Leaderboard

Popular Content

Showing content with the highest reputation on 03/26/24 in Posts

-

12 points

-

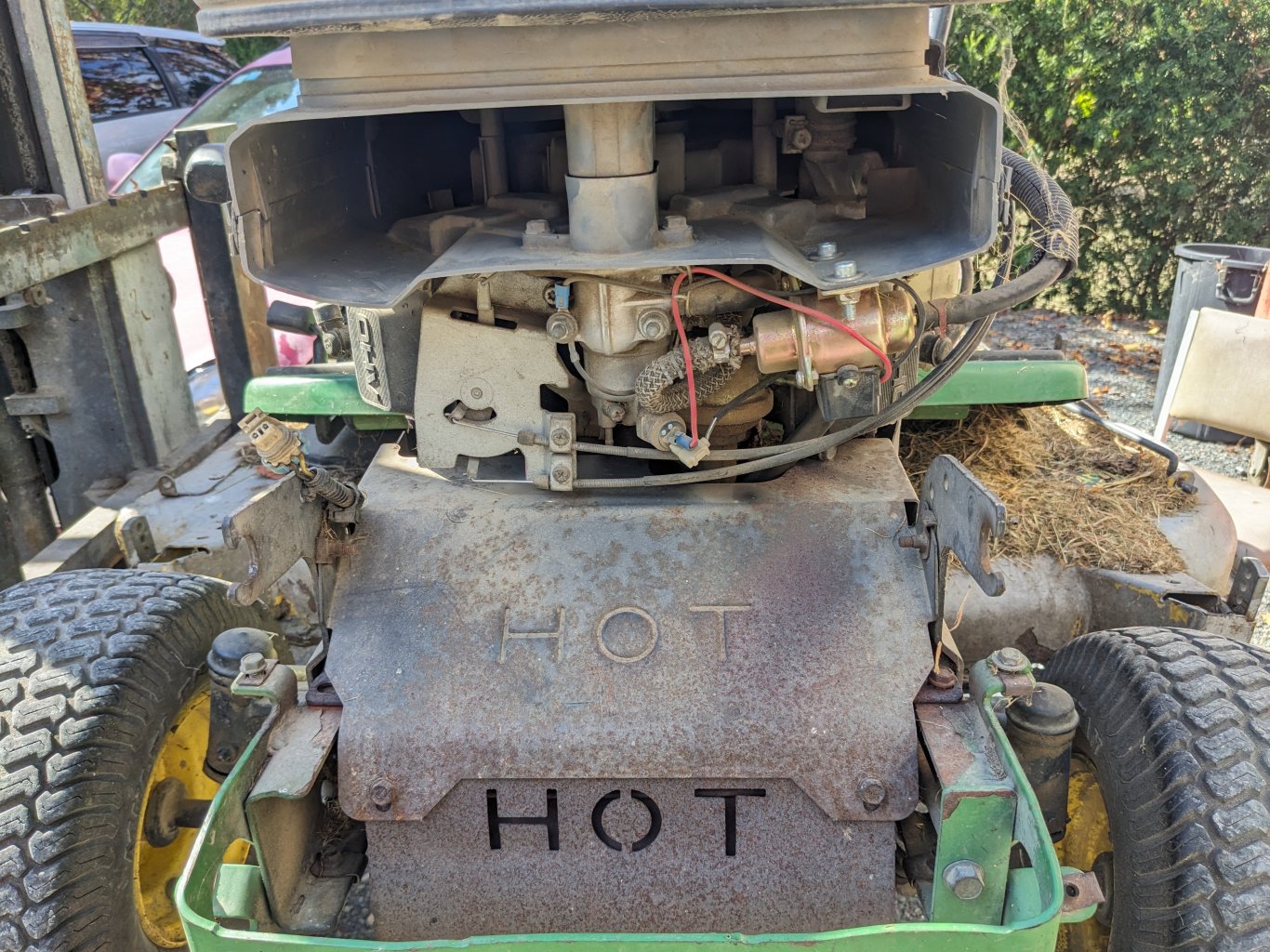

Organized time off and ferrys etc and a cool 10 days hanging in Fielding. Real barn find! Her names on it so this must be it. We pumped up the tyres and had a general look around one day Then cleared all the stuff out over the next few days, did a lot of gardening too, Hooked it up to the van and pulled it into the light9 points

