Rhyscar

Members-

Posts

921 -

Joined

-

Last visited

-

Days Won

1

Rhyscar last won the day on January 8 2024

Rhyscar had the most liked content!

About Rhyscar

- Birthday 26/03/1988

Profile Information

-

Gender

Not Telling

Converted

-

Local Area

Waikato

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Rhyscar's Achievements

Post Fiend (4/5)

2.8k

Reputation

-

Iwanttobeamole's Mates Mk1 Cortina - 4AGZE - Forgotten Princess.

Rhyscar replied to anglia4's topic in Project Discussion

Wow I wondered where this got to after Matangi closed up, glad it's still around and keen to see it come to life! -

Yeah was a bit nervous cutting the carbon up... but they'll use some black epoxy or similar to make the repairs and it won't be noticeable. They key is that if I want to make another one, the mold can be used again with some small post-molding mods.

- 417 replies

-

Life's been pretty hectic lately with kids, work and being sick. Managed to make a few small bits of progress. 1x door car nearly all fitted up. Still need to do a few mounts across the top and drivers side when I get a day that I can push car outside, I have an hour or two free, and it's not raining. Had issues with rubbing in the rear with the 215 semi slicks being about 7mm wider than the cheap shitty tyres I had to push it around on. Meaning I had zero camber in the rear, and more rubbing than I was comfortable with, and no room between the tyre and the strut either. Luckily, I have a spare matching set of rims that's 7.5" wide instead of 8". Mounted tyres onto these rims and offset worked out pretty good. I created about 15mm extra inner space so I could use the camber washers to lean the tyre over, then push the LCA's out. Ended up with about 3.5-4deg which I'm happy with, and may even take a little more out and raise it 10-15mm for more clearance. Going to be annoying not having even-sized wheels front/back and unsure what I'll do for spares, but it's a good solution for now. Radiator ducting done. The main goal was to hide the white lower rad cross-member, but also won't hurt cooling. So the design isn't optimised, but it should look the part once powdercoated. Ended up metal-glueing a few pieces together to make the shape because my brain/cardboard failed me with some silly mistakes. Oh well, it isn't visible so it'll be fine, and I reinforced a few areas I knew would get high load/vibration with doubler plates. one of the main goals was to make it easy for bumper to come on/off. So the lower section is attached to the bumper and slides into place. Once powdercoated I'll be putting foam tape of every surface to prevent as many rattles as possible, but it may not be perfect. Next on the list of parts-to-finish that require outsourcing for finishing is the Airbox. I put this on the back burner when I was working towards the last dyno session, but picking it up again now, as I've figured out what I'm going to do with it. Basically, it has some clearance issues (hitting stuff) and fitment issues (flange being warped from mold, and not quite right angle). I've figured if I solve the clearance issues (easy mods to make), the fitment issues (hard/$$ mods to make) can be addressed more cheaperer by printing another set of trumpets. After some testing, I've concluded the flange has quite a bit of flex in it, so can be pulled straight with bolting flange, so it's mainly the 4-5deg angle I need to work out. This approach will allow me to use the next dyno session at KPR's to work out the ideal length and adjust my design for what the engine wants to do, then incorporate the flange angle/position change to close up the gaps I've got. Durp got this measurement wrong.. Needs a 15mm notch where it sits on top of radiator to help with bonnet clearance. Can do without this if needed, but it will help it fit a lot better so going to get on with it. Shouldn't impact airflow, it's plenty big enough. The extra bulge around the battery post is a bit tight for clearance, but my gut feel is it'll be fine once the trumpet gets (probably) a little longer. Current length is 370mm to valve on the centreline. Should have these fixed up in the next week or two. Car is now ready to head back to the Dyno, but I haven't managed to find time in my calendar until probably August, unfortunately. Keen to see what a bit more testing can do. The list is slowly getting shorter, but the jobs are getting more complex!!

- 417 replies

-

- 9

-

-

Awesome, glad to hear you're enjoying driving it. Near on 300kw is a lot for anything that's street driven!

-

Keeping all the oil in would be a big feat! Road legal might be another challenge, not quite sure which way the cards will fall on the budget to get it road legal at this stage But keen to lock in a weekend away regardless!

-

Yeah keen on an OS weekend away to watch some motorsport. Getting the car down there will be a bit of a stretch, unfortunately, unless someone is planning on driving down and could tow it for me?

-

I’m putting it down to the thread adapter walking out of the poorly machined housing… pretty over all the issues, so time to make it simpler and less custom. https://au.helperformance.com/hel-thermostatic-oil-filter-sandwich-plate Should be able to reduce number of fittings to 2 and use a standard oil filter and thread adapter.

- 417 replies

-

- 1

-

-

Valve spring in exchange for a few litres of oil on the floor seems like a steep price to pay?!

