Leaderboard

Popular Content

Showing content with the highest reputation on 14/09/21 in all areas

-

Just in from alexandra.. drivers floor pan, tunnel section and more firewall patches.. By my calculations, that’s all the main fucking holes filled, we have a god damn shell again!! Still some hours of checking it over, finishing spot welds and the usual completion stuff then we wait for the repair certifier to give us an inspection appointment15 points

-

Still busy prepping boot have re-epoxied, seam sealed, and filler primer, all ready for top coat. Have also cleaned up cabin, ready for some colour to seal it off. Dash and boot lid filler primer applied also. Purchased a new elcheapo spray gun for top coating inside car, and settled on Blak Mat for sound deadening. Full kit of 2x packs, roller, and tape was $375, still cheaper than 1x dynamat pack so I'm happy12 points

-

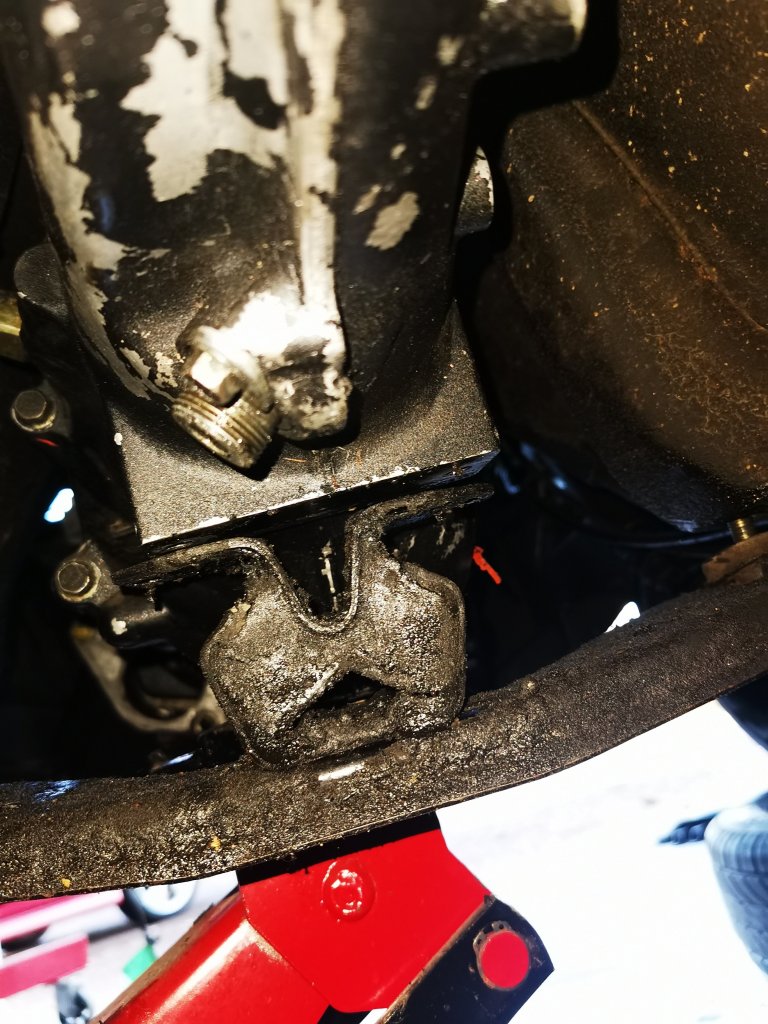

Starter motor time. I had bought a Subaru leone 1.8 starter from the fella I'd got the gearboxes and 1.8 ring gear from. Made sense to use all the same bits. Only thing I'd have to do was move the mounting face for the starter forwards towards the engine to suit the new ring gear position on my home made flywheel... Easy as I thought and I had it all planned out. I shall start at dawn! However that's not what happened once I got a friendly query from a fella about the starter motor turning the engine the wrong way. Oh yeah. Bugger. Of course it will do that. Yay. So after a few ideas and suggestions from various folk I had a few options. My first option was to mount the Subaru starter on the front of the bellhousing adaptor, facing backwards. Essentially turn it 180 degrees and it would spin the Honda engine in the required anti-clockwise direction I needed. But would it fit? Yes it does... It wouldn't be too tricky to mount and on extension the pinion almost lined up perfectly with the ring gear. It sat down in place quite low too. So this solution was a strong contender. But it had a couple of weaknesses that meant it went to the back burner. One: the ring gear would need turning around so the leads shaped into the teeth faced the pinion. Turning it round and having the pinion strike it from the opposite side then meant that the step I had machined into the flywheel would have been on the wrong side and the gear could potentially work off over time. I was reluctant about the idea I could add a few welds, as some folk will do, because it adds stress risers, could affect the balance. I really didn't want to muck about with the ring gear. Two: having a fairly large ugly starter motor plonked right there on the top of the motor was something I never had in my minds pictures of how I wanted the engine bay to look. It would be right where I might want some linkages for the itbs, possibly a centrally mounted plenum between the itbs and there was also going to be some water pipes around that area too. So back to the other options- the main one being to look for a suitable Honda starter that's mounted from the gearbox side or a starter from any standard clockwise rotating engine that mounts from the front. The pinion had to have the same pitch and ideally the same tooth count. I did some research and it seemed that all the Japanese cars of this era all shared the same pinion pitch and were all around the 9 or 10 teeth. This was handy indeed. Off to the wreckers then... I went through the various shelves of starters, starting with Honda and found a possible candidate within a couple of minutes. Feeling pretty satisfied with my find I still double checked the other shelves just in case there was something even better but eventually I was spotted skipping out of the door happy with my Honda Civic/accord starter. Back home I looked at my booty. Subaru one is on the left... They were so close but not close enough. The Honda item has a smaller diameter 'locating spigot' that centralises it in the hole on the mounting face of the bell housing. This was a better turnout than it being bigger than the hole though! I would machine the hole in the plate to suit the new starter, which I was going to have to do for the original plan using the Subaru one anyway. The holes for the starter mounting bolts, that go through the bell housing into the engine, were 5mm closer at about 115mm and they were also offset to one side, not in line with the starters centreline. This was handy though because I could then have separate bolts holding the bell housing and room to turn the Honda starter about its axis, having the solenoid positioned in the least obstructive way. A plan was forming in my head. I took some measurements, did some scribbles and it all looked like it should work ok... I had already bought a hefty bit of 12mm plate