Leaderboard

Popular Content

Showing content with the highest reputation on 08/01/19 in all areas

-

Got another throttle body adapter plate made in ali this time, thanks to @Stu . Plus some more throttles, which still need more mods, but done enough for test fitting. Been working through some clearance issues. chopped up and shortened water outlet as fouls on the front throttle, it welded horrible because old cast ali, but should be good enough. alternator is in the way, think have a solution sorted with a smaller alt and modding the bottom water pipe so it sits closer to the block. Blah, pictures:7 points

-

Progression. I drilled the steering knuckles out on a 20 deg angle, and then fucked around for aaaaaagggggggeeeeeees playing with different hights and angles on the struts, trying to get the best all-round set up. Once decided, I welded the piss out of them with Mr Miggins, and then put the front end together. It's got some decent steering angle, I just hope the racks quick enough. It's 3 turns lock to lock, and the steering is nice and light. Looking more like an offroader, I also did some highly scientific suspension testing, It's got about 5 inches of travel in the front, and 7 in the back, which is not too bad really. I started it last weekend and managed to free up the clutch (was seized from sitting so long) by standing on the brake while powering on in first gear, so pretty stoked that worked. Excellent. Regards, VG.6 points

-

Double post.. Might as well write a list of things to do -Re-core radiator (unless there's a drop in replacement) -Balance driveshaft -Sleeve clutch slave as it leaks -Fix a small spot of rust at the bottom passenger a pillar -New exhaust -Get wof then drop springs @Valiant5 points

-

5 points

-

Not much to update other than in trying to find a voltage leak spent an hour trying to find a fuse box only to discover there is no fuse box.. fucken poms.. Turned out to be in part an old switch the previous owner had installed for spot lights and also the shit stereo that was in there.. The only thing I've done for the last 2 1/2 years is the old man's funeral.. Figured the cops wouldn't pull it over in a funeral procession.. (reg on hold)4 points

-

Bought one of these from Moortool for the same $139 this week. Tried it out tonight, and it's amazingly better than the cigweld one I have been using. Might actually be able to see what I'm doing with the weld pool now.3 points

-

9 Wow 7 months without an update! To be honest I lost all motivation. Everything I tried to fix either turned to crap or created more issues. It's felt like a constant battle, I've quite literaly got a piece of shit. But I'm to far through to give up! So not much has happened. I have fitted a complete set of standard viva springs. I have plans to get them compressed or at least get the rears compressed and chop the fronts a little. I want to lower it about 30mm. So this should not be an issue. In getting to this point I have learnt alot about suspension springs and can swap them out pretty quickly! I got the radiator recored. It was an expense I didn't want to endure but getting a brand New looking radiator back was a lovely feeling! I was keeping an eye on eBay UK for a nos one for a couple of months but nothing came up.... until 2 days after I got mine back! Typical! I fitted the bigger front brakes from the donor car. Unfortunately one of the calipers is damaged so I'm going to refit the original front brakes for now and upgrade to the bigger ones at a later date. I'm hoping to do the swap over the weekend and finaly get to test drive the car! I still have the rust to get sorted. Which I think is worse than I first thought ! I have lots of little bits and pieces to sort. I'm feeling motivated so hopefully progress will be made! My biggest concern at the moment (and it shouldn't be) is the bodywork and paint. I want to return the car to standard wheel arches and then the whole thing needs a respray. It doesn't need to be perfect but it's not gonna be cheap! But I shouldn't really be even thinking about that right now. I just need to actually get it on the road and use it. So overall not much of an update but hopefully things will start moving forward at a bit more pace! Heres how it's sitting eagerly awaiting the open road!3 points

-

3 points

-

I want to see them chopped up and made into a multi cylinder engine3 points

-

Finally have this turbo back in one piece and have finished the flanges needed. Ive made up some -4 line for the oil to it and set up a tee from the oil gallery on the engine (yes this engine actually has a pressurized system) Waiting for some weld on AN fittings to finish the oil lines, then the manifold...... the manifold hmm i have the steam pipe to make a log style but thats so boring. If i hold off a bit i can make it two into 1 out of stainless i just dont think i can wait.2 points

-

Make sure you've got a water trap on the compressor that you're spraying epoxy with, otherwise water straight back on your steel2 points

-

Paging @Spencer I put a lot of effort into this on the roof of my wagon, including sanding, wire brushing, metal prep (phosphoric acid) and undiluted hydrochloric acid (concrete etch type) multiple times. Still had some black spots/pits after all that so I just etch primed it and carried on.2 points

