Leaderboard

Popular Content

Showing content with the highest reputation on 03/20/24 in Posts

-

So it turns out when... your daily/operational fun car breaks down and you decide to take on a huge DIY job to fix it that you know eff all about you specifically lay out your mortgage repayment strategy in front of you and truly understand the ramifications of paying off even tiny amounts of principle early in the loan and decide to restructure to get every little spare cent going into it that you can scrounge up you pick up a second job the remaining work on your project car kind of hinges on either a stupid amount of unappealing and tricky skilled labour, or collar-tuggingly large amounts of money to pay for said tricky skilled labour ...things on your project car tend to slow down. But I figured I should post something because otherwise I'll totally forget everything that I've done and I don't want this project to fade away. Before I put all the fuel tank stuff back, I was messing with panels. One of the pre-reqs for the panel work is obviously that it needs to be all stripped back, and I decided (with panelboi's blessing) to do it myself rather than mess around with the local acid dipper or with transport to a more reputable one hours away. The idea is to just pick some reasonable panels, strip them, fit them, and then I've got a clean no-surprises job I can show around and get some better quotes and info on. I test-fit the rear bumper from the original black car and it didn't quite sit right - the panel gap was inconsistent no matter how I fudged the fastenings - no pix unfortunately, so I went with the red's bumper. It fits a whole lot better! Next up is all the front panellage. The two bonnets have their issues so it's really a toss-up, but I opted for the red one as it seemed to be a bit more contained in its damage. Both nose panels are totally fucked so... not sure what I'm doing there just yet. But fitting the nose panel reveals some fun. Uh-oh. Fitting the bonnet and popups makes the problem a bit more obvious. The black ones are just as bad - no pix soz - so it's not just a "different donor car" thing. The frame repairs were done with the fenders and bonnet available, though not the other panels. I need to get in contact with the panelbois to sort out a warranty claim, but the last couple times I tried they didn't pick up or reply. Hopefully this doesn't become a struggle :\ Anyway, forging on. Key and clean. Apply stripper and keep wet with plastic. Create murder scene. Scrape. I probably should have applied more stripper here but newb. The fenders are all pretty crap. The one I've already lightly beaten into shape and stripped and durepox'd is the one that had a minor collision, so you'd think it'd be the worst, but it's actually probably the best one. There's no rust and it's otherwise totally straight. All other fenders... well... So I decided to just keep the fender I've already epoxied, because it's probably easier to bang it into shape than any of the others. The red driver's side fender seemed marginally better than the black one so I went forward with stripping that. I busted out the paint stripping wheel for the grinder to finish it up. I'm not really sure this was a good move - it's nice and shiny, but possibly a bit tricky to spot the imperfections in the panel now? Then the nose panel and popups.. Everything back on. You can see here what I mean about the swirlies making it hard to gauge if things are okay. I'd already taken a sanding block to the driver's side fender in this pic to try and make the flat bits even. As you might be able to tell, there's a fair bit of damage to it... there was quite a bit of bog at the front and the rear of the fender. I think it worked, so I did the rest as well. As you can see, there's a few low spots and dents, but I think they'll hammer flatter without any major headaches, and even if they weren't, they could probably just be straight filler'd without failing. The chunky spot is the part I already knew about - the front corner which had a giant slab of filler applied and has subsequently received a lot of pitting. There's also a spot on the front edge of the bonnet that has numerous rust holes, hidden under a small but deep patch of bog. Honestly, it seems saveable - though I'm also far from an expert here! The pop-ups are fine, no dents. As expected, the nose panel is worse than the surface of the moon. It's probably not worth trying to save and I should just find another one. It's also super easy to dent these to begin with; they're the most natural place to push the car from, and there's almost no structure to them. If I do get a new one I'll try mod some gussets into the back of it. Side quest to put the very first thing I restored on this car back onto it: the fuel pump access panel, which a few years ago was extremely rusty. The CRC black zinc has held up strong . Spot the fasteners and grommets stolen from the red car... Speaking of the red car. It's door time. On both cars, passenger sides have a couple of dings but nothing crazy. Also on both cars, the driver's side is absolute dent and bog city. I have pix but they suck so just hold on till the strippy bit to see what I mean. All the doors also fucking suck at the bottom. So I just went with the black doors since they're both right there, already half-stripped, and the red car is currently sealed from the elements. There's a few holes at the top as well. Annoying, but the rust seems fixable. I completely stripped the doors - which was a massive PITA when it came to the door latch, only removable via black magic / the completely wrong method. The mirror blanking was just gooped in place to fix a broken bracket. Also there was a little protective metal edging strip along the open edge of... just one of the doors? The red doesn't have these. Japanese mod + replaced door? Anyway, it's strippytime. This time I put it on thicker, and did several passes. It made the job a bit easier. The starion makes for a decent workbench... <.< I haven't finished these yet, there's still some bog to remove and then get it all nice and flat. And that's where I'm at. If the panelbois are kind with their warrantying, and the lack of surprises makes the price right, then I might be able to eek something out in this space before we pay off the mortgage :P. If not, I'm buying a welder and the scope of the project shrinks from "like new" to "guy in a garage job but the engine bay looks sweet"...16 points

-

Hey good news I've fixed all the broken image links in this post.... Soon I'll update it on everything me and the wee car have been up to.13 points

-

Pulled the tappet cover and sump, all looks well; Printed a new faceplate for the heater mech with the knobs set back a few mm as the cables were pulling it a bit, plus I printed a white insert for the indication to make it tidier, this just got coloured in with permanent marker for the red and blue bits; Clutch arrived; Also my younger self had bodged something for the top engine mount as the original one didnt work with the new engine, this was an unconvincing effort. So I spent some time with the lathe and the welder and made something much nicer with replaceable standard bushings;11 points

-

As per title. I'd love to have something to aim for and look forwards to this winter. Hanmer is always good because cold + bbq + hotpools + frostpot of hell = a good combination. Who's keen?8 points

-

Minor maintenance tasks update. Thought I'd give the air filters a birthday day to protect my newly rebuilt Dells. Cleaning kit is only 40 bucks from ripco/supacrap autos. Stage 1, clean all the nasty. Once dry, stage 2, re-oil and done! Colour match filters. Other thing I've been chasing is this very annoying oil drop from the filler/breather. I wasn't sure exactly were it was getting out from. Pretty sure now it's from the breather hose connection as it's the factory fitting is slightly smaller and doesn't have a barb like the ones I put on the catch can. I had hoped just hooning on the hose clamp would work but no so I'll ad that to the list.6 points