for the Subaru starter repositioning and luckily it was still going to work with the new starter. I swapped the 4 jaw chuck onto the lathe and set it up. Drilled a big hole... Bored the hole out to suit the Honda starter spigot... Marked and drilled holes to suit... Recessed and spot faced one of the holes for the bellhousing to the engine bolts that just happened to slightly clash with a bit of the starter casting. So I now had a plate that the starter fitted neatly into, with not a hint of slop. The bolt holes lined up perfectly with the bellhousing bolt holes so lining the starter up the correct distance out from the ring gear. Now I need to move the face of this plate closer to the engine... So I cut a big lump of alloy from the bellhousing with a grinder and a hacksaw... This allowed me to move the plate closer and let the pinion fully engage with the ring gear... I tested the fit of the starter... The height was good but I wanted it to be perfectly parallel to the face of the flywheel so I really had to mill it. Luckily I was just able to squeeze the gearbox into a position on the mill that allowed me to face it perfectly... I must have some pretty honed hacksaw skills because I only needed to skim off about .75mm to get it flat. Sweet. Now I bolted the plate in place, then the starter and tested it... Oh I forgot to mention that once I had decided I was going to use a starter mounted in the original position I popped a hole through the adaptor plate in line with the starter pinion. This was to allow me to check the pinion mesh... I was super happy with the mesh so I marked the excess on the plate to be trimmed off and gave it a hair cut in the bandsaw... I also milled out the back of the plate where it just clashed with the rivets and pressings on the outer edge clutch pressure plate. Bolted it back in and welded it up, taking lots of care to avoid any chance of movement or warping. It went well.. Added some little filler plates to tie it in neatly and gave it a tickle with a flap disc... Bolted the starter back in, stood back and admired it all, really happy that one of the trickier jobs had been completed and that the starter was sitting in there very neatly and tucked away nicely, no higher than the top of the bellhousing... Next step was to make a cover for the 'front' of the engine, adding a connecting link between the oil filter outlet and the main oil way into the engine, a filling point for the sump, a dipstick and allocations for engine mounts to suit a cross member. Still lots of work to do but I'm getting closer...8 points

-

Note to Starion owners: there's only two more of these left in NZ...5 points

-

So... center console had no armrest. I'd really rather have one, I find it makes a car much more comfortable. I don't have a really good before picture, but this is the type of center console I had: Went through my parts and pulled out a grey center console which was from a later car. Had an arm rest and was all one piece. Tried it in the car and it didn't fit very well, possibly because it was from a car with an MT75 gearbox? Not sure. Regardless, the colour was off compared to the rest of the interior, twas a much bluer grey. So I had a look online and saw that there is an arm rest option for the split style console that was in the car. Couldn't find one locally so looked to the UK and found one advertised without the lid/armrest part. No problem, I have that part already, I can swap it over from the one I have right? Surely that part is the same, why would you make another one that looks the same? Saved me a boatload on the price too which was already more than ideal. After about a week of waiting, it arrived and I eagerly unpacked it and screwed on the lid I already had. It went smooth to this point, then I tried to close it. The latch was no where close to hitting the keeper, out by nearly 20mm. Not cool. Quick moment of despair, then resolved to making it work. What's 20mm? Managed to slide the arm rest back, remount the hinges into it and just get it to latch. Success! Now to get the handbrake to work with the concertina shroud thing which I new needed to be done. Cut a bunch of the existing plastic shrouding off the handbrake leaving just a small sleeve to cover the lever until it disappears into the console. A fresh new spot to lean. I think I'm out of level 4 things I can do to this. Need some freedoms so I can go get bits off the parts car. Near the top of the list are a set of Cossie Recaros in desperate need of recovering. Anyone got any suggestions for an auto upholstery places in Auckland? Keen to hear people's recommendations. That'll almost finish off the interior I think.5 points

-

Protip Ensure that your vehicle is up to wof standards before taking it in for a wof5 points

