium water pump along with S4 N/A aluminium water pump housing (stock are both cast iron) which should save about ~10kgs up front. Will eventually convert to electric fan (apparently early 90s Ford Taurus fits almost perfectly and is super powerful and somewhat plentiful here) Have started pulling out all the original components (along with radiator, radiator bracket, shroud, air box, battery & battery tray etc to give them all a much needed clean up and give me space to do the water pump + housing swap. Also got the daily road legal (it had a leaking clutch slave cylinder, which lives inside the bellhousing on the throw out bearing, because Volkswagen) but couldn't help myself by getting some OEM Tiguan Savannah (how fitting) 19x9 +33 and some used Bilstein struts with H&R 1" lowering springs hopefully to achieve this look (pictured is a Passat CC but they are basically same car under the skin): Have got some Racing Beat lowering springs and sway bars on order too so hopefully they arrive soon! ** discussion here - https://oldschool.co.nz/index.php?/topic/74793-helium-elbows-magical-rx-7-fb/ **3 points

-

3 points

-

Fixed the Steering clearance issue with some Altezza/crown/jzx parts. All surprisingly similar to ls400. But fit 15inch wheels much better. Fuel Tank is still slowly coming along nicely. Just a bit more welding to go. Rear Bumper back on using factory irons. Cardboard air tank also in place. Alloy version should be ready this week. 8 weeks after ordering. Fitted Grill and Front bumper today. New bumper "iron" made up to work with the lack of room. Time will tell if it was a good idea to weld to the spring steel. haha Almost have most of the air fittings I need. Possibly enough to just mock it up temporarily to be able to push her outside for a proper look at how everything is sitting.3 points

-

Turned out the vibration was tyres. I took the fronts off and chucked them on the balancer to check the balance and straight away you could see they both had big lumps in them. Weird. Because all 4 tyres did it at pretty much the same time. Fuck knows. Anyway it's fixed and here's a picture of a tyre so you've got a picture to look at.3 points

-

its coming along. im just tidying up all the little things that need doing. ive got some generic belt line rubbers coming for it then i can put the door cards back on. the bumpers are away being chromed and ill get them back in a week or so. not sold on the black center caps and i have another set on order should be here middle of next month. i drove it up the road to get some milk and i fucking love driving this thing, its fucking slow but its cool to just cruze along in and i can see myself doing a bunch of Ks in this as soon as i tidy u the last few things. believe it or not its still got a warrant! 2021-03-18_07-56-27 by sheepers, on Flickr 2021-03-18_07-56-37 by sheepers, on Flickr 2021-03-18_07-56-45 by sheepers, on Flickr 2021-03-18_07-56-52 by sheepers, on Flickr 2021-03-18_07-56-58 by sheepers, on Flickr 2021-03-18_07-57-04 by sheepers, on Flickr3 points

-

2 points

-

Picked up some shiny pieces Also picked up some more 4AGE accessories Twin dellortos 45mm on a bigport manifold, will make swapping into the KP a lot simpler. Was told if I touch the coil it will kill me. So that's nice. Started on replacing the cam. Needed a new sump gasket so out with the old. The timing cover gasket did not survive so will order a new one tomorrow. also got picked up a new crank seal to stem the oil leak. Much oil. Need to find somewhere to skim the head a bit. Gonna go with 0.25mm. anyone have somewhere on the north shore they like?2 points

-

Well I think I got scammed on a cylinder head, payed a guy for a motorcycle head but no head yet. the one on this engine has the Finns going in the wrong direction for a motorcycle, but apart from that the JAP engine is an ok fit, I have over 50mm to make a new ignition system. A shit load of work is needed now2 points

-

Looks like most of the F44 spec is due to smog stuff. 1978 was the last without cats and egr or something. Pre smog!! Give that that leaded fuel!2 points

-

If you tidied up that snub nose so it was more of a defender look in terms of lamps, I reckon that'd be pretty decent!2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

