Leaderboard

Popular Content

Showing content with the highest reputation on 01/03/21 in all areas

-

Made some more progress today, gave it an eyed up wheel alignment, fitted up the new booster and master cylinder, repinned all the door hinges, refitted the cert plate and cut off the old exhaust ends. Also pulled out the pedal box to give that a small birthday while it was easy to get to it. Back on its own 4 wheels for the first time in 9 months.20 points

-

Seam sealed beneath and in the trunk. Undersealed over the seam sealer beneath. And while waiting for that to dry etc. I made a start on mounting the 50s chevy pickup wipers. Work well and much easier to purchase than the sedan's cable driven factory units. Then made a start on connecting them to the cut down lexus wiper motor. Is working Well. Even has an extra motor to park the wipers. Which should bring them to a rest on the windscreen rubbers very nicely. Will continue once Ulrich is back open again. So I can replace the wood. Today I reassembled the rear subframe and reinstalled.11 points

-

After 2 hours on the rotisserie and the internal temp to just over 60 I took it off, wrapped it and let it rest for about 20mins. Removed the string and cut it up and damn, not too bad. Juicy and tasty as, sticky on the outside. Made a quick sandwich for a snack and will be using it in noodles tonight. Probably freeze some of it for future ramen.10 points

-

Got the sump inner core pattern assembled and painted. Should be a lot easier to sand than the outer pattern! This gives a visual on what its making. The main inner core. A couple of smaller cores attach to it.9 points

