Leaderboard

Popular Content

Showing content with the highest reputation on 03/30/24 in Posts

-

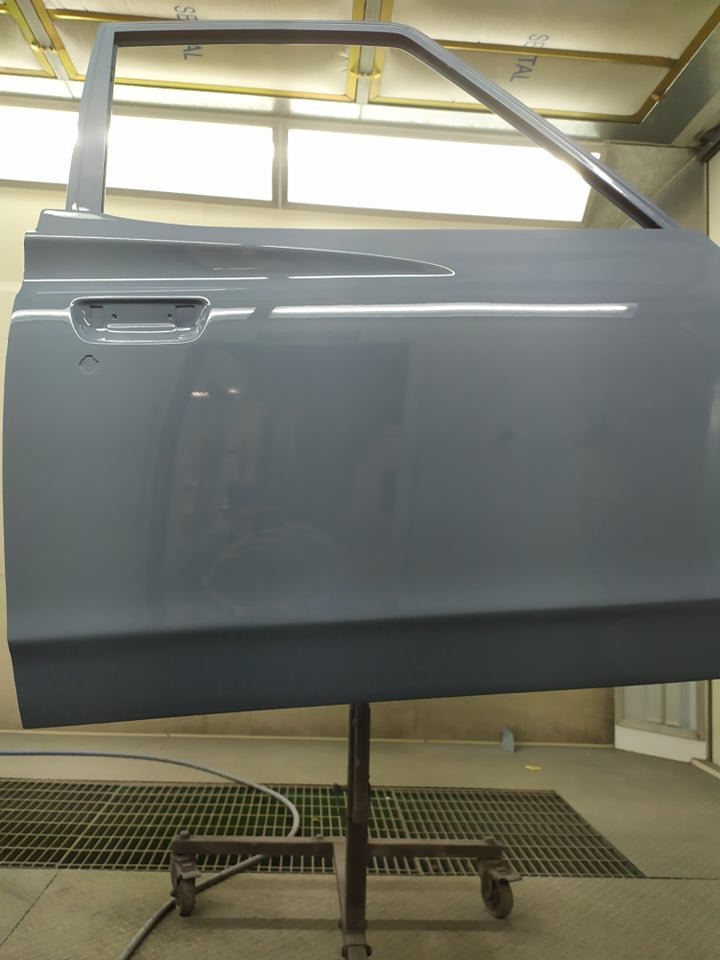

Car has been delivered! Currently organising it to be stripped and off to panel/paint/repair cert so hopefully have some updates in the coming few months.13 points

-

Yea so today I fixed a couple of issues with the windscreen washer, firstly trying to get the aftermarket nozzles to actually fire at the screen, then fixing the washer tank which for some reason is about 8 litres, most of which got dumped into the frunk overnight due to a crack. This I filled up with poo and hoped for the best. Then I addressed the extreme force needed to make the washer run, which meant pulling the stalks off and doing an excellent bodge which you dont need to know about in case my good name as an engineer is ruined, suffice to say they work perfectly now. Then with the few hours still left in the day I made a rear valance thing, although the mesh looks pretty sparse irl so I might smash something slightly denser on there; And I think thats pretty much it, I'll book a wof for next and see how that goes....8 points

-

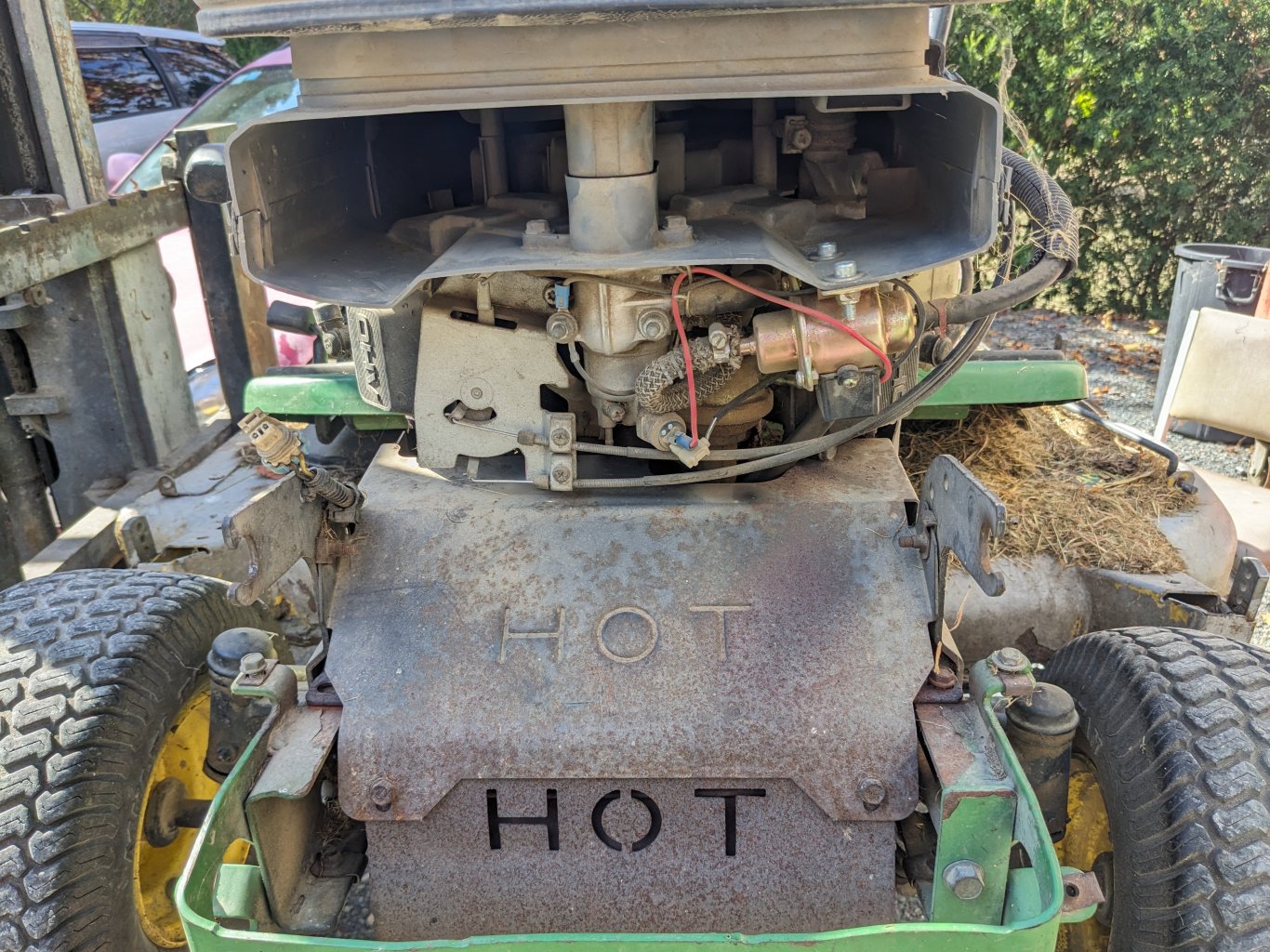

Took the Hunter away for the garlic farm budget Nats .. had brake issues the morning I left, and throughout the weekend, but managed through it cos Slow car.. I knew what it was, the little valley type thing inside the remote booster/slave vh44 deal threw a shit fit and decided to stay put and no longer do brake things. i already had a new unit on the bench, but procrastination took hold and I never did swap it until today. im taking her to Waiau Pa hop next weekend, so keen to have brakes. fairly easy deal to swap it. and it brakes now, and releases.. winning while I had the brake mojo and the flaring tool, I decided to run the brake lines on the trailer. What a Kent, but it’s done and it has brakes and no leaks. ive left the brakes locked on overnight to check for any leakage. Should be good. also clamped the conduit up. so only have the 4 mudguard stays to weld on, then screw the boards on before getting it registered.8 points

