-

Posts

4,099 -

Joined

-

Last visited

a.craw4d's Achievements

Committed (5/5)

11.5k

Reputation

-

How do you provide proof of ownership on a deregistered vehicle? Car in question still has plates but the rego has lapsed. Can you change ownership with the plate details even though they’ve expired? Cheers guys.

-

https://www.facebook.com/share/1Ce34tCxnz/?mibextid=wwXIfr $30 thermette if someone’s keen.

-

Discuss here about Yoeddynz's little Imp project...

a.craw4d replied to yoeddynz's topic in Project Discussion

I think you’re going about this muffler problem the completely wrong way. Everyone knows you start with straight pipes. From there you progress to a coby hotdog or two. Then it’s a downhill spiral of random scavenged straight through style pre silencers to full nana spec mufflers. At some stage you’ll even float the idea of a vertical truck stack with flapper gate on top. In all honesty though I’m loving the development of ideas on this whole build. Keep up the great work. -

V belt pulleys also get worn, so a new belt on a worn pulley isn’t going to last long. And there’s many different profiles of V belt. The wrong profile belt will look like it’s sitting nicely on the pulley but it won’t be contacting the full face of the pulley, and vice versa. Many people swap and change parts without thought to what profile belts or pulleys are in play. A set of V belt gauges is a good start to see what’s what. Pulley alignment is the next issue that’ll give problems.

-

https://www.trademe.co.nz/a/motors/cars/nissan/cube/listing/5219906887 When do you pick up this one to start the official “collection”?

-

What year is it? And are the guard mounted side mirrors original? Reason I ask is my parents had an 84 wagon they bought new with the side mirrors in the corner of the glass on the front doors. They only recently sold it and the first thing the young guy did was ditch the original mirrors and fit some guard mounted ones. This annoyed the crap out of me lol. I’m not a fan of the guard mirrors, especially when not original. Otherwise sweet car and motor choice. Looking forward to some updates. ^^All the old pics I could find of my parents one.

-

From the tein website in regards to their springs in a z11 cube. FT: OE BUMP RUBBER NEEDS TO BE MODIFIED. WARRANTY VOID BECAUSE: RIDE COMFORT DOES NOT MEET THE COMPANY STANDARD.

-

Im guessing a manual conversion is well beyond the abilities or thoughts of the average cube owner. A recent post on a FB cube page was asking what the lock button was beside the auto gear lever. (Not really mechanically minded people). Although cube owners love their cars, most of their modification abilities only stretch as far as rocking into mag and turbo and buying “from the book” wheels, and getting a vinyl place to do some graphics. The cool thing with cube’s though is that generally they’re a lot tidier than other cars of the same age. This again comes down to the type of owners. People don’t buy a cube to just get from A to B, they buy it to be quirky or different. They genuinely love their car and look after it to the best of their abilities. A Tida on the other hand, although the same chassis, is the epitome of a zero fucks given shitbox. Forgot where I was going with this. Z11’s are awesome! I drive past this one almost everyday, it’s on my Wishlist.

-

One of the bookface groups you lead me to just had a post about a k24 swapped z12 that going to be made 4wd. I’m watching with interest. Love your cube btw.

-

Sheep grease would be lanolin. I’ve read about using polish to remove surface rust to prevent damaging the surrounding painted areas.

-

Anyone here used one of these airbrush’s? Designed for makeup, nail polish, cake decorating etc. Wondering how well they do hobby stuff.

-

Am in 2 minds of doing this. Many conflicting opinions about the motor’s longevity after governor delete. As it is with the governor, anyone can jump in and give it heaps with no fear on my part of it going pop. I can tighten the spring to increase revs / speed and still keep it within its limits while at the same time I still get wide open throttle up to that limit. Also bear in mind this has been an almost free build so far. Purchases to date include the chain, sprocket, brake and throttle cables.

-

Terrible video as promised. Filmed with my left hand, left hand also on brake duty’s so terrible braking as well. I also drove this to a local supplier to pick up stuff. There’s a video floating around somewhere of me high siding it, almost getting thrown out then crashing into their shop wall. Was fcuking hilarious. We then loaded it up with bearings and housings and hooned back to work. Got many thumbs up and a couple photos snapped while waiting in traffic at the train crossing. It’s such a hoot to drive.

-

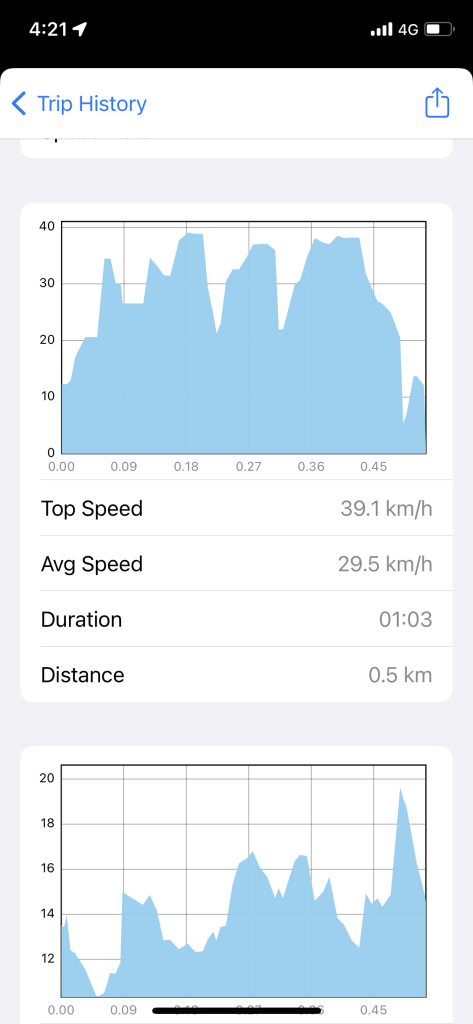

Did a run around the block with a speedo app. Time to tighten up the governor a bit. Can’t be holding up traffic. edit. I tried to take a terrible one handed video of a ride in this. But it’s, well, terrible. As I need 2 hands to drive. Might upload it anyway.

-

Tried this. Hate to admit it but it was terrible. Surprising amount of grip until there’s none at all. And being rear heavy I could hold very little drift angle before it spun very quickly. Did eventually add a chain tensioner as the chain was super slack. Drove this a few blocks away to show a mate, got chased by a dog on the way. Dog was bigger and faster and wanted a piece of me. Luckily (for me) it got a little too close to the rear wheel and got clipped, tumbled and gave up the chase. Scariest moment so far on this thing.