-

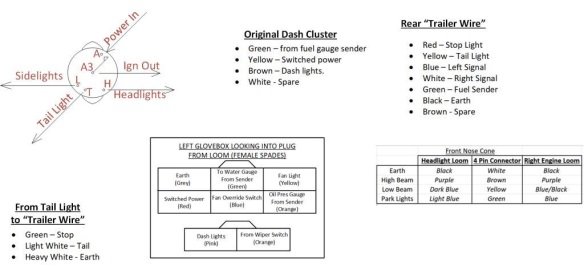

With space in the nose cone so tight the only way to wire the headlights and fan was to take the front off for the umpteenth bloody time….grrr….! So much easier to wire on the bench. Found some heavy connectors to make disassembly easier in the future. Love using the old school fabric wrap. I’d bought a big box of connectors off Banggood for a price that was too good to be true…….. … so I wired up the headlights. I refitted the front………. I installed the gorgeous over-priced P700 headlights…. ……..and started blowing fuses whenever I powered them up! After an evening of uttering nasty horrible words and throwing thinly veiled insults at Rigamortice re the marital status of her parents at her time of inception, while going round and round in circles with a variety of test lights, test probes and multi meters - I discovered the f****** “too good to be true” Bangood connectors were………. You guessed it ‘too good to be F****** true’! After a quick trip to Jaycar the following day, I paid through the nose for the right connectors…and we now have head lights. And as an added bonus they even worked in the dark! So I stuck the bonnet on and discovered it didn’t fit…. I loosened it off and started pulling things into line before re-tightening. Finally, it all fits, (sort of).5 points

-

Better give this an update... Yes I did find some genuine replacement parts, and so back together it goes with new bearings/syncros etc.... While I have a transfer box I rebuilt for the back end of the conversion I thought it best to rebuild the one I had here. Needed a new set of main bearings (which cost a few $$$) but everything else was in fair condition. Its way easier to assemble vertically on the bench. Though I havent yet gone to the effort to move it off yet.... With that done I need to give the engine a good clean up and external refresh, more soon.4 points

-

And new shocks all around. 4x4 d21 up front (shorter than the 2wd ones) and Nissan Quest rear shocks in the back which are shorter than the factory ones as well. All bolted straight in and feels as good as a 35 year old truck on bumpstop should feel like ...haha. Front is touching bumps, rear not quite. So need to have a play there.3 points

-

3 points

-

Wow that was a while ago. I went to hook up the brakes and found the little adjuster thingy had gone south on the last joyride. I didn’t have any adjusters in my stash that fitted so chopped up an old mountain bike brake/gear shifter combo. Now I had brakes it was time for more hooning. At this point I’m still sporting a decent exhaust burn on my right hand from the last test runs. So I wedge my hand in hard against the choke/ throttle/ spark plug area and go for gold again, still kneeling in a similar pose to driving a dingy with an outboard. So fun. So fast. So dodgy still. Work mate watching from the roadside reckoned 60 clicks easy. I was catching up on cars real quick and the brakes were only slightly better than the foot dragging on the road option. By the time I pulled back into the workshop I’d cut my hand up fairly bad, blood down the side of the motor. And one knee was sore as fcuk and starting to swell up. All in all a great time was had and received many roadside thumbs up. Glad @xsinclairx wasn’t patrolling the area that day3 points

-

+1 hanmer West coast will be all rain in winter3 points

-

3 points

-

Well after the last novel length wall of text I'll try to keep this update shorter otherwise I'll never finish the thing. Lots of little jobs starting to pop up on my 'to do' list. Driveshafts. Connecting the scooby shafts to the imp axles. A job I wasn't sure which direction I'd take as there's so many different ideas out there on the nerdnet showing 'the best' way to join shafts. First thing I did was to double check the suspension travel allowed by the stock shock absorbers and then use those datum points to work out if there was any growth in the length of shaft required as the wheel moves through it path up and down. There was minimal amount, like maybe 5mm at the very most. I guessed as much because the stock Imp driveshaft doughnuts dont allow for much sideways travel. I then cut one of my 22mm scooby shafts down in length so I could work out the lengths required with the CV joint in place. This move I soon regretted. I was allowing for plenty of plunge into the CV joints to make sure the whole joint could be removed from the box stub axle with the box pushed sideways when removing the transmission. I was happy with the length and then decided to go visit a local hotrod builder friend for some advise. He's well known about for his many many full scratch builds and has done heaps of driveshafts in his time (a fellow machinist by trade too) I showed him the two ways I was considering doing the join. He showed me a better way. Shrink some bored out yokes cut off from some spare axles. Plenty of meat, will never let go and even if they somehow did loosen and spin they cant come out because there's not enough travel in the CV joint to allow them to. No welding needed. He's run axles done in the same way with some serious big block power and they never let go. Just has to be accurate and luckily its the sort of machining/fitting job I like. But i needed to start with almost full length scooby shafts to do it, of which I was now down on.. Roll eyes and back to the wreckers to see this beauty get pulled from the hedge... Hannah helped me remove the shafts. It was her birthday too so wow, what a treat. She got visit the wreckers and get oily. Got home and the shafts didn't fit my CVs. Bigger diameter end. Really weird because I checked online... ha. It lies. Turns out some late 4wd Leones had even bigger axle ends than the imprezzas. Also odd is that one shaft is 22mm and the other side 24mm, although both the same length. Back to the wreckers. This time I got larger 25mm shafts with the smaller ends from front wheel drive Imprezzas. I grabbed two pairs. Same again, 22mm on one side and 25 on the other. Now I had two of each. Got home and spent some time cleaning them up, outside because petrol fumes. Cleaned up the spare pair of axles in the lathe to make sure I had an accurate clamping spot for the later boring. Good quality steel! I turned them down to less than the 23mm bore size and chopped the yokes off. Made lots of swarf Bored out to bang on 23mm with nice radius. Double checked and triple checked I had my lengths required correct. Chopped the two 25mm scooby shafts down to length and turned a step down on one end of each, a radiused step to stop any stress risers. I went for .0015"~.002" interference. Go online and see the debates between all the barries about what a good shrink fit should be There's many variables as well. I consulted my old faithful machinery's handbook. I wanted it tight, but not stressed. Luckily the axle is of good steel. I also made a sample first, using one of the cut off bits of scooby shaft and some 4340 I machined to the same outer dimensions as the yoke. This way I was able to test how hot I needed to get it to expand enough to drop in place. I'll take this to a local engineers who have a press with a pressure gauge and see how much force it takes to wreck this thing Here's about a one hundredth of a millimetre (iirc) getting removed.. Then things got hot.. photos taken after it was done because I had to move bloody quick! Hannah would grab the torch and I would drop the yoke in place. It was a tense bit of time. If the yokes teetered and grab they'd pull the heat so quick and shrink in place before getting to the shoulder. No removing them without damage and I only had the one pair of spare axles. It went well. I was happy and relieved. The light rust flashing off on one is simply due to that one having been left nearer the front of the workshop to cool down and it was a chilly damp start to the morning. They wired brushed up neat as, got painted with black epoxy and when that was set they had new universal joints fitted. I cant try them on the car until I remove the existing axles from the hubs but it should be fine. Next up was to sort the fuel tank out to suit fuel injection. I brought the blue imp in and checked a few ideas out on what I could do. I don't really have room for a surge tank and I never liked the noise on my Viva from the external fuel pump anyway. Nor did I like the way the fuel in the surge tank heats up. Enter the humble Nissan Micra k11 intank fuel pump and surge container... It actually looked like it was just going to fit into the pressed depression at the bottom of the imp fuel tank.. With enough room to run the imp fuel float sender next to it. Cut a hole.. It fits. I'll cut the bracket off the side at bottom of pic and it'll move sideways a bit more.. Made some metal brackets Welded them in and now I have a cradle that takes two cable ties across the top to secure. I needed a flange.... Made this. Its designed to recess the lid about 10mm below the tank top. I want to keep the tank top as flat as possible. It'll have the usual layer of foam over top but I don't want things sticking up proud when the 'frunk' is being used (cant be tearing those bags of concrete now eh....) Many holes drilled and tapped.. Carefully welded in place. Was a tricky job. Thin steel on the tank that had some sort of (probably poisonous) coating. But happy with result. I made another hole... That takes the sender. Drilled and tapped more holes to suit. Now I needed to get fuel from the outside in and from the inside out. I machined up these in stainless.. Thought of a neat way to hold the little bits together for tacking. Blue tack. Or blue tack tack? welded up.. I made an angled recess into the hatch cover so the fuel hose goes even further below the tank line. Visible in that photo are the cable connections. Again - I needed to get power in. I machined some shouldered fittings in plastic.. Luckily the micra pump so handily just uses a simple connector with 6.3 spade terminals. Under the lid... Tank hard work done. I'll paint bits and cut some gaskets. Speaking of gaskets. One of mine between my oil filter pedestal and the block is weeping oil. Plus one of the bolt heads weeps. Typical. Put a Japanese engine in a British car and turn your back for a minute... I've already drained the oil cleaned it up and ran a smear of paintable sikaflex along it and around the bolt head. I didn't take photos because not really exciting. I'll paint it silver and no one will know. Except you the reader. Next up is the exhaust I think.3 points