-

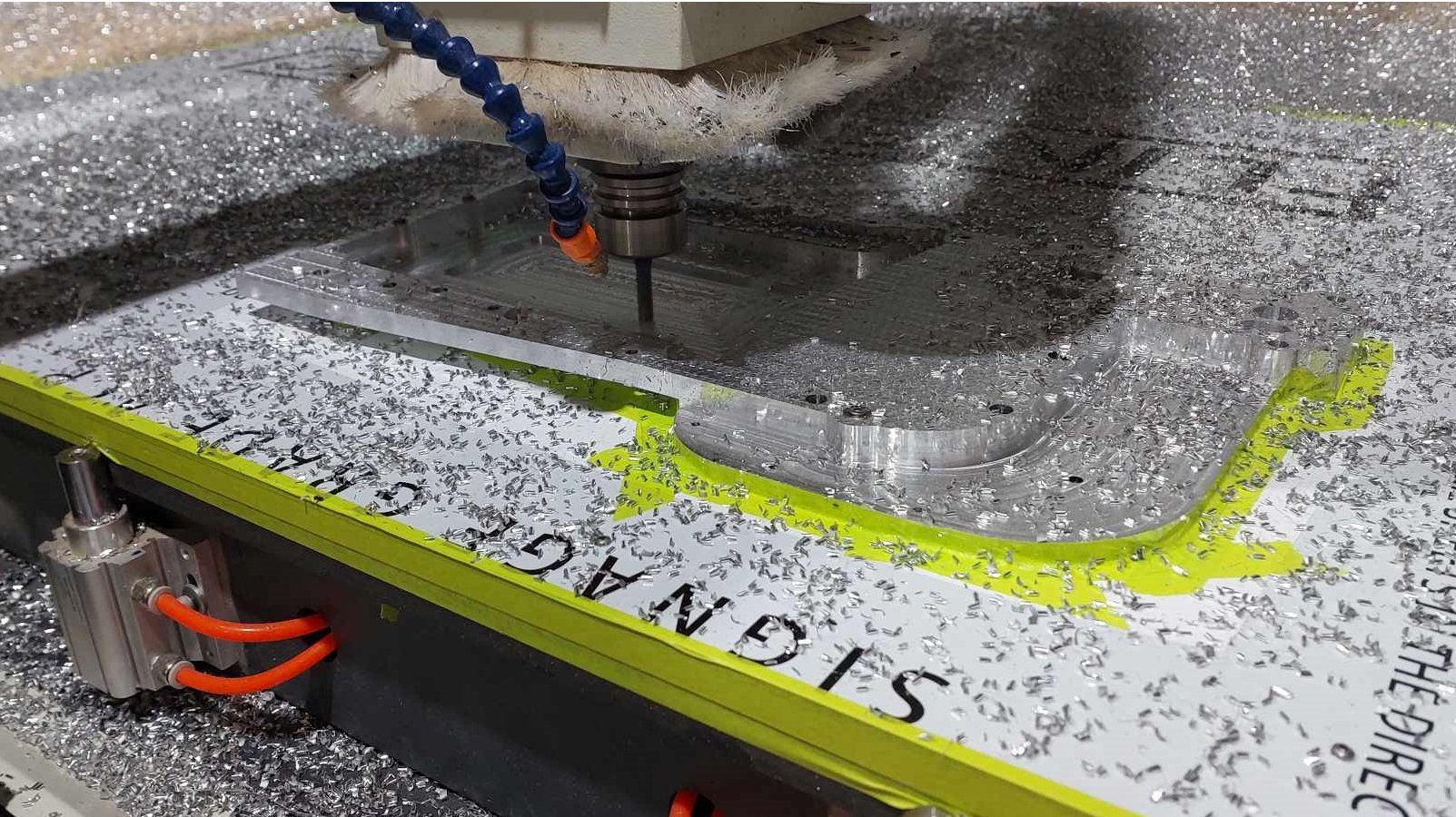

Had access to a large plotter table at my last job which was super handy for reverse engineering or taking prototypes from the computer to the real world, could print notes and datums to cardboard before cutting out for test fits or confirming bolt holes before longer/expensive processes. Today step one of bringing that capability home began, a vivid/sharpy holder for my cnc router. 3/4" mm seamless tube offcut has the same id as the markers, weld 1 stainless washer to the end completes the holder body, complex eh! All I needed was a suitable compression spring to ensure the marker holds a constant pressure without needing a perfect level bed. Awesomely, big green and big orange hold stocks of these things, sadly they are both closed today, buzzkill. Wanting to test NOW a full workshop search was initiated with a suitable donor found in an old BB gun, the slide spring happed to be 110% perfect for the job. Length is set to hold the two types of marker I usually have littering every corner.... Fitted up into a tool holder and good to go7 points

-

Nick the sparky gave me a hand and we got the right plugs for the air bag and figured out the steering wheel controls for the stereo. I've got to get the right connector to connect the radio to the steering wheel output but that shouldn't be too much of a drama. Once that's done I can program the radio and heypresto! Steering wheel controls that work.6 points

-

Pics from the port in Kobe! All looks good, appears that the owner that flipped the car put new tyres on it which is a bonus. Due to leave Japan this week Two gremlins to note: - Car looks to be started up in the images as rev gauge shows 1500 rpm however the charge light is on.. - From photos I've just noticed that the chassis plate is also not in the engine bay. I hope this isn't an issue come VIN time, hopefully the TE27-XXXXX stamp on the firewall is ok on its own?6 points

-

The last few months I've been looking through the USS Auctions in Japan, bid on a few TE27's. Funnily enough, I bid on one particular TE27 in October. Lost it to someone. The buyer must have been doing a buy and sell flip for some quick money as it came back up for auction the following weeks but with the reserve higher so I wasn't successful. Come the new year, they dropped down their reserve and I was able to nab it for a reasonable cost! The plan is to swap all of the good stuff out of the KE25 I have to it, and flick the KE25 off. If you're looking to purchase the KE25 project below get in touch. https://oldschool.co.nz/index.php?/topic/52400-pbaines-1971-toyota-corolla-ke25/ Photos from inspection. - Interior is average which is perfect because I have a great interior in my KE25 to get goods from - Underside has some rust, especially in the sills. But for a car this age, can you really be surprised? No stress to be honest. the rest of the car looks like a great base for a resto. More to come at a later date. 20231116_121909_copy_2000x1126 by phillipbaines, on Flickr 20231116_122016_copy_2000x1126 by phillipbaines, on Flickr 20231116_122315_copy_2000x1126 by phillipbaines, on Flickr 20231116_122314_copy_2000x1126 by phillipbaines, on Flickr 20231116_122304_copy_2000x1126 by phillipbaines, on Flickr 20231116_122300_copy_2000x1126 by phillipbaines, on Flickr 20231116_121947_copy_2000x1126 by phillipbaines, on Flickr 20231116_121940_copy_2000x1126 by phillipbaines, on Flickr 20231116_121939_copy_2000x1126 by phillipbaines, on Flickr 20231116_121912_copy_2000x1126 by phillipbaines, on Flickr 20231116_121910_copy_2000x1126 by phillipbaines, on Flickr 20231116_122104_copy_2000x1126 by phillipbaines, on Flickr 20231116_122103_copy_2000x1126 by phillipbaines, on Flickr 20231116_122100_copy_2000x1126 by phillipbaines, on Flickr 20231116_122057_copy_2000x1126 by phillipbaines, on Flickr 20231116_122046_copy_2000x1126 by phillipbaines, on Flickr 20231116_122029(0)_copy_2000x1126 by phillipbaines, on Flickr 20231116_122028_copy_2000x1126 by phillipbaines, on Flickr 20231116_122025_copy_2000x1126 by phillipbaines, on Flickr 20231116_122007_copy_2000x1126 by phillipbaines, on Flickr 20231116_122256_copy_2000x1126 by phillipbaines, on Flickr 20231116_122254_copy_2000x1126 by phillipbaines, on Flickr 20231116_122143_copy_2000x1126 by phillipbaines, on Flickr 20231116_122139_copy_2000x1126 by phillipbaines, on Flickr 20231116_122129_copy_2000x1126 by phillipbaines, on Flickr 20231116_122126_copy_2000x1126 by phillipbaines, on Flickr 20231116_122123_copy_2000x1126 by phillipbaines, on Flickr 20231116_122122_copy_2000x1126 by phillipbaines, on Flickr 20231116_122121_copy_2000x1126 by phillipbaines, on Flickr 20231116_122106_copy_2000x1126 by phillipbaines, on Flickr 20231116_122105_copy_2000x1126 by phillipbaines, on Flickr 20231116_122326_copy_2000x1126 by phillipbaines, on Flickr 20231116_122321_copy_2000x1126 by phillipbaines, on Flickr Discussion thread:4 points