The Dynafari continues to do the things it does amazingly well, in particular looking absolutely fucking banging from every angle, and moving all sorts of shit about the place with aplomb. I took it to the Nelson swap meet and sold fuck all, but talked myself hoarse with all the questions about it, so that was fun. On a side note one dude crawled right under it for inspection and solemnly informed me that it was illegal due to how I had welded the cross member brackets on, I suggested that the fact it had literally just been certified might be a contraindication of that, but he wasn't having a bar of it. We had to agree to disagree... Now for the adventures; I decided to take a punt on that fuel pump and slapped it right in there. This must be the 70billionth time I have removed that fucking seat and covers. I timed it up and got it to fire..... And it fully fucking red lined from the get go. I turned off the key but it turns out the cut off solenoid won't seat when there is all of the fuel pressure keeping it up because the governor is gummed open. I kept a relatively calm head though, grabbed the 17mm spanner and cracked injectors until it stopped. Yay. I then wiped the atomized fuel from my face and the inside of the truck and went out into the deck and had a quiet ten minutes of reflection. Then I unbolted the pump and bolted the old one back on. I started it with much trepidation, however it seems to have handled the fun with no ill effects, phew. This turned out to be more useful situation than I expected, because when I drove it the clatter was exactly the same but 100rpm further up the rev range. I had timed the pump differently than prior, so this tells me the clatter is almost certainly pump related. At this point I finally came to terms with how stupidly expensive getting pumps rebuilt was and caved in. I dropped the 11mm pump off to Jake at Marine and Engineering who stripped it and told me it was fucked. I then dropped off all the bits of the other pump and a half from my previous escapades and he confirmed they were also fucked. He did say the 11mm plunger and the compensator were salvageable, so I told him to just sort it out. I then frantically sold as much shit as I could in the next two weeks, which fortunately netted me almost exactly what I needed to pay for the rebuild. So here we sit tonight, with this resplendent bit of kit just waiting to be mounted by yours truly... I shall update y'all after the weekend.....2 points

-

1 point

-

1 point

-

1 point

-

Not much to add ‘cept I reckon a Watts linkage is far betterer than a panhard rod. And if ya going to the trouble of 4 linking ya might as well add a Watts.1 point

-

Move the wedding to day two, and we can all front up to drink the bar dry at your reception!1 point

-

1 point

-

1 point

-

This was on tm a couple of years back; It must be the only factory beam axle 4x4 dyna in NZ, they wanted moonbeams.1 point

-

WOW! Long time no update. So with moving over to WA this got left in storage, for 4 years. The place it was ended up closing up shop and they were nice enough to move it for me to another location,but it is a much smaller yard and its for timber importing/ exporting so you can imagine the movement in the yard. Got a call last week and it was pretty much a " bro, you need to get rid of this" So i jumped through a few hoops, bought a ticket and got over here. How i found it this morning: The bonnet rust was always there, has just got worse. the good news is the rest seems to still just be surface rust. STOKED! ANd after a new battery, fluid checks and a cheeky prefill of the carb, she fired up first pop. FREAKING STOKED! Let her warm up and burn all of the oils that made its way into the engine, poor bugger in the yard thought it was going to burn down. And omg unburnt dino juice, literal haze while idling. BUT IT RUNS AND MOVES! Now have to figure out a way to raise it back up because it is currently too low to get on a transporter. one more vid,1 point

-

Finished off the engine bay loom. I brought an ebay injector loom since it was way cheaper than buying the plugs from nzefi. Its off an old skyline they share the same plug as these rx7 injectors. Anyway it's held up at customs so once I have that it's all done. Things left to do before I can fire it up. Injector loom. Center the trigger wheel as it's off by couple mm. Install radiator/shroud with fan. Get the AIT sensor bung welded into the charger intake right before plenum. Get the o2 lambda sensor bung welded into exhaust. Run the meth/water lines to engine and tap in the injector pre supercharger. Get some methanol ** if anyone knows where to purchase in nz lemme no in discussion thread I Googled and tried a few including mere mere dragway but no luck. Set up ecu, timing, injector dead times etc Thanks for looking Discussion thread1 point