-

Aaaaaaannnnddd car is still in the weather outside. But i just found and paid for something i have been looking for since 2005ish..... AN INTERMITTENT WIPER SWITCH!! This may not seem like a big deal but only having a 2 speed wiper switch in rainy reporoa is a problem. And yes while i could have wired in an aftermarket timer that wouldn't have felt right. So long as david from gumtree doesn't let me down.....2 points

-

So keeeeeeeeen! Port and cheese at lake Tennyson plz2 points

-

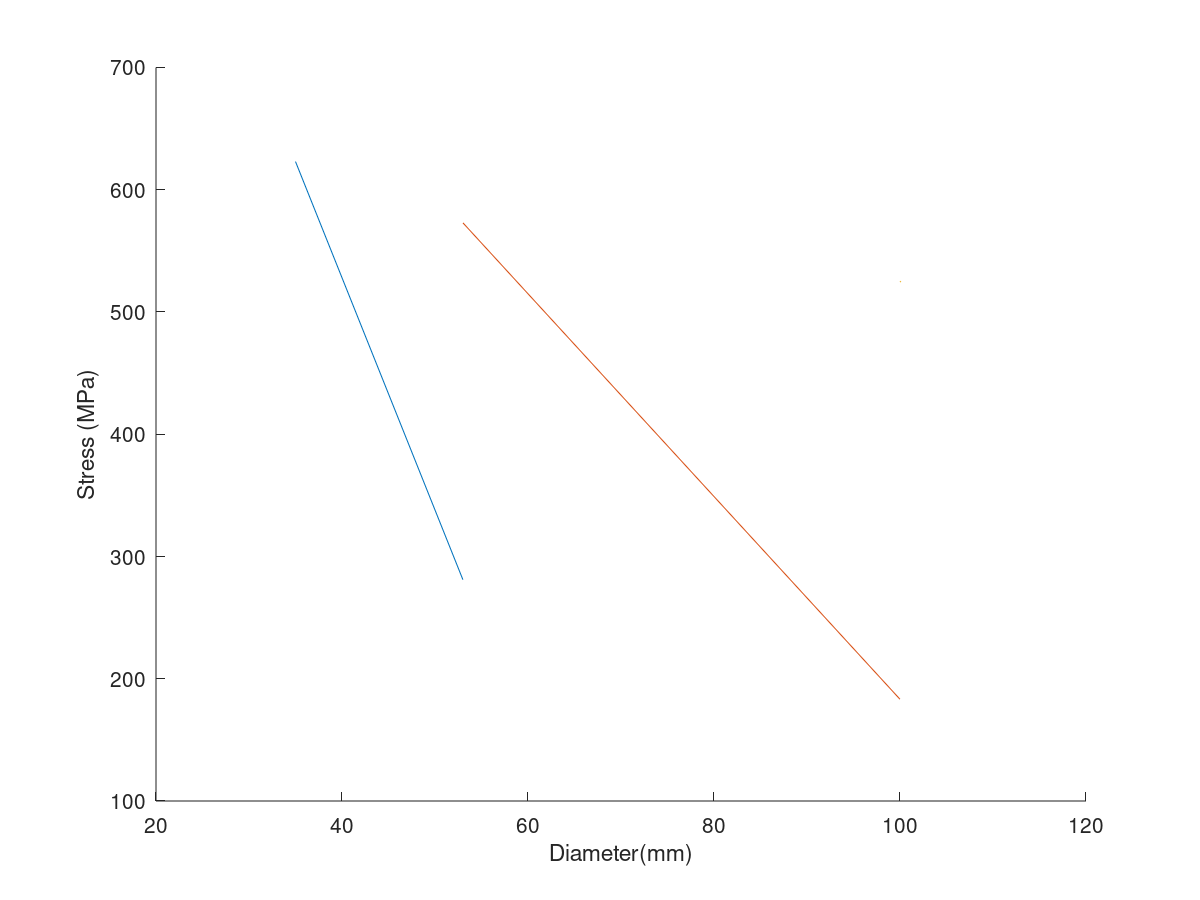

Shrink fits are legit. About 4 or 5 years ago I had to design an extrusion container for making magnesium rods, the container needed to be made of multiple shells of high strength (H13) steel that are shrink fitted together to get enough strength. The shrink fit was used to put something like 600 MPa of compressive stress on the inner liner, giving almost 2000 MPa of pressing capacity. I think it was something like a 0.15mm interference on about a 53 mm diameter sleeve, required temperature difference was about 250 or 300C to get it to all fit together. Was quite stressful as the liner was about 150mm long and had a nitrided surface so any lathe tooling would just bounce right off if it grabbed and needed to be redone.2 points