-

4 points

-

4 points

-

Still the daily driver with barely any issues! The auto trans is the main one still. Chucked the 3rd trans in after 2019 drag day. It's a bit slow changing from 2nd to 3rd and still seems to burn out if giving it some. Also has the same issue as before when you thrash it, it goes into limp mode so stays in 3rd. Bought a 300zx and ripped the 5 speed manual gearbox out of that to eventually throw in, just waiting for the Starlet to be back on the road. Drove it up to Beach hop 2020 and took out the best under 25 award! Dump of pics from the travels. Have been trying to do a bit of maintenance recently, fixing up some annoying things. At the start of the year the steering rack bushes basically disappeared, so I machined up some aluminium ones. They worked good but got sick of the vibrations at 100km/h, so put some poly bushes in. Next was the 4-link rose joints making knocking noises over every little bump. I had them on the chassis side of the 4-link bars and poly ones at the diff end, so swapped them around, and that quietened it down. The front tyres were down to the canvas on the inner edge, hoping most of that was just caused from the loose steering rack. Got some new tyres on and repainted the whitewalls. Made them a bit wider and more proportionate front and rear. The steering makes a horrible groaning at low speed turning occasionally too. Hopefully it's the bearing in the column, otherwise I have a new powersteering pump sitting there, but that's a front clip off job so that can wait until the manual swap.4 points

-

I have no recommendations, but my, what a lovely motor vehicle you have3 points

-

Have registered. will apply for leave this morning. Now to shall try get accommodation at said places unless people have empty beds or want someone to spoon with, can be big or small spoon to sweeten the deal.3 points

-

Picture less update... But had the dizzy and modules off to a sparky who is only 2 doors down from the shop, he checked it over and gave the all clear to 2 out of 3 modules.. Chucked the dizzy in with some eyeball timing, some crude wiring with jumper cables etc, tipped in some fuel.. A few cranks and it popped into life.. Had it pulsing away for about 30seconds before shutting it down. Then virtual high5 fist pump pat on the back dealio, then started going through the hunter wiring. Made a new dizzy loom. Ran the gauge wires to the sensors. Only need to connect an Acc power source to the coils, reroute the alt wires and make up a new starter cable. Have ordered the rest of my exhaust components and a driveshaft hoop. All gaskets for the water pump, carb manifold and exhaust. Need a ton of P clips for the fuel line so I can finish that side of it off.3 points

