-

Posts

1,261 -

Joined

-

Days Won

1

piazzanoob last won the day on October 24 2017

piazzanoob had the most liked content!

About piazzanoob

- Birthday 30/06/1995

Profile Information

-

Gender

Male

-

Interests

oldschool cars

Converted

-

Local Area

Auckland

Recent Profile Visitors

3,637 profile views

piazzanoob's Achievements

Committed (5/5)

3.2k

Reputation

-

+1 for Ben at A/C shop was involved in a couple jobs where he did the install work of the A/C system as a retro fit on classic cars and knew his shit and also stocks vintage air and all other related A/C parts

-

I did it once in a honda odyssey at waikaraka park. did the jalopy race going hard in the van and it stopped going on the last lap... didnt quite get to roll over the line and it ended up being i snapped the camshaft right by the spocket. not one dent and was sad i didnt make the derby haha so if i did it again would bother doing the jalopy race

-

Help!: Pickup some wood trim - Flat Bush - AKL

piazzanoob replied to Goat's topic in Upper North Island Region

Sweet once I know an exact date heading that way will shoot you a message. As heading onto the other island via boat -

Help!: Pickup some wood trim - Flat Bush - AKL

piazzanoob replied to Goat's topic in Upper North Island Region

I can assist with getting closer to you if you can wait till November or December. Could do next month if it worked out also -

With the oil pressure thing. my guess is not with the Ryco z9 filter used them plenty as common yankie v8 filter and definitely haven’t had that when priming oil pressure before starting. As was done before a start on a fresh motor. not something like running the pickup too high or not enough oil to maintain that pressure? could also be something like pump spring has lost its tension as guessing not a new one? im also not sure if I would want to run a new motor knowing that could be a issue even worse if it gets lower after longer periods of engine running

-

is the regulator you talking about an external bosch one? re55 part number?

-

Mr.mk1's Mopar or No Car '70 Dodge Coronet

piazzanoob replied to RUNAMUCK's topic in Project Discussion

What Clint Said is what it needs. wide open throttle on carb should be wide open on the trans linkage. Sometimes easier with 2 people one underneath moving the lever and one checking at the top. and as others have said only real adjustment is the bands and kick down. But would only adjust the bands if confident in doing it. Otherwise normally 727s & 904s as quite smooth during gear changes. also check throttle travel too as with aftermarket carbs they need playing with and the amount of throw on carb can be wrong. Also how is the motor running? As you were asking about timing -

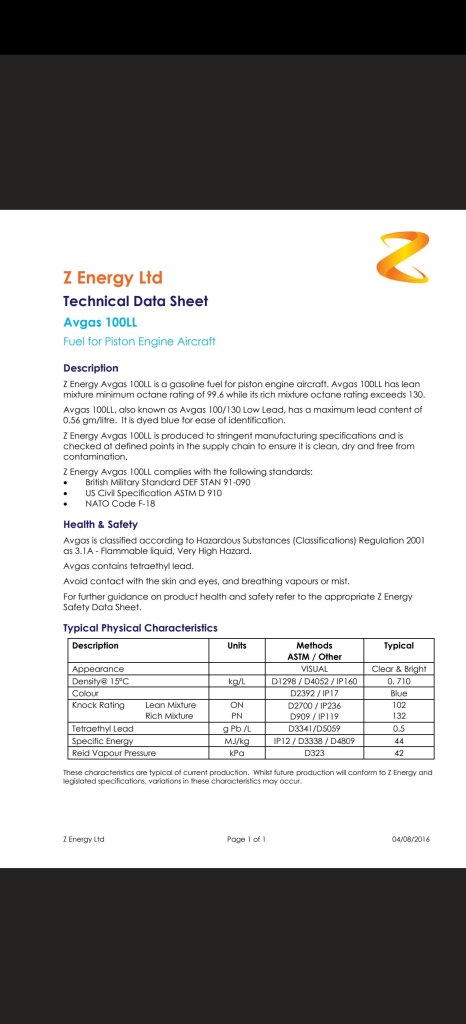

Ah right thanks Seen that avgas in rich form can get 130+ octane rating but nut sure if that is true or not

-

Anyone on her had much to do with avgas? Looking to do some testing with it on a 2stroke motor to try get more power. How easy is it to get and where is the easiest place to get it? Cheers

-

Rotormotors' 1990 FC Rx7 Brapta$tical coupe

piazzanoob replied to rotormotor's topic in Project Discussion

If your looking at doing some upgrades on the gearbox to help it last then i would look at getting the gears and shafts super finished. from what i know it was invented by NASA and is used on items under high stress. many racecars and bikes get it done on engine gearbox and diff parts. standard practice on high end racecar stuff. but gets done often now for things that get pushed to their limits. im not sure if anyone local to you does it but there is a crowd in auckland that does it. Morgan engineering in penrose. i have personally not had it done but seen the results of it done. -

K-Trips 1982 Holden Commodore VH Discussion

piazzanoob replied to KKtrips's topic in Project Discussion

That’s a good oil to use as definitely want a high zinc oil in it. as with lifter noise if it’s bad I would run it without the valve cover on the side that seems noisy and place a piece of cardboard to stop it splashing on the headers. Then use a hammer handle while it’s running and apply pressure to each rocker on pushrod side and find the one that goes quite. Or just get a long screwdriver and place your ear on it to find the noise. also hate to say it but comp cams haven’t got the best lifter reputation out there. I personally wouldn’t use them and would only use Johnson lifters myself. It’s a big issue with v8s and lifters. Not just comp cam ones either im guessing they were all stripped and cleaned prior to installing? As really want to catch the issue with the noise before it wipes a camlope off. although if the preload is currently zero then that would definitely cause a noise. How was the preload when you checked it? ive always set all that up before the inlet manifold is fitted and can see the lifter preloads. Then remove and fit inlet. Im guessing you already know all of the information I just wrote but if not here ya go goodluck as never is fun doing the job twice or having to lean in the engine bay. -

K-Trips 1982 Holden Commodore VH Discussion

piazzanoob replied to KKtrips's topic in Project Discussion

What engine oil are you using? also what brand lifters did you use? new carpet colour I think looks good too -

I did find this https://www.hawksmotorsports.com/82-92-camaro-firebird-dash-harness-used-select-application/ as im guessing your dash loom is cut up. otherwise might have to ring around some of the wreckers here or find a facebook iroc page and post. and im not sure also if an 89 loom will be the same or not. the engine bay as looking as if doesn't have any factory stuff anymore like engine related i would just start again and possibly just buy a rewire starter kit as has the wiring and colours and fuses and relays already. I think there is a few auto sparky type people on here

-

I kinda have a soft spot for these too. just not with the smog 305s or 350s they come with. sweet project seem like it needs much to get on the road?