-

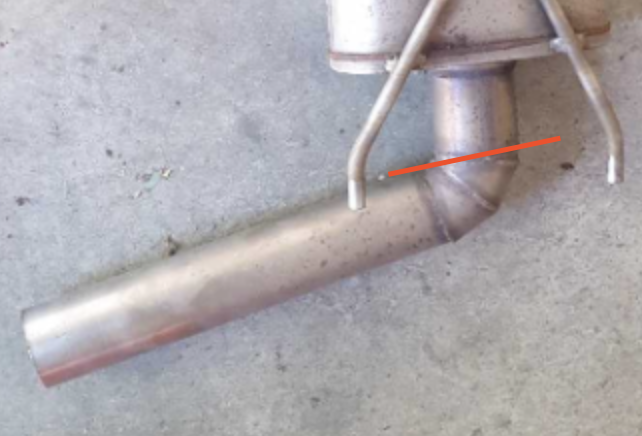

Another few months of nothing and then I decide to sign up for another sccnz motorkhana. At this point it is 10am saturday, and the motorkhana is 10am sunday. Last time I checked, my TPS is falling off, throttle #4 has a vacuum leak from being yanked about when the tps was knocked, and there is maybe a slight misfire. Instead of even opening the engine bay, I decide the exhaust needs more work and I have a muffler just lying about SOOO a plan is formulated... I'm also critically out of stainless filler and argon, but that won't stop me Contemplating new muffler position, was tempted to have it riight out the bumper but I don't hate myself that much. Instead, we tuck the muffler right up underneath the car and do a downturned exhaust tip. At this point I was chopping up the old muffler to save argon. Here is where the downturn tip came from: After procrastinating a fair amount, I get the muffler all tacked and have completely exhausted my argon bottle. Nice, its about 3pm and I'm making dinner for some friends before a comedy show. Make a lasagne then quick trip to bunnings at 5.30 for an argon swap, comedy show and start "welding" again at about 11.30pm. Do I need more gas coverage? Sure. Are my "welds" shit and rushed? You know it. Do they work? To be decided. Midnight:30, job done. Car lost some rasp, gained a LOT of bass. Right at 90Hz at motorway speed, heaps of it. So much bass I was getting a headache, and that was not fun. I figured its about time to actually make the car quiet, so I make a (suss) slip in silencer after the motorkhana. It had to be short and on an angle to be able to get up the downturn exhaust tip, but it does the job. Bass is gone, rasp is gone, car sounds pretty reasonable for once!2 points

-

If it's all standard steering, and just roll center spacers, bump steer check is not required2 points

-

Some bits from the UK arrived surprisingly quickly, a sump and tappet cover gasket, a boot for the gearshift, suspension bushes etc; I made a battery bracket to suit the most likely battery I found in my stash of many; All those untidy wires are not part of the car you will be pleased to know. I also printed some things; Cos that link for the lock on the passenger side has gone walkies somewhere. And over the last couple of weeks I have been designing and iterating a set of heater controls that I think actually should work. Cool beans. Also I wired up the clock. It works all nice. The clutch couldnt get uprated cos they couldn't find the parts to do it and additionally the man said it looked like that cover springs had been over extended, this might mean it was slipping due to wrong adjustment, so I will order a new standard clutch and see what happens. Also I found another X1/9, and have spoken to the owner, so there might be a very small Nelson X1/9 owners club.2 points

-

2 points

-

New springs made it more consistent,although slightly slower. Different wheels and muffler off when it did the 11.35 previously 11.5@118 every pass I have turned the 2 step rev limit down slightly as it was having trouble holding on the brake which I can probably fiddle with to improve I'd like to get it down to 11.0 so it's more competitive at the night drags https://m.youtube.com/watch?v=kdfGgT2pKHw&pp=ygUMVW5kZXJjYXJ2aWV32 points

-

2 points

-

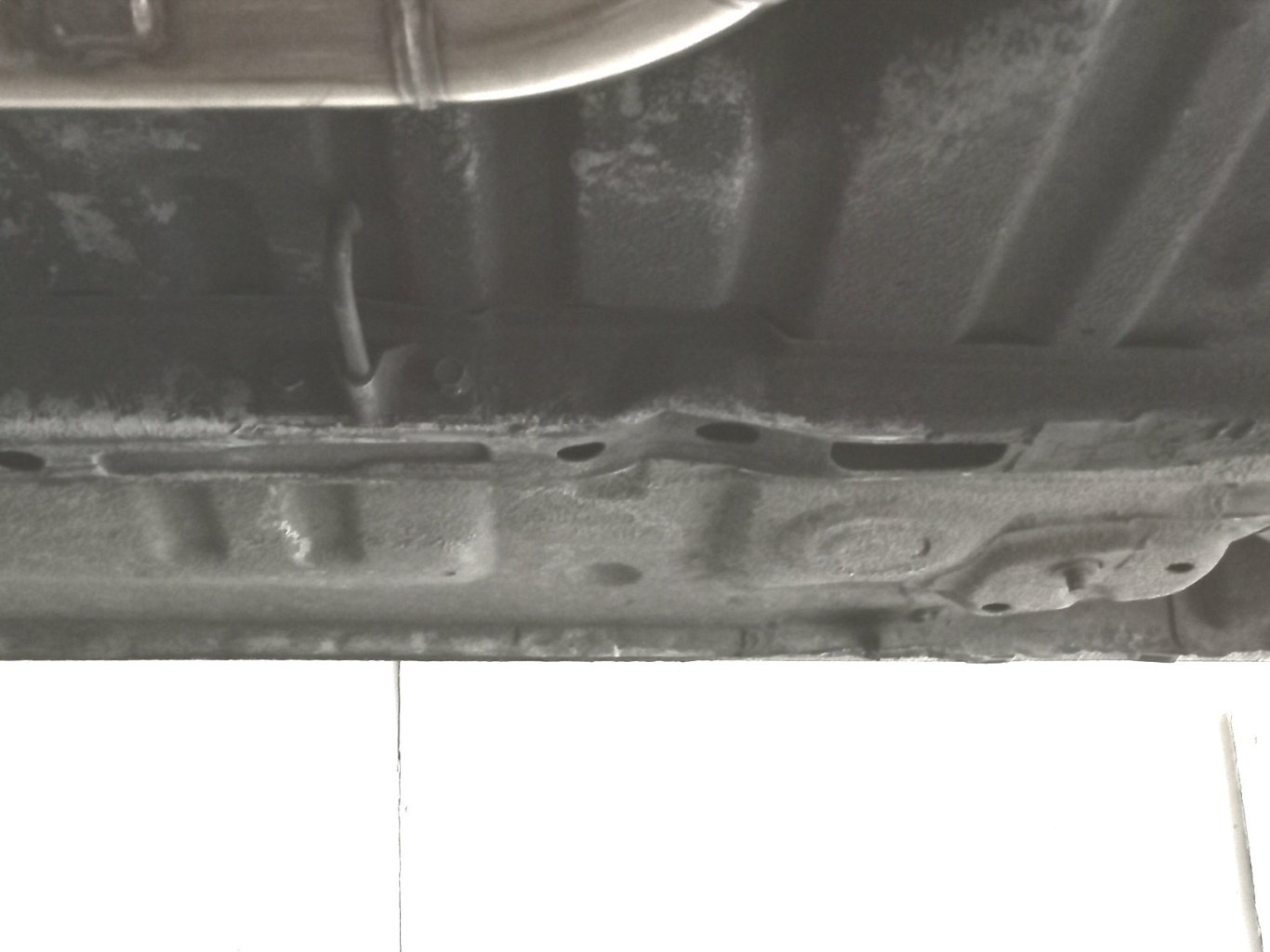

My chassis rails were a bit pushed in, and most likely would have failed a wof, so i took it to blairs panel repairs, he did an awesome job and even fixed the pinch weld areas that were also bent up, and undercoated it all for a great price and all done in a day, couldnt ask for more really, one less thing to fix on the road to a warrant ..2 points

-

I was reading somewhere that some large camshafts are constructed with the lobes shrunk fit in place. I'll try find it. Figure it cuts down on material and machining costs a lot when dealing with big items.1 point

-

Lots, I can’t remember, I left the tech drawing pie wrapper on the workbench in the shop1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Plodding continues on the Armoured Recovery vehicle. No modelling time and I'm not feeling it like the HST but will hopefully get painting tomorrow & it'll all be better. Fancy doing the wheels for me, @Indiana_Jones ? /shit pics1 point

