Leaderboard

Popular Content

Showing content with the highest reputation on 12/27/20 in Posts

-

Wife wanted a long dinning table bought a 2.4M slab of cherrry? Wood measure twice and it actually test fitted the first time! turns out it’s a bit long once we put it in the lounge..... so have cut shorter belt sanding for hours sucks, maybe 1/3 of the way there now (should of hired a floor sander) recycled some legs from scrap at work19 points

-

17 points

-

Merry Christmas everyone! I picked up my Christmas pressie on the 24th, after months of being at the paint shop. It has been painted Ford :"Ermine White" although it does appear more creamy than I think it probably should be. No matter, I am quite happy with the result, it has been many years, decades actually, since this van was one solid colour! https://oldschool.co.nz/index.php?/topic/45289-browndogs-1972-v8-transit/page/4/14 points

-

10 points

-

9 points

-

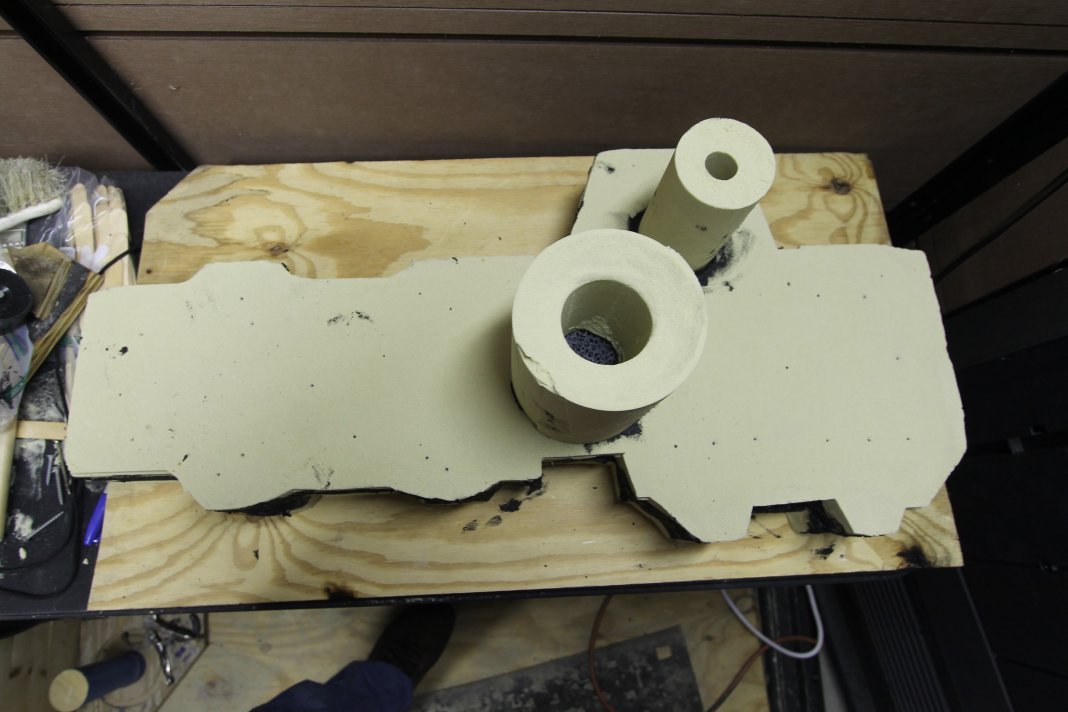

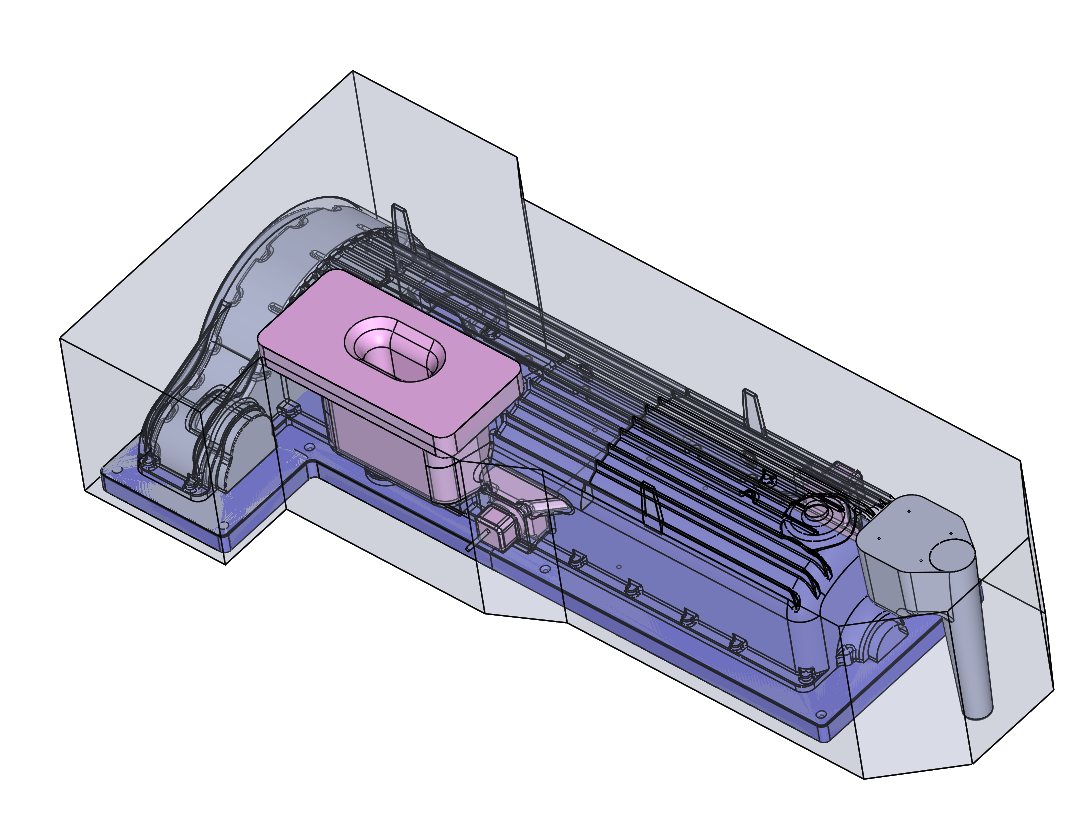

I was learning as I went, and some of the molding techniques that I use now are different, but you get the idea. At the time, I had not mastered gray iron, and so I was only able to make two flywheels in iron. The remaining parts are in 356 aluminum. These days, I can make any part in iron, no problem. Here is the finished engine that I cast. It is a 60% scale model of an engine I saw from 3 photos from the UK. 3D model was made using Solidworks. .9 points