-

Then of course it was time to have a good look while cleaning it a bit, and taking stock So, its a 1974 Holden HQ Belmont Sedan in Orchid Red. Last wof/reg in 2001, so was on the road into Kpies early 20's around the same time i met her. Seems it also got the Torana front seats, maybe the centre console? Interior looks pretty good under the dust. Overall looks pretty straight and complete. Some rusty bits of course but not too bad at all for one of these 8s out back and 7s up front, massive CNG tank in the book gives it a rake. This car was a NZ new factory 202 manual 3 on the tree car. Bill bought it cheap from a guy who bought it to put the v8 that was in it into something else, or something - bought with no engine in it anyway The engine and box now in it is a 173 (2.8l) with a manual 4 on floor from the aforementioned rolled Torana, which had recently had a fair bit spent on the engine (??) It has a single barrel Stromberg and also has CNG. Only $4.20 to Whanganui! Took the plugs out and oiled the cylinders, cleaned the sparkplugs and filed the points and hooked up a battery. Neighbours come to assist. Many opinions were shared We managed to get it to fire off on squirting gas down the yap, but it just wouldn't keep running. The consensus is that the timing and/or the electrics are weird Brake pedal does nothing till halfway then hard stops, no braking action. Handbrake kinda works. Engine isnt stuck and clutch is free and gearbox goes into all gears. Bill is stoked it fired up, Kirsty is happy, and that it rolls at all is good enough for the transporter man. We push it back in the shed to wait for the transporter8 points

-

After nearly three months my half shafts are done. Thankfully they fit really well and no binding with the full suspension travel. How he did it was to make a jig out of angle iron. The Imp end was a few mm smaller so he stepped the jig to compensate. Then notched a V into the ends of both and lots of welding to fill it up. He checked the balance and said they were fine. In the meantime I have installed the slave and bled it with the trusted broomstick method. On the hoist the gears shift fine and no crunching and I can even find reverse which is novel in this thing. I presently have the coolant bleeding itself and have remade the radiator mount. The bolts welded into the side for mounting it were flimsy junk so I had to come up with a new solution which seems ok but may hinder my chances of putting on an electric puller fan. I have a short list of works to finish before going to LVV but mostly bodywork and fine tuning. I'll see how it feels after the test drive which all being well should be this evening. Sadly I have to spend time sorting my C20 for the wof fails. I really need to find a new place. 3rd wof in a row I have failed on a ball joint that was fine the previous wof. The chances of three ball joints that are 60 years old failing one at a time every six months is a little disappointing for me. Especially as the replacement always feels worse to me but passes. Oh well. I have this year to get down to 2.5 wofs and I'm on a mission!8 points

-

Sounds like a great excuse for a large sump with a 2 stroke detroit dewatering pump. You care about your neighbours so it has a muffler but it mostly just rattles around on top.6 points

-

Went for a decent blat into town tonight. A few things to note before I forget. Cruises at 2200rpm at 100kph and has buckets of power upwards from that so the gearing is spot on. Maybe because Im used to a shitty old slow chevy but it feels like a rocket. Makes a weird noise for a second on startup. The sump is too low. Either I have to put in stock springs or modify the sump. @cubastreet got any spare sump pans? The oil filler pipe is now hitting the firewall so I have to modify that again. Second is a bitch to find from 3rd but I'll get used to it. It has enough torque to take off in 4th but I'll leave the clutch alone. I might make the aux water pump booster linked to the ignition as I forgot to turn it on. It's criminal me having this car and living 10kms from a decent corner. It wants to corner.5 points

