-

Posts

439 -

Joined

-

Last visited

Contact Methods

-

Website URL

https://www.youtube.com/channel/UCu2GCxUctQoqAXpDLbezcOQ

Profile Information

-

Gender

Not Telling

Converted

-

Local Area

Christchurch

Recent Profile Visitors

Hyperblade's Achievements

Advanced Member (3/5)

1.4k

Reputation

-

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

Damn a lot of effort has gone into that! Does it allow you to run a bigger axle? What was the reason for doing the change? Do you have custom hubs to fit as well? -

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

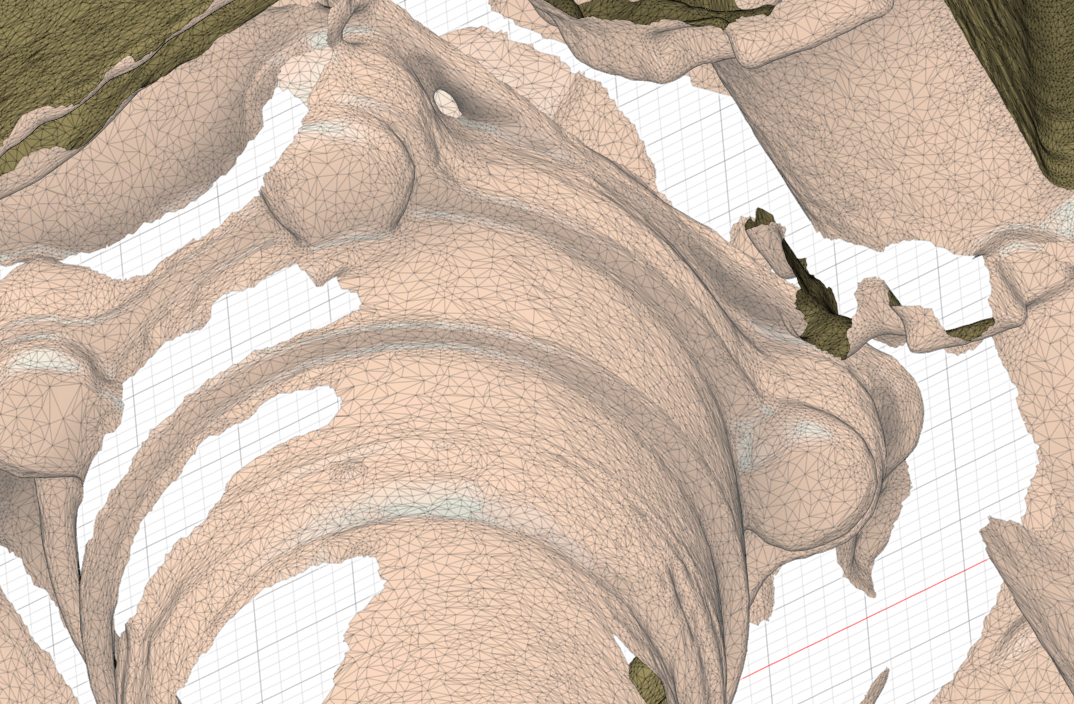

Here's roughly what a standard one looks like (your's has had a fair bit of modification done to it). -

I just looked at B series gearsets and not actually that expensive (if you do labour yourself), especially compared to the BS K series prices. Just for the driving enjoyment I would consider it (as long as trailering the car to the racing location) I think making the car fun to drive should always be up there on the todo list as it's the whole reason we have this hobby may as well enjoy it (without going overboard). Steel exhaust makes a difference to the note, B > K in terms of sound everyday. But then again I liked Roman's video of his V6 where he said it sounded like an RB... 🤣

-

The Quaife K series sequentials are ones in particular to avoid at all costs. My understanding is they weren't actually designed by quaife (but by Momentum Motorsports) so had some fairly serious design flaws. A few people here have had to rebuild them at very large costs. Even just the ongoing maintenance on sequentials is interesting. HGT are great in that they give you the life on the components up front. https://www.hgtengineering.com/transmissions/ice-rear-wheel-drive/3mo-rwd-600-6-speed-ultralight-600-nm-450-ft-lb/ So it's not like drop it in and that's all the costs done. The more racing you do definitely the better driver you will be, also on the day you will get comfortable and up to speed faster which can mean you can focus on other improvements through out the day. However, having driven dads EK with a close ratio box I can say man it was fun even with 1600 it really made made it feel much more like a real racecar as you went through the gears (especially with the b series engine noise).