-

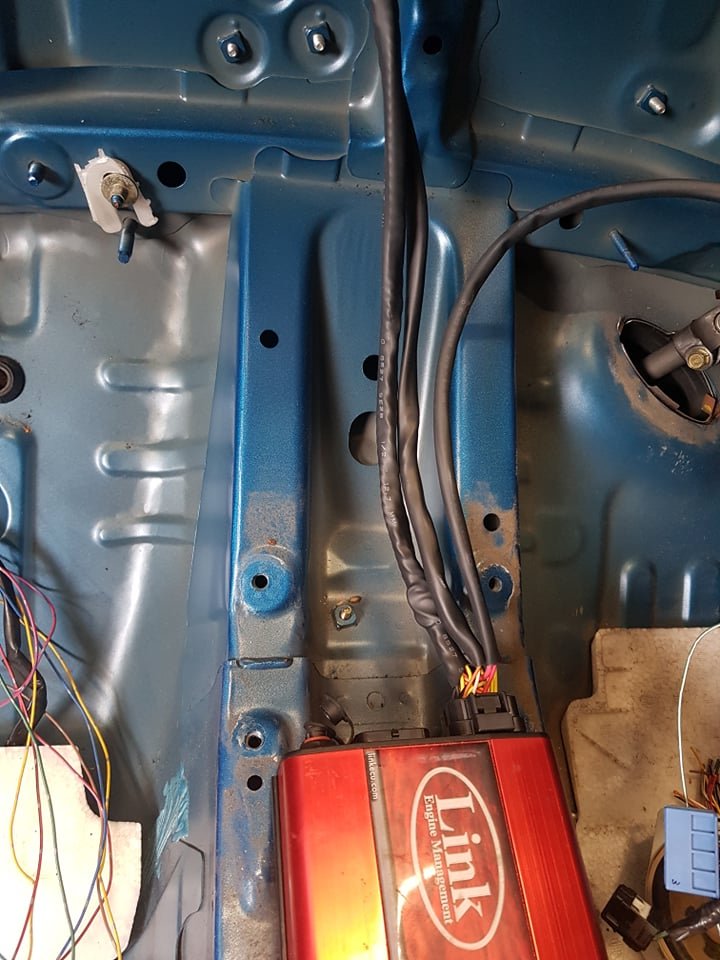

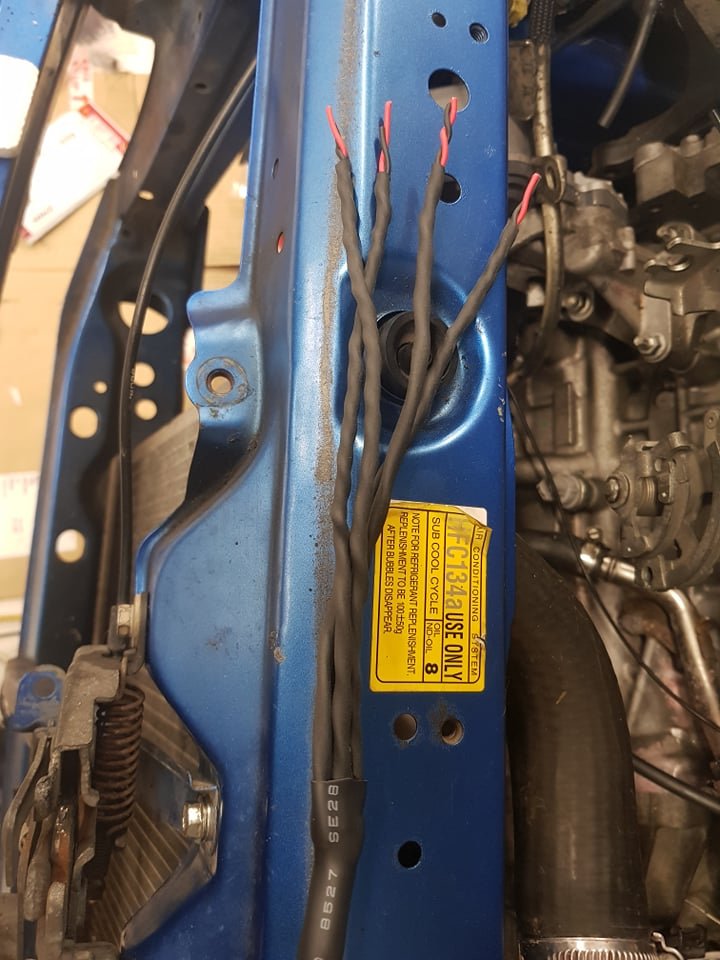

Still making progress on this thing. Have been a bit slack at taking detailed progress photos. Engine was dropped in a while ago. Radiator and overflow bottle finished up too. Fuel lines are done as well as the brake and clutch lines, they bleed up perfectly! Built the exhaust too. Went with a twin 2" stainless system and made the muffler as well. It's now fully welded and mounted properly. Swapped to the SSR MkII's Have put the original loom back in and hooked up most things again. Need to reroute the wiper motor plug, rewire the dash to suit the tacho cluster and redo all the wiring that runs through the front guards so it can be tucked away. Then I need to figure out how to wire up the engine with the Link ecu!3 points

-

And that’s my last day on it, back to reality next week. brother still has a wee list of holes to fill but she’s bloody close! Diff back in, wheels on and rollin! rear valence almost dialled Hard to scale but that’s a big pile of cast-off Chrysler3 points

-

Hi team, have a few things coming up in summer that would be cool to have this going for, just having a sudden burst of motivation to get it out of the shed. Looking for workshop recommendations, have been a bit hesitant in the past as I'm really looking for a place that won't crush my sills/leave car parts leaned up against it/leave head torches on top of the aircleaner that ding the bonnet when you shut it (true story). Needs a crack in the radiator welded up and a transmission leak located and repaired, had a big puddle of ATF under it when I wheeled it out last. Not necessarily looking for a super cheapy box-o-piss old-school-hookup backyard Barry bodgy bog over, happy to pay the money to do it right but yeah just the priority is getting it back without me having to look at old photos to work out if that ding was there when I dropped it off...thanks team.2 points

-

I have just realised that as I typed that I'm actually wearing an almost identical top and I've got my thick rimmed glasses on. Oh dear.2 points

-

2 points

-

Well those two posts cover 2019-present day fairly well. Car got a new WOF after the exhaust was done and then on the way home the diff center pin worked its way out again, i was about 2 blocks from a mates place so limped it there and came back with the trailer. Unfortunately this time it had contacted the pinion and taken some chunks out. I pulled the center out of the diff hoping that I could replace the crown wheel and pinion with better spares I had but unfortunately one of the thrust washers had come out and been chewed up so I decided to quit there and find a replacement that hadn't been messed with, ideally in a 3.9 ratio which would be less revvy at 100K, Fortunately a local guy noticed I had asked for a shipping price on a diff in Auckland, messaged me and said he had just pulled one out to install an LSD and we did a deal. Whacked a new pinion seal and diff gasket into it for good measure and into the car it went. Much nicer at 100k now and really didn't notice much of a drop in acceleration. In June we moved house, currently renting while we build and the Cortina made the 45 minute drive without a hitch although that damn vibration was coming back with a vengeance. The car now lives on a set of roller dollies and gets pushed over to the side of the garage without a door so getting it out it a little bit of effort but hasn't stopped a bit of progress. During some Level 4 boredom I had another crack at the diff and gearbox angles and made the vibration better but it was still apparent. I did some more research and found out the gearboxes have a bush in the rear housing that is prone to wearing out and causes vibrations of the driveshaft that increase with speed. This prompted me to go searching and I found Burton Power in the UK stocks them. Next thing I know my original noisy gearbox is in pieces, turns out to get the bushing out the entire gearset has to be taken out so I ended up ordering every bearing, seal, gasket and a new bush which arrived about 5 days later, some parts were fiddly but I managed to get the thing back together after paint stripping the casings and giving everything a really good clean. I had to wait for level 2 to be able to buy some paint to pretty it back up. I also found out while looking through the Haynes manual that the box is a GT unit with closer ratios just for a bit of cool factor. Spent most of this weekend swapping the rebuilt gearbox back in, had to modify the exhaust slightly as this box didn't require as bigger spacers to get the angles right (see above in the exhaust pic) and while I was under there I also tended to a little bit of surface rust and gave everything a good check over, Road tested last night and absolutely over the moon with my silent and smooth rebuilt gearbox. Feeling quite motivated to keep up the build now, I came on here this morning and read through my build thread and was cool to see old pics of what I had done so far and thought I would update. Next job I am going to tackle is the starter solenoid is playing up so I have sourced the correct style starter and ordered a new external solenoid to wire in. Hoping to do that over the next week or two ready for its next WOF at the end of the month ready for summer cruising.2 points