-

5 points

-

Nah 20 years is a new car that only needs a wof once a year.5 points

-

Yeah nah. I'll just have a backwards shift pattern tyvm.5 points

-

Been a minute or two.. had shoulder surgery late last year which slowed me down a bit. Just prior to that I got dad to come up and help me build a retaining wall. Still got the ends to finish off but it turned out pretty neat for a first timer. Moved the bus up to the building platform and built a sketchy roof over it so it could dry out better. I’ve since removed the tarp. I’ve also got my container down there now and the place is looking more like a builders storage yard.5 points

-

This is not my car. Im just the low rate mechanic. What i knew about this car was: My Father in Law, Bill, has 'The Holden' in a lean to shed. Kirsty learned to drive in it, and shes always wanted it and Bill said she could have it one day. It has the engine and gearbox (exact details unclear) from the Torana her older brother rolled when he was 16 'dodging a rabbit' on a gravel road. Its been in the shed pretty much since they moved into the 'new house'. He used to bring it out sometimes to wash it but hasnt for a long while. She put her name on it a few years ago and sent me a pic. My first and only view of it till now. Then a couple months ago, he said 'come and get the Holden' So, we did.4 points

-

4 points

-

4 points

-

4 points

-

A few hurdles... Only one side worked for the hoses. The next size up is 495mm long and sounds like it would work good. It's over $100 for the hose which is spendy. But for once in my life I want no joins in the radiator hoses damnit. So will just do it. (The non fitting side is currently 305mm) Then I've been making good progress on the wiring, a new roll of DR25 turned up so I finished the injector loom and tested it. Injector 1 - working fine injector 2 - working fine injector 3 - nothing injector 4 - nothing injector 5 - nothing Injector 6 - working fine I figured I must have derped the wiring somehow, so I pulled my loom back off and test it, traced wires back, blah blah. All seemed okay. Well, turns out that the wiring wasnt an issue, but the injectors are. 7 out of 10 of the BMW injectors are seized. BMW life! hahaha. No big drama, as it's probably a good idea to start with some slightly bigger injectors anyway. Internet says these factory injectors are somewhere around 248cc which might have been borderline for high rpm, depending on the deadtime. For interest's sake I will chuck these in Dad's ultrasonic cleaner and see if they unjam at all. Anyone got some suggestions on a good set of long pintle EV14 injectors? Over 250cc and under... say... 500. If there's some common 6 cyl car that is pickapartable I'll go grab a set. Needs the long pintle.3 points

-

Paint "free candy" Or "Hannah Montana concert shuttle" on the side.3 points

-

in new zealand it always needs to be licenced/rego paid to be on the road at 40 years it becomes "classic". this means a slight change to "continuous licencing" in that it takes a little longer for it to be come deregistered if you forget to put it on hold3 points

-

3 points

-

0.9mm is quite a common compromise wire size. Do alot of solid core mig at work and its my go to for a little bit of everything. Would have gone through over half a ton of it over the last 3 years. I do find its quite lacking at anything big but if I do have 10 and 12mm work to do ill chuck a roll of 1.2mm on for the occasion. 0.9mm can do comfortably about 2mm to 8mm with correct prep all day.3 points

-

So I decided to make it one piece which I should have done the first time. It makes it much easier to get both sides the same. Pretty much the same design apart from that, with the boots sheet metal sandwiched between the two pieces. All just being tacked together for now until I am sure it is right. Shouldn't need an additional brace between the two sides now.3 points

-

I won't bombard you with 50 more Panel Barry Hakosuka photos but this one is a huge milestone. The majority of the fabrication and rear end structure have been completed and the final weld up is on! The chassis is now razor straight, likely straighter than when it came out of the factory. I can't remember the last time it had a rear end on it? It's been over 5 years for sure. The back panel you see there is the original one which he's using to get the correct holes for welding then will be replaced with a brand new reproduction item that I've provided. Onto the front and to my amateur eyes it doesn't look nearly as bad as the rear but I'll leave it to the professionals on that one. He will have a poke around, clean up what can be cleaned up and replace what needs replacing.2 points

