Leaderboard

Popular Content

Showing content with the highest reputation on 07/12/24 in all areas

-

Well she’s ready to go off to paint tomorrow (I hope). its going either way. i guess i need to find some shims for the axles cos when they’re bolted up tight it isn’t free moving, loosen them off and it moves. Joys of putting things together that someone else pulled apart. so apart from the last minute body work i have started on the interior work. this build has really been an in house deal, aided by useless trades giving me the run around. thats ok, i get to upskill and try my own ideas. Im not scared of it turning out crap, I’ll just redo it and learn more along the way. so I cut out the door cards, kick panels and roof panel a while ago. went and purchased some upholstery this morning. went with a plush interior vinyl and 6mm foam backing. have it glued together ready for the patterning phase. Then will get the Mrs to help with stitching. once the ute is back I can do carpets and final fit out. while it’s away I’ll continue with the dash panel and procurement of brake parts (hard line, fittings, hoses, pads etc). I’ve also finalised the deck panels and have some more finishing to do with fit and finish. I added in the roll panel over the diff. This is prep for any future notch/4 link set up. i will complete the floor once the fuel cell is in10 points

-

6 points

-

Cutting into the lower sill reveals some more rust, but not as bad as I thought it might be. Will have to spray some rust convertor down through the whole lower sills and make sure the drain holes are cleared as there was a big blob of bog covering the rear one where this rust was. Going to be doing the bottom sills on both sides where rust holes have appeared just to make sure that I can check the whole inner structure.5 points

-

https://lvvta.org.nz/documents/infosheets/LVVTA_Info_01-2022_Wheel_Adaptor_Minimum_Specifications.pdf If they meet the requirements in this info sheet he might be able to get them machined down? Alternatively if they aren't doing something mental like moving a -44 wheel another 38mm, he might be able to do a design approval process, and get an exemption It would probably be less hassle to just get some 30mm adapters made here by znoelli.co.nz5 points

-

4 points

-

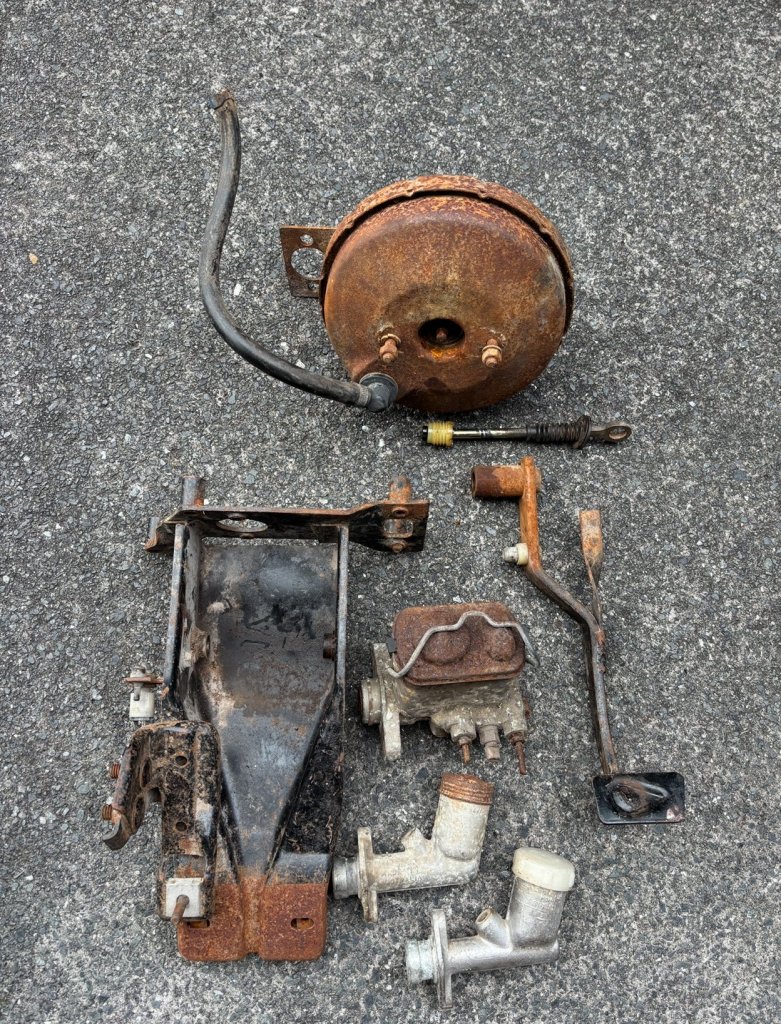

So started cutting out the rust patches and have had to go deeper than expected due to internal rust issues. Sand blasted the metal and removed areas that have gone past being ok. Will have to reinstate inner structure before welding in new metal and have also been using rust converter to stop further rust spreading.4 points