-

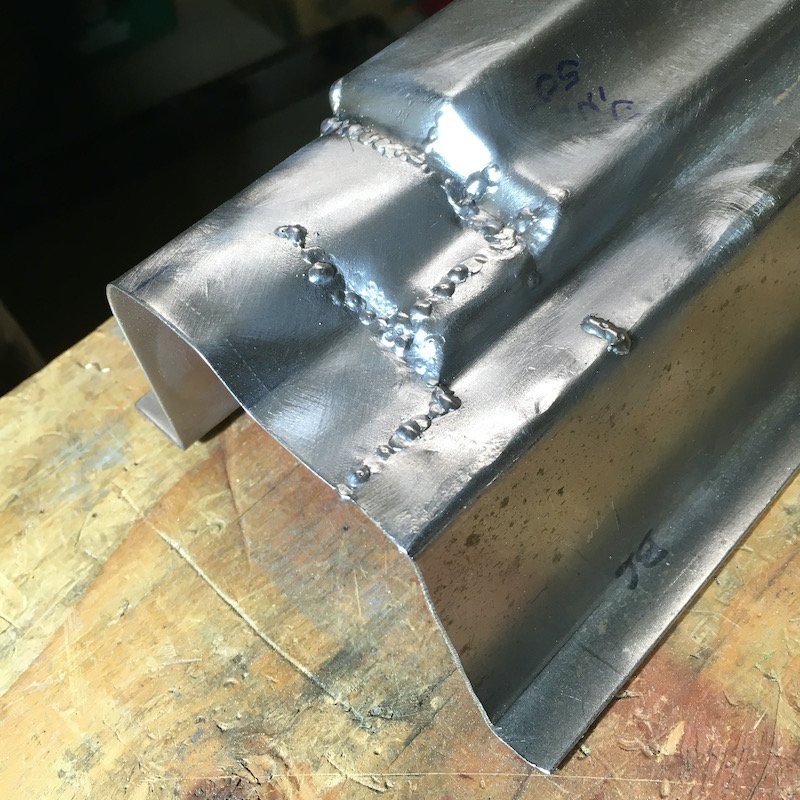

Building the 1961 Datsun 310 Bluebird - RHS Outer Sill Weld Together and Details. Time for an update reporting progress on the RHS build. Outer sill segments are welded together, including most details; end stub, end stub cap and inward joggle at B-post base. Lower A-post below the belt line and down to the sill (about 2 feet w/hinge mount points) is fabricated, tack welded together and temporarily fitted (mock up installed with Teks). The Inner body skin behind the A-post is repaired with another patch. The RHS front door hinges are rebuilt. Both RHS doors were dragged out of the backyard shed, temporarily installed and checked for fitment with the other repairs and all is well. The lower half B-post repairs are underway and nearly complete. Posting the outer sill progress/pics. Other stuff noted above to follow later. The three RHS outer sill segments welded together. Fully welded on both sides since outer is to be sanded flush. Trimmed and fit checked. Kept the weld heat under control by alternating tacks between the different joints and sides and it all came out exceptionally straight. It could have easily warped and created a nightmare. I don't recommend this approach but with a cheap 18 inch metal folder it was the only way to make it. Looks good enough now to proceed with the forward end stub. Next, making the RHS outer sill forward end stub. What follows is the detail required to allow the sill to have clearance with and tuck under the inner front fender support structure. I had no reliable original stub to copy from and just made my best guess to reverse engineer this new stub from the mutilated mess of the original as shown in the pics below. I got lucky and it does test fit snugly with the inner fender structure with just a millimeter or two of clearance. Then, after dressing the stub welds, I made a forward end cap to fit it based on best guesstimate. Stuck it together using a resistance spot welder from Harbor Freight. First time use where I may have been holding the dwell a bit too long. It's permanently stuck on at any rate. In preparing for future repairs and fitment work on the B-post, I made a cutout about mid-length down the outer sill to fit the base, same as on the original. Then filled it in with a custom small inward joggle piece that, though small, took several hours to build. Tacked it in and left it that way for now until the B-post is complete and fit is assured. Made several other minor joggles along the pinch weld flanges to accommodate overlap of bracket flanges and such. Not worthy of pics. That's it for this post on the RHS outer sill. As mentioned in the beginning of the post, hopefully more to follow soon. Discussion: https://oldschool.co.nz/index.php?/topic/60267-marts-pl310-61-datsun-bluebird-sedan/ Build: https://oldschool.co.nz/index.php?/topic/60264-marts-pl310-61-datsun-bluebird-sedan/7 points

-

So we did a few things in between family obligations. We replaced the oil and oil filter - well partner did, I remain an oil change virgin. Not too much mess, at least nothing a rag and some dirt won't clean up! We found top dead sexy and got the distributor installed - 50% chance it's right, gotta figure out if it's on the compression stroke but #1 cylinder is too hard to reach rn - we'll find a cork or something. We also dropped the dizzy nut and it entered a portal to another dimension. So now a windscreen wiper needs a new nut. We followed this guide and so have the timing 10 units before TDC. Pulled all the spark plugs to check them out, visual inspection seems good even if they're two different brands for some reason. Metal isn't bent, can't measure gap but it seems okay, no crazy build up of stuff, threads are dry (ignoring penetrating lube), except... ... #3 is cross threaded >.< It took most of my strength w/ a breaker bar to get out and required the use of the bar for almost the entire journey out. It's definitely the socket that is the main problem as other spark plugs struggled to go back in too. The socket itself looks like it has some crap in it - I got a pokey magnet in there and drew out a fairly substantial amount of shavings and dust from the threads, but... eek. Down the line we'll try a back tap and see if we can avoid removing the head. We're still lacking the dizzy cap (on its way) but we hooked all the bits back up and the battery and tried to turn it over just to see if that was all good - but nothing, just a click. Full charge on the battery with plenty of CC's tasting like these. The click doesn't seem to come from the starter but rather inside the car on the passenger side which is confusing, but the day was long so we called it there. To do: figure out exactly what's making the noise, also remove starter and see what it looks like / poke it with some electricity. ---- Bonus older gif: pop pop up and down headlights! The left hand horn likes to sound when the lights pop up. I'm guessing there's a short somewhere. The left light also is sliiightly slower to come up giving it a lazy eye effect. Features?7 points

