-

Posts

67 -

Joined

-

Last visited

Converted

-

Local Area

Auckland

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Themi's Achievements

Advanced Member (3/5)

309

Reputation

-

Yep! 226/233, less lift. Same with the ZM-DE (I've had a friend measure the ZM-DE cams and theyre actual trash). Also yes, unfortunately. Its the only VVT motor Mazda made with this cylinder spacing so I'm almost certain its the only cam thatll fit. Thanks for the suggestions though, I wish I could grab some off-the-zebra (RIP you will be missed) cams for this but I think getting regrinds is the only way, given the fancy oiling they had I don't even think brand new cams from a billet would be cost effective. On these cams, the intake cam has all of the oiling setup for the VVT system so I'm not so certain anything will drop in. The cam journals are all oil fed from the head. On the exhaust cam, the cams self-lubricate from a single feed on the frontmost cam journal, which is distributed throughout the cam through tiny wee oiling holes on the rest of the journals. The exhaust cam has more lift and duration than a B6 intake cam I think, so it could maybe end up being a cheap drop-in exhintake cam for NA 1.6 mx5s? To be looked at further, by someone other than myself. Another point of interest is that the backs of the lobes (in the base circle) taper really narrow, does anyone know if this is an issue with re-profiling cams?

-

Woah 2 updates in less than a year? I must've had too much caffeine. The plan is: Remove the intake manifold. Grind down the clutch master where it touches the TPS. Less sketchy than it sounds, its just a mounting tab for the old reservoir. I kept the master wet to cool it while cutting. Remove the throttles. Tidy up the mating surface between the intake and throttles. Drill out the threaded mounting holes for the throttles. The tapped aluminium was always a bit sketch, I never had the confidence to really tighten down the mounting bolts for the throttles. Grey RTV the mating surface, longer bolts with nylon locknuts on the back. Re-install the things. Hoon. So, intake off: Clutch master cut down: I did the things I needed to on the manifold, I also trimmed down the flange a bit to be less intrusive (compare with older photos): Back together: Aaand in the car: Results: Started first pop, was running like shit and my exhaust spat out more fuel than the last 15 seconds of a prepaid BP pump (not hard). Turns out you need your MAP hose connected (seen by my washer bottle/chassis tag in the previous photo... lol). I guess the vacuum gave enough fuel for it to run super rich, basically WOT fueling. On the first drive the car was fine. The cyl4 vac leak was gone as expected and I'd spent more time grinding out the inside of the intake manifold, so some of the weird whistles I used to get seem to have gone. Datalogs looked expectedly poor. I had some help from a very knowledgeable friend about some oddities in some analog sensor readings and we have determined I should probably both chase my grounds and make sure everything looks fine, and also change back from a hybrid SD/alpha-N tune to pure alpha-N, with a bit of analog smoothing on the TPS signal. This will help resolve the very difficult to tune accel-enrichment values and hopefully result in a better driving experience. Future: I think besides all of the constant fixing of past-me's neglectful corner-cutting, I need to really look into longer duration cams. I believe the 230/240 8.5/8.9mm values really aren't enough for the kinda tomfoolery I would like. As the ZL-VE cylinder head has really never done much more than haul groceries, nobody makes cams for it. Regrinds are in order and I will try to take as much inspiration from the NB VVT engines as I can. Maybe 270/270 9.5/9.5mm which purport to be fine for shim-over-bucket lifters. Realistically, moving to shim-under-bucket will cost more than the cams. I think my engine will become interference with the cams I'm wanting, mostly because the stock b6 pistons have the valve notches for the wider cam spacing (obtuse valve angle) and the valves being closer to the piston when at rest in the ZL head. Oh well, it'll be fun while it lasts!