-

Think the point was to try do it before the clocks move back (forward? Fucked if I can remember) so maybe midweek next week or something.2 points

-

2 points

-

When did you fullaz wanna do this? This weekend or nekweek sometime?2 points

-

2 points

-

Trust me to turn a one hour job into two days. Ever since I had the SSR MK3s built there was some fender scraping on one side in the rear (which is why I decided to switch it up briefly and have one side swapped around front to back). This is partially because the rear arches are probably uneven and filled with bog and partially because I had the wheels built without measuring anything. Seeing as I was doing a Whiteline stock order I added one of their adjustable panhard rods and try to square up the rear diff. First issue was one of the nuts stripped threads so I had to cut that off and made a hash of it, then I was trying to do this job without unbolting the 4 control arms which meant the diff was super hard to move around so I gave up and went home to sleep off my hangover. Day 2 I straight away unbolted the four control arms and life was considerably easier. I need to get another castle nut to replace the one I cut off but otherwise it's on now. Also a little bonus is the control arm bushes appear to have been replaced so they're still nice. Seems like I was also adjusting it the wrong way so rectified that and I think it's about even on both sides now. Keeping in mind the guards are filled with bog so also not really even. I was thinking about doing a slight one way height adjust on the rear but might leave it for now until car is back to driving and see how the clearance is. Long term plan is not to use those wheels anyway.2 points

-

2 points

-

Driveshafts in Oil in Coolant in Popping and banging when I try to start it Realising the plug leads are 180deg out Boom Then realising the fuel pump is leaking like a sieve and it is a $14 AliX special so not unexpected. Then finding the original Facet pump and checking it works, it does Then realising you have no fittings to make it work so no driving2 points

-

Car back on the trailer and off to Christchurch to have exhaust fitted. Corey from Elite Exhausts has got the job and after discussing what I wanted he sets to work. We are going with a 2" system with standard oval muffler before diff and a Coby after. I really like watching someone working who knows what he is doing. He has it all mapped out in his head. No tape measure, just a piece of wire to help form curves.. He cut off end of headers to start 2"pipe and fitted V-clamp, welding in place. Next placed muffler in place and bent up pipe for first section. Welded in place and fitted mounting bracket. Next put Coby in place and bent up section over axle and welded to first muffler. At this point Corey said we should see how it sounds. While he held Coby in place, I started car. Perfect, has a nice throaty note but not to loud. Welded Coby on place and mounting bracket. Finally put on tip and all done. Just a few more things to do. Wof, Wheel alignment and tune. Shouldn't take to long ??? Project Discussion https://oldschool.co.nz/index.php?/topic/84912-petes-mk2-escort-1600-sports/page/3/#comment-26256862 points

-

Scooped the engine back out the hole. Then put the gearbox back in so I can do the clutch and brake lines. I'll also be redoing the engine mounts as cert man wanted them thicker. And I can weld in the relocated steering column lower mount. I'll also be clearancing the chassis rails a bit more for the passenger side exhaust cause I put it in the wrong place the first time. And some clearance for the steering intermediate shaft. Epotec goes a bit toasted marshmallow if you use a MAP gas torch to soften underseal for scraping it off...2 points

-

So when I left off the motor was back to completely disassembled. I got the cap machined and now it's back together with the correct crank end float. The other thing is that I got the head flow tested with the porting and bigger valves. It shows about an 11 percent increase over stock. I was kind of hoping for a bit more but using the "no science just hog it out" method is probably why 11% was the result. Anywho, now it's time to get the head all sorted and I can bolt it on. Need new valve springs, new spring washers and retainers - all of which will need to be custom or at least sourced from some other engine. In preparation for this I shortened the valve guides to suit the machining that the head needs to clear the higher lift. 3mm off the exhaust and 6mm off the inlets2 points