-

Give her a rev just before you shut her down to clean the plugs out m83 points

-

The new front springs turned up today. I had cut 50mm off the original springs and welded the flat bit back on top of the coil so it sat in the perch reasonably well. I wasn’t going to increase the spring rate so all I had to do is give them the compressed height of the spring. Anyway I will fit them tomorrow and see how the car sits.3 points

-

2 points

-

2 points

-

Put all new bushes in the rear. Trailing arms, panhard and swaybar. I think it's already been done once before, the rubber bushes came out fairly easily and they had no outer steel sleeve I had to fight with so I'm assuming not factory. Anywho they were a bit fucked and I changed them. Does feel better in the bum now.2 points

-

2 points

-

Could be a high spot on one of the bearing journals. Put some valve grinding paste on the bearing (the fine stuff, not the course stuff) and spin the crank over with a large drill. Barry.2 points

-

I trusted the internet..... I should of Come straight to oldschool.co.nz where people don't waste their time posting shit advice I'll pull another 5% out of the base injector rate see how that cleans things up its gotten much richer since new fuel pump went in2 points

-

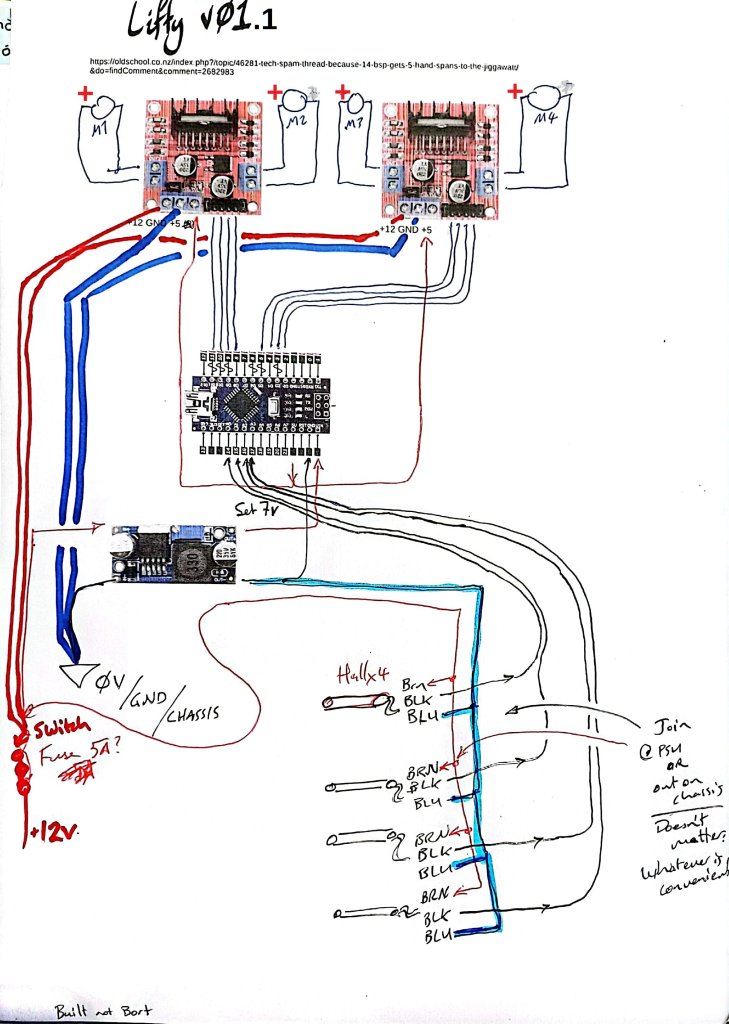

Oh yeah, here's why: ^^Note the retcon of the motor polarities. Lifty_input_test.ino // Input test // Using Analog inputs just as digital pins #define sense_pin_1 A0 #define sense_pin_2 A1 #define sense_pin_3 A2 #define sense_pin_4 A3 void setup() { // put your setup code here, to run once: Serial.begin(115200); Serial.println("\r\n Lifty input test"); pinMode(sense_pin_1, INPUT_PULLUP); pinMode(sense_pin_2, INPUT_PULLUP); pinMode(sense_pin_3, INPUT_PULLUP); pinMode(sense_pin_4, INPUT_PULLUP); } void loop() { // put your main code here, to run repeatedly: Serial.println(); // newline Serial.print( digitalRead(sense_pin_1)); Serial.print(" "); Serial.print( digitalRead(sense_pin_2)); Serial.print(" "); Serial.print( digitalRead(sense_pin_3)); Serial.print(" "); Serial.print( digitalRead(sense_pin_4)); Serial.print(" "); delay(500); // ms } Lifty_output_test.ino // Output test slow drive #define Motor1_1 11 // driver board 1-1: pwm #define Motor1_2 10 // driver board 1-2: direction #define Motor2_3 9 // driver board 1-3: ... #define Motor2_4 8 // driver board 1-4 #define Motor3_1 5 // driver board 2 ... #define Motor3_2 4 #define Motor4_3 3 #define Motor4_4 2 void setup() { // put your setup code here, to run once: Serial.begin(115200); Serial.println("\r\n Lifty output test"); pinMode( Motor1_2, OUTPUT); pinMode( Motor2_4, OUTPUT); pinMode( Motor3_2, OUTPUT); pinMode( Motor4_4, OUTPUT); } void