-

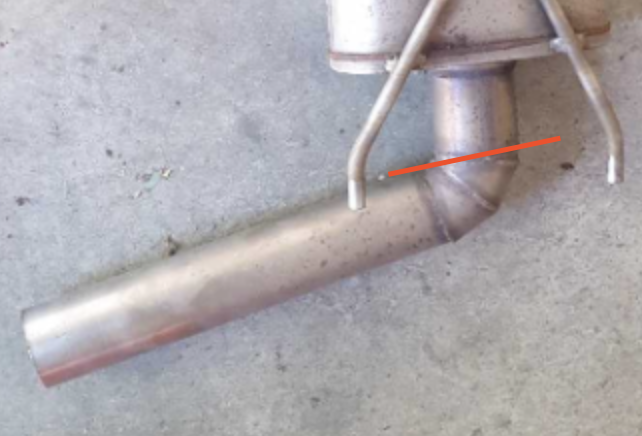

Another few months of nothing and then I decide to sign up for another sccnz motorkhana. At this point it is 10am saturday, and the motorkhana is 10am sunday. Last time I checked, my TPS is falling off, throttle #4 has a vacuum leak from being yanked about when the tps was knocked, and there is maybe a slight misfire. Instead of even opening the engine bay, I decide the exhaust needs more work and I have a muffler just lying about SOOO a plan is formulated... I'm also critically out of stainless filler and argon, but that won't stop me Contemplating new muffler position, was tempted to have it riight out the bumper but I don't hate myself that much. Instead, we tuck the muffler right up underneath the car and do a downturned exhaust tip. At this point I was chopping up the old muffler to save argon. Here is where the downturn tip came from: After procrastinating a fair amount, I get the muffler all tacked and have completely exhausted my argon bottle. Nice, its about 3pm and I'm making dinner for some friends before a comedy show. Make a lasagne then quick trip to bunnings at 5.30 for an argon swap, comedy show and start "welding" again at about 11.30pm. Do I need more gas coverage? Sure. Are my "welds" shit and rushed? You know it. Do they work? To be decided. Midnight:30, job done. Car lost some rasp, gained a LOT of bass. Right at 90Hz at motorway speed, heaps of it. So much bass I was getting a headache, and that was not fun. I figured its about time to actually make the car quiet, so I make a (suss) slip in silencer after the motorkhana. It had to be short and on an angle to be able to get up the downturn exhaust tip, but it does the job. Bass is gone, rasp is gone, car sounds pretty reasonable for once!

-

Okay so the handbrake is still NFG but the brakes themselves are awesome. It's probably just having fresh fluid and non glazed pads but the brakes feel far more linear to lockup, whereas before they didn't do much until the fronts just completely locked up. (I didn't hit that cone, somehow) I did a sccnz motorkhana yesterday (Sunday), placing 5th overall which I'm stoked about! I think the bigger cars struggled on some of the tight courses and I'm sure it would be a different story in an autocross. My dad also drove my car earning a very respectable 12th place in what might have been his very first time trying to drive a car with more than 20% throttle! Someone also took a video of my slower run of the fourth course: https://drive.google.com/file/d/1aCg9DYelcsQd_GZSELs4I_Cb2tV9oiOn/view?usp=drivesdk Still need $$ for further car improvements. Up "next" are new equal length headers and probably replace the muffler as I am now pretty sure the combination of my crap unequal-length headers and a cheap muffler are causing the last of the tinnyness in the exhaust note. Then I'll need to replace my suspension, the car still behaves very soft even with the dampers set as firm as they will go. Photo from @mooffy_photo (@mooffy_photov2 on insta)

-

My mx5 is not 6lug nor does does it have a big brake kit, so the arrival of GMC sierra/Chevy avalanche/Cadillac Escalade front rotors for the rear of my mx5 was a bit of a shock. Rockauto was good about the refund and I guess I now own some shiny wall ornaments. The fronts and front pads arrived just fine, but rear pads were gifts from a friend but are also incorrect (nb). I want a refund on those too... Anyway NZbrakeco sorted out some rear rotors overnight and BNT had some nice pads for the rear so now the brakes are all pretty much done. Just need to mess with the handbrake adjustment points and check everything is okay (cable isn't stretching or frayed etc). And yeah drilled/slotted aren't necessary for me nor are they as "good" as plane Jane vented rotors, but I think they look cool and they were on special, so cost about the same as any other coated vented rotors. Edit to point out the crustiness of my old rears, and the reason I wanted to replace them:

-

My hopes were up Nah I was pretty convinced that it wouldn't help my handbrake, but I know my fluid is bad and I'm sure my adjusters are unhappy, so this is a good thing. I'll probably try get new discs all around and new pads too. Actually thinking back I believe at the last wof I can remember that was at a place with a brake machine, my rear balance was out of wack anyway... oops

-

Completely unrelated to any important task at hand, but I've found a box of calipers that "we" gave up on a few years ago, and started working on them again. The fronts were already reassembled, rears have a painful circlip around the piston adjuster mechanism. They're down the back of the bore and really difficult to get at, so I had to make some ultra long circlip pliers. I don't think this ranks in the top-50 on the list of sketchiest things I've done. It did however get the job done, so now I have some rebuilt rear and front calipers to go on my car. I'm hoping this will help with my non-existant handbrake before the next motorkhana in mid October. Also my car is probably far overdue for new brake fluid and I can now kill 2 birds with 1 stone.