- 417 replies

-

- 2

-

-

- 417 replies

-

- 7

-

-

-

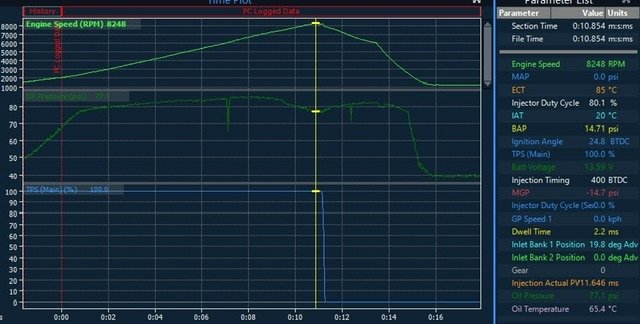

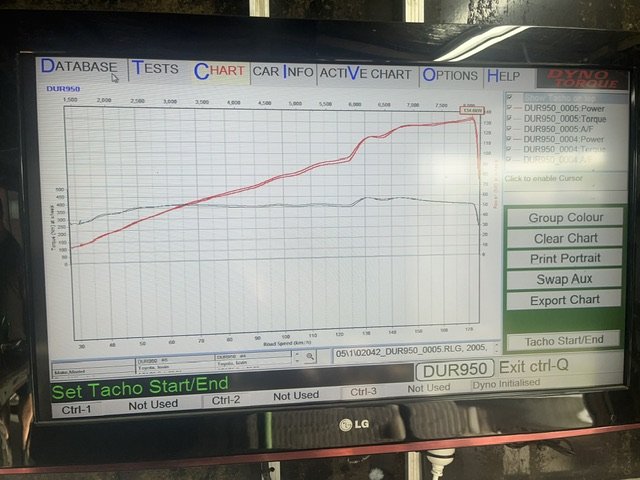

So be finally found some time to write a little about the time on the dyno with @kpr. Been a busy few weeks travelling for work and being sick, so finally getting back into the shed 😮💨🤢 Lexus gs350 being a boss daily and towing with high volumes of comfort, sport and doort 😉 So everything looked ok straight off the bat. Massive amounts of oil pressure, dropping off a bit up top but still 76psi! First big issue was fuel pressure. After the last dyno session, I bought a turbosmart fuel pressure regulator I was assured would solve the problem of the non-adjustable c5 corvette regulator. It did not, and in fact, showed similar symptoms of not holding a steady pressure on throttle so we went over everything in the fuel system trying to find something that could explain this. Fortunately, KPR figured out it was a low pressure spring in the regulator. amazingly, a old 20v valve spring came to the rescue, being about the right size for its a bit of grindering to hold steady fuel pressure! This all makes sense when you look at the model code…🤣🤣 So now I’ve got the high pressure version of this. Good thing about having multiple cars is this is actually perfect for the ke20 rally car which we’ve had regulator issues with being too small for the pump it runs. So this should solve that problem at least. As @Roman predicted scarily accurately, he was in fact needed to catch the oil filter 🤣🤣 the 2zz managed to empty all its oil over the dyno and floor making a massive mess (sorry Kris!!). The link did and awesome job of catching this - dropping rpms as pressure was lost. So anyway a bit of background on power number. First run of the day was 110kw on the old tune (120kw at HPR, had reduced fuel pressure, which the Link should have adjusted for), so confirmed dyno readings are comparable-ish. As soon as Kris put his tune in, it picked up to around 130kw… managed to tune the bottom end vvti before all the oil exited the engine. With these small improvements it made 136kw, with plenty more refinement to come once the rest of vvti is tuned and crossover comes down a bit. Good new is it doesn’t have any limitations or weird stuff going on anywhere in the rev range - which hopefully means there’s plenty of head room left. One thing that is a little limited is the injectors. The factory injectors are starting to struggle a bit, will make a bit more power but not heaps more. So it was back on the trailer and back to Hamilton that night. After some investigation, I found the oil filter seal blew out thus time around. It could have been slightly loose, but I actually thing it’s wound itself off due to a very shoddy internal thread on the relocation kit. One positive I guess is it confirms I need to throw this whole setup in the bin! been looking into sandwich plates (which I’ve always ruled out as not fitting) that look like they’ll fit. Can also get fitted with a thermostat to get the oil warm faster. For now, I’ve just chucked a standard filter in there and it works great no leaks 🤣 I’ve replaced all the autometer senders so my double check gauges actually read the same as the link sensors. Been doing the last few sheetmetal jobs this week or two when time allows. Bead rolling and fitting door cards and making the front bumper radiator ducting. Lots of work still to go, but starting to see the finished solutions come together. Once I’ve finished these off, it will be the last load of parts for powdercoating 😭 onwards and upwards, this bloody thing ain’t going to finish itself!!

- 417 replies

-

- 14

-

-

-

Geez thats great power from an old b20! Imagine if a 3s made that sort of power @Truenotch 100% +1 for 3" inch exhausts. Just got to go with a good muffler to keep the tangs in check.

-

Truenotch's BEAMS AE86 racecar discussion

Rhyscar replied to Truenotch's topic in Project Discussion

Damn, shits gotten expensive. Plus queenstown tax no doubt. Just wait for it to start snowing and you'll know its the right time to paint it yourself. Perfect opportunity to treat yourself to a chillyrim too! -

Ga3_zo and kp60nick's honda logo of head turning fun.

Rhyscar replied to kp60nick's topic in Other Projects

This is cool. Great to see rear swaybar worked a treat. Bonus cheapo upgrade might be stiff front swaybar and upgraded bump stops all round. Will improve handling until such a time you can properly address spring rates. -

Not the silliest idea ever @Stu. Lotus Evora with the 2gr V6 came factory with a Eaton M120 looking supercharger.. no doubt it was too small for any serious performance, but would be an easy upgrade (if you could fit it under the bonnet). Looks like around 400hp is possible with a simple supercharger install. More than enough for a small car.

-

2GR bolts up to (roughly speaking, minor mods needed) E-series GT4 box. Guys in jamaca have a lot of fun with them. Not necessarily the 4cyl screamer you might be hoping for, but cheap, easy to do and an easy 300+ hp before you boost it.