-

Built a ghetto sheet metal folder thingy on the end of my welding table 2 sections of grader blade from the scrap bin at work and some gate hinges from m10 +angle iron for handles+ random bolts and some old handles from my hoard - also has some cut spring from a fox 40 bicycle fork so it springs back up for loading and unloading Not bad radius on the bends may need to reinforce and tension the middle of the blades2 points

-

Couldn't help myself. Needed to ditch those heavy cast iron leak prone calipers and replace all the brake lines anyway. Splashed out a little more for the 6 pistons up front (even though they visually look like a 4 pot). I need to replace the rear leaf spring and sort out the play in the rear wheel bearings before I can swap them on.2 points

-

2 points

-

Always been intrigued by these pressed steel frame 2 strokes, and with the forum filled with small bike shinanigans decided I might try it for a laugh. Inspiration was always this S90 posted somewhere else here: @Yowzer's huge fire sale made me think of taking the plunge. Although the thought of getting a bike to the 03 from the Tron seemed near on impossible, he did point me at @ThePog who was holding a couple of bits bikes for him. So a deal was done and the Sierra was duly dispatched to drag the carcasses home.....to where it met with an appreciative audience who no doubt will end up being the owner. So here we are......I'm putting together an initial shopping list to at least get it going, namely both levers, throttle, starter and gear pedals, chain, rear sprocket, brake pads, engine cover, headlight etc.....all available and doable if Ali and EBay are to be believed. Probably wont have it ready for the Molesworth but one can dream. Oh, and this would be nice....1 point

-

you can buy generic type heater fan resistor units off old american type things then un solder the resistor coils off them and put them onto your OEM resistor mount. is super easy. i can give you a part number if you need it.1 point

-

Lockdown is good for small jobs Made the exhaust come out the side Then re made the mount because I fucked it up and it was too low Blast and painted the wipers and fixed the flaky paint on the mirror, couldnt pull them apart because the screws were loose and also siezed so ordered some smaller mirrors off rockauto Also being in lockdown means looking at things that would be nice to change so another rock auto order turned up today, thermostat, tail gate straps, new door handles, and some new headlights . The only thing I actually needed was one tailgate strap, ha.1 point

-

1 point

-

About 3 weeks till Taupo trackday I've nearly finished my loom, just need power wires to ECU and connect some stuff back in before I can power up and test things. I'm not going to win any awards on instagram for my wiring techniques however I'm getting better with practice. My branch lengths suck but some I can shorten up later. Learning some lessons for next time, anyway. It is considerably nicer looking on both sides of the firewall, anyway. Looks yuck at the plug end when you dont have a boot over it, but will be hidden and will get some strain relief by cable tying the loom further up. Also @Testament finished making me this absolutely friggen excellent alternator bracket on his CNC. This time everything is about twice the thickness so hopefully it lasts. It really does need to be beefy to prevent bending issues. I really underestimated it with the last one. Current issues are that I need a shorter throttle cable, to suit that I've flipped the throttles. These cars have a weird cable mounting arrangement at the firewall end. So older toyotas usually have a 2 bolt flange, mounted from drivers side. Vitz/Echo just clips into place from the motor side. Even same era 1ZZ cars have a bolt on flange. So a cable from an earlier car doesnt work, and later model cars moved to e-throttle. I bought an earlier corolla's cable that's the right length to see if I could make it work, but it wont. It looks like a cable from an SCP10 Vitz would perfect. But I cant get to Auckland to get one from pick a part. None in Tauranga. There are a few in Wellington, though. Is anyone heading to Wellington pick a part soonish and could pinch me a cable? Needs to be a throttle cable from an SPC10 with the 1.0 litre engine that looks like this I can make the current cable somewhat work but it wont be a good long term solution. However I really need to get this motor going and test that the gearbox is okay, and all that. Making good progress.1 point

-

1 point

-

1 point

-

1 point

-

Been a while since I've been able to muck around with minibikes. Lockdown presented a good opportunity to see if I could get my bike going again. The blue bike lost it's motor long ago, not sure why I removed it, although I recall it being pretty tired as most flatheads are these days. So I replaced it with another tired flathead of larger proportions, a 5HP. Slammed it together, did a skid, and jammed the chain between the rim & sprocket bringing my fun to an abrupt and smoky end. A good mate of mine is taking one of my original Tru Test rims and whipping up a hub, so I can run a 420 pitch smaller diameter sprocket for more go. Here is said bike = Got me thinking... ...it needs a friend Years ago I bought one of the roughest Tru-Tests around, a super rusty original, unmodified frame with custom stainless forks. Motivated to pull it out of the garden and do something with it. Seems a shame to have it sit when I could instead be riding it around. The bike in question = My plan is simple. I'm going to use cheap 4" wheels, and fit an equally patina'd motor into it. Probably won't take a great deal of abuse but if it moves under its own power that's good enough for me. Figure I'll use this thread for all my future updates on my little NZ made machines.1 point

