Leaderboard

Popular Content

Showing content with the highest reputation on 09/08/19 in all areas

-

9 points

-

Long time between posts as usual, made another mission back to the Marshland yard before it's all gone. Managed to get four decent 14 inch rims to put the Sabre back to original and so I can fit the NOS hubcaps - will look the part once blasted and painted. Also found a floormat for it amongst the grass, I have the passenger side but had been missing the driver's so I'm a happy lad! Also dragged this monstrosity home because I couldn't bear the thought of it being crushed. I'll clean it up and then decide what to do with it.8 points

-

I picked up the completed radiator, the dude supplied a high quality fan and modified the thermo cover to have a rad cap as that's the highest point in the system now. Unfortunately this has evaporated a pretty significant proportion of my financial reserves, so much so that I cannot afford the chassis coating I did scrape together enough wedge to order what I needed from Trundles after checking the rest of the engine, which appears to have been recently rebuilt and looks pretty good. There is some weird shit going on with what happened to it tho, it was probably turboed already, but this had been removed and the oil feed to what I presume was the turbo had no capping on it. This explains the shitload of oil on the diff and engine on that side, and the lack of sump oil, and the seizure.. But why? Anyway, I have been steam cleaning all the bits and prepping to get it back together; Trundles bits should be here next week sometime. I also cleaned up the diffs, with cleaned up caliper insides and new brake lines; Then I put a whole lot of shit on tardme, might have to sell some bikes and shit I don't really want to...7 points

-

6 points

-

6 points

-

Driving home the other day, and my shifter become incredibly remote. Very odd sensation. Also annoying that it broke off in neutral so I had no drive. Thankfully the underseat storage box contained the ideal assortment of rusty tools, along with a singular used bush, one set of brake shoes, a single u bolt and an owners manual missing multiple pages. Took the high range lever cover off and pushed the selector into second and drove home, chucked it in low range to get up the hill. New one is coming from Australia. Had to take the floor panels out to remove the selector. Currently in flintstone mode. Exploded shifter, the circlip was under a fair bit of tension, didn't expect the spring to be quite that large5 points

-

So I've been getting sick of rebuilding my front calipers regularly as they have been getting to hot. After the last club day of the season, the disks were again to hot and so had significant micro cracking and was only a matter of time before the cracked through again. I've also had major issues with pad knock back and stub axles cracking from the forces, also bearing life is an issue. So time to put a big upgrade into motion. I had decided to replace the front calipers and disks once and for all and to do it right. I was running Wilwood calipers with a Toyota Yaris disk (254 x 20mm) machined to fit. I went with AP CP4567 calipers with a 267 x 25.4mm ap disk on a bell (directionally vaned) which is pretty much the biggest i can get in 13" rims without going to another setup which is like twice as expensive. The setup is what's used on rally Escorts and is the Monte Carlo version rather then the forest version. The idea is the wider the disk the more heat capacity it has. Also bigger diameter helps the caliper leverage. I went with the AP's as I wanted a proper motorsport caliper with decent seals, knock back springs and pad availability. I could have made it fit the Starlet stubs axles, but i've had issues with them cracking and with the areo load i plan, i was even more worried about them. So I decided to upgrade to AE86 front stub axles, which meant new suspension, but did let me buy a "bolt on" kit for the brakes. Oh and also a new pedal box as I need different master cylinder sizes for front vs rear. So begins a long process...4 points

-

4 points

-

4 points

-

Haha, thanks but no. Does it have 28x1/2 wheels? Have a look behind the filter housing, if it does have an oil cooler it's a great place for bits of old bearing to sit then go through your new bearings once it's running again.3 points