loop() { // forward Serial.println("\r\n Forward"); digitalWrite( Motor1_2, 0); digitalWrite( Motor2_4, 0); digitalWrite( Motor3_2, 0); digitalWrite( Motor4_4, 0); analogWrite(Motor1_1, 64); // 255 steps, so 25% duty cycle analogWrite(Motor2_3, 64); analogWrite(Motor3_1, 64); analogWrite(Motor4_3, 64); delay(2000); // ms Serial.println("\r\n Reverse"); digitalWrite( Motor1_2, 1); digitalWrite( Motor2_4, 1); digitalWrite( Motor3_2, 1); digitalWrite( Motor4_4, 1); analogWrite(Motor1_1, 191); // now referencing motor drive from +ve, so need 255 - (1/4), so 75% duty cycle analogWrite(Motor2_3, 191); analogWrite(Motor3_1, 191); analogWrite(Motor4_3, 191); delay(2000); // ms } @ThePog None of this will work first time of course, what with never testing any of the code on the actual hardware. Impossiburu!2 points

-

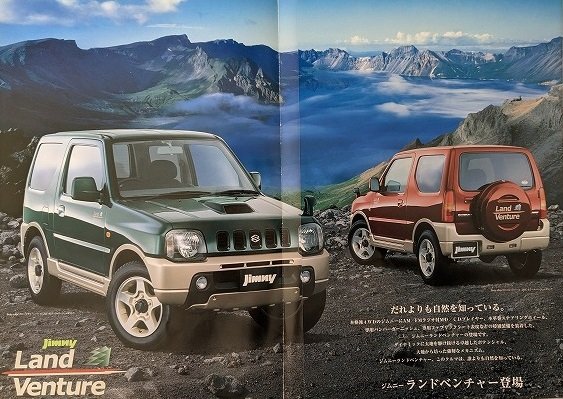

So after many years of wanting a kei car of some sort and also a Jimny, and much exchange of banter and links between myself and my old fleet manager over many years about such vehicles, I became aware of a very cheap kei spec Jimny on Trademe. I thought I'd keep an eye on the auction and see how it went - I didn't need it, but I would be interested for the right price. Anyway, it was pretty rough - seller was pretty honest about the state of it - blown head gasket, cracked windscreen, and it was not in a condition to win any concours events. It was in the top of the South Island so no way I could check it out, but it only came into the country in 2022, and had current reg and wof so I figured it couldn't be too bad. I managed to win the auction for a very sharp price (after a painful '$10 increment every two minutes' bidding war with another bidder). A price sharp enough to justify fixing it or even throwing it in the bin if it was no good. The seller was a GC and managed to hook me up with his mate who was coming over to Wellington and could bring it over on the ferry for me on a trailer. First impressions - pretty rough, the interior was disgusting but overall a solid car. It was definitely BHG with water and clouds coming out of the exhaust so it got driven all of 10 metres onto the trailer. Everything about it is so tiny, especially the engine - a baby 3 cylinder 660cc turbo K6A. According to the internet they produce 47kW so this has now probably replaced my white Viva as being the least powerful car in the fleet. Homeward bound to see what kind of junk I'd managed to buy. Everything needed a decent clean and going over to understand how good or bad it really was. Oh yeah, it also had three different air fresheners hanging from the mirror and a collection of tasteless stickers on the rear winder.1 point