-

Seat is all mounted with new brackets at the front, spent most of the day on the front wheel, I had to grind down all the spoke niplels and give the spoke holes in the rim a little grind as that rim is drilled for another hub, i highly recommend using the correctly drilled rim unless you want to waste time. When lockdown finishes i amm off to the brittish bike parts library where i can exchange stuff for more parts1 point

-

1 point

-

Mine and Clints party areas actually measure up the same. We compare regularly. Hes just got the ability to fit a few midgets in the back of cab. I'l slide into ya dm's with the dirty pics.1 point

-

I'm just gonna leave this here........ New intake day.. IDA for max brap. Found that all 3 of the ignition modules I have are duds... Great I found a xf Falcon one I had lying around from the stockcar, wired that up to the leading circuit.. Got sparkles on the leading plugs.. So will need to source a 2nd module now. So if any of you good folk happen to have any 4 pin ignition modules I would be keen to trade chats. And In other news for the red car, I have obtained a few parts for this build. Originally picked up a 1.6 zetec for it, however not being able to source a T9 box I have dissolved that idea in exchanged for a better set up.. Was originally planning on another 12a build, but flat peakers expect too much for junk parts, so I'll keep the mint housings as spares for the greeny. I will start a separate build thread for the red car I think as its taking a very different path than the green machine.1 point

-

Got a WOF back in July no problem which was a bit of a relief. After that it wasn't long until we were thrust back into lockdown again, which limits what can be done for the next little while. So time for some more low level interior upgrades. I'd already ordered a set of NOS car mats, so chuck them in, simple. Then I had a search through the garage to try to find a box of parts which had a Cosworth steering wheel in it. Managed to find it, gave the wheel a quick clean and put that on as well. Much better. Before: After: Then as mentioned, the front speakers needed to be swapped out for something less crap. Ordered them after lockdown had started, wouldn't have called them essential myself but I'm not complaining that they turned up a couple of days later. Gave me something to do between bike rides with the kids. Front speakers are in the dash, so a stupid amount of trim has to come off to get to them. But managed to get the old 4" speakers out then modified the mounting plates to accept the 4x6" replacements. This is with the first one done, second one was the same. These were essentially the largest size speaker that would fit in the space. This has made a good improvement to the sound but definitely need some rear speakers to fill in the sound. And bonus being I managed to get all the trim back on with no left over screws lol. So my car being pretty poverty spec, didn't have the rear tailgate mounted speakers. I pulled the trim panel off to see how I might go about routing the speaker wires only to find the boot had the speaker wiring in place. The wires disappear under the roof lining but they don't go all the way up to the dash, anyone got any idea how far they might go from there? Discussion thread:1 point

-

I put a cyclone separator on mine and it works quite well,you can buy them for under $40 locally. Mine feeds a vacuum cleaner with a variable speed controller so I can turn down the airflow when using super fine media. Pulled an old vacuum apart, stuck it in a ply box and fed it to an outside vent so there’s no fine dust in the shed which was fairly important as at one stage I was blasting some old bronze pieces and the dist from that it pretty nasty I've been told\ Bolted a tall round Systema container I stole from the kitchen (Shhh!) on the bottom of the cyclone so it’s easy to remove and clean out, the whole thing just hangs off the side of the cabinet as the input Port fits the dust outlet perfectly on the cabinet Have been toying with making a small vapor blaster with one of those 220l cabinets from topmaq1 point

-

1 point

-

The seats are immaculate in this car.. Its a shame to sell them and put race seats in it.. But oh well, skids If anyone is after a full set of matching seats, front and rear, door cards, door tops and under dash pad, I'll flick them up on trademe. Reclining High back super seats. Pic for you @cletus1 point

-

1 point

-

1 point

-

Another weekend, more rain and a sick daughter conspired to provide me with a few hours this afternoon to tinker away on a few minor things. First thing to go was the bulbous wind deflector on the drivers window, it was massive and didn't look right only being on one side of the car. Other thing that managed to sort was the radio, had an ancient Sanyo tape deck in it which had power but no sound from the speakers. Swapped in a spare mechless Sony unit I had in the garage and got sound coming out of the fronts. Apologies for the rubbish photo. Highlighted a few things; first the front speakers are horrible and need to be replaced and second, it really needs some rear speakers. One step at a time though.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