-

So in the vein of do it once do it properly. I chose a set of custom MCA Reds all round. Here they are fitted up with the brake mounting kit and cooling I adapted to fit. I went with T3 AE86 steering arms and used the T3 Adapter bushings from the standard Starlet Lower Control arms. A set of MRP RCA's finish it all off. The T3 steering arms are shit to be honest, they are far to heavy, far to large, and just over built all round, and I only got them as I couldn't get AE86 PS arms in time. Of course with 13 inch rims there was no way i could fit the steering arms on the outer hole, so I had to chop that hole off and move them in, just means slightly heavier steering, but more responsive which i'm fine with. However with the RCA's the angle of the steering rack ends meant the ball joint (or whatever it's called) hit the steering arm, so we had to do a fair big of clearancing to give a free range of motion. Of course I only got this all sorted just in time for a shakedown on the Friday before the new racing season started on the Sunday, nothing like leaving it to the last minute. Shakedown didn't go well either as I couldn't get the front/rear bias sorted, and flat spotted a set of front tyres. So Saturday I removed my original in line bias valve (supposedly can lock on when high fast pressure applied) I got out to the club day with a new pedal box, suspension and brakes. Took me a wee while to get comfortable with the car... They had discounted the entry fee, so there was a pretty big turn out of cars, which was good. First race I had a fairly good battle with what i believe was a WRX Second race I took advantage of a bit of carnage on the first corner to get a gap to an Integra which was faster then me and managed to hold him off. Handicap race for the last one, a lot of faster cars coming through (mainly porsches), got overtaken while behind traffic, then managed to get it back a few laps later when he got stuck behind traffic. Overall was a weird day with the wind, everyone was a second or two off their normal times, best I did was a 1.37:000 flat. Suspension was a lot more complaint with the bumps, still getting used to the grip, and the brakes were amazing, pedal box with the throttle pedal was a lot better for position.3 points

-

Fitting a pedal box in a starlet is a bitch of a job at the best of times, but add in an existing roll cage to work around and it becomes a nightmare... Frankly I would not have attempted this without @Snoozin and @sheepers posting their detailed write up of what they had to do to create one for Snoozin's starlet. So a massive thank you to them for sharing their process! Rather then go the normal route of using a Wilwood box, I went for Tilton as I needed to be able to adjust the pedal positions vertically as I had very little room to move the pedal box around, I also wanted to replace the throttle pedal at the same time so I could eventually Heel and Toe if I wanted to. So start with working out the only position the pedal box can go in to clear the firewall, tunnel, steering shaft, bulkhead and cage (get oh so lucky it actually fits)... Get the position right for all 3 pedals: Lots of cutting and fiddling later and a bracket is tacked up: Realise you can't actually get it out now... so adjust slightly and you end up with this... Needed to hook up the brake lights, so used a micro switch which goes to a relay, nice and simple and allows adjustment if required. Since I was changing the throttle pedal, it was no longer a direct pull through the bulk head, so had to make a cam up to translate the movement, this took a bit of thinking to get the right movement in relation to the throttle bodies so it was linear the whole way. Work out that the reservoirs absolutely need to be remote mounted, start buying gold plated fittings to make it work: Reservoirs mounted and plumped in:3 points