-

The door with the plasma cutting was pretty wonky, so ended up finding a replacement. Managed to get all of the doors paneled and into paint. A bit of dust and a couple of runs, but I'm definitely getting better with the paint gun. Now working on sandblasting the door hinges and cleaning up the boot lid, before reassembly, wet-dry sanding and a final coat. Stoked to be making some good progress again.1 point

-

1 point

-

Im still thinking about this once in a while. Tracked down a less fucked right front guard. It was up welles ways. @Goat kindly let me use his house as a freight forward depot. The seller dropped it off, and a mate who was passing by collected it the next day. Picked it up tonight. Defo needs a wee bit of work. But i can buy the inner and outer bottoms off the shelf from Automotive Panel Craft in Oz. Thanks to @Classicdat for lugging it south for me too!1 point

-

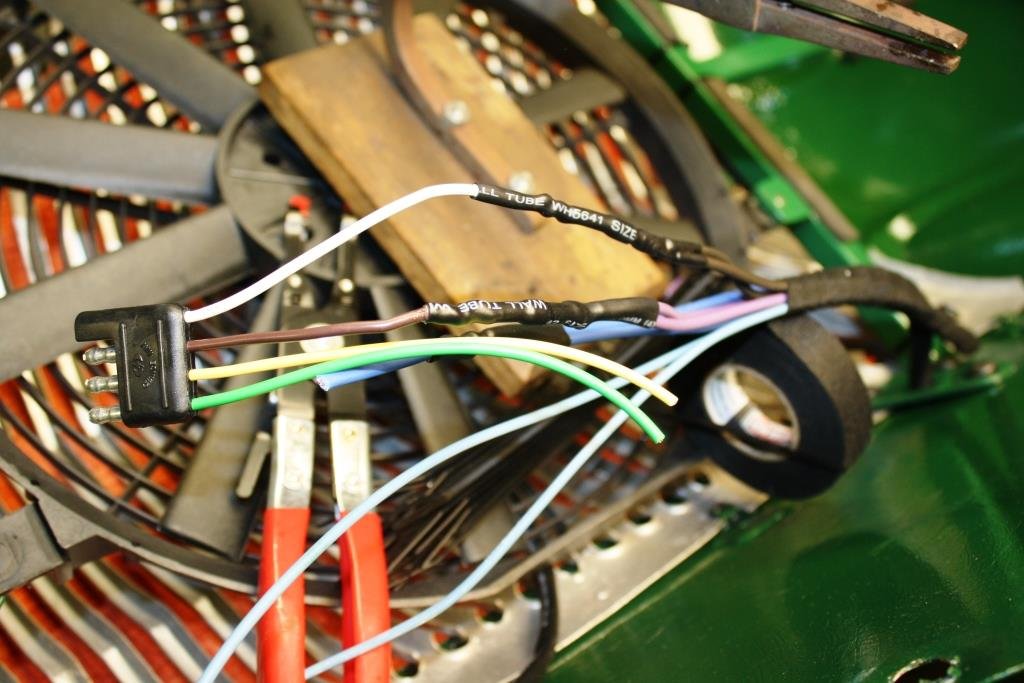

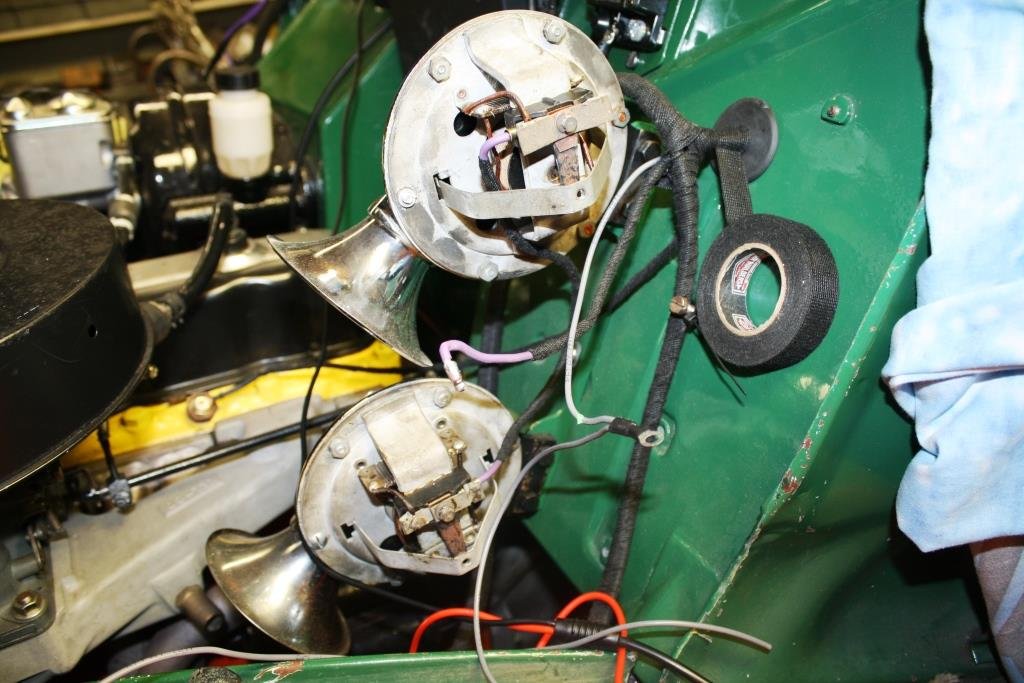

…………Yes I know I’ve been a slack prick, re: this thread. With final arrival of summer the good ship Aquaholic insisted that I take her and some of my disreputable mates out fishing… (What could possibly go wrong?). It was a hot day, we got thirsty, we drank heavily and we “got fush”…….(as you do). A few days later my brother turned up at the Viaduct in this bloody monstrosity, and the good ship Aquaholic (and a certain part of my anatomy) felt very, very, …. small…….(Sibling rivalry can get complicated!). ….so we headed north. The view from the bridge was cool…… Accommodation wasn’t too shabby…. …. And the lounge was bigger than the one at home… Thankfully there was a bar on board for self medication! Back home I was stricken with a bout of the much feared “home handyman-itis” and I accidentally started rebuilding the front of the house… (Note the cunning accumulation of Brownie points with the “ever lovely Mrs. sr2”). After the above brief hiatus I’m finally back to Rigamortice’s wiring. I’m trying to document as much as I can because my memory is like a sieve. I managed to source some cool old fashioned bullet connectors…. I’m almost finished under the dashboard, getting sick of working upside down. The dip switch still works so I hit it with some contact cleaner and we’ll see how it lasts. I’m running relays on the lights so it won’t be carrying the amps that it used to. I’m using my 70 year old meter just because I can. The horns are all wired up but they sound like two strangled cats, I’ll have to do some research on how to tune them. Circuit breaker in place instead of a fusible link. Mounted the battery earth cut out through the fire wall Repurposed an old offset ring spanner for a battery clamp. Managed to get some life out of the interior light with a new bulb and fresh wiring. Cleaned a ton of crud of the diffuser…. And it works.1 point

-

Did a chunk of the back end wiring today, not much to see as I have tried to keep things tidy so it pretty much blends in. I tried to fit a new power plant, amazing that for the size this unit only makes one pogpower.1 point