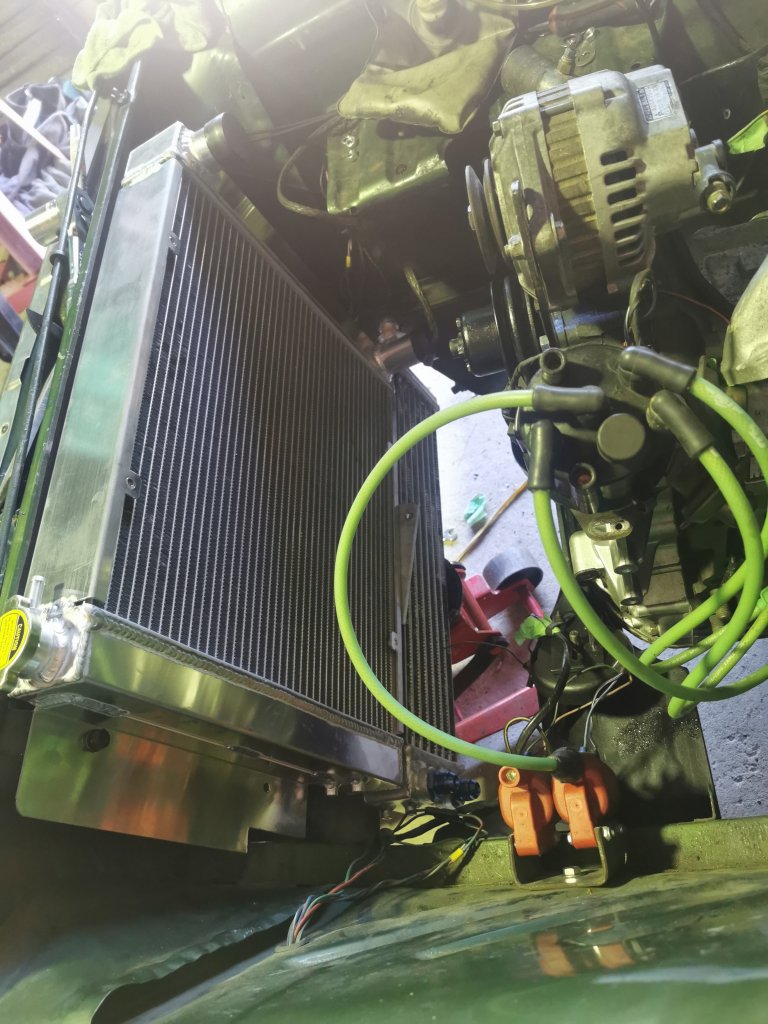

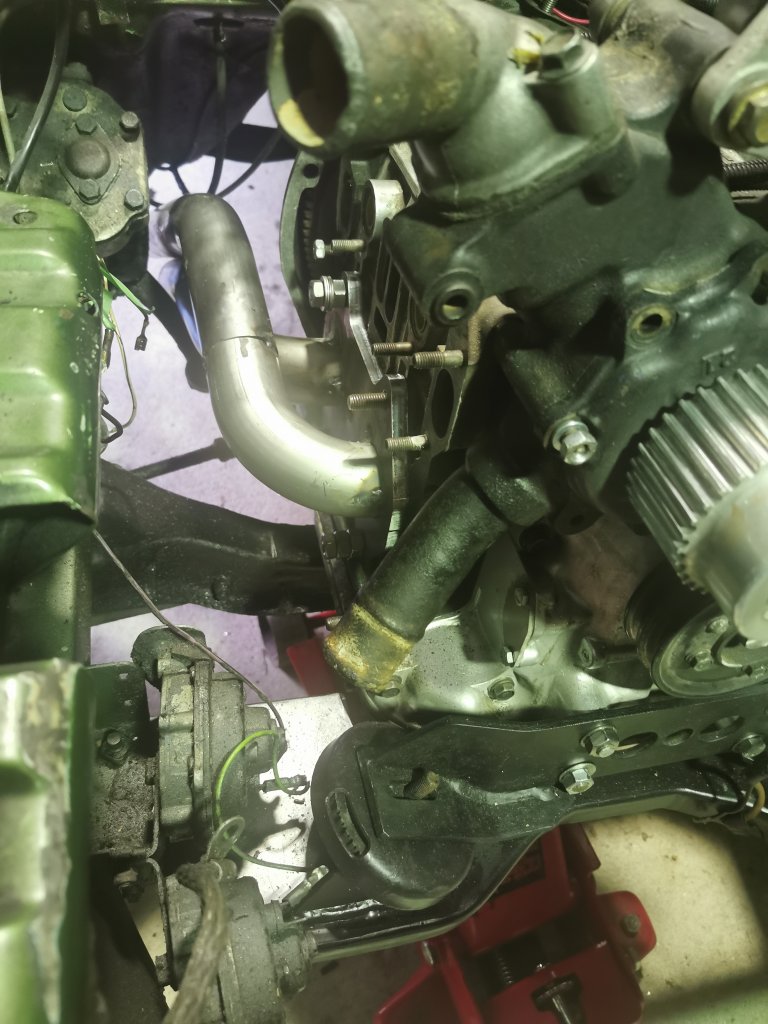

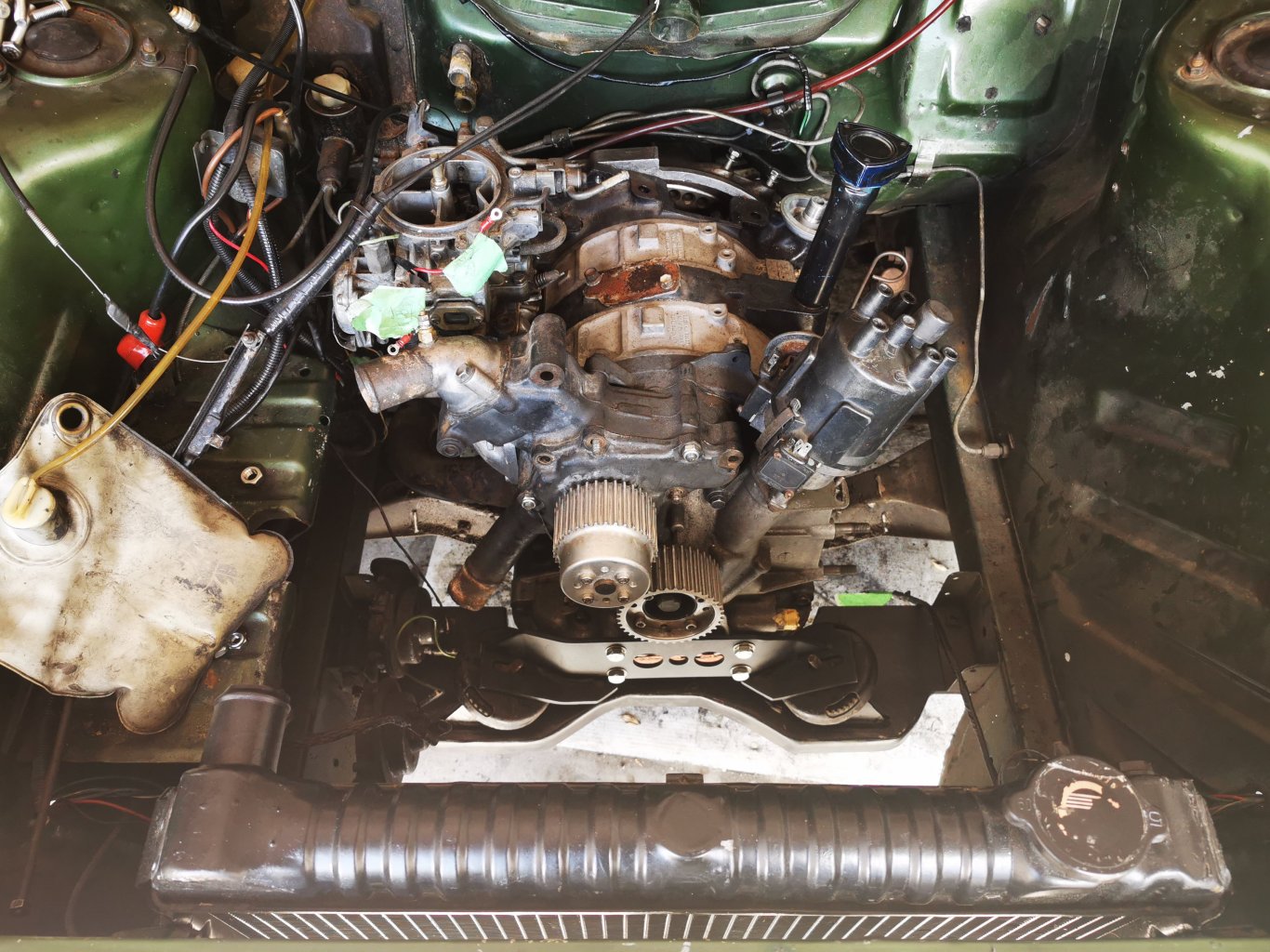

Page 4, shame... Haven't done much lately due to working on the stockcar to get that ready for opening night... Didnt happen cos the headgasket let go. So back on this today. Got the engine and box fully mounted. Headers bolted up, carb on. Stock accelerator cable will work. Wiring is all in the same locations. Radiator is bolted up to the hunter mounting points, oil cooler mounted. Just need shorter oil lines. Only fab work left is the new driveshaft, and slightly mod the headers to get it away from the steering box a bit more. Cut the shifter hole 50mm back.. Then pull the lot out to rebuild and clean it all up. Will run a howe/quartermaster release bearing to do away with the fork and slave.. Saves smashing the bulkhead for clearance. Tons of room in there for activities.1 point

-

1 point

-

Engine and box is mounted. Does need to come back out so I can chop off the factory mounts, thump in some clearance for the fork and slave 10mm if that. And remove the reverse switch. And believe it or not, the hunter gearbox mount bolts directly to the rx7 box. No mods at all on the gearbox crossmember or mount. Dafuq..??? Rx7 radiator practically bolts directly to the hunter bolt holes too. Just need to cut 100mm of the shifter hole out and spin it round.. Too easy. I would like to space the crossmember down 10mm to see if it gives enough clearance for the slave, and a slightly better yoke angle.1 point

-

1 point

-

It's happening. Engine will need to be stripped and rebuilt.. Its a 12a bridgeport. S1 5 speed for more than 100kph of fun. Would love to do a diff swap to something stronger but that's way too much $$ right now. Also plan to upgrade to escort calipers with the spacer kit and capri vented discs1 point

This leaderboard is set to Auckland/GMT+12:00