-

Minor maintenance tasks update. Thought I'd give the air filters a birthday day to protect my newly rebuilt Dells. Cleaning kit is only 40 bucks from ripco/supacrap autos. Stage 1, clean all the nasty. Once dry, stage 2, re-oil and done! Colour match filters. Other thing I've been chasing is this very annoying oil drop from the filler/breather. I wasn't sure exactly were it was getting out from. Pretty sure now it's from the breather hose connection as it's the factory fitting is slightly smaller and doesn't have a barb like the ones I put on the catch can. I had hoped just hooning on the hose clamp would work but no so I'll ad that to the list.2 points

-

1 point

-

The start of a probably long process of repair and conversion Get my hands on it in a few days finally. Will upload photos then Link to discussion:1 point

-

1 point

-

Took it in for a WOF, needed to replace an axle seal, front left brake line and repair a tear in the sill that looked like it’d been there for the last 20 years. Giving a rap to Tuakau Panelbeaters for doing the job on such short notice. Car is sold, I’m happy/sad.. time to focus on building my shed now.1 point

-

1 point

-

1 point

-

Been a while and I have been pretty shit about up loading on here. . But the car is running and driving it is still on a factory motor (apart from ARP head studs) she is running 10psi at the moment and is happy with it.. We are still road tuning and she not legal at the moment ...but I have taken her to a bunch of meets and to work a few time... (its a fun car Lol).1 point

-

The SW20 radiator turned up, and thankfully it was indeed 755mm wide, not 770. So just needed a small snip up one side to fit. There isnt actually too much in the way of the fins being shrouded by the front panel, because those side parts are mostly the end tanks. So ended up better than expected, it will mount up to the front panel nicely. This is the amount of room to the crossmember level: My next problem was that the radiator outlets are 32mm, but on the motor they are 38mm. Wellllll, turns out that you can buy flexi hoses with 32mm at one end, 38 at the other. At what looks like good lengths (400 for one side, 300 for the other). So ordered some. Too easy! I'm glad to not need a join in the hoses this time. I printed some lower radiator brackets which bolt onto the crossmember similar to the ones I had for the Altezza radiator. I remember we made the altezza ones out of aluminium, and it seems like it took forever and was a really hard job. Now with a printer it's just incredibly easier to test print and test fit a few iterations within hardly any time at all. I've also got all the fuel lines connected, throttles are now mounted on carbon nylon manifolds, throttles are balanced and connected. My to-do list for getting the motor fired up is rapidly shrinking!1 point

-

Rack in, u joint angles aren't stuffed.... Be it a touch short. Everything rotates and doesn't bind. Tried jazz axles, too long by about 10-20mm both sides, need to trip to pap and conduct some research. Passed pictures and vid to Julian cert man, so we'll see if this is going to the metal recyclers or not soon1 point

-

Go take a marketplace Hilux for a test drive and switch them out. Thats what Billy T would do.1 point