-

Yeah .. I could have held for way more money ..but I got the car back cheap and sold things for what people offered..... I made my money back and enough to get my mk3 all legal.... so happy as with that3 points

-

Fixed the rust hole, no pics cos boring. Made a heatshield for the alternator, first drilling and tapping some brass hex to stand it off, then some CAD, then some shiny so it reflects heat; Then I grabbed the pretty non functional catch can that I made for the truck, modified it so the wire wool was less in quantity and right before the outlet rather than at the inlet, which is why I suspected it didnt work well, then gave it some chode so it would fit in the engine bay; Went and filled it with some 95 as it was pretty low and it definitely needs some time spent on tuning, the low throttle popping and banging sounds good but the afr tells me its not right. Man it feels good to drive tho, the combo of the gogo and the noise is pretty great. If anything it sounds better now the air filter is on, a really purposeful growl.3 points

-

A few people have asked why theres no thread for this vehicle. (Because the owner is so useless tbh) i showed some pictures on my phone to some people at Garlic nats. And one of them convinced me i should post them up. (Thanks @Sungai Sungai) The story begins quite some years ago when i bought a datsun 620 ute of @Mr.Mk1. He'd rescued it from scrap. He also found a pretty fucked wellside tray for it. (Which is also rockinghorse shit 8n terms of rarity) it would seem i only have one picture of that truck. It needed plenty of work, but the rego was on hold, and it was (mostly) complete. When josh and i did the mission down to Alexandra to collect it, he showed me another 620 ute. It belonged to the landlord from whom his brother rented his business premesis from. Daily driven, and a real sweet honey. Because Alexandra is as dry as fuck with no foreplay, it was completely rust free too. (For what its worth, 620 are without a doubt the most rust prone vehicles on planet earth) Some time later, i learned that the elderly gentleman who owned that truck stacked it. And some time later it popped up as wrecking in Christchurch. Hoping to get some parts, i shot around there. Where i met @Agent75. The truck was still pretty rust feee. But unfortunately Shane had cut the radiator support panel off to make removing the engine easier. The inner gaurds were a little bit puckered, but it could have been straightened out. A deal was struck, and i dragged it home. Another mate had another 620 he wanted ro move on. ( @I'm new here) it had been completely dismantled. And had some prettt cunty rust. So i bought that, and had a coachbuilder mate graft the inner gaurds and rad support panel off that cab onto this one. Unfortunately i have no pictures of this. I also picked up a pair of front guards off another mate. As i didnt get the nasty, underpowered, leaky, J15 with the truck, i opted for an S14 SR20 that i bought off @mint16. With the gearbox attached, i had to make the centre of the rad support panel removeable. After id painted the engine bay, @fletch have me a hand to do the final engine installation. Because id slung the engine so low, and so far back, the sump had to be notched to clear the drag link. Seeing as this chassis is the later model/last iteration of the 620, it was fitted with ball joints, rather than king pins. This is a wicked bonus, because i learned that if the top ball joint is swapped over, that D21 navara hubs and stubs are a bolt in affair. No more gawdaful drum brakes. Best of all, a mate gave me a set for free. (Less calipers, which i then sourced of marketplace) because im not a total broken arse any more, i threw on a pair of new rotors too. Discussion,2 points

-

Yo, Long time no see, I figured that because im about to embark on phase 2 of this heap that I should probably make one of these. Anyway, I needed a new daily so I went shopping and found this sweet 82 long bed, I was after a long bed specifically as I needed/wanted it for my shop truck to haul choppers round with. The 350 had a sweet cam and gear drive so it sounded cool and had the requisite chop chop but the 4km/l fuel consumption meant that the daily part of the new car purchase didnt work quite so well. Luckily I had done my due diligence before the purchase and also bought a 2005 Mercedes Benz E320 cdi. Anyway @98cc hit me up and said he wanted to come visit so I put him to work and we pulled the 350 out and swung the OM648 in. Then at some point a @peteretep came and visited so we did some more work, anyway, I had a deadline, I made it, the truck got its maiden voyage with its new motor around Norway chasing a bunch of bikers, good times. Basically the rundown of the swap were: OM648 3.2l inline 6 diesel, the same one the Blacksmoke Racing dudes use. Baldurs Control Systems DID1 stand alone ECU 722.6 Mercedes 5 speed Auto with lockup OF Gear TCU 3 inch intercooler Built 10 Bolt with 30 spline axles, 9 inch housing ends and bearings, Eaton Trutrac and 3.08 gears. At this point it turned into my summertime daily and did truck things Then doing the usual facebook marketplace thing late at night I found a truck camper for sale, so of course I had to have that... At this point I found the limit of the 1/2 ton suspension so with the camper and the 6/8 drop that it has, so I had to do something, I made a bag over leaf setup in the back to help with load carrying capabillity. So about here is up to date, the engine swap is legit, it now gets 14 km/l and will happily cruise at 120 on the highway, because of the 8 foot bed it hauls all manner of things without asking, and does a skid. Discussion2 points

-

Also the coldest part of the year so great for max enjoyment of hotpools!2 points

-

First weekend in July would be good as I already have the time booked off for SI adventure2 points

-

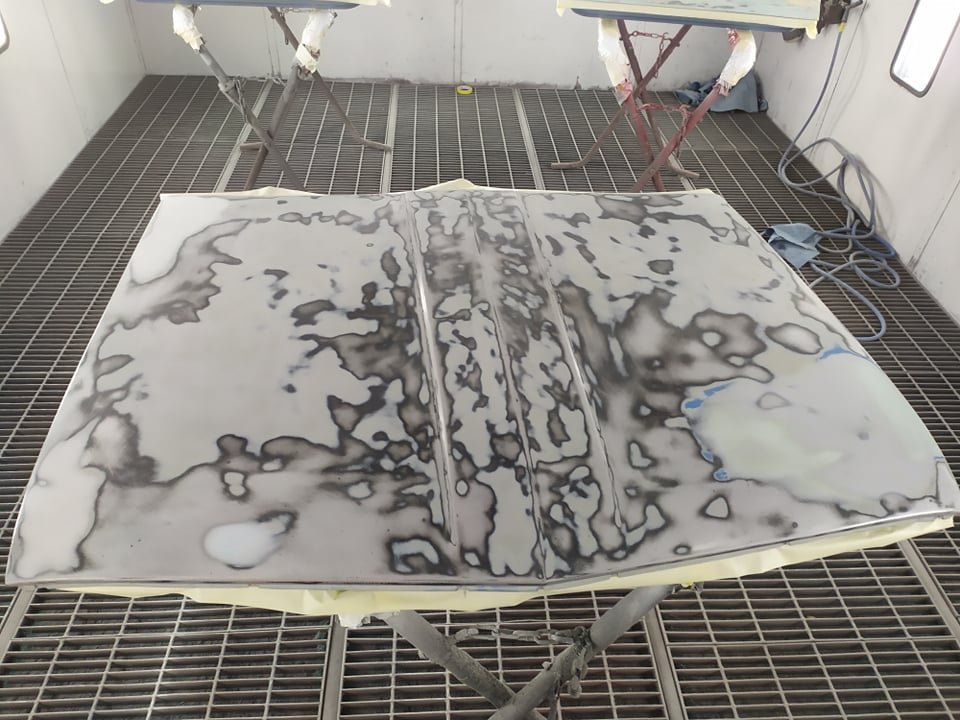

How about that wellside tray i hear you ask? Well, thats an ongoing saga. To start with, i had is sandblasted. Yep, she was a "bit" rusty. it must have been left sitting full of geass or the like i think. Anyway, i was somewhat worse for wear. Dropped it off to a mates shop, and he sid this with it. fast forward to lockdown, and i removed the floor. (It was fuuuuucked) I disovered this was a new Zealand made tray. (Possibly made in Timaru) they had a different profile on the floor, different wheel tubs, no swage around the whel arches to match the front. I replaced the floor with like for like. And a sheet metal mate halped me make new wheel tubs too. ( @JustHarry grafted these in) the same mate helped me reproduce the top edges which were also different. (Harry grafted those on too) Harry also grafted in wheel arches out of some fucked front guards to mimic what a proper datsun tray would have had. The tail gate is actually off a proper datsun tray, and its needed quite a bit of fettling to fit. (The NZ tray is a bit deeper) The tray is still a work in progress. Harry has opted to make new lower sections from scratch, rather than attempting to strighten the mangled mess that was there before.2 points