-

Got the spare tyre well sorted. Working on making up a patch for the boot floor. Made a template out of some rebar and plywood, used my hydraulic press to form the steel. Came up fairly well. Next step was to bend up the edge, I used two bits of EA welded together to make the basic shape, then hammered using a bit of flat bar.8 points

-

7 points

-

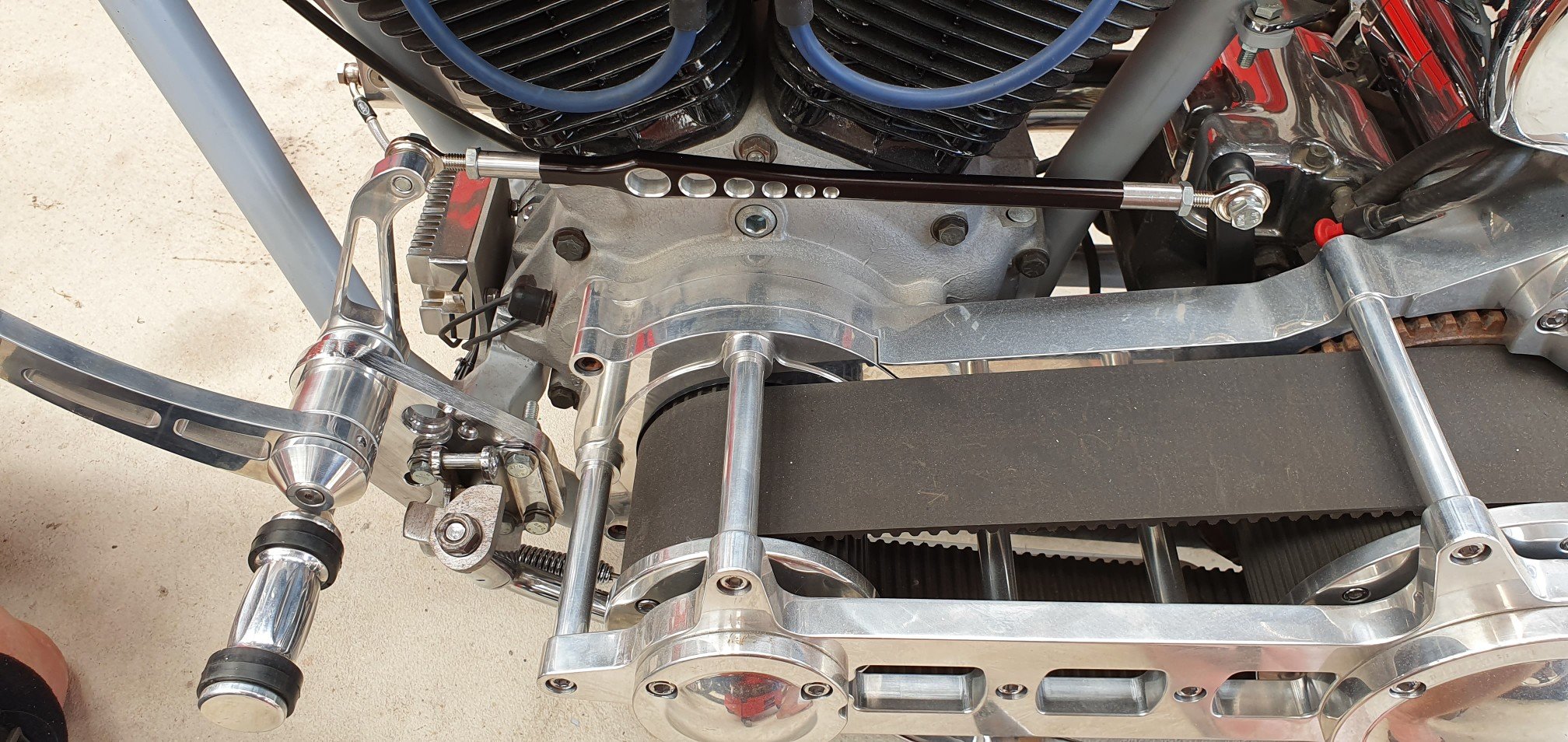

@Guypie has some concreting projects coming up so he made a concrete mixer. Works quite well. He also used the left over 3rd of a drum to make a fire pit that he sold on fb for $60. So the total cost of the concrete mixer came out as -$35. The only expense was the belt, everything else was stuff he already had lying around.7 points

-

I bought this for my daughter probably 5 years ago. When I was a kid I would have given anything to have a go kart so as any good parent does, I project my childhood dreams onto my own offspring The first time she drove it, I was pretty lax with the explanations, and she was 4. It's a 2 seater so my mrs sat on the other side. I'd backed the throttle right off but on grass with 2 on it, it was frying the clutch and wouldn't get moving so I had to give it more She started doing laps of the grass paddock but freaked out and forgot how to take her foot off the gas so she's going quite quickly, my mrs started freaking as well , kid starts screaming... I took a lunge at the spark plug lead but missed, luckily she hit a bump and her foot came off the gas Left it parked under the house until she was 6. Had another go, gave her a lot more training this time, and took her to an asphalt car park. She was going well until she turned too sharp and rolled it, her and the wife got a few scrapes and bruises. Parked it again, was going to sell it but daughter was still keen to have another go, she's 9 now and asked about it this morning so finally got around to fitting some smaller tyres to gear it down and make it less likely to fall over6 points

-

Have all the interior door handles back on. Modified the rods and clips from the Lexus doors. To join the Chevy Handle mechanisms to the Dakota Digital Bear Claw Latches. I had to modify/weld the lever on the Dakota Digital bear claw, so it would pull forward/Back, instead of Up/down. And had to cut the existing holes in the door a little bigger. They work beautiful and reliably so far. Latch smoothly. And have a good amount of movement in the handle, before they release the doors. Next up was the brackets for the rear bumper. Folded up a couple of 50x5mm steel brackets to bolt onto existing m12 holes. Couple more to make for the front of the bumper irons. Then all will be spot welded through the double skin beam in the floor, that the factory tow bar and hooks is mounted to.6 points