-

1 point

-

Waikawau Tunnel beach, north of Awakino on the road to Marakopa https://maps.app.goo.gl/4BhL6kFBTfmgc6Tm81 point

-

@tortronRev limit is to 4000rpm for such things Have just given it the service of its second lifetime running real nice for 1/2 a million clicks. Fresh oil went 20/50 penrite synthetic and 1/4 bottle of moreys still has a lifter tick at idle it goes away by 1500rpm so I'll pretend not to hear it, Flushed the cooling system and filled it up with Coolant so when the crank falls out the guys at the track will say jeeze looks like it "was" looked after while sweeping up my engine.1 point

-

1 point

-

1 point

-

1 point

-

Have read the same, the thicker electrodes of copper (actually nickel on the business end, even iridiums have a copper core) erode much faster with the high voltages in modern ignition systems, leading to misfire and other issues. Great for an older none boosted engine running a single coil and leads from a dizzy etc. I had 2 fresh sets of NGK copper nickel plugs die on the dyno in my old Subaru, anything over 10psi boost and they'd start breaking up and misfiring, swapped them out for a set of platinums from memory and then it was mint even pushing 22psi into it.1 point

-

1 point

-

Good morrow young Alex, it's one of these little numbers. https://www.trademe.co.nz/a/marketplace/computers/networking-modems/wireless-networking/adaptors/listing/5049309357 Worse thing about it is the power wires are finer than human hair, I ended up twisting the fuck outta it and heat shrinking over the top.1 point

-

Reinstall the pistons and rods one at a time and turn it over to see if one of them kicks off the sticky spot? Could it be something weird happening with one of the big ends not being true?1 point

-

My grandad had a old straight 6 mariner. Was good when it was going but it also broke down lots. Sounded pretty good at WOT!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Indeed, it was most excellent. Great bunch of chaps and some outstanding roads, bloody top notch work guys. I didn't take many pics, this is about all I got,1 point

-

Yep, pretty sure all of Taumaranui was awake at 7.05am when that fired up! Epic weekend guys, thanks to all that came along and made it such a great time. Who would have thought it was so hard to get back off the beach. A+ Shannon send there too btw1 point

-

Driveshaft hoop is done!! yeow!!! I had a different method mocked up but hated the way it looked. so thought of how to tie everything together to make it strong , as well as being able to mount other stuff off it like the exhaust and handbrake cables. pretty stoked with the outcome and only took about an hour from start to finish. used 2 x 32nb pipe, notched to slot in between both ute crossmember thingys. question now is can the handbrake cables run between the hoop and shaft? I’m guessing no, so I’ll still need to trim down the generic upper hoop so I can run the cables over the top. then once I get a suitable (low profile) handbrake unit, I can get it mounted, drill the hold through the tunnel and get that finalised. she is ready to go to paint too. had an ulphosterer lined up to do the work but he got back to me finally and said he can’t now until March, what a cuntface. guess I’ll tackle this myself now also ordered many bits from Franklin performance to tart up the keg. assembly should go well once it’s back from paint1 point

-

Now it was inside I could muck around with it. First job. I noticed the radio didn't work and the pocket in the second DIN slot wasn't mounted so that should be a quick fix. A loose wire was culprit as to why it wouldn't work. I found two screws to mount the storage pocket properly and reassembled. It's a JDM headunit so only receives one local station and doesn't have bluetooth - but plays CDs okay and also has iPod connectivity via USB so can play Spotify off my iPhone. Second job - while pondering and procrastinating I thought I'd quickly clean up the headlights which were very yellow. Here's the job 50% done for comparison. Last job of the day - why doesn't it start? Intercooler off, coils out, plugs out. Everything is so tiny. Turned it over with plugs out and it was like a water pump - a lot more came out of the bores than I had imagined and I forgot how far it goes under pressure. What's that smell? Petrol. That ain't water. Not sure what was going on but it was a mix with a lot of petrol in it, and it evaporated/flashed off pretty quickly. When I've got it apart I'll clean and check the injectors as well to make sure there isn't a sticky one or some other reason why it may have flooded with petrol. After all that I rewarded myself with a cold beer and thought about what next. Engine out over the holiday break (if not before) and see what is needed. Parts will need to come from Japan but they appear to be readily available. It can sit and wait for now.1 point