-

You can see the grill just didnt look nice enough with the rest of the truck painted. So once again i called on Hamish to give it a birthday for me. And the grill badge likewise looked pretty used. I enlisted the help of @filthy one mrs (Gemma from twisted sister customs) to give it a birthday for me.2 points

-

2 points

-

Then theres the body work, So it began pretty rust free. But sitting around outside in Christchurch, a bit of cancer began to show. My coarch builder mate fabricated me a new drivers side sill, and @governorsam grafted it in for me. (As well a couple of other small bits) i dont have any pictures of this either. And one of the gaurds needed a patch too. Again no pics, but i got a panel smasher to come weave his magic. Id fitted the front guards, and they did not match the shape of the doors at all. Also i found that old repairs etc meant that the drivers door was beyond economic repair. And needed to be replaced too. So mister panel smasher had the guards fiting beautifully afternonly a couple of hours. I removed rhe back window, and dropped the headlining down so he could pop some dents out of the roof. (It had been a working truck in its former life) he did a bloody good job all told too. I told him, im not some file finish fuckwit. Its a datsun, and its a ute. You can use as much filler as you need to. Because i knew he wont use more than is necessary. I also said, u donr expect a show car result. If its good enough fo you, its good enough for me too. But as a tradesman, i also knew he would do a good job. The last car he did for me came out really really nice. After the panel smashing was done, a mate brought over one of those paint spectro camera thingos. We took a picture of the paint on the underside of the roof skin. This gave me the colour the trauck was when new. Most of the rest of it had suffeeed 40+ years of central otago UV degradation. Some paint was procured, and it was sent into @I'm new here work on a long weekend. Hamish really pushed the boat out with stopping all the repairs, before paint2 points

-

2 points

-

I was given a John Broadwood a long time ago that was badly broken. My wife went to the UK for a month so I sat the action on the dining room table and slowly worked my way along it replacing springs and tape etc. Getting the parts was hilarious as the man at the piano shop had a full on rant at me cos i asked if he also had a tuning key I could buy or borrow, he lost his shit and told me loudly and in the thickest Scottish accent that he had been fixing pianos for 40 years and what made me think I could do it in any way shape or form. I suggested that playing guitar for 20 years might have developed my ear for these things somewhat and he lost it so bad that he had to walk out. His boy was cracking up in the background and sold me all the parts I wanted once the old boy was gone. I didnt get a tuning key so jimmied one out of some square sockets in my socket set. It was never spectacular but played and sounded pretty nice. Unfortunately I had to store it in a shitty shed for a few years and it got ruined again. So when my daughter had her 16th we had a piano smashing party and they laid into it with sledgehammers and axes while drunk. She has one friend who is an unusual girl but holy shit she could wield a sledgehammer.2 points

-

2 points

-

1 point

-

It's going to have to happen. I'll be needing some nice Hanmer cycling, bbqs and hotpool to look forward to later this year.1 point

-

1 point

-

I have updated the main meet thread. 7pm Wednesday 3rd April at Spitfire Square1 point

-

1 point

-

1 point

-

The donor front/radiator support panel came from a farm ute, which had had an L16 repower. Some butcher had gas cut the radiator supporr panel out so they could fit the larger L16 radiator. I tidied this up as best i could (not very well) and got a mate to make me a custom Aluminum radiator to fit in the space i had.1 point

-

[SHARN] The NZDM 620s all came with the quarter windows. And im not a fan. Im sure in the days when everybody smoked they were great for drawing away the smoke. But they leak, they whistle, and they offer another place for someone to try break in. The USDM trucks all had one piece door glass. A good while back, my dad gave me a heads up. " one of my mates is imporring a couple of boats from the states. Theyre being shipped out of seattle. If you want to get anything shipped diwn here for free, get them sent to qhere the boats are, and they can be put in one" So i jumped on SeattleTacoma craigslist. I found a guy wrecking a 620 KC in Seattle. And although i was fairly sure that the doors were the same between KC and regular trucks, i wanted to be sure. I jumped onto ratsun.net, and explained my situation/asked the question. Yeah theyre the same was the response. Sweet! But then i get a PM from a user on there named @bananahamuck saying his mate has heaps of that stuff, heres his number. (Turns out its the same Bananahamuck as the one on OS! So i ring this fella up, and he says yeah i got heaps of rusty doors etc. I tell him, ill need him to freight them up the Seattle. (This guy is actually in Portland) he says, oh, our shipping is really slow, and expensive. Ill drive them up there on Saturday. Im like how far is that? About an ahour and half drive! Fucking hell. I offer to pay for his gas etc. So i ring my Dad and get the address of where these boats are in the container. Turns out its not Seattle, its a place called Yelm. (Its actually closer to Portland) i email Ted with the address. He replys, oh i work in Yelm. Ill drop them off before work one morning. So a couple of months later i get the call that my glass is here. And after having them tinted, they went it beautifully.1 point

-

1 point

-

Ma te wa to Bill and whanau, then we headed home, with our van loaded up with other treasure from the shed(s) Forgot to mention i got jealous of her getting new car, so I got me one the same colour as hers on the way up. Given i had to drive this, Kirsty was driving the van the whole way home, she was none too pleased about it (But, yes it is better than my current 2005 Forester X its replacing in every way, thanks for asking - 2002 XT, totally stock, sub 200k and after a few wee issues (MAF sensor, oily connectors, new spark plugs) it really kicks when the whirly boi winds up!) Good Day in Welly before overnight sailing Breaky fry up in Kaikoura a quick stop to rise the north island off And about 3 days after we got home, this turned up. Used Classic Towing - worked out fine, but lucky both Bill and myself are home most of the time because the communication around changes of plan was a bit lacking tbh. The man can sure back a trailer tho. Its a fricken whale compared to my 'big' Fiat, an easy foot wider. Time to poke the bear First thing, remove the CNG stuff from the engine bay. Not only is it unfillable, the electrics are one of the layers of fuckery (the least bad to be fair, but also totally redundant), the tees that loop into the factory heater coolant lines to stop the regulator freezing up were corroded apart, and the carb hat gas injector thing made the air cleaner butterfly nut rub on the underside of the hood. 'New' heater hoses (from the old CNG line) and a bit of a wiring tidy up Fuel pump clean (no go in Feilding, leaks like a sieve now, still no pumping action), now bypassed with a clicketyclack, needs a rebuild kit (diaphram and gaskets) Carb cleanup, was pretty clean inside the bowls etc, works ok now, needs a kit too (tore a gasket) Sitting clean on the still very oily 173 Dizzy removed, cleaned and oiled, gap reset, but all the points, cap, rotor, leads and sparkplugs all look relatively low miles Changed the oil and filter (black and smelled like petrol but no chunks), re-crimped a new loose connections, taped some twisted wires, removed some vampire taps and chock blocks as well Put it back in starting from first principles (ignoring the marks, get cylinder 1 on compression stroke at as close to tdc-ish you can with a long thing in the spark plug hole, rotor pointing to lead 1) and it was about 90 degrees off where it was before - dizzy couldnt be turned enough to get the right timing, so i wonder if it had been tutued with before and the hassle of it not running well was why it got parked. Bill did say it had several minor issues needed sorting out and they got a newer, better car and he just stopped driving it. Anyway, buttoned up and after some further fine tuning it starts on one pump of the pedal and idles smooth. Not smoky (any more) Still no coolant or brakes.1 point