-

I'll get to the "current" exhaust video one day - however these are before videos of the old setup (bad intake, shit resonator) at a motorkhana held by SCCNZ in march. Not the tidiest I don't think this course was meant to have a loop Cue excuses: no handbrake, no power steering, no abs, bad driver The reason I have few/no "current" videos is that I have this annoying "chirp" at mid throttle: it sounds like the intakes are whistling? I believe I need to take my intake off and really smooth down all intake surfaces so there are no lips/edges for air to flow over and make noise, because it is super frustrating to drive like that. It also makes cruising super frustrating because most gentle inclines cause the chirping noise again. I'm also going to get a new rear muffler, I think my current one is fine but I want something that reduces the total exhaust volume significantly, as it is a bit loud at motorway speeds, reducing the top-down comfort I'm expecting to need this summer. Gratuitous overrun on the way to a meet in Tauranga.

-

Themi started following Honda EK4 Civic

-

Apologies if it has been discussed already in the last 17 pages but a quick ctrl+f didn't find it. Regarding DBW control - RusEFI boards have open source DBW hardware and firmware available for you to look at. I mean I'd suggest getting some proteus boards manufactured (including 2 for me ) however component shortages are a right pain. The Proteus handles dual-DBW so the hardware/schematic could be taken from that repo, and to control it perhaps picking apart the rusefi firmware would be the way to go. https://github.com/rusefi/rusefi/blob/master/firmware/controllers/actuators/electronic_throttle.cpp https://github.com/mck1117/proteus

-

Alright Friday night shenanigans. Im making the drive to Tauranga on Sunday and it's time to remove the drone and rasp from my exhaust. Previously I had the absolute cheapest stainless resonator I could find but I splurged for a Vibrant Ultra Quiet 2.5" resonator to replace that. I ordered it late last night, arrived today and I was very happy (jump scare face reveal included). And yeah. The money shot: Some late night welding: And the old resonator: New one welded on: And the end result... Well it's not ultra quiet, but it has none of the old farty rasp that my exhaust used to have. Finally an NA setup that doesn't sound like trash! I really like the new sound. Growl and bite but no bark. Ready for a good weekend! Oh and I got a wof, with a few minor suggestions...

-

The suggestion given to me last wof was to tidy the front bumper mount and tow hook points. I did that, plus tidied the front sills and most of the engine bay. Its amazing how much the engine looks more at home in a halfway tidy engine bay! I'm also reassembling the interior and tidying up the guards and front bumper a bit before final reassembly. Should be able to take it for a shakedown soon to see how the intake behaves, then hopefully wof this week. Meet in Tauranga next weekend so I'm hoping for a pass first try... (Broke a lamp...)

