Leaderboard

Popular Content

Showing content with the highest reputation on 06/25/22 in Posts

-

18 points

-

I made a start on the head today ( bit of work ). the exhaust ports are going to be opened up being a turbo so I started with that side .. might just do a bit in the evenings after work.. this is a standard pinto exhaust port. the manifold is allready matched to the gasket so I just put the gasket on the head and painted it to give me some guide lines. and here's what I've done so far ... I'm paranoid about going through in one side where it is thin so I didn't do that much that side ... just opened it all up.. still only roughed at this point.11 points

-

10 points

-

9 points

-

Thanks to the replies in the tech spam thread which basically reinforced what I was thinking, which is it doesn't have enough air flow and needs a better fan I thought I'll live with the fan noise if that means I can actually drive it So I embarked on the mission of finding an engine driven fan that fits Found the one I wanted on an NZ website , sweet, ordered it. Nope, " no stock sorry" Bugger. Found a different supplier who had one, ordered off their website "Sorry, no stock, they might be here in 3 weeks? " Poos. Local guy had a plastic flex fan , I didn't want one of those as they are a lot deeper but meh I'll give it a shot , chucked it on, needed a bigger spacer so the blade cleared the alternator. spent ages rummaging around for some bolts Started it, ran for a bit, moves heaps of air, good Gave it a rev to about 2500, the inch or so clearance at the bottom became 0 clearance and the fan hit the tank and broke the tip off one blade Ah yes that's why I hate these fans Luckily no damage to the radiator apart from some dinged fins Found a stock 245 steel fan I had in a box under the house, chucked that on, it will do for now and I'll find the one I want I think with a shroud on it should be OK, the mechanical fans move heaps more air. It still creeps up at idle in the shed but no shroud and a slower fan speed than stock due to pulley sizes are the reasons I think9 points

-

The subframe has a bit of surface rust. And some oily greasy stuff that the water blaster didn't shift. This is a bit of a no-effort experiment. I know the electrolysis will remove the rust and after a few days it may lift some of the paint(from previous experience). But I want to see if it will lift any of the oily stuff. I could do with a deeper container... but where can I get one that's as cheap as a $18 warehouse paddling pool? An IBC tank with the top cut off would be good, but I can't find anything nearby and I also don't want to spend ~$1007 points

-

Yea so I have set up a budget recording studio in my shed, it works pretty well. I have been playing with getting a good sound when recording acoustic guitar. My main go to acoustic is a K. Yairi that I bought brand new in 1992. It has amazing looks, sound and playability, but access to the battery for the pickup has always been a drag, you have to loosen off the strings and get a fat hand in through the soundhole. Also if it is left plugged in it will drain the battery. So I ordered a Gotoh panel mount battery box and got to work. This was pretty scary as this guitar is pretty much my most prized possession. All seems good. I added a switch to isolate the battery as well, so if I leave it overnight plugged in and set up it will still work the next day...7 points

-

bits and pieces have arrived for the motor (still bits to come) but most importantly the pistons have ..so I can putva rod and pistion together and check the compression ratio to see if I need to deck the block.. turns out it's 8.263 -1 .. I'm pretty happy happy with that to run boost.. also huge thanks to nismo-Capri for rods... and info on porting heads... that will be next on the list . while I wait for some bit to turn up.5 points

-

"800W is only the theoretical power. Most of our customers are happy with the actual power of 72W"4 points

-

The poor neglected thing hasn't had a tank of gas for 6 months wof ran out march. Will drive it around and get the fuel tank emptied get the new fuel pump fitted and think more about an engine swap everything ive bought so far bar the head gaskets will work well on another engine. Hmm what would the purists think of this combo. Just spitballing but would give me everything I want.4 points

-

What you need is an ld28 with a 100a alternator on a run stand.4 points

-

I pulled the heads off a while back on the l67 have come to conclusion..... its fucked heads are full of cracks and bores are scratched to shit looks like someone pushed on with a skid when it was clearly starting to seize. I'm tossing up throwing a set of good rods and forged pistons at the bottom end some ecotec heads as I don't need the injectors in the ports anymore. Or.......... fitting a honda k24 and not wasting my money on the buick the turbo ive bought would be excellent.4 points

-

Haven't done an update lately but I've been driving her every 6 months or so. Getting a bigger engine for the old girl. Gonna get rid of the 1.6L 4G32 and put in a very very low KM 2L 4G63. And a 4 speed auto instead of the 3 speed it has now. I think I may be missing the letter T at the end of 4G63?4 points

-

often the cat light will iluminate, so the wire needs to be grounded. sell cat to pay for str8pipe3 points

-

3 points

-

It drives. Got a few bugs to work out though. The main one is it gets hot, and can't cool itself down. This might be a bit of a prick to sort out as there's no room left I think it has more boost than it should do Brakes are a bit spongy, might need next size up master cyl, might improve once they bed in a bit Seats are a bit low Needs something to stop the pinion angle changing under accel, driveshaft just knocked the floor slightly3 points