-

Then of course it was time to have a good look while cleaning it a bit, and taking stock So, its a 1974 Holden HQ Belmont Sedan in Orchid Red. Last wof/reg in 2001, so was on the road into Kpies early 20's around the same time i met her. Seems it also got the Torana front seats, maybe the centre console? Interior looks pretty good under the dust. Overall looks pretty straight and complete. Some rusty bits of course but not too bad at all for one of these 8s out back and 7s up front, massive CNG tank in the book gives it a rake. This car was a NZ new factory 202 manual 3 on the tree car. Bill bought it cheap from a guy who bought it to put the v8 that was in it into something else, or something - bought with no engine in it anyway The engine and box now in it is a 173 (2.8l) with a manual 4 on floor from the aforementioned rolled Torana, which had recently had a fair bit spent on the engine (??) It has a single barrel Stromberg and also has CNG. Only $4.20 to Whanganui! Took the plugs out and oiled the cylinders, cleaned the sparkplugs and filed the points and hooked up a battery. Neighbours come to assist. Many opinions were shared We managed to get it to fire off on squirting gas down the yap, but it just wouldn't keep running. The consensus is that the timing and/or the electrics are weird Brake pedal does nothing till halfway then hard stops, no braking action. Handbrake kinda works. Engine isnt stuck and clutch is free and gearbox goes into all gears. Bill is stoked it fired up, Kirsty is happy, and that it rolls at all is good enough for the transporter man. We push it back in the shed to wait for the transporter1 point

-

Organized time off and ferrys etc and a cool 10 days hanging in Fielding. Real barn find! Her names on it so this must be it. We pumped up the tyres and had a general look around one day Then cleared all the stuff out over the next few days, did a lot of gardening too, Hooked it up to the van and pulled it into the light1 point

-

Been a bit slow last few months as been trying to get new shed finished but finally in there and got hoist up so back into the car. Motor and box need to go in as one piece from underneath with front subframe so bought a trolly lifter thing which made life so easy. Chucked the motor and box back in with the cooling system last weekend to work out a plumbing list to order all the oil, water, fuel braided lines and fittings. Also working out brake line routes and working out what else i need to do to finish off prep to strip it and get it back to the painter. Basically want to have the car dummied up in full then get painted/motor built etc so once painted its just assembly to finish.1 point

-

1 point

-

Spent an hour with the wire brush on the front of it, this was like an archeological dig to uncover a special world of poor decisions and welding fuckery. Further digging on this spot tells me the windscreen will need to come out, this area and the same on the other side was there when I first had it, but the new layer of bog hadn't really solved the issue; This had bog all over it for no real reason, there is a dent but no attempt had been made to pull it out; Im going to cut out all those patches and do them again, but this time with feeling.1 point

-

The lux is back at my olds place in the barn now as most the major fab work is done so I can easily get the rest finished with my basic setup there so loaded up my tools this morning with the intention of fitting the brake calipers to get steering lock back Balls, maybe the ute at pickapart wasnt an SR5 as the calipers are too small for the disks. Do 90s SR5s even have bigger brakes than a povo spec? I dunno something to look into. Got the clutch bled up and it feels decent enough. Looks like my cobbled together setup has plenty of throw so it should work Stripped down the passengers seat rails ready to make mounts for the passengers bucket seat Made a small bracket out of alloy so the grille badge off the crown will mount up. Looks almost factory And a few weeks back I swapped some 1G bits with @Jeffs_Emporium for this sweet old school Blitz boost gauge. Had a bezle off a vacuum economy gauge thing kicking round so swapped it into that and it looks perfect. Wont look too out of place tucked somewhere on the dash1 point