-

I spent the whole afternoon cleaning it. Started by waterblasting and scrubbing the outside, removed all the stickers and other shit from the glass. It actually looked pretty good when it was clean. The inside needed a decent vacuum and scrub of all the plastics. The door cards had spilled drinks, one side had something resembling dried tomato sauce which had dripped down it, the centre consoles, dash and glovebox were also filthy and all got a scrub inside or outside of the car. I really want to pull the seats and carpets out and give it a deep clean, but I'll leave that until it is running again. We pushed it into the shed so I could look into why it wasn't starting. Putting it inside next to my other 'small' car made me realise just how small these really are. If you are space constrained, buy a kei car instead. After all, that's why they exist.1 point

-

I got it home and unloaded without any problems and dumped it in the driveway. After sorting a few other things that needed doing, I thought I would move it into the workshop and start to clean it up a bit. Problem #1 - it wouldn't start. Despite starting several times already that morning, it did not want to turn over. It wasn't a starter problem and felt like a seized engine so I suspected it may be hydrolocked given how much water was coming out earlier. Cool. It could stay where it was and I'd clean it first. What had I bought? A 2001 Suzuki Jimny 'Land Venture' edition which is some sort of trim spec. It seems to have better wheels than the standard kei spec Jimny, and cool green upholstery. It also has cool checked floor mats. The previous owner must have done some regular offroading because there was the remnants of a CB radio install, extra lighting and also a 12v compressor mounted in the back, and the bodywork was extensively scratched. The bonnet is dented and scratched in a way I can't figure out how they did it, the roof has been resprayed a different shade of green and the original edges have got a lot of sunburn/clear coat failure. The original roof rails have been removed leaving only their sockets. The spare wheel cover is also dented which is a shame but can probably be beaten back into shape. The other feature was an extensive amount of filth everywhere. All the plastics, carpets and seats were disgusting. Exhibit A1 point

-

Mounted the overflow bottle and washer bottle. will get the washer bottle powdercoated to match the overflow bottle. Not going with polished stuff. then decided to fill a couple of dormant firewall holes (heater pipe entry’s, handbrake cable hole, column shifter hole). Plated over, epoxied, filled, sanded, epoxied again. made up and fitted all door cards and kick panels. still waiting on my new seat mounts and need a hand to hold sheet metal with the bead roller.1 point

-

While it can be fun to change cars, the current market isn’t great for changing at the moment. There seems to be a lot of cars for sale at the inflated prices people were paying when interest rates were 2%. If you sold it, what would you get for the same monies? I was thinking of selling the Ute but these are the questions I have been facing so have decide to keep it for now and maybe tweak a few things. So I vote to keep it. It’s a cool car and definitely a bit different to a batty/808/323 etc. By doing the manual swap and getting it certified will probably make it easier to sell in the future too. It will be like a new car! Besides they are super lush to cruise around in (by design) and has the extra doors for extra… people. Keep it, manual swap it. Cert it and enjoy it. Then maybe in a couple more years think about changing it up.1 point

-

1 point

-

Just to clarify what's going on with the MAF the stock one outputs up to 10,000hz which works out to about 256 grams per second of airflow and im tagging this at 12-13psi the PCM is now mapped to read up to 16,000hz which would allow me to run up to 510 grams per second. Once the L67 bottom end goes in with some ring gap it will take 20+psi and I've got everything else in the car to support it now which is awesome. It's also less used hardware as people rip them out and go for a maffless tune. I might try rockautoparts.com1 point

-

Got stuck into a couple of tasks this week. picked up a battery today, went with an optima with the extra side post. main posts will be for the starter/earth only. side posts for accessories. scratch my head and nads a bit to decide on a mount. Canes up with a basic plate with 2 wedges as the side mounts, 1 up 1 down. then welded on 2 studs underneath for a remote jumpstart terminal block to sit in front of the rear wheel. on the rear panel behind the seat I have mounted a circuit breaker, fuse block and the auxbeam style relay/control box. I also figure out all of the combo switch wiring and how to get power etc to the wipers and other stuffs. not much more to do now before blowing it apart for some paint.1 point

-

1 point

-

Pie dispenser controls I'd wager. He's gonna machine one up on the lathe that mainlines minninchee's directly from his roof tent to his face hole.1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.570970b401ac8d26ce9af7c1bf2bd8cd.jpg)

.thumb.jpg.aae541ffc8f2df9564e6589745851139.jpg)

.thumb.jpg.e15fd413471b3b3085736b29a1c10381.jpg)