-

And .... that's the last of the rust proofing done. Pumped two litres of goo into the driver's side rear quarter inner as well as both front chassis braces. Then spent the rest of the morning cleaning up the mess. With that mucky job behind me at least now I can get on to the good stuff, being the reassembly.2 points

-

2 points

-

I was! Can still get it if needed2 points

-

I decided to replace the front seats with something that gives some lateral support. The original bucket seats didn't provide much more than a bench seat and one had been reupholstered in a different green so I thought these would do the job nicely. These seats have detachable head rests. I will need to get the rear seat redone to match and spraying the door cards with black vinyl spray should do as they are in good condition. Just working out how to mount them. The original seats were held in with two bolts at the front and the rear of the seats were on slides. The bits that were bolted to the seats and engaged the slides were only made of plastic.2 points

-

2 points

-

While I was in town picking up the new wheels yesterday I dropped by the paint shop and purchased a 4 litre tin of the rust proofing goo, so this morning I slapped a few liberal coats inside the passenger door. It's a real mucky task, but I'm feeling much happier now. Just the driver's side door and rear quarter cavity to go and then the assembly work can kick off in earnest.2 points

-

2 points

-

2 points

-

2 points

-

Set float levels, idle mixture, decided there was no better time than now to get all the piping back on for good. Now goes waaahhhpishhh tested all gears, wheels go round. I think the cooling might be borderline, it gets pretty warm (195f) and twin 10" fans was as big as I can fit. I'll see what it's like once it's mobile and can be driven in traffic, I might have to get some better quality fans2 points

-

2 points

-

Just checked all mine, largest is 200W and all 12V. I do have a spare 200W 24V supply if thats any use for testing? Or, buy the 600W Ali express supply, by the time it turns up summer will be here and you can dump it in the pile of unfinished projects.1 point

-

I may as well leave it running in the room and forgot the heater completely.1 point

-

NZ$ 82.35 55%OFF | 30V 10A Laboratory Power Supply Digital Display Adjustable Switching DC Power Supply Voltage Regulator 220 V /110 V New Arrivals https://a.aliexpress.com/_mM5FeCa what about flagging the batteries and running one of these? We run them at work as laptop chargers as way cheaper than multiple laptop chargers. I assume the the 24V is just running a fan?1 point

-

1 point

-

Mate has a 4cyl petrol surf, temp sensor has rusted out of the catalytic converter. Unplugging the sensor doesn't seem to make any immediate difference, guessing swapping cat for a straight pipe is the go?1 point

-

1 point

-

More wiring Sat head on so I could figure out where plugs etc wanted to go Intake for the same reason Some split conduit and a roll abd a half of tape later Vtax wire is pinned into the ecu, reverse light switch wires are run to the plug and I'll pick a couple of wires from the inhibitor/auto stuff that I can repurpose for the lights. I grabbed a jaycar speedo corrector as the crv has a different final drive etc and it'd be nice to have a correct speedo. Other ring set arrived from rock and my dipstick and some seals arrived from amayama Got a decent list of stuff to do tomorrow, hopefully I can get most of it done and have it drivable in a week, my tuner only has a small window of time and I start a new job in a couple of weeks so it'd be nice to have everything done before then/before I loose access to the hoist at my current job1 point

-

9 years, 2 weeks and 2 days of ownership now. Just passed my 100,000th km in this thing today. Happened to be on the same piece of road that I test drove it too. Trade in value must have just plummeted to near zero.1 point

-

Even although the underlay and carpet are going to hide the 4 floor mounted cover plates, the OCD in me just couldn't leave them looking shabby. So to reward myself for a good job done on the rust proofing I treated myself to a bit of flapper disk work followed by a light tickle of primer and then a dusting of satin black. Even did the screws cause it's a sad life that I lead. Smeared a little bit of non hardening sealer on the edges before screwing them down. Final score : OCD - 1 Me - 01 point

-

^ I'm talking about difficulty in sticking things up your bum of course?1 point

-

I used a 2 speed electric one from a Volvo 850 I think, on my 13B. It was awesome. I might even have a spare one1 point

-

1 point

-

so things have slowed down a bit now. was trying to get it all drivable for end of October but I was also hoping the motor I was using to set it all up ......would last .. so wasn't factoring in a motor build . I could have found another running motor but I would have had swap the head over anyway (this one is matched to adapter plate for inlet).. and it would probably need a gasket set ... so I may as well build one....... and then I thought if I'm building one I may aswell build the one I want.. I wanted one with standard bore to start with.. and out of the other 3 motors I have I have 1x 2.1 bottom end 1x .50 over bottom end and 1 that will need crank ground as run bearing had fucked it .... so the last motor was the one in the car ......out it came pulled it apart and pulled the head off...so far so good .. original size SOHC pistons . (what a great sight). so at the moment I'm just doing a whole bunch of waiting ...for funds and parts. but in the mean time I have stripped and cleaned the block and it looks good (gave it a paint ) but all in all damage was only to big end bearings. gave the block a quick hone and it looks good ..will give it a better one once the postions arrive and I can put a rod and piston together and see if I need the block decked. I'm also going to have a go at porting a head myself ... I have a few heads and it turns out the best casting and condition is the head off that motor .. so I stripped it and bolted it to a mates stand (just waiting on some carbide burrs and I'll get into it). so the plan is standard bore and stroke bottom end ,forged rods,YB cosworth pistions ,under pistion oil squiters (still researching that).higher pressure oil pump, cosworth 1.3mm head gasket , ported polished head ,bigger valves, and I'll have a talk to mate PK at kennelly cams to see if he can work some magic for me... so just waiting on parts , money and researching1 point