-

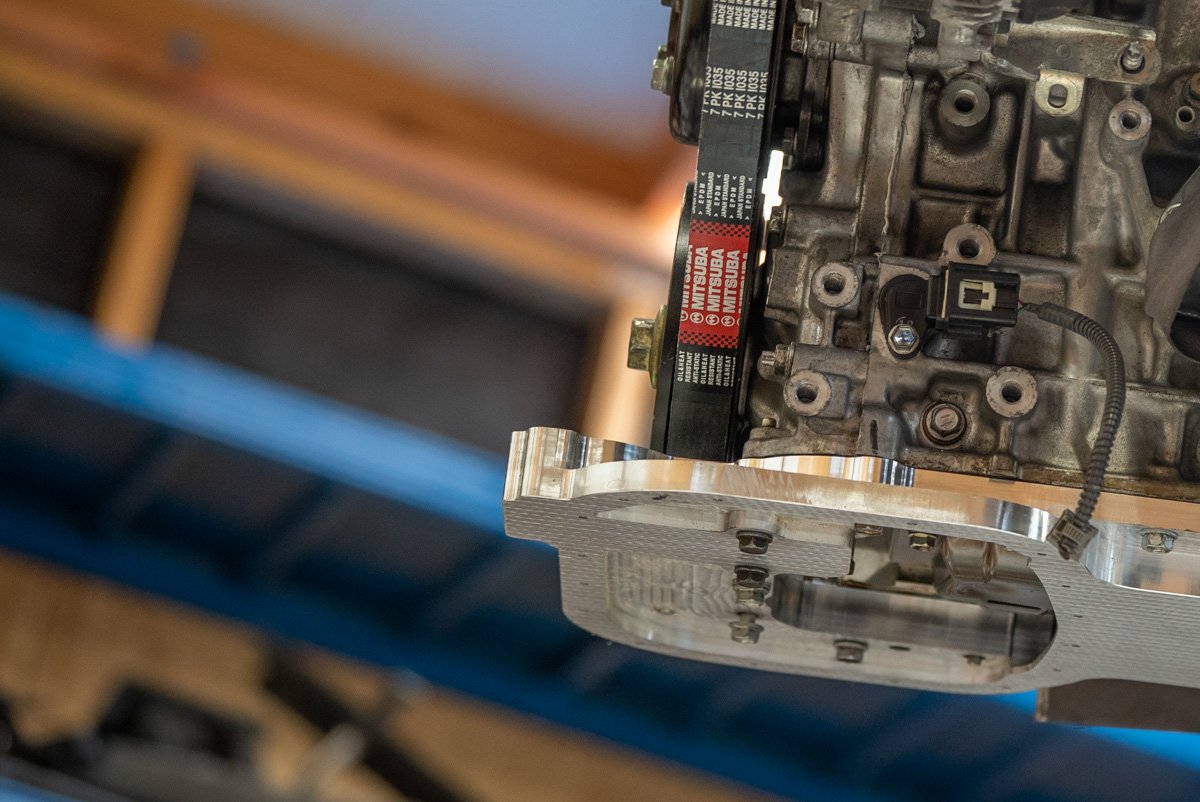

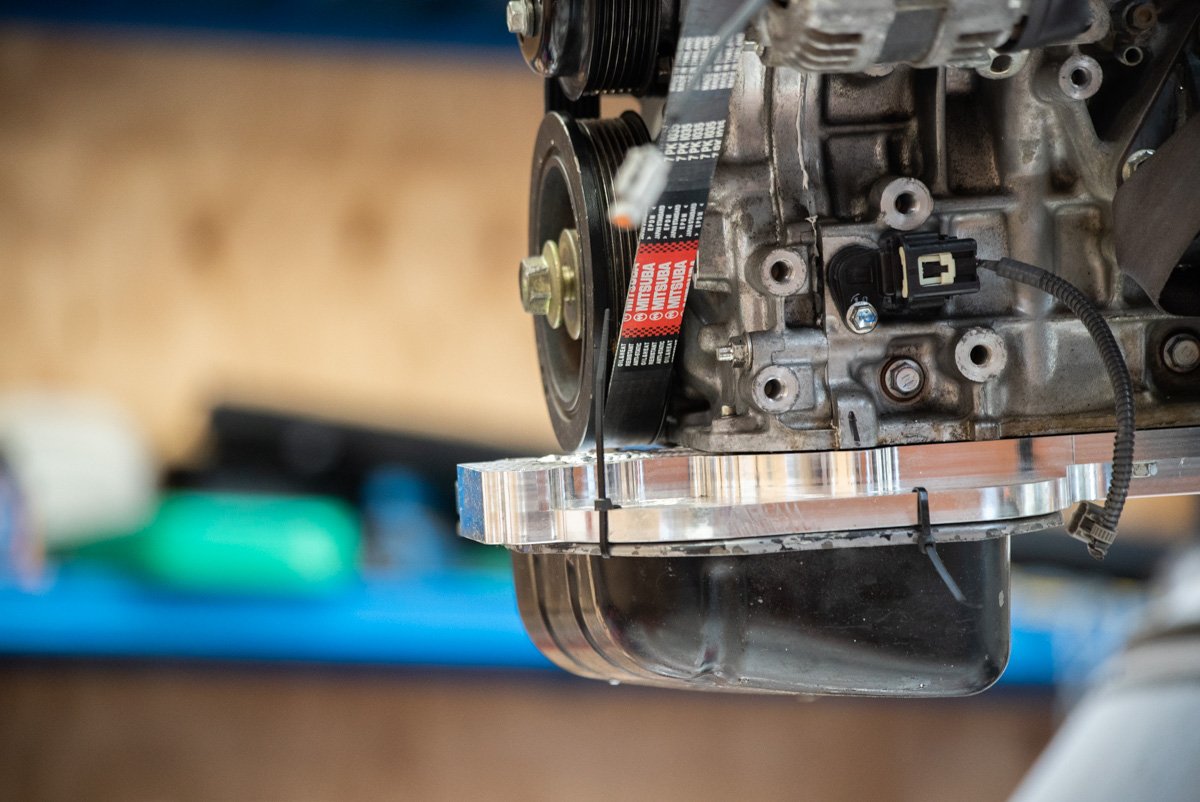

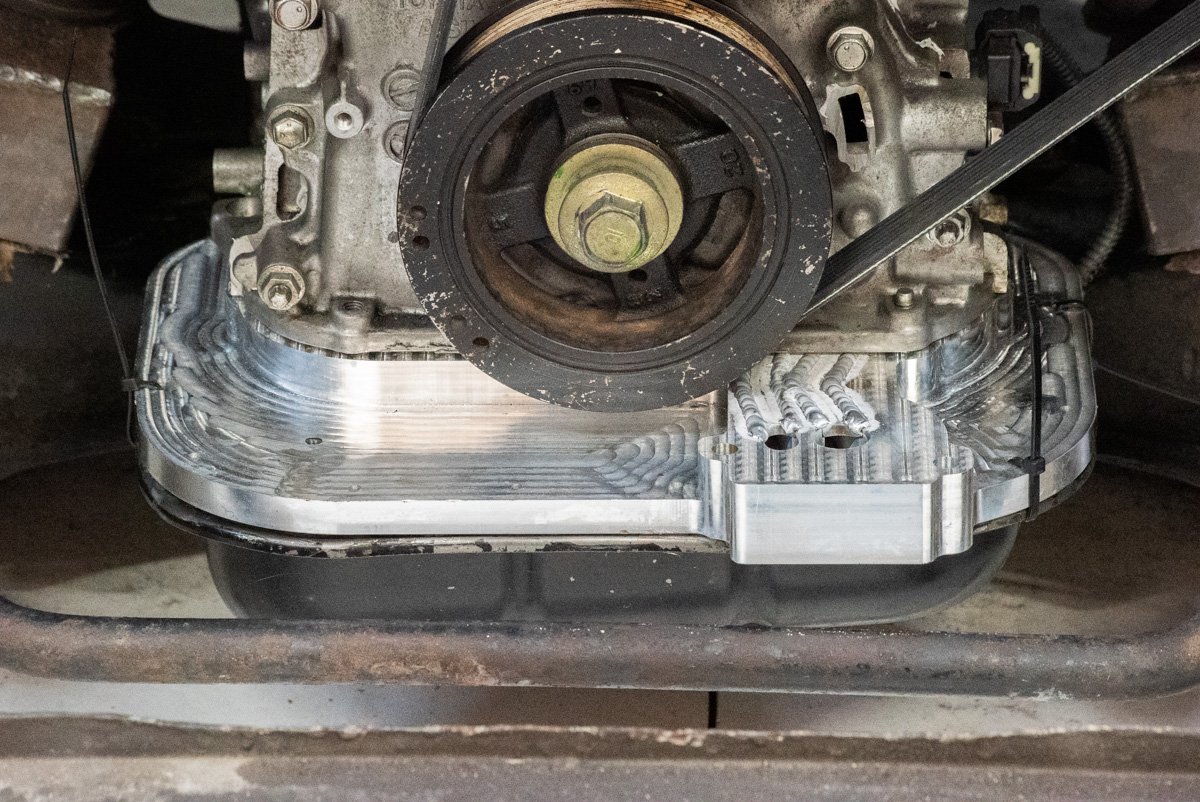

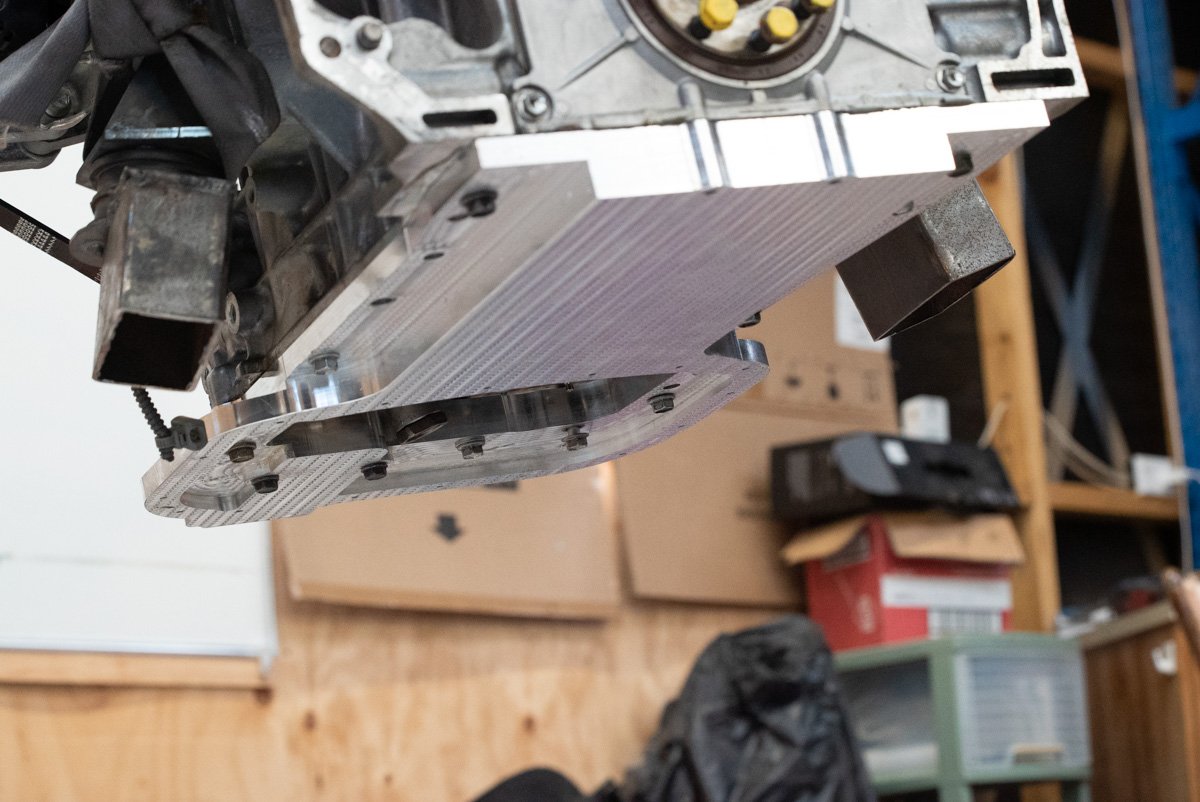

Oil pan activities! Absolute GCs @Stu and his workmate Sam found some time in their incredibly busy schedule. To spend a night programming some cutting paths and cutting a big slab of alloy down into an oil pan. I went along to watch and learn some things and it was awesome. Firstly, start out with a 22kg block of 32mm thick alloy plate. Then align this onto the bed of the router, and the it gets sorta vacuum sealed against the bed. Then one side was machined, making an absolutely hectic amount of mess. Then it was flipped over, and a a template was cut to align it onto the bed again. Making zillions of glitter carving out the other side. Then once it was all cut, we are down to around 1.8kg from 22. So there were plenty of chips for me to sweep up, haha. we needed to look at drilling the oil galleries for the filter, that I mentioned a few posts ago. Problem - the depth needed was too long for any available tooling and the height of the machines etc. So we decided to mill two slots in, and then weld a cover plate over the top. We made the slots do a bit of a zig zag, so that they would avoid one of the threaded holes for the oil filter housing. Which previously penetrated through into the oil gallery as there was no other way. Then Stu on the tig to zip it all back up: Then ready for a test fit. How good! (It still needs the welds flattened off and some threads tapped, havent done this yet) Much to my relief, it fits up great. Just zip tieing the oil pan on for now, until I can tap the holes. and back in the car... everything good! So that's one of the last remaining big tasks mostly sorted. And a big relief that it looks like everything is going to work as expected. Hugely grateful for the time spent by Stu and Sam to help get this done. I think its the most complex and coolest car related thing I've ever drawn up. Next steps are to thread a few holes for the oil pan and oil filter, flatten off the welds, and make an oil pickup. then I can fit it on for good, and fill the motor up with oil. Getting closer! Exciting.1 point

-

1 point

-

To make the pivot point for the Watts linkage I started with a piece of 38mm round bar and a twin row bearing. Milled a slot in it for the bearing to slip inside and bolt through. Then I drew up an arm in Solidworks, 3d printed and then got Dad to make a pattern to get it cast from aluminium. We had it heat treated to add some strength to it too. Bent and welded some 38mm rollcage tube on to the ends of the pivot boss. Made up some arms from some pipe, threaded bosses and rod ends. The whole process would of been a bit easier if I hadn't welded that crossmember so close to the back of the diff! This pic is fully laid out. And at ride height. Decided to strengthen up the lower rear arms. Tried pressing in the original style bushes, but gave up very quickly after they kept crushing the c-channel arms. Stupid design really! Welded in some bits of pipe and got some tophat style polyurethane bushes. Way nicer to use and same size as what I used on the Watts linkage. Also replaced the one in the upper arm with same bush.1 point

-

1 point

-

Oh yea shit I forgot to tell you why everything got covered in oil. So right after I moved the oil cooler I took it for a drive round the block to check shit out. As I pulled away from the kerb I heard a weird sound and it continued as I got to the end of the road and round the corner. I was coasting along watching the gauges and trying to figure out what they noise was when the oil light came on. I shut er down quick smart and got out to have a look. It had inexplicably pushed one of the oil houses off the push lock fitting (that it had been on with no issue for about 3 years) and sprayed all 5 litres of oil all over the entire engine bay. And all over the road. Richie just happened to turn up at the right time and with his help, and the help of Nick the sparky (who, despite being forewarned of the ground being covered in oil stood straight in it and fell over) we pushed it back up the hill and into the garage. There is still oil on everything despite emptying can after can of degreaser all over it.1 point