-

6 points

-

I had mixed success at the rubber place in town yesterday. Managed to get a pinch weld style rubber for my front doors so I was chuffed about that. Sadly they didn't have anything near as large as the 70mm rubber grommet that I need for my steering column. Hopped on fleabay when I got home and the only listing I could find for a 70 mm OD grommet was a crowd in China so I've resorted to ordering a few in. Thanks to Covid estimated delivery date is early March so I'll fabricate the plate in the mean time and will fit the grommet once it arrives. This morning I thought I'd make a start on the second portion of the steering bracket which is the part that the L300 angled steering box mounts up to. Did a bit of plywood aided design and successfully managed a test fit. With the Thames steering column mounted in its final position the L300 UJ that I had welded onto my Thames steering column runs nice and true. Tomorrow I'll replicate the plywood mock up in 6 mm steel plate and will then glue it to the existing part. Thanks for looking.5 points

-

So the new joints arrived this time but they were packaged incorrectly and for a different car. Because the theme for this project is buy things at least twice I ordered some more of the 'correct' ones and am now waiting for those to arrive. I was bumbling around in the garage and looked at it and thought 'I wonder if the spindles and brakes fit the other way around ' as the mount holes for the balljoints are angled. Swapped side to side, did a bump steer check , that got it down to 13mm, it had what appeared to be a shit ton of caster and the top ball joint was getting close to binding, so adjusted the top arm a bit and rechecked it, down to 5mm now with camber and caster in the ballpark Other people are having xmas parties, I'm in my garage quite excited at improving my steering and suspension geometry, what a nerd5 points

-

I'm pretty sure they were NZ made in the 90s. I used to race a kart when I was 13-15. Roundabout kart shop was where we got my kart and parts from and I vaguely remember seeing a brochure for these It has a 4hp 2 stroke briggs on it that has been turned from vertical to horizontal shaft , it has a carb and fuel tank from an iron horse mower by the looks of it I made the exhaust longer cause it used to just chooch straight up out of the muffler4 points