-

That's just the start, you want the decent CL7R gearbox so add $2000 and your hoping it's actually in decent condition (most have issues) as they are all high k's these days. And that's with stock LSD which isn't good enough for serious race cars, so add another $2000 for a plate LSD. Already up to $4500 (That's just part costs not labour...) Then you putting in a chassis that didn't originally have it so start adding $$$ from there, it is easy because of all the parts available, but it's not cheap. Here in CHCH 2.4L na puts you into the 2L to 3.5L class (which includes 2L turbos and Rotarys including 4wd) so how competitive are you really? On the flip side you will have a very reliable consistent race car with easy access to parts, and a cheap engine swap if you break it. Sometimes makes sense, other times not really.

-

In circuit racing, you do some of the above, and then you are now no longer racing with the cars that you used to be around, so just end up lapping the circuit on your own, which isn't that exciting. And there will always be a car faster then you even when you've spent all that money... The best moment I've had on track was driving side by side with someone (I trusted to race) pretty much the entire circuit (can't even remember if i beat him...). One thing that could actually be an investment is driver coaching, the right person can make a very big difference on how you drive the car and therefore speed. So easy to say all that, however I personally can't stop myself from improving the car, and all the shiny go fast bits are so tempting...

-

DIY casting (rubber, silicone, cement, polyurethane etc casting)

Hyperblade replied to Roman's topic in Tech Talk

Just to give you another option. You might be able to just 3d print it direct in TPU. Tricky thing is probably getting the stiffness dialed in, which could be done via amount of infill or TPU type (probably better in this case for strength). Here's a steering rack bush i did in TPU 95a. -

I use this Franklin Engineering kit and can confirm had absolutely no issues with it doing circuit racing. https://franklinperformance.nz/collections/oil-coolers-kits/products/oil-filter-relocation-block-fitting https://franklinperformance.nz/collections/oil-coolers-kits/products/remote-oil-filter-mount Granted when I brought it I'm pretty sure it wasn't $460, but it's definitely a quality item. For the centre adapter I got mine from Amayama, but that was Honda parts bin stuff.

- 418 replies

-

- 1

-

-

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

As with all aero what you should do is a trickly balance with being practical! Temps were always my concern, takes some thinking to trying and keep some airflow through the bay. At least steal the diffuser... -

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

I'm not a fan of aluminum splitters, they get bent easily (which makes them look a but rough very quickly, although all the ones i've seen were unpainted) and don't have a nice leading edge. My recommendation (from someone not currently running his splitter 🤣 ) is plywood, you can get 2 of them out of one sheet of plywood. They are easy to shape and mount and strong, and easily replaceable. Use plywood as R&D first (with testing on track), then once your happy make the carbon version. Either way having some pucks will definitely help anything you make last a lot longer. One thing to note from an aero point of view, i was recommended to have my splitter go back to the firewall (and seal to it), and also seal off the wheel wells. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Thanks, I record all of them just for fun. No I didn't, it does actually have that mode available but it then does purge tower which seems like a waste of filament just for a photo. I just got lucky with timing between shots! -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