-

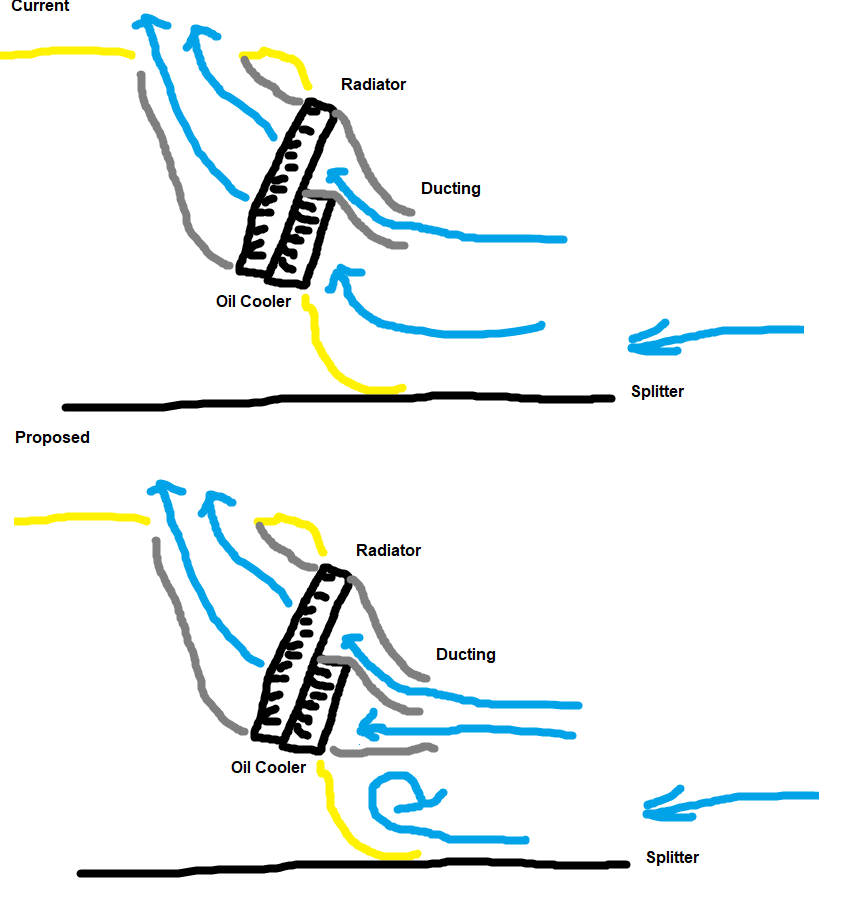

So went out for a shakedown with a new diff of 4.5 from 4.3 and the car looking like this: Some interesting results... It's all very well talking about PB's but in reality while I may hit a time, i'm far from consistent, and repeating it is often a matter of luck (bit between teeth chasing a car etc). So in the past i've always been around the 1.36:800 to 1.37:800 with the diffuser and splitter i was even more inconsistent and the laptimes were down, i just didn't feel comfortable with the car. I had a very unnerving experience going through pothole (fast left hand 150kish turn) where the whole car nearly under steered off the track, I've never ever felt the car like that before. So thinking being that the diffuser was working a little bit to well we pulled it off and just tried the splitter where i've felt I had an improvement in my times before. So so, nothing really different, less understeer but laptimes were about the same. I think where i previously thought it gained an improvement was just me driving better. So pulled off the splitter and just went back to basics, and did a 1.35.800, with consistent times between that and 1.36:500. The new diff made a massive difference, the car is just on song now, and still accelerating well at the end of the straight. So onto the last club day where i had a great day with my previous competition (Honda Integra DC5) unable to keep up: I took out the overall championship again and also won my class for the first time. So breaking it down, the diffuser is working really well, but the car isn't balanced with the diffuser on. I've always been told a splitter adds one second a lap, i've never really felt that with mine, i've actually never felt a major difference in the front end. So I don't think the splitter is doing it's job at the moment. I'm guessing the issue is the bonnet vent, I've now got a straight path from the top of the splitter through the radiator and out the bonnet. I think this is stopping a high pressure zone from forming on the top of the splitter. So i'm looking at changing the flow of air into the bottom of the radiators to create that high pressure zone. <3 points

-

Tophats are fitted to rotors with a cap screw and a lock-nut, usually a distorted thread type or similar due to the high temperatures involved. In 22 years of motor racing I've yet to see one come loose. If one ever did you'd notice through the steering wheel very quickly, I don't think you have a safety issue there. The main thing I would be concentrating on would be that your tophat was hub-centric on the hub and the rim was hub-centric on either the tophat or the hub.3 points

-

I had one of these cut down into a buggy 30 years ago. Survived a Derby, only thing that stopped it was a fan blade broke loose, threw itself around the engine bay randomly and broke the side off the carb. Adapted a 1500 VW carb onto it. Was insanely fast, we got 80mph out of it on a tarseal road just out of Dargaville. It would wheelstand if you weren't careful. Far faster than mates 1600 VW one. Sharn aside, this car looks a real gem. Good to see someone showing a underrated marque some love it deserves. Keep up the good work!3 points