-

believe it or not, i still have all of these and remain even after every clean up and cull in the shed ive had every few years. One day when im old and grey and retired maybe hahahaha1 point

-

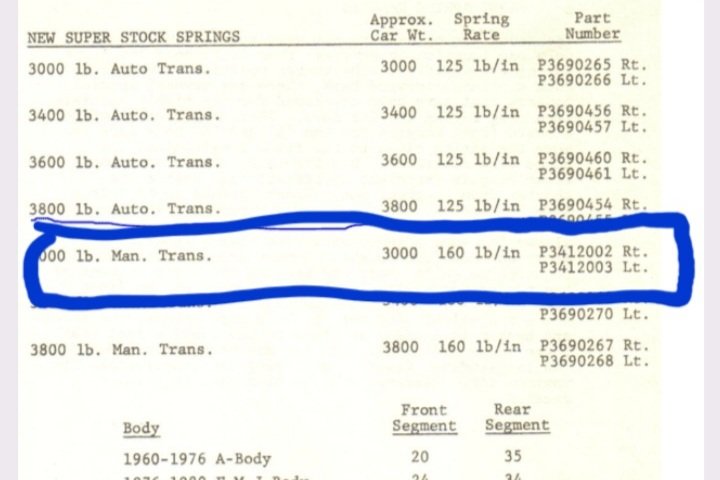

Ages ago someone gave me some mopar super stock springs which are meant to be pretty good for these things, I never really thought much about using them though because they are a bit wierd, they are different side to side with different shape and length leaves in the pack, apparently to counter the torque effect I thought I'd try them so put them in The leaves are considerably thicker (7.5mm vs 6mm originally)and the front eye bolt is bigger, plus they have a bigger arch so I knew it would raise it a bit, so I put them in and took it around the block. It is definitely stiffer, but not unpleasant, the height is now within 5mm per side, but looks dumb so I pulled them back out to get reset 50mm lower1 point

-

1 point

-

Okay maybe not entirely done. Since the previous hoses leaked everywhere I really wanted to get the high pressure EFI ones redone professionally, so I took them to the same place I went to last time for the ruptured hose in the engine bay. They presented me with two lovely EFI rated hoses <3 The one on the right is the one I care about for now, it goes from the fuel pump to the hard line. The banjo fitting needs copper crush washers and I decided to re-use the ones from the red starion. I gave them a quick go on some sandpaper on each side, heated them up to a stupid degree with a propane torch and quenched in water to anneal them. There's a chance I melted one of them a bit and used the black car's washer. A chance. Then, with difficulty, jammed everything together as hard as I could. The manual I have explains every detail of the fuel system EXCEPT for the fuel pump, which is quite both surprising and annoying. I thought for a lil bit over the next day about testing this. The last time I did this up, it leaked everywhere - mind you I was told bad info on how tight to make it, but still. It was also super easy to access at the time, thanks to it sitting in its L&P bracket instead of sandwiched between a fuel tank and a car. I could have hooked up the loom to a 12v battery and fed the hose into some isopropyl or something, but I don't have anything handy on me to block the other end of the line and create pressure, so in the end I just sent it. The tank's bolts were all underbody coated so I chased them, Then began the arduous task of lifting this asshole into place. It's not that heavy, but "not that heavy" is still too heavy when trying to connect the hard lines up to it without actually bolting the tank in. There's a lot of space for activities when the tank is dropped and I wanted to try and make things easier on myself. However, I couldn't quite get the right angle. The jack was in the way, boxes I used for additional support were in the way, and the EFI line had decent flex but didn't exactly meet perfectly so was a biatch to try and wrangle whilst also wrangling a large unbalanced tank on a jack. In the end I just jacked it all the way up, put some nuts on and dealt with the shitty access. This image does not adequately convey the amount of bullshit it took to get those lines on. Then I used new nylock nuts and washers to get the tank into its new forever home. I really hope I don't have any leaks or I get to do all this in reverse, then forwards again. I'll leave the rubber boot etc for the fuel filler until the body is properly zhuzhed.1 point

-

OK. Since that last post, Nick the sparky got a replacement, new alternator again, tried that, no go. Took it off again, put regulator from 300km alt in to new one, worked. So regulators are the issue, that's a total of three different new regs either in new alternators or from a bosch box that didn't work Nick spoke to the warranty guy at their supplier who said "oh yeah, we've had a few problems with those" Fffffssssss Nick found a new old stock reg which had bosch part number etc on it , put that in , he came around this evening and we bolted it back on. Warranty guy said the alternator light MUST be 2 watt as well so replaced that (it was 3watt) So now I'm back to 14.2v with an all new alternator . Huzzah I must say, Nick has been an absolute top level GC, I think we are up to 5 visits in his own time coming out to my house to sort this problem out Ron wood auto electrical is his business , in Western springs1 point

-

Somewhat dropped this into a few other threads... A decent parts truck same up for sale in Invers which I couldn't say no to. Where many would see something suitable for the scrapper, I see original petrol running gear, good condition front fenders (will swap from S3 headlamps to S2 panels), a front apron, better condition bumper, a wiring harness and a whole bunch of misc.... I took the water blaster to it when home, and while it is rusty as hell, it has the essence of farmer ute. Note the steel box tubing on the steering wheel and the uni joint shaft - went through the cab window to another wheel mounted on the tray so the cocky can put her in low box and drive around a paddock throwing hay off the back. Big question is will this run... it turns over at least which is a good sign. Time will tell....1 point

-

At least I get to go back to the parts I really like - panel work. These front guards are pretty bad but typical for age - fill of dents, bog, cracks, holes etc... There is no point to try and fix what is there, its a pretty simple panel to make from new. Note that there is only a factory pressing for the park like and not the indicator (these were added by local dealers depending on the requirements of the export country. Getting more of the hang of welding alloy, its not easy and filling in holes is a prick. The lower section of this side guard is pretty crumpled, it got most of it out, and about half way through filing it clean. I cut the flange section off as it was pretty thin/bent and in the way, I'll fold up a clean section and weld it in.1 point