-

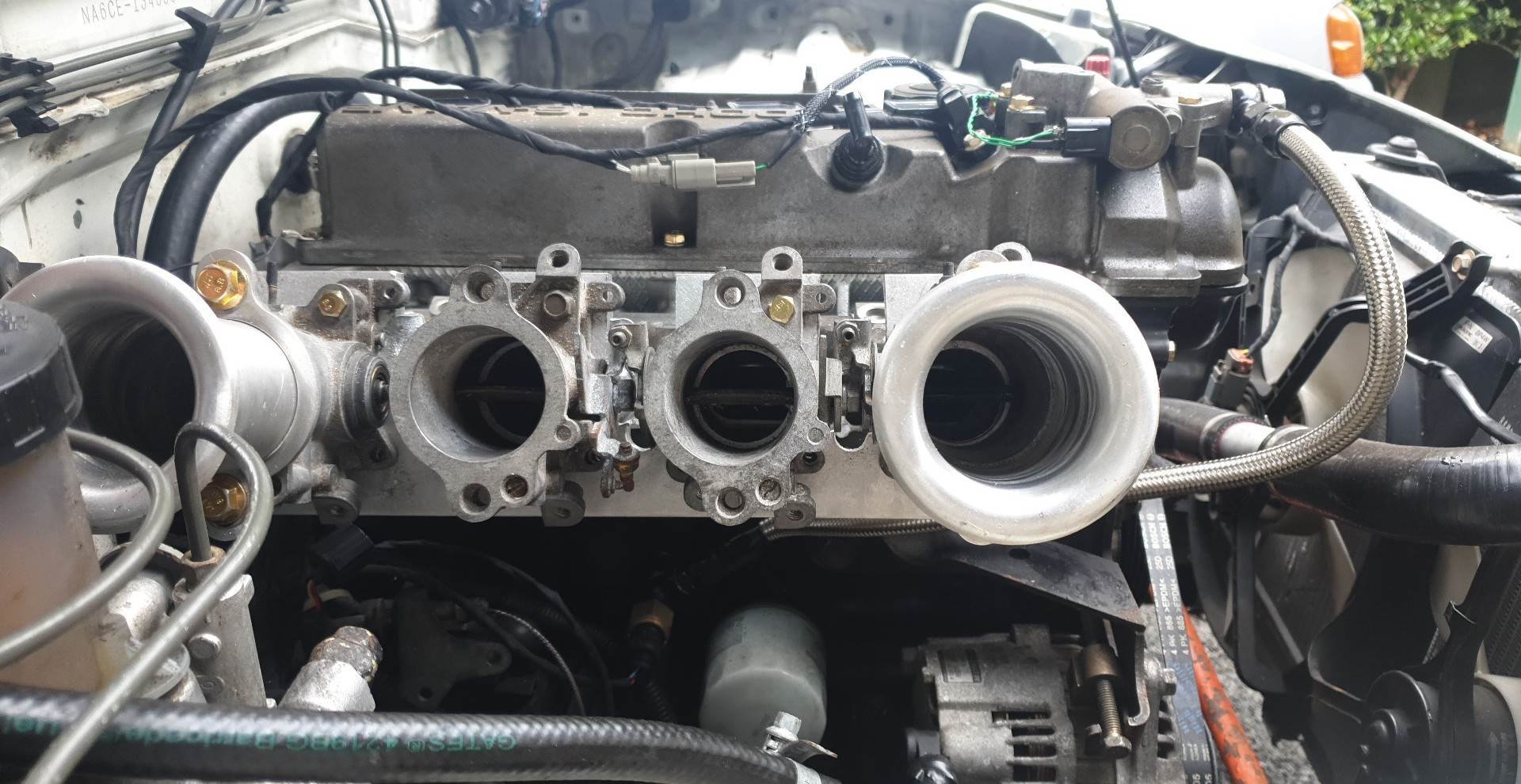

Alright air filter time. Bare trumpets are cool, but every bit of roadworks or loose surface scares the shit out of me. I don't have an engine undertray so rocks are a very real concern! Some cheap filter socks came up which fit great. I don't mind the look, but they are very restrictive for airflow. A friend had an ITB'd BP on the Dyno and gained 10kW removing his socks, so they aren't excellent for performance. Some may have seen that I used to have a pipercross px600 box air filter, which I had modified to clear the clutch slave in my old setup. Well I wanted to un-modify the backing plate to save money, and possibly eventually replace the box filter with an unmolested one. I welded a new plate on where I cut earlier, then ground it flat and cut the shape up. Now I have to replace the box filter but we have option number 3: a badass box filter setup. My trumpets don't fit under this filter and the filter is a bit hacked up at the back, however I love the look. Soo yeah, filters are cool but the box one will prove expensive. I'm not sure what option I'll settle with but if anyone has any thoughts (or a cheep box 80mm or domed 120mm px600 filter) let me know!

-

Lights out and away we go, the new manifold is on. I had to flip my brake booster to clear the trumpets, painted it again at the same time to tidy it up. Also I had 10,000 vacuum leaks. Turns out my aluminium welds are just as shit as ever, thick casting doesn't help my problems. Eventually I noticed that one little bump on a weld was touching injector #3, stopping a good seal at the base of the injector. Rectifying the air leaks and solving fuel hose routing, plus a few other things done. Now the car is back to running and driving but still always more to do! Wof is expired so I'm needing to tidy up some of the gremlins that have appeared before taking it back in. Video of dorts here

- 68 replies

-

- 11

-

-

I've been busy with a major milestone at uni, which I have (un)officially completed as of Friday so I could spend the long weekend carrying on with this. I've tacked together the intake manifold. need to get some roloc pads from blackwoods to do proper surface prep before continuing as the tacks are pretty dodgy to say the least. The ZL casting is far worse than the old 4age flange I had on the old manifold, this is full of crud and loves to pop and splatter, however once new material is infused into the casting it doesn't do too badly. As I was hoping for, it clears the fuel rail, brake/clutch things and bonnet. Perfect. One day I'll get around to making a plenum for it, but for now it'll remain open to atmosphere.