-

3 points

-

Time to strip the head down. Suddenly I realised I’d lent my valve spring compressor to that guy we all know who never has his own tools (and we always forget his name), who never returns tools……….grrrrrrr! As I’ve said before, combining the lack of an appropriate tool with a good mig welder and the obligatory collection of scrap steel under the work bench is the mother of many a good man-cave invention. Found an old screw Clamp…a bit of cutting and welding. A lick of paint…….. And the custom (i.e. beer, bullshit & bad manners) “Oldschool Holden Valve Spring Compressor” makes its debut.2 points

-

2 points

-

@MACKAZ Sounds like an absolute weapon! I've heard similar stories re the fan - A guy told me he had the fan explode which threw the blades through the bonnet/bootlit and give it shark gills haha. Cheers2 points

-

2 points

-

2 points

-

@Valiant Ep70 starlets have solid rear ends. Same as altos I think there is still a starlets at pickapart2 points

-

Just as a quick follow up. I have ordered a set of new injectors, and will be removing the fuel distributor to inspect/clean the plunger. I'll be setting it up properly from a zero setting after cleaning everything. Just waiting on parts/tools to arrive. I've noticed the AFM sensor plate is way out of setting (should be sitting a lot lower than it is) so either its sticking or its been setup incorrectly (50:50 on either). Chances are the system was running a bit average due to a lack of maintenance, so it was "tweaked" to compensate and now its all out of whack, seems pretty common for people taking on projects with KJet.2 points

-

Also today the horn jammed on, it has never worked, the button dosnt even move but I had to drive past people with it blasting away like some arsehole.2 points

-

2 points

-

Door is being a pain in the ass to hang. The problem being that every point of reference has been dicked. Got the lines pretty good, but the bottom of the door over hangs the sill by a good 1cm in places How, I measured and checked everything and used the other door frame for reference. The sill is dead straight. Oh the door is bent Some hammer and dolly work and it's coming into shape. Looking at unmolested utes, there is a prominent angle here. Mine is smooth and bulbus . I assume it was either bent out to match the previous sill, or was bent already and the bogged the sill to match. (Same issue with the roof lines, bogged over and rounded off)2 points

-

I’d been keeping any eye on a bloke in Whangerai who had been trying to sell a 186 on TM while doing his damndest to scare off any potential buyer by abusing anyone who had the audacity to ask a question on his auction. God I love those grumpy old traders! He was insisting that someone had painted the standard head yellow and refused to post any pictures of the inlet ports. After some months of his relisting I finally put the poor deluded old sod out of his misery by buying it for $300. An early 2-hour drive had me rolling down his driveway at 8 am in the morning, one look at the inlet ports confirmed it had at least a stage 2 Yellow Terra head. When I suggested that as an honest principled rogue, I felt a moral obligation to throw a little more coin in the pot he started accusing me of being a ‘lying young upstart that was talking through a hole in his f***ing head’. As I beat a hasty retreat up the driveway waiting for him to set the dogs on me (with the booty in the back of the van) I had to admit that at 63 years of age, despite the verbal tirade it was great to be called ‘young’ – ya gotta love those grumpy old guys! Couldn’t wait for to to get the head off but work pressure had me waiting for the weekend. As I said in the 1st post of this thread ‘sometimes you just get lucky’ - I stuck it in the engine stand, flipped its lid off and discovered a rather virgin stage 3 Yella Terra covered with the type of carbon that only prolonged over rich running can ever produce. Double valve springs and classic 70’s inlet porting. And just relish in the vintage YT valves! Once cleaned up the flat top 30 thou over pistons felt firm in the bore so Rigamortice and I made the call that we’ll clean up the head, sort out the appropriate sump/pickup combo and see how it runs.2 points

-

2 points

-

As those who are more familiar with us will know both Rigamortice and myself have a great affinity for the environment and take climate change (i.e. the thing we used to “call global warming” before it got cold again!) very seriously. Stricken by remorse and overwhelmed by guilt over the tons of negative carbon credits I’ve released on the global economy through years of motor racing, driving cars for the love of it, and behaving like a typically irresponsible older ‘Oldschool’ member I have acquired an EV! You may scoff at the fact that it’s a clapped out old warehouse sweeper with buggered batteries saved from the scrap heap but to Rigamortice and myself it is a powerful symbol of our indefatigable commitment to a green and politically correct future. With help from my brother providing advice, encouragement and the Wild Turkey may I present the definitive green, negative carbon credit, EV solution to taking the wheelie bins out when you live down a long driveway, (what could possibly go wrong!). Commentary and camera work courtesy of the ever lovely Mrs sr2.2 points