-

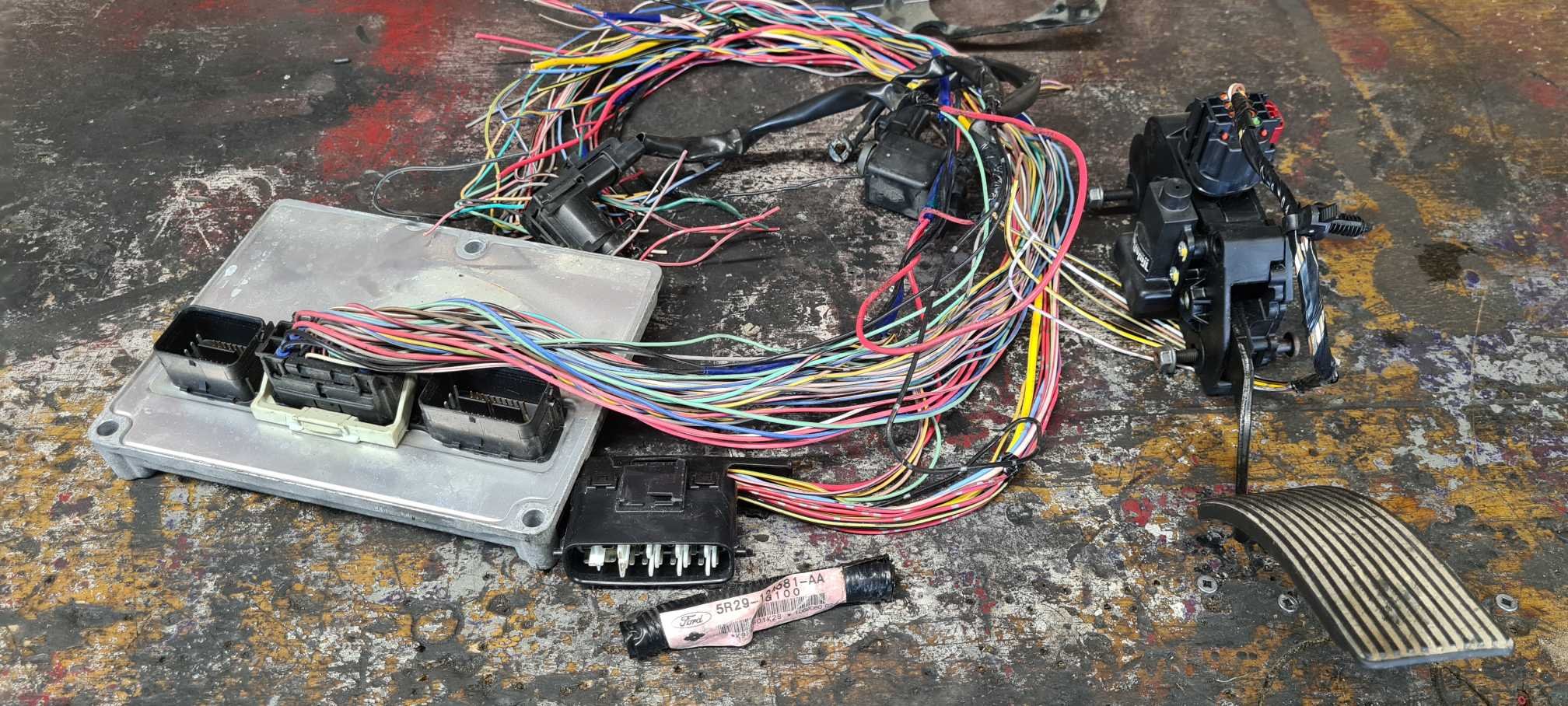

Pulled the engine out of the falcon and got all the turbo goodies bolted up, been setting up the ECU to take the Fg throttle and injectors and converting the tune file with HP tuners while on nightshift, should have the engine wiring finished off in the next day or 2. Getting rid of the falcon body soon so will get the wagon back on the hoist and look at getting the engine in and mounted6 points

-

We've got some mates coming around tonight so decided that we'll make some Soba noodles, and thought about doing some chashu pork on the rotisserie to break it in. Picked up about a kg worth of pork belly, had a crack at rolling and tying it up (one end had more meat than the other and I didn't want to trim it). I salted the meat and let it sit for about an hour. After I made a Japanese style marinade using soy (light and dark), mirin , sake, rice wine vinegar, sesame seeds, garlic and ginger. Let it marinade in that for about an hour and a half then setup the bbq. It's been on for about 45minutes since that last pic and tbh it probably doesn't need too much more. Will keep you guys posted shortly.5 points