-

1 point

-

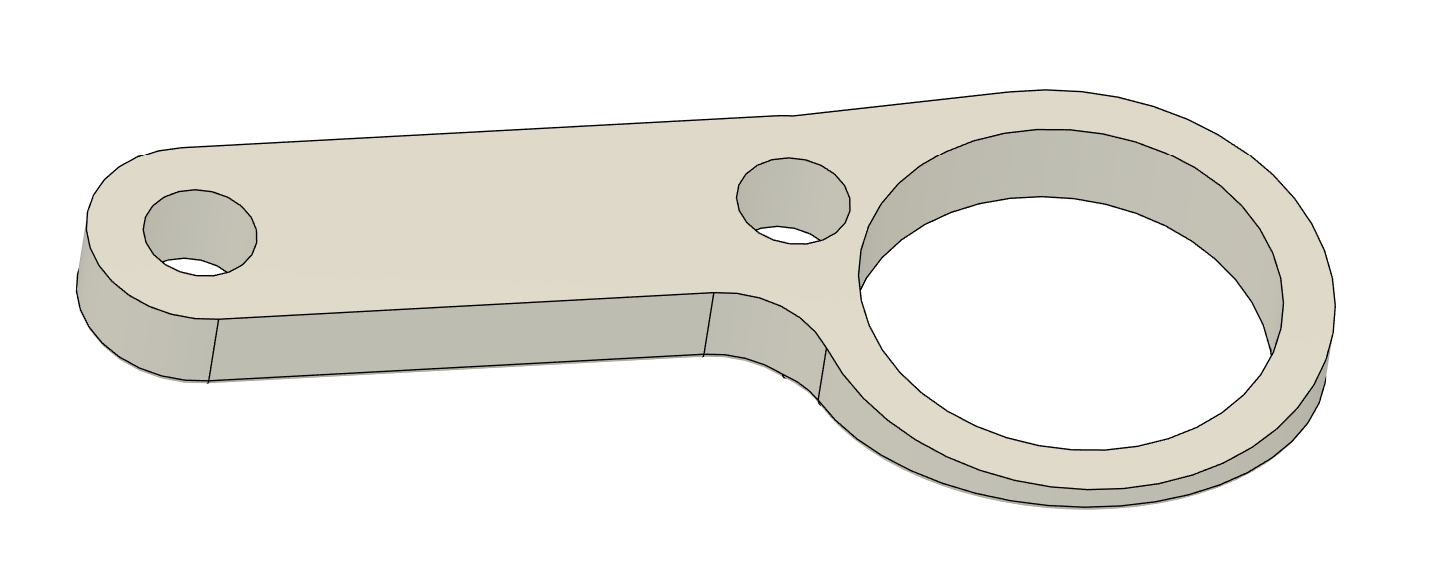

Some bits from the UK arrived surprisingly quickly, a sump and tappet cover gasket, a boot for the gearshift, suspension bushes etc; I made a battery bracket to suit the most likely battery I found in my stash of many; All those untidy wires are not part of the car you will be pleased to know. I also printed some things; Cos that link for the lock on the passenger side has gone walkies somewhere. And over the last couple of weeks I have been designing and iterating a set of heater controls that I think actually should work. Cool beans. Also I wired up the clock. It works all nice. The clutch couldnt get uprated cos they couldn't find the parts to do it and additionally the man said it looked like that cover springs had been over extended, this might mean it was slipping due to wrong adjustment, so I will order a new standard clutch and see what happens. Also I found another X1/9, and have spoken to the owner, so there might be a very small Nelson X1/9 owners club.1 point

-

Nearly ready for first startup. Just a couple of jobs to do, one being to attach old exhaust to new headers until i'm able to get a proper system made. Don't laugh but I cut both ends out of a baked bean can, slit it down the side and with the help of some hose clamps, made a sleeve and clamped over both pipes. Should be ok for a while. Checked all fluid levels and filled radiator with hot water as mechanic suggested as been sitting for a while since build. Removed plugs and cranked motor until oil pressure light went out. Replaced plugs and turned key. Motor started straight up and sounded really good. Ran it up to temp and checked for leaks of which there were none. Time for a trip around town. Goes well but needs a tune. Brakes are good and everything else works except fuel gauge. If anyone has a suggestion of where I could get my 32/32 weber carb tuned around Christchurch could they leave a message on Project Discussion page. Cheers Project Discussion https://oldschool.co.nz/index.php?/topic/84912-petes-mk2-escort-1600-sports/page/3/#comment-26180391 point

-

Just slowly picking off jobs as time allows. Fitted the carpet and cut all holes for seats, seeatbelts, gear stick, brake handle. Installed gearstick and rubber gaiter. Next put in seatbelts and also fitted door cards. All looking pretty good. Next in was the seats which took a while as quite hard to line up holes I had cut in carpet. Starting to look like a new car. Next put badges and number plate on rear also mirrors on doors. Time to put some petrol in the tank in anticipation of startup but it all ended up on the ground. Didn't see that coming and had to take tank out to find hole. Rust never sleeps. Luckly had another tank which I checked more carefully. Cleaned, painted and installed. No leaks Result Project Discussion https://oldschool.co.nz/index.php?/topic/84912-petes-mk2-escort-1600-sports/page/3/#comment-26180391 point