-

1 point

-

So I’ve been pottering away on this since rolling it into the garage. I'm rubbish at taking picture while working on stuff so this is mostly words sorry (not sorry). Locksmith took aaaages to cut a new key so I couldn’t do much on the electrics/starting/running side while I was waiting for that to happen. In the meantime I pulled the carb off, stripped and cleaned it and reassembled. There was a bunch of varnish and crud in the bowl so gave that a good scrub out. Gasket still looked good so reused it. The main jet currently in it is a #190 which is 2 sizes smaller than the factory spec #210. I think I’ll get some extra jets to bring it back to stock so I can tune from there rather than have it be (potentially) too lean. New AGM battery arrived. Connected up and slotted in nicely. All of the control cables were either extremely stiff or completely seized up so I squirted some lube down them and worked back and forth until they were smooth(er). If these go bad again I'll look to replace. Sprayed/brushed some phosphoric acid rust converter gel stuff on the header pipe and muffler which actually worked pretty well. The chrome is quite pitted but not too worried about that at this stage. Finally got the ignition and new key back so it was time to fire it up. Connected everything and put some premix in a syringe connected to the carb (fuel tank still locked shut) and she fired up 3rd kick! Was a bit rough at first but settled down to idle pretty nicely. Stoked as, so good to hear it ring-a-dinging away. All lights and signals work. Charging system is putting out 13.5v at idle which is a little bit below the 14.0v @2000rpm spec but no worries? The 2T oil tank had a bit of rust inside and around the outside seams. I wire brushed and scotched of the loose stuff from the outside. The oil that was left in there had gone real gross and started to separate with some big globs of gross suspended. Sloshed some petrol around to try and dissolve it and it cleaned up ok. Still some crud on the mesh filter around the outlet so I got in there with a very long toothbrush and some more petrol and got it pretty clean. Poured in some evapo rust to deal to the rust spots and left it for a few days. Cleaned up really good, that stuff is magic. Also threw miscellaneous rusty fasteners and other gubbins in a jar with evaporust to clean them up. I cleaned up the autolube pump and had to add quite a lot of shim washers to get the idle stroke set correctly. Bled the air out from the supply hose and checked it was pumping oil through into the case. All good! Then I looked at the petrol tank again. The new ignition key didn’t fit in the tank lock (boo) so I had a go at making a tension wrench and lock pick from some old wiper blade spring steel but obviously I’m rubbish at lock picking as this didn’t work. Screwdriver time. Put one in the keyway and started turning it with a spanner and the whole cap twisted open :o. Turns out I’m also rubbish at checking things properly and the cap was unlocked the whole time but seized up just enough to not open easily by hand when I first checked. Good news though, it’s mint inside so quick rinse out and chucked it back on. The chrome side panels came up pretty well with some autosol and elbow grease. I will redo the white lettering on the Yamaha badges at some point too.1 point

-

Not really an update but this thing is going pretty well so far, I've put 8000km on it (more actually as the speedo/odo wasn't working for at least 500km as we couldn't initially get it to read a pulse from the speed sensor - a moderately long story but it's working mint now). So what's been happening? I entered this in 4&Rotary Nats show, because I wanted to tick that box really, nothing more, nothing less. So myself and @oftensideways made the trip up, both trailered - in my case now wanting to get it all grubby due to spending hours cleaning and sprtizing. As it turned out, this was the weekend those hectic rains came in and hit Auckland, so we drove up in generally garbage conditions, and the car was coated in a thick film of schmutz when I got theire (engine bay included) which meant a hurried cleaning mission to get it ready. I reckon we presented pretty well though! KP61 4nR 2023 Show1-2-Edit by Richard Opie, on Flickr KP61 4nR 2023 Show1-5-Edit by Richard Opie, on Flickr KP61 4nR 2023 Show1-3-Edit by Richard Opie, on Flickr KP61 4nR 2023 Show1-11-Edit by Richard Opie, on Flickr Lots of sweet car yarns and hangs ensured throughout the following day, and when prizegiving rolled in I was pretty humbled to receive the Best Toyota trophy, against what I think were some pretty wild cars (Supercharged LS KE70, a big power JZX100 dripping in all the lush Japanese parts etc). So when I got home I wiped it down and took a few pics - note the addition of the limited edition Momo Heritage Prototipo, with a TRD horn button I've been hoarding for some time. This is likely as good as the car will ever look. KP61 Orakei Rd-219-Edit by Richard Opie, on Flickr KP61 Orakei Rd-230-Edit by Richard Opie, on Flickr KP61 Orakei Rd-44-Edit by Richard Opie, on Flickr KP61 Orakei Rd-48-Edit by Richard Opie, on Flickr KP61 Orakei Rd-111-Edit by Richard Opie, on Flickr KP61 Orakei Rd-147-Edit by Richard Opie, on Flickr KP61 Orakei Rd-144-Edit by Richard Opie, on Flickr KP61 Orakei Rd-137-Edit by Richard Opie, on Flickr KP61 Orakei Rd-158-Edit by Richard Opie, on Flickr KP61 Orakei Rd-172-Edit by Richard Opie, on Flickr KP61 Orakei Rd-175-Edit by Richard Opie, on Flickr KP61 Orakei Rd-218-Edit by Richard Opie, on Flickr KP61 Orakei Rd-89-Edit by Richard Opie, on Flickr KP61 Orakei Rd-239-Edit by Richard Opie, on Flickr KP61 Orakei Rd-102-Edit by Richard Opie, on Flickr1 point

-

The rear brakes are more complicated due to the extra hand brake stuffs. The handle pulls a lever which pushes a pin down through the caliper and into a little freely-rotating bracket on the underside of the piston, forcing it down. No idea how common this method is. Bleh. Let's clean that up. Here's what it looks like all disassembled... not pictured is an extra retaining ring and a forgotten seal which is still inside the bore. The pin bearings also haven't been pressed out in this picture - one side's bearings were all rusted up and they cost $$$ for some reason so I hacked apart red's brakes. I fortunately was rewarded with another pair of good ones (and a pair of shit ones) for a total of four good bearings. Phew. As mentioned with the fronts, the rear pistons from the black car are fortunately in good condition and can be re-used So once again I went through the motions - except spread out over a month~: derusting solution overnight, a good scrub, let dry in the sun... ... fix the sandblaster, sandblast it all, rust preventative, caliper paint. We painted our house recently (still need to paint the garage) and I'm really over brushing things. But it's done - for now. Not pictured: I scrubbed all of the parts I was re-using in the parts cleaner, left in evaporust overnight, scrubbed again and they came out great. The aforementioned starion angel who gave me a bunch of rebuild link and advice pointed at these washers to replace the old crappy ones. They're slightly conical washers that provide resistance and springage for the brake lever. They're cheap so I grabbed a set (14 required to do both sides). Unfortunately they're a little chonkier than the originals Five will fit. Angelman went down this road and says he has no problems. However half of my original washers were perfect and after the evaporust the other half looked pretty good (red's ones were all trash), and should survive for a while covered in grease, so I decided to re-use them. Here's after the evaporust and before wire wheeling and greasing. Reassembly time! You can see the post-brush washers front and centre. Everything here has been slightly greased with brake grease. First I put the bore seals and pistons in with their boots. The rear boots have locking rings in place which I found extra scary. After a bunch of fiddling I got them in place and I think they seem to be operating fine - I tested with some compressed air. We'll see! For the hand brake stuff I will be following this guide by kev from the star quest forums as the manual calls for a special tool and press to squish the washers down for re-assembly, so there's a knack to it if you don't have it. The idea is to re-install the bearings in a particular order so that you have extra room to fiddle the arm into place. First bearing in on one side... The rebuild kit came with a new o-ring for the plunger so I put that on after greasing and placing all seven washers, then screwed it down into the piston and aligned it like thus: The key and spring then go into place. Now the bullshit starts. Put the other bearing on the lever arm and push it through, and use a screwdriver to push the key back. The problem we're overcoming is that the washers need to be pressed down to get the arm all the way through,. The idea is that with only one bearing in play, there should be plenty of angle to feed the arm through to it. In reality this is a massive pain in the arse; the arm still won't go in without pressing down somewhat on the washers and there's a lot of force required to do so. I'm not sure how but I managed to get it started with the first side. Then it's just a matter of pressing it home the rest of the way in the vise and locking it in place. However, the other side did not want to co-operate... so I found a much easier alternative. 1. Place the caliper in the vise such that the hand brake assembly is pressed up against one end. 2. Use your favourite chonkdriver to lever down on the arm; this is supremely easy to do thanks to l e v e r a g e. 3. With the arm lined up, give it a few taps with a mallet to get it started. Then pick up where you left off and press it home per above. Now I find myself in a greasy situation. A tiny sachet of brake grease is $20. I'd need many many sachets to fill up each caliper assembly per factory standard. The manual states which types of grease to use, but in an unhelpful way. "Orange" grease for much of the reassembly, and the hand brake area, and "pink" for some key spots. I couldn't find a translation for these on the net* but I'm guessing it's a combo of brake grease and then some kind of generic high temperature grease. (* something I'm picking up in the auto world is that everyone has an opinion on how something should be done right, and they get angry at the way other people do things and call them clueless muppets. However all of these people have functioning working cars so clearly it doesn't matter as much as these commenters wish it did) My compromise is to use a combo of a $20 sachet and the sachet the rebuild kit came with to fill the bearings and the cavity with the washers in it... ... and high temperature wheel bearing grease for the remainder of the space under the hat. This feels okay to me. The only mechanical action this area gets is when the hand brake lever is actuated. The part of the pin going into the piston is on the brake fluid side, no grease in that equation. And the wheel bearing grease is high temp so should be able to deal with the high brake caliper temps that make it to it. Then the hats get filled with more grease and snugged into place with the old retaining rings. I had some dramas with paint sneaking its way into the pin holes on the brackets but nothing a dremel couldn't clean out. Boom, rebuilt rear brake calipers! Nice to (a) tick these off, (b) clear my work bench and (c) delete this info from my brain ready for the next thing. There might be some more paint cleaning to do to fit little brackets and what not but calling this done for now.1 point