-

Finished the runner system pattern. So now all the sump patterns are complete, waxed and ready to go! . Only took 4 months.haha1 point

-

This is serious stuff in patrol 4x4, don't belittle it; JFF45 Import Safari are a special mix of components. For Australia we have Silvertop 8/87 to 7/95 Valve recessed pistons 28mm pin 950 grams piston and pins. Regardless of rocker cover colour. 25mm camshaft followers, Vac pump on alternator. Short squirters. Rear oil seal press in 86mm. 6 bolt crankshaft 61mm PCD, 58mm front oil seal. 18mm long oil pump gears. Blacktop 8/95 to 5/96 flat top pistons 28mm pin 1070 grams piston and pins. 26mm camshaft followers, Vac pump on alternator. Short squirters. Rear oil seal press in 86mm. 6 bolt crankshaft 61mm PCD, 58mm front oil seal. 18mm long oil pump gears. Blacktop 6/96 to 9/97 flat top pistons 30mm pin 960 grams piston and pins. 26mm camshaft followers, Vac pump under IP. Short squirters. Rear oil seal press in 86mm. 6 bolt crankshaft 61mm PCD, 58mm front oil seal. 18mm long oil pump gears. GU N/A 10/97 to 11/2002 flat top pistons 30mm pin 960 grams piston and pins. 26mm camshaft followers, Vac pump under IP. Short squirters. Rear oil seal Unitised 86mm. 6 bolt crankshaft 62mm PCD, 58mm front oil seal. 18mm long oil pump gears. GU Turbo 02/99 to 7/2007 flat top pistons oil gallery cooled piston 1150 grams piston and pins. 26mm camshaft followers, Vac pump under IP. Long tube squirters. Rear oil seal Unitised 96mm. 7 bolt crankshaft 72mm PCD, 60mm front oil seal. 21mm long oil pump gears. The change to the vac pump is very difficult to confirm seems there is lots of conflicting data even in the manuals of AUS supply. The 25mm camshaft follower has a very different camshaft fitted to the silvertop. It is quite different to the camshafts fitted after the actual silvertop model. This has quite a bearing on why the turboed silvertop produces torque and power differently from all models after. Also added to this the head for the actual silvertop is different for the black top even the 28mm pin blacktop it also has different precomb which have a slightly smaller chamber volume and shape. I can confirm this outright it seems all 26mm followers camshafts are the same timing and profile right through to the T model engine. But there is 5 part numbers for the TD42 engine world wide, which is interesting.1 point

-

She's been purring of late. I struck a deal with the neighbor for a row of shelter belt trees she had lopped off at ground level by one of those diggers with a massive claw. She asked him to lay them out evenly to make things a bit easier to move but she got home and there are 2 massive stacks all pick up stick like. I have spent the last couple of months just here and there towing a few through two gates and about 50-60m to our place. Ive only got a pile of ones she had 'topped' left to go now, so without the massive trunks on them which should be an afternoons work. Love the tractor has high and low box, a few of those logs are pretty heavy and it would only move them in low 1 and full tilt. Ill take a couple of years worth of wood for us and then should any OSers need some pine next year ill have it split and will be selling by the trailer load / cube to help recoup mine and the neighbors costs. First mod - removing the door - bloody thing keep swinging around in the breeze and was generally getting in the way. Exhaust fell off - luckily a temp one was an EL Falcon away (fits on for now, as it came off the car, didnt even bother making it look better.) Will have a straight pipe with flap made up, because sounds boss with no muffler1 point

-

This is scarily accurate, he was a 50 something with a cowboy hat and thin mad scientist in lieu of a mullet. 'Careworn' would be a nice general descriptor. Although TBH that describes nearly everyone at the swapmeet so maybe not such a great guess after all.1 point

-

The noise was hilarious, 2 stroke lawnmower followed by a car bonnet being dragged down the road.1 point