-

2 points

-

Have a look, it's cheap insurance. I'll pass on the bike thanks.1 point

-

I got it from Kedall welding supply in south auckland, I think they are gone now, I welded up a cracked bell housing and an engine block with it, I got the wire for welding bronze castings together but it was a different color1 point

-

1 point

-

Drum Brakes - why do I keep having to bleed the damn things? Where is the air getting in - it seems to be at the wheel cylinders but hard to be sure.........1 point

-

1 point

-

1 point

-

I got soooo drunk there on Fri. Holy fuck, that ginger wine stuff.. Jesus1 point

-

Ride the fast post, then there's no worries about blowing fork seals again if the front wheel never touches the ground!1 point

-

1 point

-

As mentioned previously, I'm having some running issues and I need to try and work out what it is. The issue has been getting worse the more I run and drive the car. It previously only happened under load at about 4000rpm, where the engine would fall on its face and cut out like you had turned the key off. If you kept the throttle steady it would recover with a surge as the revs dropped, but as soon as it got up to about 4k again, it would cut out. When stationary, and not under load, it will happily rev to its 6k redline. It's a very annoying issue. I had a couple of suspicions of what it could be, but I needed to do some testing to narrow it down. My first suspicion was that I must be losing spark, as the engine cuts so abruptly and I felt that if it were fuel it would kinda stutter out. The first thing I noticed was that the replacement coil the previous owner had fitted was a Bosch GT40. This is a 12v coil, and from what I have discovered, widely known to have issues with electronic ignitions. Now, the ignition system on my car is both a ballasted system and electronic. A ballasted system runs a resistor on the power feed to the coil, dropping the voltage, meaning the coil doesn't see 12v. So I was already running the coil under voltage. After testing and confirming the resistor was still in place, I removed this coil and refitted the original Ford coil that came with the car. Changing this resulted to a smoother idle (maybe, but probably a placebo), but the engine still cut out. The next thing was to check the lead positions, cap and rotor. I note that the cap and rotor have been replaced, and the old ones were with the car. The old cap is stuffed, but the old rotor looked OK, so I swapped that in after a quick clean. No change. Next was to confirm if I did lose spark or not. The only way I could think of was by thinking out of the box and using my timing light... So I connected it up, and strapped it to the wiper so I could see it when driving. Sure enough, when the engine cut, the light was still flashing away happily. That indicates I have spark (although, not if I have a good strong spark, but some spark is better than none). So this points me down a different path. I have air, and I have spark. Could it be fuel after all? I posted up on a few forums asking for help, and got some great tips on where to start looking. One of the easiest to do was to check the sensor plate in the AFM was clean. This plate is hinged, and lifts up with airflow as it gets sucked into the engine, which in turn pushes a plunger up and down to control fuel flow. Well, although the top looked reasonably clean, the underside was filthy (probably thanks to the incorrect air filter that was fitted) I gave this a thorough clean and made sure it was spotless. This made no change, but its good to know its clean now. I also, once again, checked the intake tube and boot for splits or cracks, but none found. All vacuum lines (all two or three of them) were checked, all OK. One thing that makes me suspect its possibly fuel, is the state of the new plugs I fitted. Even after a couple of runs around the block, a couple look almost unused. Maybe lean? From 1 to 6 in order. This is leaving a couple of possibilities, ones that I cannot test without further equipment. First is an intake manifold leak or the likes. Today my smoke machine arrived, so I could test this. It's just a cheapie, but makes a good amount of smoke, and has a pump to actually blow it out under pressure. After a quick test, I modified it to work how I needed it to. I salvaged a cap from a CRC rust convertor can, drilled a hole in it, glued some hose into it, and glued the cap onto the front of the smoke machine (as it just has a big nozzle on the front normally, for maximum smoke dispersion in da clubz) This hose then goes into a rubber glove with a finger cut off it. I find using one of these seals the intake pipe nicely with the wrist of the glove, but doesn't crush the rubber hose. I don't know if it's good or bad, but smoke testing the intake shows there are no intake or vacuum leaks. I tested with the throttle open and closed, to check the intake hose for leaks as well as the plenum/manifold, but nothing, not even a weep. So what left? Well, two things really. I need to test the fuel pressures of the system, but because the fuel fittings use banjo bolts and hard lines instead of rubber hoses, I can't use my existing pressure testing kit. I have a new kit on the way, which has all the fittings I need to connect into the KJetronic system. This will tell me if there is an issue with the Warm Up Regulator or the main pressure regulator. The whole system relies on having the correct pressures, so even a few PSI difference can make it all turn to custard. The other thing I need to do, once I have tested the pressures, is to remove the fuel distributor and injectors. I need to see if the plunger in the fuel distributor is clean and moving freely, or if it's sticky. I also need to check the flow and spray pattern from the injectors. It's possible either, or both, of these things are causing an issue. My main theory at the moment is a sticking fuel plunger, which is causing the engine to starve of fuel when it demands more. The worst thing you can do with a KJet system is to leave old fuel in it and not run the car regularly. This car has been off the road for years, and I don't know when it was last started and run, or how old the fuel in the system was. KJet runs at such fine tolerances that even a slight gum or varnish on a component can make it upset. I'm determined to work this issue out and get the KJet working properly as it's a cool system, and one I haven't worked with before. I have everything I need to convert to EFI and Speeduino, but I'm trying hard to resist that urge. Now we wait. Once the pressure test kit arrives, Its game on.1 point