-

Yeah nah, every weekend has been jam-packed with activities so far. Anyway I threw some steering stuff together and loosely attached it all to the car, using up annoying nuts and bolts in the process. Now it's blocked waiting on the steering gear box - have barely touched it and it's less important than the hard lines so... I guess I should stop putting that off... They've got some manky brackets which at the least I want to refurb. The lines themselves seem okay but could look less grotty I suppose. I dragged the plating kit back out and flailed at it until it did what I wanted it to do, which includes some misplaced bolts scavenged from red car. I'm surprised how much I've forgotten already. Not my best work but it'll do. The zinc anodes had some weeeeiiiiird schmoo dribbling from the stainless hangers by the end of it... what the heck! I separated the hard lines out and then threw a wire wheel at one of them. Nothing much happened, so I decided whatever let's just smooth them up a little bit with some sandpaper. At this point I'm assuming that they're stainless steel and they've just gotten a little discoloured so am not worried about exposing fresh material. But as I scuffed away I noticed that it wasn't too labourious to expose nice shiny stuff... so I moved up a couple grits and went to town. I mentioned what I was doing in passing to my mate and he asked "what are you doing about replacing the passivated coating?"... doh. They're not stainless and I've polished one back to bare steel. I thought about a few options - just trying clear coat, some combinations of different coatings, taking the plunge into making my own hardlines, getting someone else to do it.. and decided to just put some rust preventative on and then colour with the etch black. First step, art installation. Second step, POR-15 rust-preventative - two coats. Third step, off camera, paint the plastic brackets black with etch. Fourth step, wrestle these god damn things back into line and hold with plastic brackets. Fifth step, two coats of colorpak black etch primer, shifting the plastic brackets between coats. Et viola - ready to go back on. Started raiding boxes to see what other bits of hard line needs restoring - which I'll do later - and found a sneaky bag of missed hardware. Doh. Anyway I got the lines on, and what I'm now going to show you is the end result of a bunch of pain. These things were an absolute bitch to get into place. First, there's three different kinds of brackets. And some of the plastic brackets don't anchor to anything. I had to go under the red car to figure out exactly what went where - also to salvage yet another misplaced bolt. Second, the lines themselves have been jostled enough to be slightly bent out of shape in places. However paradoxically they absolutely resist being bent intentionally. They're also all slightly different and I had to go back and forth between photos endlessly to figure out the exact correct position of each little line such that they didn't cascade and suck on some other bracket. Third, the bolts holding in the brackets usually resisted finding their threads... and every bracket that goes on makes subsequent ones harder to fit and the lines harder to wrangle. But I got there in the end :). Now I can tackle putting the rear subframe back in, which so far has had its own challenges. I'm not super happy with the black etch so far, wrangling the lines scratched it back to the rust preventative in a few places just from things like sliding the plastic brackets along them. I scuffed and degreased after rust preventativing so I don't think it's a me thing. Eh, we'll see how it goes.1 point

-

Also earlier this month a wonderful fellow called Stefan messaged me on FB - a fellow Starion enthusiast who had seen this thread and wanted to trade knowledge and pep talk. And red's engine. He came offering knowledge of how to rebuild the rear brake calipers and where to source their bits from. Up to this point I'd been avoiding the brakes. Hell I avoid everything really. Probably not the right attitude but my already-shitty memory has been trying to juggle the location of every bracket that I ever had to take off this shell over the last year and losing. I compartmentalise what I can and the easiest way is to just put something off until something is fixed and I can free my brain up for it. Stefan gave me a nice firm little burst of momentum to get the brakes seen to. Fine. Here are my rotors. Gross. I've been trying to find replacements for them with no luck. Facebook lurking already informed me a while ago that these things are no longer available. Everything online is super generic ("oh yeah here's some front rotors for an '83, don't mind the 5 studs in the picture"), I'm suspicious as hell of all these rando ebay places claiming that they're actually going to fit the car and that they're of reasonable quality. So I just decided fuck it let's try and get them resurfaced. But first I should get the rotors from red too - that way the brake guys can mix and match a good set for me. The calipers will be good to get a hold of to mix and match as well. So, what better thing to do on a sunday than to wrangle another 40 yo car's dirty supension out? Oh and some more shocks to look at too! I don't really know what I'm doing. Red's rotors at first glance seem thicker but they actually have a good mm or so of bedding and are only thicker on the very edges. The Brakemen will know! I took it to MP Autoparts in Upper Hutt after multiple recommendations. Really good blokes, Gary is really helpful. They too weren't able to find new rotors but were able to salvage a good set from mine. They also offered to do their best to seal the rust for the right price so I took them up on that. One of the rear rotors is not too far from being out of usable meat but I got a good set and that's what matters . Problems are for future Tom!1 point

-

Red's back home after her dentistry. The shop welded a bar to the frame for ease of carrying - but under-estimated the weight of the car. Took them 4 guys to get it on the trailer, fortunately I was able to round up some neighbours and it got off the trailer a lot easier. The towie wasn't too happy about the surprise of towing a 2-wheeled car, which I feel awful about. He still gave me his frequent flyer rate though so I guess it wasn't too bad. The frame rails are now at the blasters, then they'll tack them on Stella, send it off for a proper body alignment, and finally get it back and properly weld it all in.1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.523072599f6a3175b22d19e08e30cf6f.jpg)

.thumb.jpg.520ee82fad7026700705e22680752928.jpg)

.thumb.jpg.cc35827ec687e7726390576a63e2a953.jpg)