-

the injectors i got for it are those ones with a cap on the top and a cap on the bottom to adapt them to different types of fuel rail and different lengths. dont get them. i fought the fucking o rings in the caps leaking for days. if the injector has even a tiny bit of angle to it as you ty and install it they leak. fucking piles of shit. managed to ruin a base seal and i dint have any spares so i had to improvise. i had a larger and thicker ones from a nissan so i set about making them smaller on the od and thinner. 2021-11-21_04-17-12 by sheepers, on Flickr 2021-11-21_04-17-04 by sheepers, on Flickr 2021-11-21_04-16-48 by sheepers, on Flickr 2021-11-21_04-16-33 by sheepers, on Flickr 2021-11-21_04-16-26 by sheepers, on Flickr with that done the only thing left to do was relocate the oil cooler and fit some fans to it. the only fans i could find that were small enough but still waterproof came from the states, they weren't expensive but they took a bit to get here. the oil cooler is now mounted on the side of the chassis rail between the engine and the rail, behind the steering rack. ive been driving it around with a thermocouple in the oil cooler just keeping an eye on the temps. its pretty good and drops fairly quickly as soon as your driving as there's a bit of air flow. so anyway i made a bracket type setup and mounted the fans onto the oil cooler. all i need to do now is wire in the relay and they should work. im back on the dyno on Tuesday so yea, lets see what happens. 2021-11-28_05-10-37 by sheepers, on Flickr 2021-11-28_05-10-31 by sheepers, on Flickr 2021-11-28_05-10-22 by sheepers, on Flickr 2021-11-28_05-10-14 by sheepers, on Flickr1 point

-

totally forgot to post the finished pictures. sorry, i finished this a week ago. 2021-10-25_04-07-31 by sheepers, on Flickr 2021-10-25_04-07-45 by sheepers, on Flickr 2021-10-25_04-07-51 by sheepers, on Flickr 2021-10-25_04-07-59 by sheepers, on Flickr1 point

-

i ordered a new intercooler ages ago but it was coming from auz and they went into lockdown right when i ordered it so it took 3 months instead of 3 weeks. anywho it turned up and i went about making it fit. its wider but not as high as the one that was on the car. a quick note about the intercooler that was on the car. its an R32 GTR intercooler that i put on the car about 2007 and it has been through hell and back and it took it all. it stoved the side of Spencer's soarer in, its taken literally hundreds of hits into curbs and driveways and fucking all manner of shit and its never had a leak or a broken tube or anything. this thing needs a place in the hall of fame. so yea, new intercooler will flow WAY better than the old one and the dyno will tell the story. i made a new bracket thing to hold the cooler and it had two mounting holes on the bottom but because i cant use the top ones i thought id add two more to the bottom just because. i only had a small piece of square aluminium so i made it round and welded them on. 3the new intercooler sits about 30mm higher than the old one too so thats a good. at some point imma make a front air dam for this thing. 2021-09-25_06-12-31 by sheepers, on Flickr 2021-09-25_06-11-50 by sheepers, on Flickr 2021-09-25_06-11-58 by sheepers, on Flickr 2021-09-26_05-10-21 by sheepers, on Flickr 2021-09-26_05-10-43 by sheepers, on Flickr 2021-09-25_06-12-12 by sheepers, on Flickr 2021-09-26_05-10-37 by sheepers, on Flickr1 point