-

I was seriously considering doing this. What's cooler than 1 motor, obviously 2 motors! But it would be gokart fast and even I wouldn't want to ride something like this at 130kph! These liquid cooled motors start at the bottom end around 8hp, and go upward of 15hp for the top of the line European motors. Very impressive for such small capacity. That's my attraction towards these motors - stupid power from such a small motor...2 points

-

Electrolysis - brass plug should fix that. Cavitation - a cavity behind the plug creating air bubbles, is the plug in deep enough? Coolant mix (but I doubt it) - no more than 50/50 mix, 30-40% antifreeze is best. Too much af to water can be acidic.2 points

-

2 points

-

1 point

-

1 point

-

Got some new TM reproduction mud guards today, will mock them up tonight, also found the bike had thrown the chain off and it has broken the plastic cap over the neutral switch and it bent the clutch pushrod, not a major but I now need those 2 parts, don't need a neutral switch but the plastic cap holds the oil in the gearbox. also got the steel to start making the new exhaust.1 point

-

1 point

-

More like 8hp between all 4 motors? . Please build a bike with 2 engines.1 point

-

Should I design up a board to slap an arduino in that has a 12V reg, inputs and will drive ignition / relays / whatever? (Carduino) Also, many of the cheap Chinese arduino clones use the CH340 usb-serial interface chip. Unfortunately the drivers for this are a bit shit. My main desktop was having power/sleep mode troubles, and ended up rebooting everynight (resetting my workspaces, and long running jobs). Tracked it down to a WeMOS board, so all is well if I unplug it last thing. HTH / H4nd1 point

-

1 point

-

1 point

-

1 point

-

Was quoted $850 to drop the old head off and pick up the new head a few days later everything changed over, valves seated, Old cam new seals. With gaskets to refit the head myself. New head is in the late $400s before GST. So I didn't think that was too bad. Local reputable builder. Can source a bottom end rebuild kid + Water Pump, plus timing gear myself for around 400 also. Confident in doing it all myself. I've never done a 4cyl 4 stroke before but they can't be that much different to Honda B&S clones on rental go karts. And I've rebuilt a metric fuck ton of those things. Just weighing up the options. If I'm going to do the head, Might as well do the block with bearings ring and seals, and frost plugs. etc Waiting on my brother and law to finish with his engine stand so I can steal it and tear the motor down.1 point

-

1 point

-

Engine build has been a bit more of a mission than expected. Found a replacement for the cam, new second hand one is mint compared to the old one. Can see the old cam on the bottom with chunks missing from the lobe and grooves ground into the surfaces. Also found some good replacement rockers as those surfaces were equally as worn. Pretty much all the internals are either new or as new in the engine, pistons, gudgeon pins, rings, cam chain, tensioner, cam, rockers, etc... hopefully this thing isn’t rattley when it fires up.1 point

-

That's exactly how I planned it, the kids keep asking me to "Adjust the drift Dad"1 point

-

thats better. also it works. 2019-07-29_05-40-57 by sheepers, on Flickr 2019-07-29_05-41-07 by sheepers, on Flickr1 point

-

That turnbuckle is genius- though not sure if you planned it to be that way? you can vary how much the rear wheels want to go straight (shorter turnbuckle = they want to go straight rather than swivel)1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

So I've done a bit more on this dirty Berty. I flipped it over to finish off the frame extension, and cut off a few unneeded bits. Seeing as it wouldn't rev or idle with no choke, I cleaned the carbs out, they had sea weed growing on the float needle things. I also welded up the plenum, and played around with restricter sizing (had to go down to a 35mm opening) this resulted in it running waaaaay better, and revving out like it should. I also removed all the washers that had been put under the needles (they were trying to make up for them not lifting due to lack of vacuum) and it ran even betterer again! I needed some way of mounting the air filter, and remembered I still had some silicon left over from the hektik Hilux, it was perfect, and pretty! Little vid of it running betterer, the linkage was a bit sticky, hence the high idle then dieing out at the end. Then I took the wrap off the headers as it was fucked, and cleaned the headers up a bit. Then I changed the muffler out for a prettier one, it's from a GSX1200, so even though it has one chamber (the other was straight through) it has a larger outlet than the original, so should flow well. I had a sprocket that needed boring and keying, but decided to go with a plate wheel and bolt it to the original sprocket hub. Bit bigger than the OG one. I then put the back end together, and ran a brake line up to the slave cylinder. Got a few hoses from the wreckers, this female - female clutch line from an AE100 Corolla made life easy, used the mounts and all. Then I made a new gear shifter linkage, as the old one was fucking rank. I also moved it forward a bit to suit me. Next was sorting the steering wheel/shaft/rack. This was a bit of a mission, but it worked out well. Managed to mount the wheel on top of the bar it used to be below, and move it forward a bit, so I can pilot the vehicle, with the added bonus of being able to get in and out of it. Also put the front suspension back together, so I could work out the pedal position, and the position of the bar that mounts the steering bearing, clutch and gas cable mounts, and the brake master thing. The brake master has to be in this funny frame thing to miss your legs and still fit under the hood. Once all that was done, I crimped the cables, but they were too short due to me lengthening the frame, so I made little extension doofers out of D shackles. Now the back ends done, all the controls are pretty much done, and it's running better, I'm getting onto doing the front steering knuckles and tie rod ends. Still much to do, but progress is being made! Regards, VG.1 point