-

4 points

-

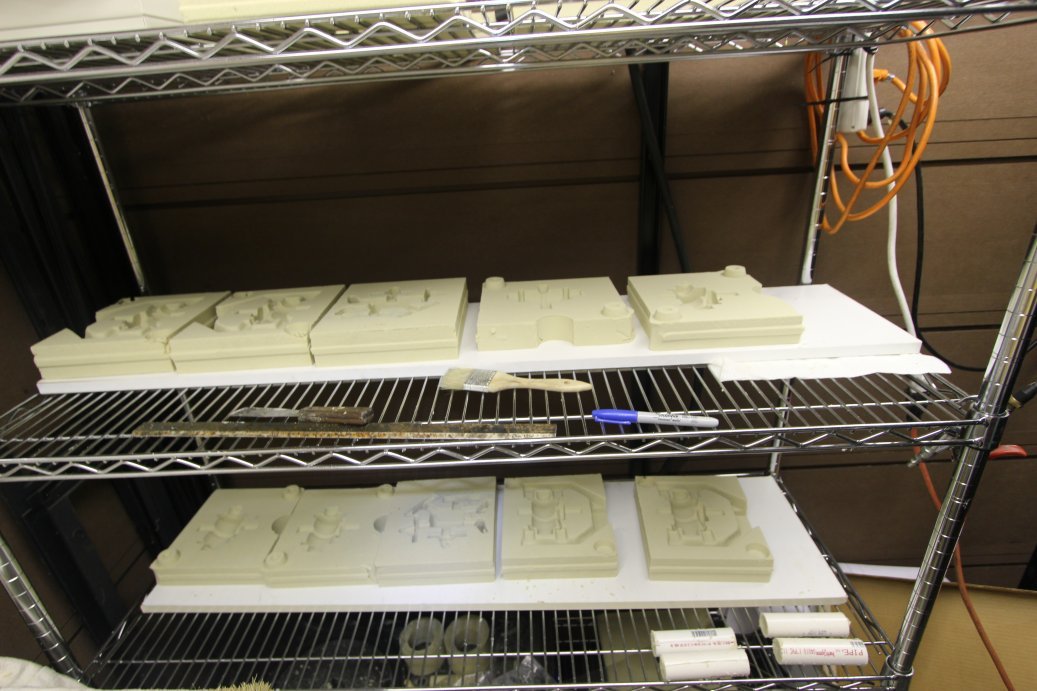

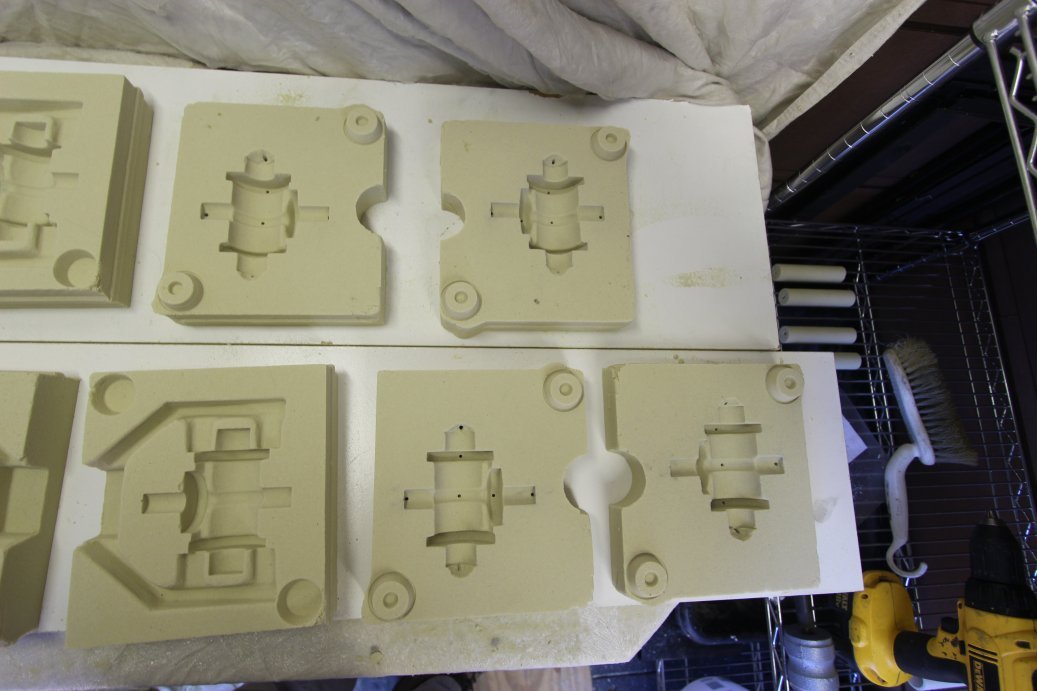

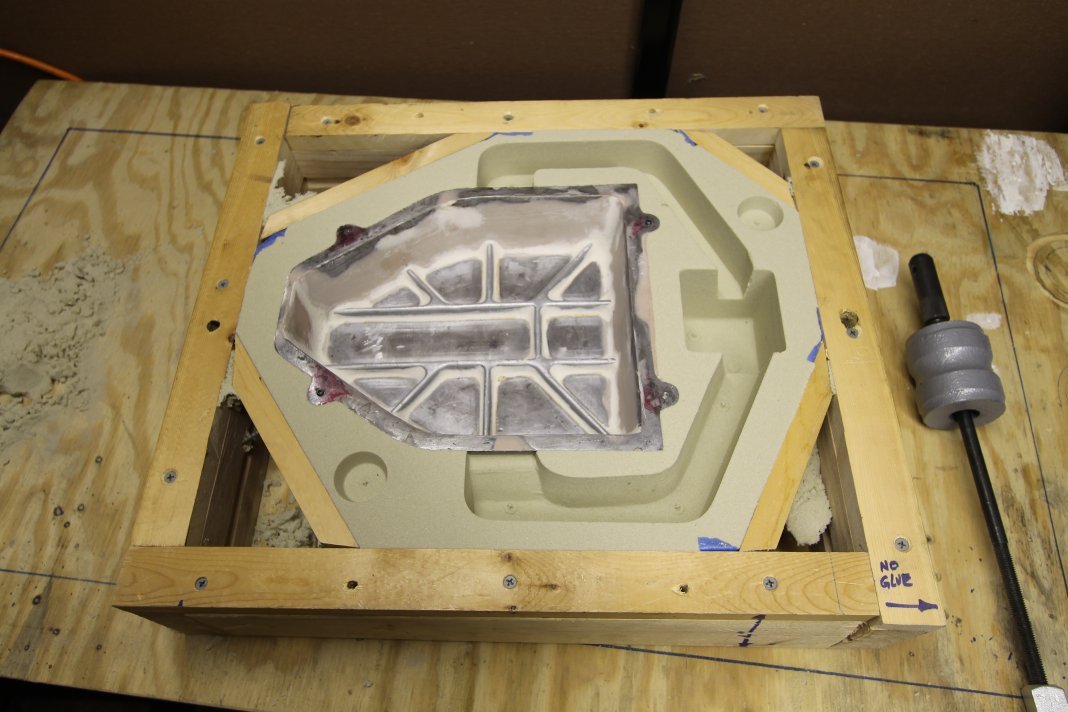

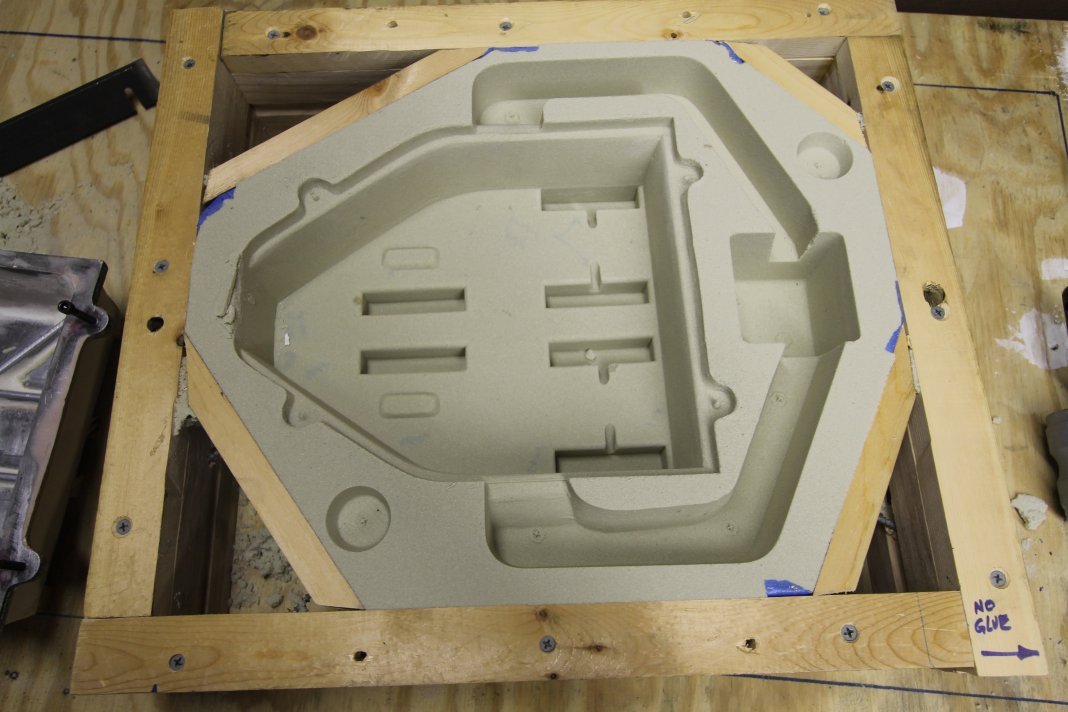

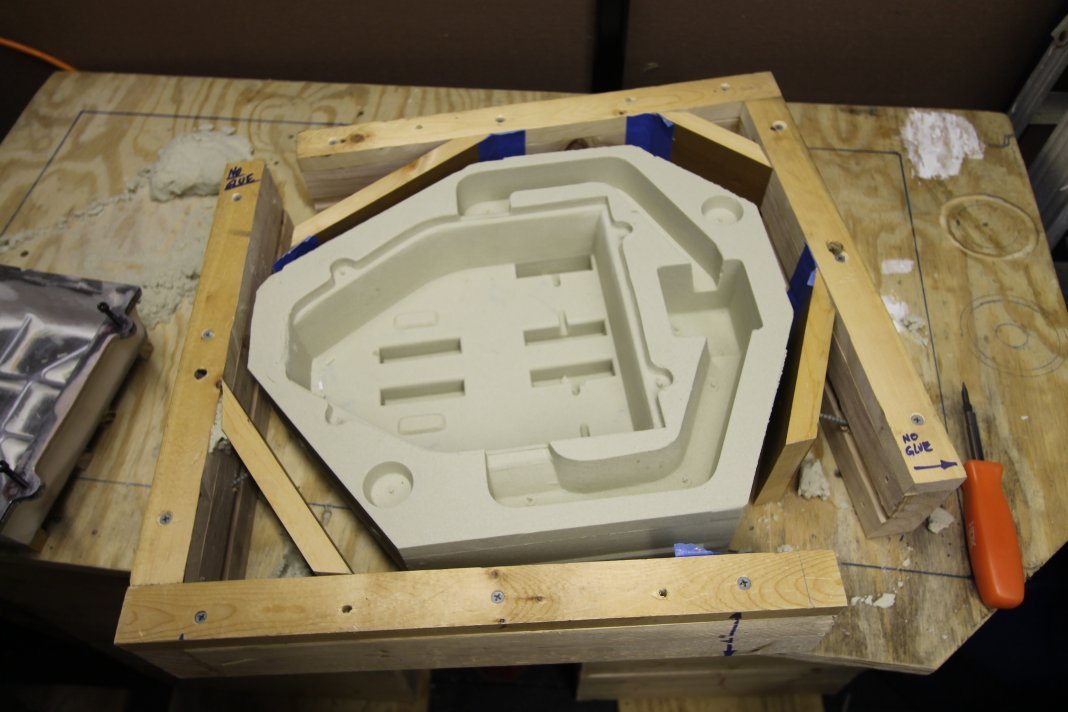

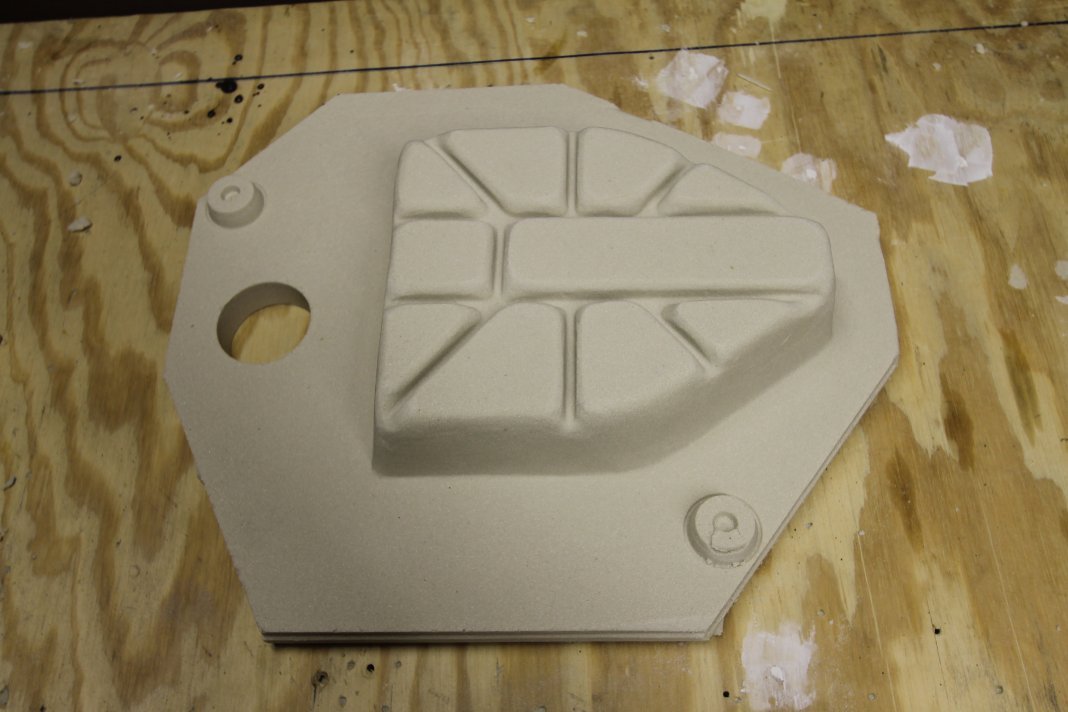

I glanced at your molds, and I would say you could probably reduce their weight by 1/2, but I don't think it would be worth the trouble. By the time you fooled around with filler blocks, and then perhaps had an irregular shaped mold, and risking one or more parts of the mold being too thin and blowing out, I think it would be wise to stay with the mold sizes you have. For me, if I blow out a mold, I can just recast the piece, and my molds are not nearly as complex as yours. I think you need extra mold strength to keep things intact during transport, and while being manhandled at the foundry. I have never had a mold fail, even with spots that are 1/2" thick, but my pours are generally 20-30 lbs of iron. I did have a mold separate once due to hydraulic pressure when I did not use enough weight on top. Below are a few molds I have made. The runner was too small on the long mold, and not all the parts filled. I typically use smaller flasks now with fewer parts in each mold. .4 points

-

While I was mucking around with the fuel system, I noticed that the sr20 fuel rail inlet line was bigger than the line coming from the tank, sure enough I had to upgrade it to 5/16 as silvia lines are, no idea why it worked fine before but I decided to at least upgrade the pump line, the return should be fine with less volume... I found an old rb25det fuel rail in my pile of hoardings from years ago, and cut the line off that. Flared the end and welded it in the appropriate location, and brought some r9 fuel injection hose from supercheap, to replace the puny hard line. The in-tank line will be r10 rated submersible hose. Dont mind my rough bending I had to make another one later on and it came out better as per last pic lol3 points

-

3 points

-

Exactly. This is what I keep a check on all the time. Im not doing sand casting because I want it to be a hobby. Im doing it because I need the parts.. So I dont like getting bogged down in stuff that isnt moving things forward. I do want to get good at it because I have a lot parts to do, so I do spend more time testing different approaches to pattern prep and runner systems by doing several castings. I can do 30-40kg of sand at a time so if I partition off the pattern I can work my way through it at home. Once Ive figured out how well the assembly goes together then Ill go to the foundry and fill the sand in one piece. This was todays job.3 points