-

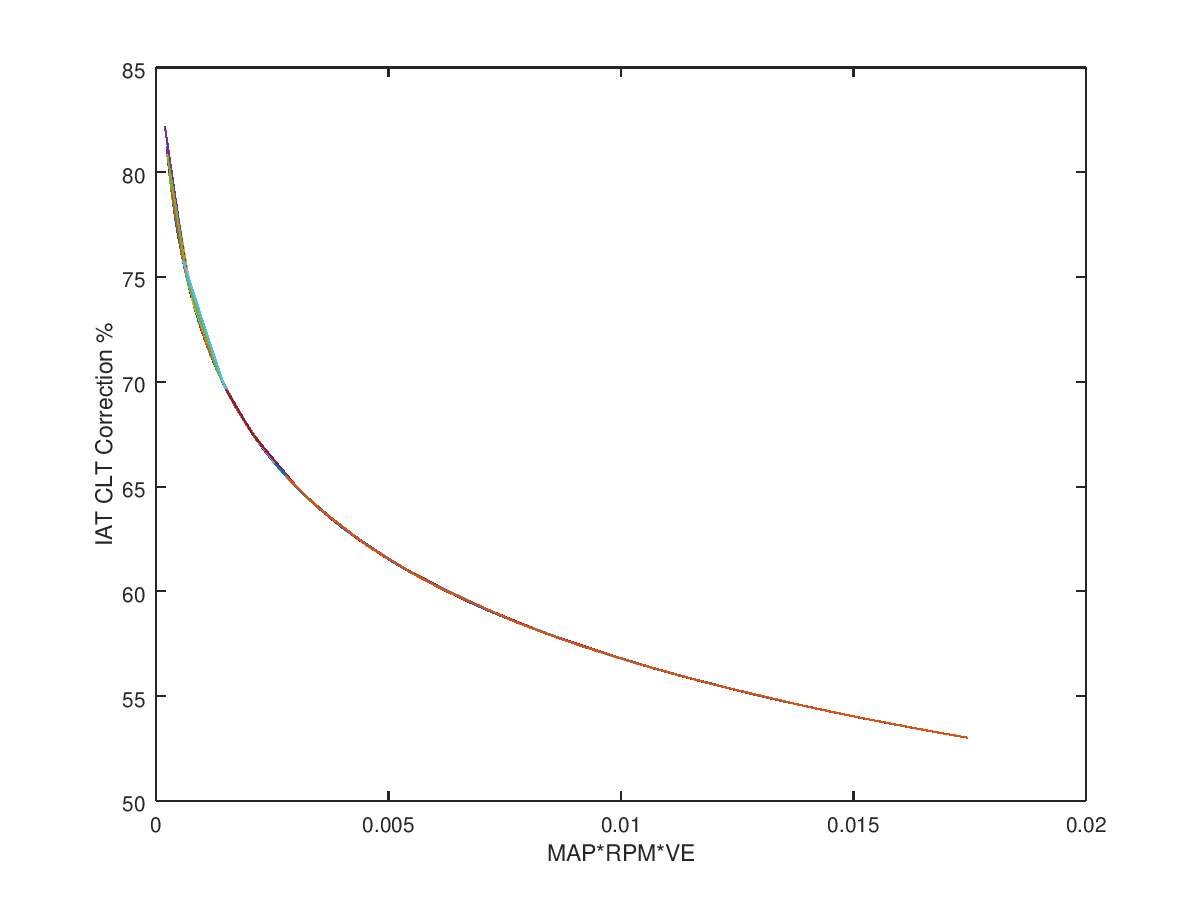

I decided to give Amayama a go for ordering a part. The Starlet has always had a bit of a clunk in the steering, a few years ago I narrowed it down to the internal bush on the drivers side having a small amount of play. I then promptly did nothing about it due to the part being expensive. Checking on Amayama, I could get the part for $32 including GST and delivery. Toyota wanted $135+GST. the part arrived after a three week journey from Japan. I pulled the rack out of the car, 1960's British car engineers really need to take notes on how to design something. It's stupidly easy to remove the rack, they even make the bolts go in from the bottom on the side where the engine is in the way. I then stripped the rack down and removed the old bushing. The bushing was quite difficult to remove, I ended up heating it slightly and managed to hammer the inner section out with a long piece of pipe. I then ground the outer section out. The bushings are four layers Steel->Rubber->Steel->Teflon. I think the part cross references to a whole load of different models and is still easy enough to get. I then had clean, grease (lithium base molybdenum disulphide) and reassemble the rack. Setting the preloads was interesting. I ended up setting the main pinion depth by feel and used a kitchen scale with a 17mm socket attached to it to push on some vise grips to measure the turning torque for setting the rack guide. I ended up getting it right at the middle of specs so I threw the rack back into the car. It took a couple of tries to get the steering column aligned on the right spline - first the steering wheel was one tooth too far to the right, then it was one tooth too far to the left and finally it was bang on. I took the car for a drive to test it all out. I'm actually blown away by how different the car drives now. There is no more clunking at all and there is no more twitching, and the tracking doesn't change slightly under heavy cornering. I always thought there was something up with the rear suspension but it handles perfectly now. The steering actually feels like something modern. I'm guessing a fair bit of the change in feel is from adjusting the rack guide. Either that or I've just tightened it too much and the rack is going to wear out super fast. Oh, and the other week I was doing a bit of thermodynamic modelling to try and improve the intake air temperature prediction, details and results are over in the DIY EFI thread. The engine behaves a lot better now, nice and smooth around town at low/mid loads.1 point

-

Oh the delays... After much looking and talking to authorities, the potential horsies versus the VW pan chassis I have is not going to fly. So I went looking for a chassis that will work with the power plant I have. I have found this in the UK. It is heading back to the chassis builder for more work ( Cotsweld engineering). Not sure when it will be down here, but a much better option and less likely to kill myself, which is a positive. Chassis is built to SFI specs to a 7.5 second standard. Intention is to add bars to get it to 6.5 s spec (not that it will ever go this fast) so completely future proofed. Rear end will be re done to make it IRS, currently a swingaxle set up. So one goes to the garage of broken dreams, and the project continues... year 9...1 point

-

Not too much news here, dragged the car out to Twin Rivers car show today. It seems that in the last year or so there has been a sudden spike in interest in old Toyotas. Had quite a lot of people stop and look at it. Noone could really identify that the EFI system was custom so it looks like I have succeeded in making a subtle system. One old guy was staring at it and said "It doesn't look like the KP60s I worked on in the 80's but I can't really tell what is different". There were no other Starlets at the show, which was quite a surprise. There were heaps of AE82 GT liftbacks though, I swear none of the 183 of them have died yet. I also got some NOS Bosch ignition leads from RockAuto the other day because they were stupidly cheap: Have to take it for a WoF in a week, should hopefully go through without too much of a problem. Might do an oil change next weekend. Also took it on a late summer high country camping mission a few weeks ago.1 point

-

Not a whole lot to report here. Just been doing a tonne of driving since the engine rebuild. Put over 3000 km on it in the last month and a half. Rebuild included going to far more mild cam, just adds about 500 rpm onto power curve Replaced exhaust manifold with some rush headers as well, no more leaks. Fuel economy is as good as or better than ever Got some new Falken ze912 tyres today, thanks to Chris @CUL8R at Mag and Turbo - should be good for a few more years Here's an adventure picture to compensate you for your time1 point

-

Low oil pressure was keeping me awake at night and I just couldn't cope So I ripped the engine out this afternoon and dropped it off for crank grind and bearings. He's also going to throw in an actually mild cam this time. At least one of the lifters wasn't rotating so it was probably good that I pulled it apart Less than 2 hours to get it out though so that's a win I guess1 point

-

So I decided "right, I've had enough of that really slow leak from the sump gasket. I'll whip off the gearbox, pull the sump from the engine and sort that stuff out" Upon removing the sump I found some cake that looked like bearing material. Connecting rod #1 bearing didn't look the most flash so I decided "out with the engine" Upon removing the engine, most of the bearings weren't too bad but definitely worn. Next task was pulling the pistons Two of the pistons are cracked. A little googling indicates this is a pretty common thing on 4Ks. So the plan now is for the following: -port match intakes on head to manifold/gasket -drop cam and lifters off for a grind, something pretty mild -drop block off for a hone (maybe bore, but the bores look pretty good), new rings and pistons, block may potentially need to be decked if using aftermarket pistons -???? -profit* *probably huge loss, but maybe a gain in power The stupid thing is the car was running absolutely perfectly. I probably shouldn't have opened the can of worms, but I'm kind of glad I did. After this is all done I should hopefully be earning enough money/retired by the next time it needs to be done that I can just pay someone else.1 point

This leaderboard is set to Auckland/GMT+12:00