-

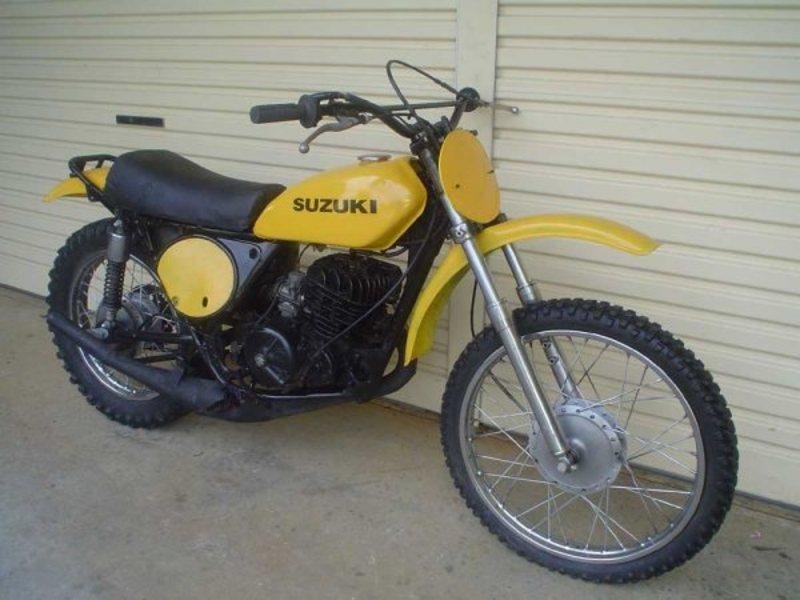

1st I will make a down sweaped exhaust, I think the yellow bike has an expatiation chamber from a late model MX bike witch has a wedge cut out to make it straight? also I need to get some guards, my old work as alloy guards like on the yellow bike but I might just go with plastic and paint them, I am thinking Suzuki TF125 mud bug front guard with the mudflap removed, if anyone has one? still looking for ideas for a rear guard Also a pair of TF125 rear shocks would work, was someone here buying one for the front forks?1 point

-

Why are the starlet itb's in this thread? Because the the inlet manifold on the hilux sucks. Not power wise, it seems to work good. but it vibrates, cracks and the big plenum doesn't work with what im trying to do. stalls out easy and any kind of cam setup other than factory, even cam timing changes on stock cams makes it a whole lot worse. wont idle on all cylinders and stalls real easy. not ideal for 4wding itb's will solve the big plenum issue, also will be able to isolate the plenum from the engine with some short silicone joiners. to solve any vibration issues. So had those bellmouths in above picture from another project, recycling; extended them by welding some thick wall tube onto the bottom machined a taper into them to suit the 52mm throttles and slightly adjusted the bellmouth so has bit more of an elliptical shape. machined some of the excess off them. could have taken whole lot more off but was over it by this stage. will probably test them on the starlet before welding them into plenum1 point

-

Unfortunately I was wrong. It still leaks oil. Not as bad as before but the seal needs to be changed again. I took the engine out of the car on saturday and will take it to an engine shop this week. The crank needs to be removed or At least loosened and lifted to fit the seal properly. I feel this is a bit more than I can handle. I can also get the engine looked over to make sure all is well. Getting quick at removing the engine now! I finally found and bought some tyres! So to cheer myself up I got them fitted and balenced and chucked on the car. They are a little chunkier than I would have liked but they look great on the car and are a good tyre and a good price!1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.384ff72c8d2b0ee0d34a7bdedb55bdcf.jpeg)