-

Did an awesome trade today. I now have a T57 crankshaft. Pretty lucky that it was less than 2hours away from me and the guy was awesome. Traded a bunch of my Lotus stuff + few $, he definitely did me a solid! Crankshaft from Engine #210 Rods from Engine #2931 point

-

The last inner core patterns prepped. Now just have the runner pattern and box to figure out.1 point

-

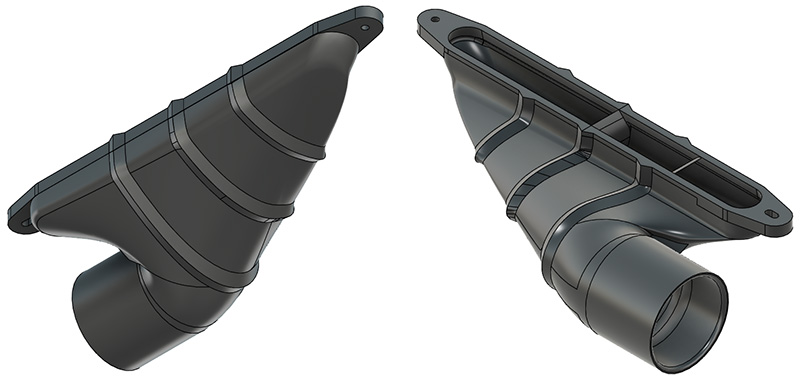

Struts are all welded up, thanks to my brother Matt for the excellent work They Passed their non destructive test at Stork in New Plymouth, And are now Painted, assembled and installed. The Front Raised and Compressed. The Rear, Raised and Compressed. Appears to be clearance. Will check again when I have some Air pressure in there. At its lowest point. It appears to be 10mm to the sill in the rear. And 20mm to the sill in the front. But I also discovered this Problem now things are going back together. Not 100% sure on how i'm going to do just yet. Few ideas. Have also modelled up some vent funnels for defogging the front windscreen. 3d Printed them in ASA plastic and test fitted them today. Fit great, direct the air as intended and leave heaps of clearance.1 point

-

Front and rear struts test fitting before welding up. Car at lowest position. 30mm to front sill, 10mm to rear sill, from the ground. Still trying to get my hands on some Moon discs to cover up these. But loving the progress. Welding next, then will be sent away for Non Destructive Testing in New Plymouth.1 point

-

Chassis Update: My Dads been working away on this when he has a spare minute. Been making various press tools and working out a process. Starting to look like a chassis rail! Not the easiest way of doing it but definitely the most authentic! Also if anyone needs a clock or a barometer restored hes your go to. As long as it doesnt take away chassis building time!1 point

-

The ideal speed for machining something so large would probably be 50rpm or less. So I bought an old concrete mixer pulley off trademe (around 560mm) and a 50mm pulley for the 3/4hp electric motor I scored from work. This gave me about 130rpm. This worked pretty well at first as I machined off the high spots, but as time went on and the cuts became longer things got complicated. The carbide inserts were over heating and wearing out well before half a pass. I found a home built saw bench on facebook marketplace for cheap, which had some different size pulleys and a stand alone shaft with bearings, so I snapped it up. I then modified my original setup and managed to gear it down using the shaft from the saw bench with an isuzu crank pulley on the other end, to around 62rpm. The lower surface speed was much better but the tips were still wearing out before a full pass, and I was starting to fight some serious chatter. It became apparent that the linear rail support had some flex, causing the compound slide to tilt forward and spring back causing the chatter. I braced it up with some random offcuts which made a big difference. (The linear rails should have ideally been much further apart and properly supported) Still getting chatter, I added 30+ kg to the back of the compound slide. This was enough band-aiding to get me through to the end, without changing the whole thing completely. I also upgraded from a battery drill with a cable tied trigger to a Nema 34 stepper as I needed a much slower feed rate.1 point

This leaderboard is set to Auckland/GMT+12:00