-

3 points

-

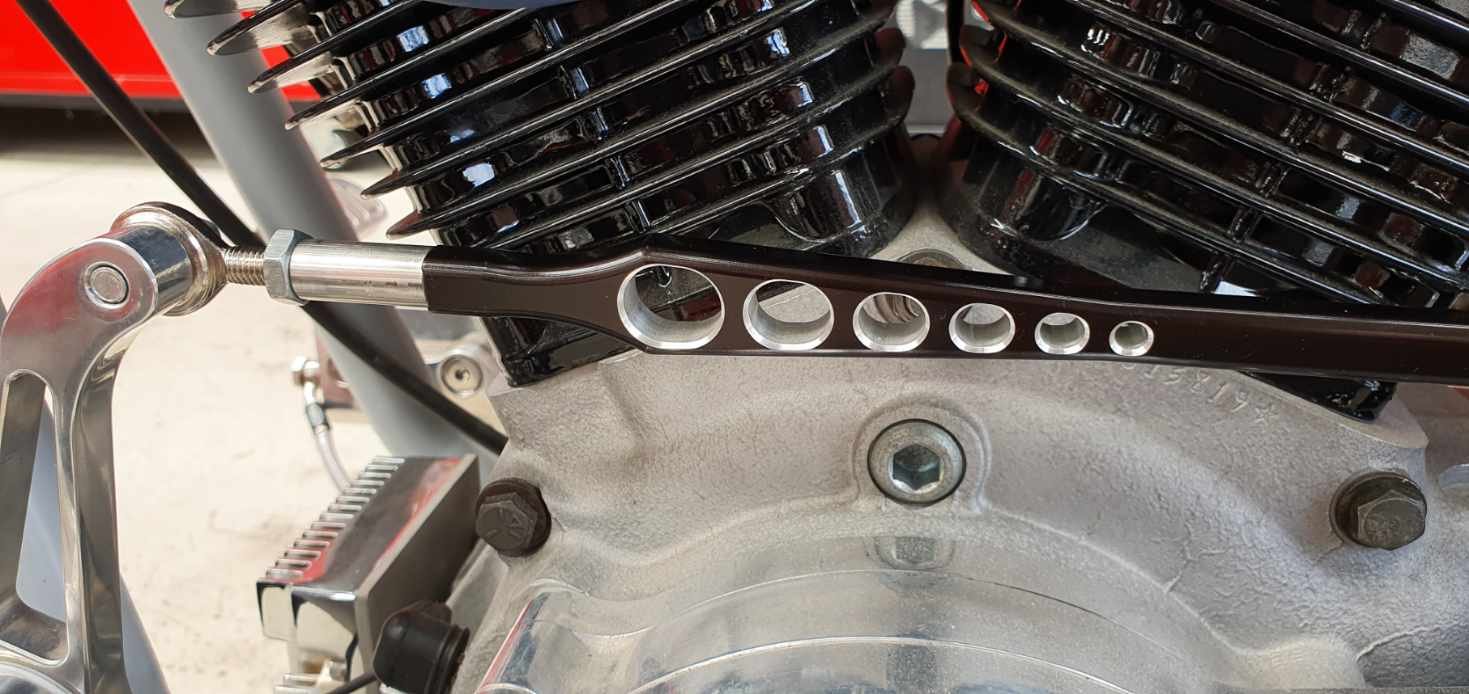

The shift linkage ended up on a less than perfect angle after shifting the centre point about 100mm. It worked, just...but was shit. So I machined up some stainless rod to extend the length, as hey let's be honest, a little more length is high on most guys wish list: I then tapped an M8 thread through it, and used about 30mm of M8 threaded rod to connect it to the existing linkage. This added ~60mm in length and i made the rest up by having the threads out a bit on the rod ends. Boom!! Now the linkage has near 1:1 give or take mechanical advantage, so about as positive as you could get in a set up like this. how does it work now? Perfectly...Fuck yeah!!3 points

-

i love me a good christmas car painting. i was looking at some of my other build threads and christmas is definitely the time i paint cars. dunno why? anywho, ive nearly finished the passengers side but i needed to get some paint on the drivers side so its got a couple of days to harden before i start sanding it. so today i applied some primer. also i figured out the blocking problem i've been having with my primer gun. turns out the pot vent was blocked. what a dick. 2020-12-24_05-22-20 by sheepers, on Flickr 2020-12-24_05-22-30 by sheepers, on Flickr3 points

-

2 points

-

Remembering how hard it was to remove the pedal assembly from the old van (an axe was used, amongst other things) I opted to splice the hydraulic clutch bracket and pedal into the new van, drilled out spot welds, cleaned it, tig welded in place with regular cooling. Then painted and assembled it all together, as good as factory I'd say, also found an interesting item behind the dash hahaha. it will join the other 10$ in change and Condom wrapper I've found so far2 points