-

Standing in for the OP. it catches the ash when you burn those incense sticks. (That stick in the first photo) you know, so you can smoke weed in your room but still keep it smelling legal-as!1 point

-

Depending on what brand of coilovers you get, it is entirely possible. The key thing is to set it up so the bump stop limits the travel before the balljoint can hit the body If I was setting them up from new I would remove the spring and bump stop and set them so the ball joint contacts at the same point as the shock bottoms out. That would give you a safe lowest setting, then fit the bumpstop and spring You would be surprised at how much the bump stop compresses It is reasonably common fix to reduce the travel at the shock via a nylon spacer above the bumpstop, as something like a BC shock has heaps more travel than it needs for that style of suspension Another option would be to get keeper springs and run the spring a lot looser1 point

-

1 point

-

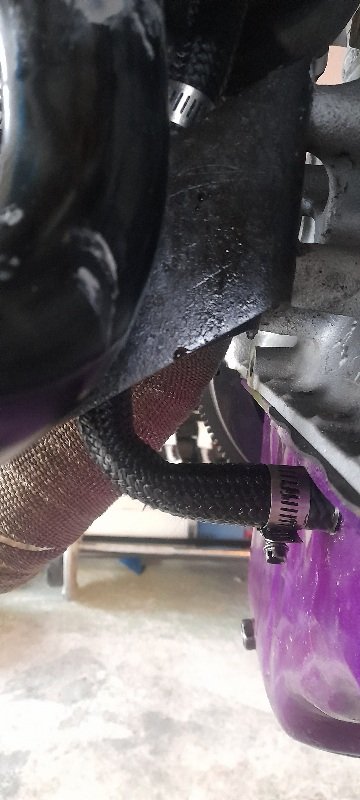

took a couple of hours ...but the motor ame out.. not all that hard and mostly complete. there are a few things...leaking. *both sump and rocker gaskets are weeping ..(rear of the sump seems pretty bad)( left rear of the rocker cover is pretty bad.)...may be another reason for the sump gasket ....get to that later. I did put a full gasket set through it in October 2020 but it's sat dry till about a month ago. *the clamp on the oil return had had slipped down and so had the hose and kinked it a bit (not sure if it's enough to stop oil flowing..maybe another reason for that ...) also might need a restrictor in the oil feed line *oil on the block from the crank breather (may be another issue causing that ) .. * the main thing is I lost about a litre + on the floor..the oil cool and lines were full... and I only put 4l in.... and drained 5 out...that smelt a lot like fuel... so I think the 1st few days of fucking around with ecu setup ..it pumped so much fuel into it that it filled the sump... enough for the gasket to leak....the turbo drain to be blocked .. so replace a few gaskets and try again... there are a few things I wanted to do anyway and would have been easier the motor out... so 2 birds 1 stone.1 point

-

well I cut all the bar 1 tooth of the cam sensor..changed trigger 2 sync mode to CAM PULSE WINDOW and then just set that to 50° and she's now running both DRIECT SPARK and SEQUENTIAL INJECTION. she basically a modern engine now with classic pinto oil leeks.. haha not much else I can do till I make intercooler piping (and our postal service dictates when I get the stuff)... but even at idle the air coming out of the turbo is pretty significant. also set the water pump temp to 70° .. engine temp got up to 68° water pump kicked in...temp got to 71° fan kicked in and bought temp down to 65° in no time.... so I'm happy with the coolant system. RX2 70mm thick radiator, 14" fan in shroud ,electric waterpimp... on a side note ... heater was awesome within minutes. cheers1 point

-

pulled the crank and cam triggers off.. from what I've read and other have confirmed the 36-1 trigger is really hard to sync with a 36-1 crank trigger... so the car runs and even if I unplug the cam sensor it still runs as the injectors are being group fired.. but I want sequential so the answer is to have just 1 tooth on the cam trigger .... so I'm just going to cut another 34 teeth of yhe wheel and go with that.. once I have the rigger sorted and the intercooler piping (ordered today) in place then I'll be able to start tuning it properly... but she runs.... huge weight of my shoulders.1 point

-

1 point

-

1 point

-

1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.jpg.c5ee675bb29516d5fdf619d5ceeed8be.jpg)

.jpg.a3b9134e316c1905d19660e24f3756d3.jpg)

(12).jpeg.fc9905565317f16f9ba57f24e93f7f3f.jpeg)

.thumb.jpg.570970b401ac8d26ce9af7c1bf2bd8cd.jpg)