-

1 point

-

Thought it was time to clean up Rigamortice’s vintage Kel-Co manifold to get the DCD Weber back where it belongs. Couldn’t resist the temptation to cut off unwanted bits, file off casting marks and give it a blast in the new blasting cabinet (only a baby one but all I have is 12 cfm). Have to say I was pleased with the results. I’d been thinking about building an engine start-up cradle for a while, found some old castors, raided the obligatory under bench scrap steel pile and started cutting and welding,……… and cutting and welding,……. Once again happy with the end result, particularly the “Hillbilly headers” fabricated from parts saved from the rubbish bin. I just had to incorporate the “inglorious welding” I found on an old muffler! And how could you not love the 1950’s JAP fuel tank. As an added bonus you can even run motors up on it! (My favourite Torana 2850cc 9 port, stock standard but what little rever – Brock discovered them before anyone else). First 2850 start-up on the new cradle1 point

-

That'd be super cool, matching walnut swirl knob for yer walnut trim dash... Do you finish those on a lathe or do they come out of the mould like that?1 point

-

1 point

-

Here is the engine, it was built at Mcintosh racing, it runs well, its around 1100cc, it dropped a valve when the retainer snapped in half but it was ok, I made the exhausts and oils lines, engine plates, mudguards, and half the shit on this bike. it has Hemmings heads, I know a guy who has a KTOR engine on the floor in his shed, I can put you in contact with people but you probable already know them?1 point

-

1 point

-

Made it back to save one of the wrecks, I was there by myself so took the white one because it was easier to access. I wanted to get the red one originally but it had black seats verses the red ones my car had new. Turned out to be quite the mission to get it out, used my XJ Jeep which has never been off the road to drag the various wrecks out of the way so I could get the trailer close enough. Then almost ripped the whole front off the Skoda winching it from the front suspension! Unbelievably rusty piece of a car. Front right wheel was fully locked on so only way I could get it on the trailer was greasing the tyre then pulling it on. Made it home once I'd got it onto the trailer (there goes the neighbourhood), got the bits off it I wanted then took it for scrap. Seats have been really well preserved, the lichen on the windscreens seems to have blacked out the sun (see photo for before/after cleaning). Newspaper found in the car would date it as being sent to it's death in 1988 so 30 years in a paddock! Also found the unrecognisable remains of a 110R coupe - sad sad sight1 point

-

1 point

-

1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)