-

2 points

-

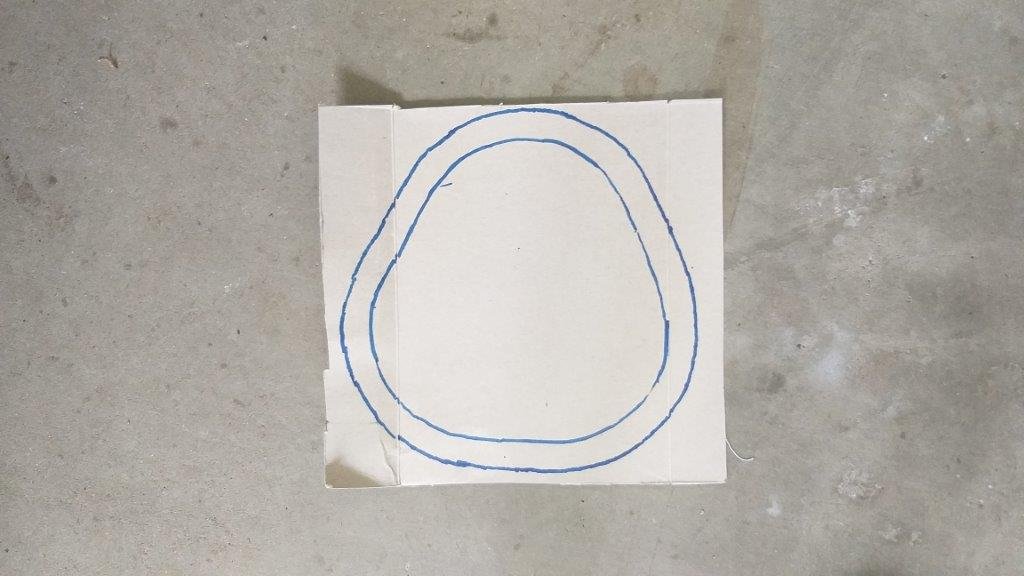

Merry Chrissy All from the team of one at Rough & Ready Restos. It being a special day I thought I'd treat myself to something other than cleaning crusty old Thames parts. Figured now would be as good a time as any to work out how I'm going to fabricate the floor plate that surrounds the steering and gear shift columns. My initial thinking is a solid plate with two holes cut out - one for the steering column and one for the gearshift column and then some rubber grommets to give me a weather seal. Started off with some basic cereal box aided design to get the rough shape of the plate. Next step was to figure out how big a hole I need in the plate to get the steering column foot through so cut a few rough holes in a bit of plywood. The magic number is 70 mm. The gearshift column is easier as it is just a straight rod. There isn't much room between the two columns so the outer grommet diameters will need to accommodate for that. My local rubber shop is having a Boxing Day sale tomorrow so I'll head along to get some pinch weld for my front doors and hopefully a few rubber grommets at the same time. Thanks for looking2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

Picked up the Mk1 from body shop yesterday, super happy with the result! Need to strip it down, and deliver to the paint shop next. Some old switch holes in the dash welded up, I will repaint the whole dash. Did a quick test fit of the NOS tail lights in the new rear D pillars. Couldn't resist the last pic, 8th gen Transit towing 1st gen, that must make the Mk1 its great great great great great grandad! https://oldschool.co.nz/index.php?/topic/45289-browndogs-1972-v8-transit/page/4/2 points

-

2 points

-

2 points

-

2 points

-

After getting my cushy posterior punished on Te Ureweras, i decided to look further into the suspension department. the rear has like 0 travel in those old shocks, might as well be hard tailed jim. So when a mudbug came up for wrecking on trademe, all i could think of was how cool this would look with those quintessential yellow springs on the rear. Took a punt and wanged them on. they are in average condition but what mudbug isnt? popped the standard suspension mount bushings out and swapped them into the mudbug shocks and was direct bolt on m9 country calendar theme plays2 points

-

Wow 250 for nos reflectors seems like a bargain now. Maybe inflation? Or I'm not as broke as I was?1 point

-

I think they are called continuous mixers. Looks like paddles on a shaft inside the tube. I think the paddles are tipped in carbide so they will last. And the used and even perhaps new continuous mixers online appear to be rather inexpensive at first glance, assuming shipping would be reasonable. Some of the mixers I see for sale are much less expensive than I could buy the parts for to make my own, and cheaper than a commercial kitchen mixer too. Not my photo.1 point

-

Awesome work! Moulds look great. I am definitely trying to reduce the sand in these big moulds because its going to be hard to pack and hard to handle. Should be able to save 100kg on the big mould. Good idea on removing the catalyst. I havnt considered that but it kind of makes sense. It would be awesome if it took a few hours to go off! Even if it took days! I use a mortar mixer and 10L buckets. It is a workout when youre doing a bunch of transferring to make sure everything is mixed and you only have 30mins to do the whole thing! Ive been considering a big cake mixer.1 point

-

I am really late to the party, but I have just recently run across this thread. I have been making resin-bound sand molds for small steam engines for the last 8 years, and the product I use is LINO-CUR by Ask Chemical. It is a 3-part system with resin, hardener, and catalyst, and it is very easy to come up with about any set time you desire. Varying the set time is very handy since the temperature around here varies quite a bit, which affects set time. I have been using my first batch of LINO-CUR for four years, and some of the hardener has crystalized, but it is easy enough to remove that. I pour the hardener into separate mason jars, to minimize the crystalization. The resin has never gone bad, nor has the catalyst, and I don't control the storage temperature for these material, so this is really a long shelf life for binder. I use OK85 commercial sand, which is a very dry fine round-grain sand. The art-iron folks use a lot of LINO-CUR, but it works very well with gray iron also, which is what I pour. https://www.ask-chemicals.com/fileadmin/user_upload/Download_page/foundry_products_brochures/US/No_Bake_USA.pdf And I spray on a layer of alcohol-based ceramic mold wash, and burn it off, and that gives a surface on the iron that is clean and shiny right out of the mod, and eliminates any post-casting cleanup. You have a fantastic thread going here, and it is spectacular on so many levels (3D modeling, pattern making, mold making, casting, etc). I started making my own iron castings in 2012, and have that process pretty much perfected at this point, and can make iron castings without defects. I was told that quality gray iron castings could not be made on a hobby level, but that is not true. Anyway, I noticed you having issues with set time, so I thought I would share this info with you. Great thread !!!! Keep up the great work. Pat J Edit: I am working on learning how to cast ductile iron, and hope to have that figured out early next year. This will be used to cast crankshafts.1 point