-

I've had some success with extending them fully (holding them extended with a clamp of some sort), smearing dishwashing liquid into the webbing, laying it out in the driveway then waterblasting what becomes a black soup out of the webbing. Probably try not to get water into the mechanism, and chuck it in the hot water cupboard to dry fully over a few days. Then plenty of silicone spray in the spring area. Doesn't make them new but seems to help to some degree.1 point

-

Bit more progress: Finally got around to cutting the rest of the kitchen components and have pieced most of it together to make sure was all going to work. Im pretty happy with the result, still basic but a big improvement over the original stuff which was really in quite a state. It will need to be broken back down again to get through the door. On the inside Ash has put in a heap of hours painting everything with many many coats of paint. She's used a bathroom paint as the top coat and while it doesnt look much different in the photos, in real life its looking really good. Theres a few areas to finish off but the back of it is definitely broken. We have templated and cut the new vinyl for the floor which was quite a dick to do. I've also removed and patched over where the original foot pump was for the sink taps - Ive got a 12v pump to go in instead. The vinyl is just sitting in there for now till I get around to gluing it down but its quite a big step forward visually. Now the flooring is down I can fit the new kitchen and start finishing things off inside. The squabs should be back from being recovered in a 2 weeks time so really want to have the majority of it sorted out before then. I've picked up a new battery for the solar setup so will leap into the wiring side of things once the kitchen is done. Ciao for now1 point

-

Hi all. been a bit slack lately ...due to little motivation , family life , work and the 1.3........mmmmm1.3 xflow thats been bugging me a bit more than i thought it would. I have found a few 1.3 motor to buy but i know ill be disappointed.... but i also wasn't keen to make it a bigger project than it actually is ..so by the time i put a 1.3 in the hole i could spent a couple of hundy more and get a cert......but i dont want to cert just a 2.0 ...so made the decision last week to go for a cert for a pinto turbo...(have motors and most of the bits to do it.... so this gave me some motivation and i got a few things done 1.. got all the heater bits and bobs together and went threw them all .cleaned,fixed and just made better the lot even down to foam around the heater core so no air is wasted....i then got it all in the car (not as easy as i thought as the car was preface lft and now face lift and its not a bolt in job) but its all in there ..2..got the dash loom in and all everything pluged in ..(even the glove box light)... cleaned all the dash parts and got it all back together . so the motor setup ive decided on is a pretty easy setup that i have thought of for a while and not tried. so for now a standard 2.0 pinto the manifold is one ive had for agers now a mate had made to take an evo turbo (plenty to chose from now).its a evo4 turbo on there now...internal wastage ...an intercooler to fit without hacking the front apart...3.9 falcon CPI (adapter for bolt to standard weber manifold).make a turbo hat for the top of it ...hale effect dizzy for trigger ..link atom x ecu. and coil on plug with built in ignitors.... then build a motor later on..1 point

-

Things recently happened as I remember them: 1) Wife gave birth to future slave labour option 2) Donated above green N600, finally out of the garage weekend just been. Hopefully the new owner will give it another lease for life. 3) N360 got it's brakes all redone, new rubber lines, new pads, master cylinder rebuilt, everything lubed up and nice. Still have sponginess in pedal, need a vac bleeder I reckon 4) N360 took a little visit to Honda Wellington dealership as part of a promo. Car got a decent wash, polish etc. Now that garage is a little more empty, not that I have any time still, I still have a few things I can work on, still need to find door and window rubber seals and bleed brakes etc. I suppose might have to wait for Spring at this rate...1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.570970b401ac8d26ce9af7c1bf2bd8cd.jpg)