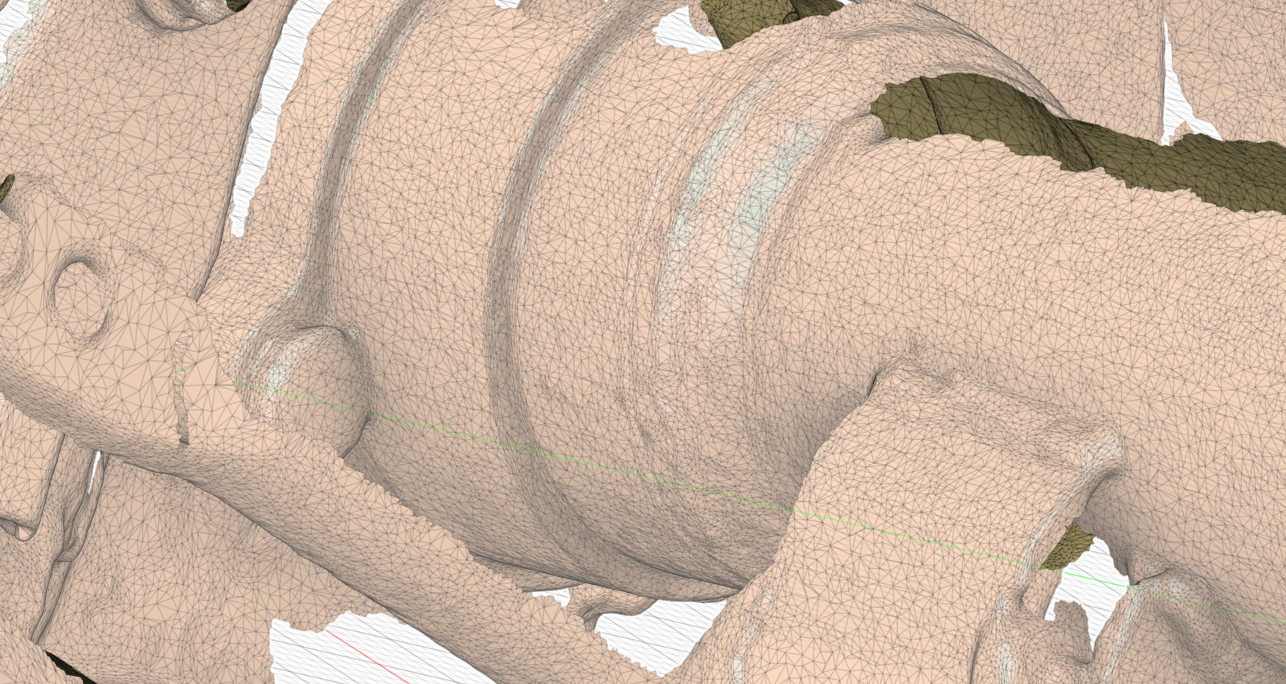

Final versions of the front brake ducting have been printed in PA-CF (Nylon/Carbon Fiber) and fitted, came out great (It's super strong), The ducts have brass heat inserts for threading the bolts into which have turned out far stronger then I expected which is awesome. I have some new silicone hose coming as the aliexpress stuff i have is clearly below par and that's the front done all done. Weight each side is 150g (including mount). Them printing: Onto the rear now, I've chopped up the already modified caliper bracket to get air into the center of the disk, will do the other side, then fit them and 3d scan and make something to guide air into them.- 78 replies

-

- 17

-

-

-

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

I'm getting old, forgot I had already showed you that too. Your best positioned to know if it's safe or not, your video may be making it look worse then it is -

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

Sorry didn't realize I had already nagged you about it. The reason why I'm concerned is that even in a slow speed impact it creates loose belts and injuries associated would be worse. We had a guy up here in roll over with similar seat movement and it wasn't good. Good to see you out racing though! Looked like fun -

Truenotch's BEAMS AE86 racecar discussion

Hyperblade replied to Truenotch's topic in Project Discussion

Watching your latest race video... The movement in your seat concerns me from a safety standpoint... Plus can't be helping with the feel of car. Do you have version with back mount? Can definitely recommend doing that if you can.