-

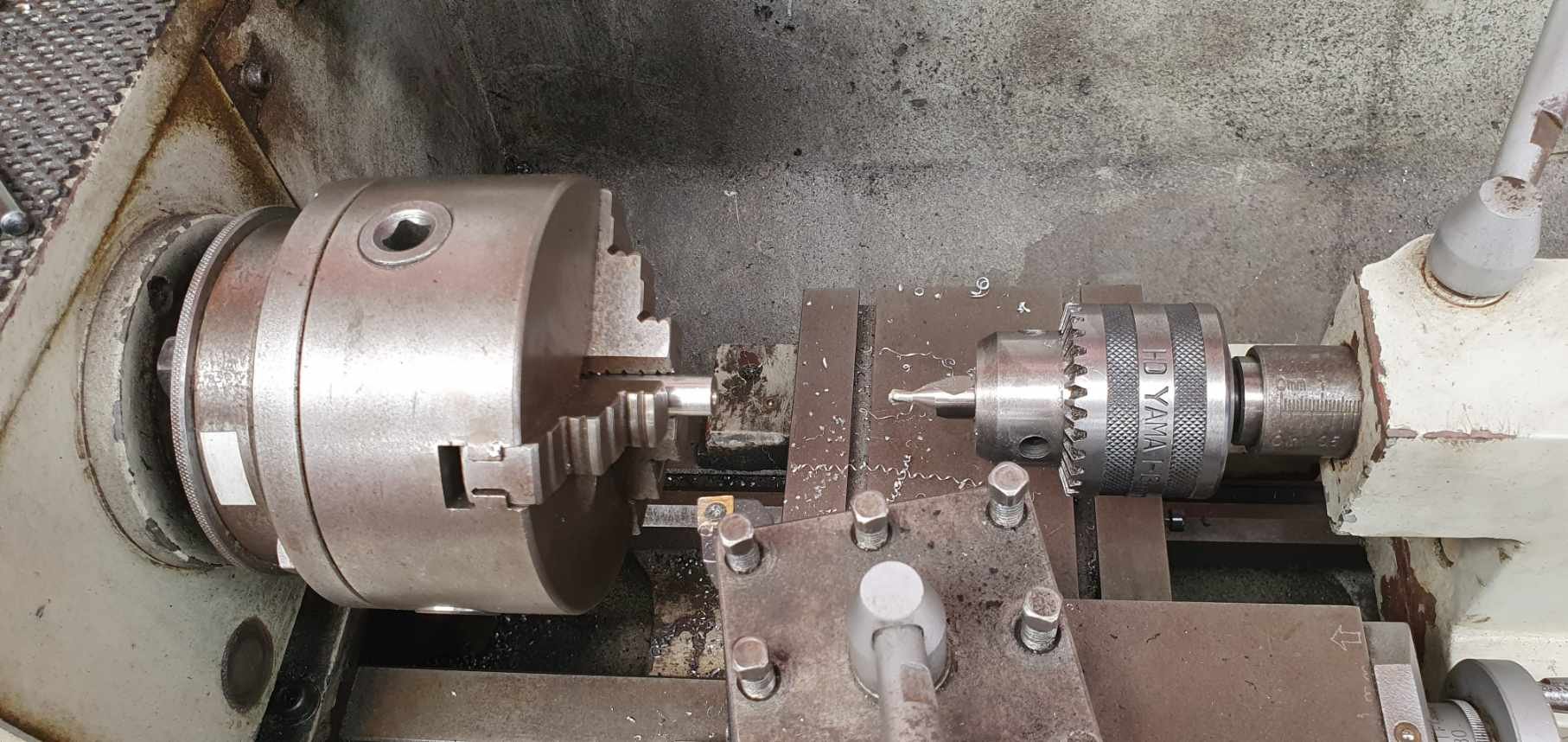

The next step was to machine in some traction grooves. I came up with a few ideas in my head along the lines of using a small router with a carbide end mill mounted to the linear rail. But after realizing that could be quite expensive if I kept burning out end mills, I came up with a rather crude yet effective method, albeit extremely slow. I mounted a chamfer tool 90 degrees on the compound slide and ran it along the face almost like a shaper would, but slower. This seemed to work pretty well on the first test cut, so I carried on with this method, and used the same carbide tip for all 475 grooves (much cheaper than carbide end mills) When I say slow... Each groove took 7 passes to get a decent depth and a decent looking cut. One pass taking around 4 minutes, times 7 for every groove, times 475 grooves = 13,300 minutes or 220 hours. I had done well over half before the lock down in April/March - I then spent 10-11 hours a day for the first 7 days of lock down finishing it off. I tried several times to speed the process up, but that was the sweet spot with this method unfortunately. It also took some time to figure out the best quality cut. (blunt tip worked best in the end) There are a few cuts with tearing along the edges, but over all I'm happy with the outcome - it should do the job at least.1 point

-

another quiet enough day at work to get some stazzin' done. paintstripped the donor door, not a single spot of bog to be found, she's honest as. very happy about that. ground off a little bit of surface rust and converted the dregs, then a coat of filler primer which came out pretty good considering the 20 knot crosswind. I will have to bog up a couple of shopping trolley dents but otherwise it's all on track the next thing to look at is the area around the wraparound rear spoiler - it'd been originally faired into the body with some substance which is absolutely fucking rock hard, and I think protruded a little too much too. I'm currently looking at not fairing the kit into the body - it makes removing anything down the line a shit as obviously everything cracks. So I'll have to chisel off all the shit that's on there to allow a really clean looking joint. thought about smoothing the spoiler in and leaving the skirts looking distinct but I'd rather keep it consistent, I dunno1 point

-

This shit takes fucking ages to do. There's no way I could afford to pay someone to do it. I made enough room to get at the engine mount bolt. Once the pipes are welded to the flange, I have to lift the engine slightly to get the flange over the studs because it hits the chassis rail. I'm aiming to be able to remove the engine with the exhaust attached. I don't even get a straight run through this gap. To keep clear of the universal, that pipe is rotated towards the block, then I can use ~25mm straight before a 14 degree bend. Then a bit more straight I think.1 point

-

Soooo, I kinda fucked my knee, as in big time fucked it. No, I wasn't riding a dirt bike, a harley, scooter, motorized mobility scooter, tall bike, drift trike, gokart...nope, not even a goped. I simply went to step up onto a deck and some shit broke inside my knee. Totally unspectacular, no cool "war stories" to tell... Now my biggest problem i was about to face is that I drink coffee like water. In fact some days I don't drink water other than what comes in my coffee or beer. So I was getting kind of desperate to solve this first world problem...but never fear, a solution was in hand, introducing the copyright pending "crup holder":1 point

-

Spent the last few Weekends making a new front lower cross member and Radiator support bracketry. Radiator is a 1954 Chevrolet style aluminium one. It is 2-3 inches further forward now, and now the bonnet doesn't quite close. Should be easy enough to fix with some light trimming. Fitting a transmission cooler and a large enough battery is going to be fun.1 point

-

1 point

-

Got the dash all finished off, pretty happy with how it looks now. Got a colour matched rattle can and a can of matte clear. Looks fairly close to the original. Found someone on facebook who had adapted a factory manifold to suit a weber 32/36 carb, similar to a geddes speed one. I think I'll give it a crack, I've got a couple of spare manifolds so doesn't really matter if I screw one up. Plan is to cut off the raised mount, make a new carb flange out of 10-12mm Al plate, get that welded on then have a go at matching with a die grinder.1 point

This leaderboard is set to Auckland/GMT+12:00