-

Changed out the cluster to the one from the old van so I've gained a tach, 100,000 less kms and 20 km/h more top speed ..haha, mucked around with the wiring, I'm not so good at it but I guess simple 80s wirings not too bad... looks better nice labelling still managed to get a wire wrong though :/ blew up my alternator somewhere along the way, so I got a spare nissan skyline one and swapped the center out to the silvia housing (housings are different)4 points

-

4 points

-

Today I made a start on tidying up some of the loose engine parts. De-greased the tappet cover and sump and then took to them with a wire wheel. Chucked a few coats of satin black engine enamel on the tappet cover and it came up mint. The indentations on the sump need a bit more work before its ready for paint so I'll carry on with that tomorrow.4 points

-

4 points

-

4 points

-

3 points

-

Waiting on a couple of seals and a number plate light, but this is about ready to get inspected3 points

-

I mounted that expansion tank somewhere convenient. Went for a drive and all seems to be behaving. I also made some racks to carry long things, did the rear a few days ago and sorted the front out today. I'll get those zinc arc sprayed I imagine; Might make the rear clamp on rather than ratcheted, you have to properly crank it up to prevent it from rocking a little....3 points

-

So yeah, after googling what wear rings are supposed to look like, and frowning at the pump from the donor banana ski, yesterday I removed the pump from GreenWaste and had a look. Two pumps on the floor, pretty much identical. IMG_20201231_102856_1 by John Bell, on Flickr I believe this is what a bad condition wear ring looks like, from the donor ski. Cracks and grooves, not toight. IMG_20201231_113413 by John Bell, on Flickr And this is what the Greenboat had in it, note the missing material around most of the diameter. Lots of clearance. IMG_20201231_113456 by John Bell, on Flickr So I figured bad was better than worse than bad, so gooped it up and bolted it back on. IMG_20201231_121347 by John Bell, on Flickr Sploot. IMG_20201231_133309_1 by John Bell, on Flickr Launched it into the harbour this morning and pootled about with VG and Keltik, it still doesn't feel 100%, but its pretty usable now and hooks up and pisses off quick enough for me. I will likely order some bits and pieces to tidy up the original pump and probably swap it back in the winter perhaps. IMG_20210101_104035_1 by John Bell, on Flickr I'm waiting for a China GPS speedo, and need to fit a hour meter/tacho, fit some latches to the hood, attach the paddles in a better way, and I think that'll do for now. What a novelty having a working toy3 points

-

Well after staring at this in the workshop for the last 3 months while we've been massively busy at work and I've been caught up on the weekends entertaining my son I finally managed to get a couple of days to spend on this so I managed to mount my seats and get my tunnel fab'd up. I had to change my plan for the seats as my original design ended up too low and too far back surprisingly. Also the cert man wasn't happy with me removing the stiffer running the width of the car. So, I went back to the drawing board and came with this Then I made up a cardboard gearbox tunnel. And decided I better turn it into steel Happy to have those big jobs ticked off. I do still have to pull the engine and box to weld underneath but the hard work is done for the tunnel fabrication which is great3 points

-

today went better. i got the little bit of surface rust of the inside of the scuttle panel and chucked some brunnox on it. poured some brunnox inside the fuel filler flap and then chucked some primer on things. yesterday i primed the car again so only the drivers side needs another coat, the rest of the car is ready for wet sanding. yay, wet sanding. 2020-12-30_02-33-07 by sheepers, on Flickr 2020-12-30_02-32-59 by sheepers, on Flickr 2020-12-30_02-32-45 by sheepers, on Flickr 2020-12-30_02-32-52 by sheepers, on Flickr before priming, 2020-12-30_02-33-43 by sheepers, on Flickr 2020-12-30_02-33-36 by sheepers, on Flickr after priming, 2020-12-30_02-33-29 by sheepers, on Flickr 2020-12-30_02-33-22 by sheepers, on Flickr3 points

-

Since I can only safely mix 30kg of sand at once Ive made some partitions over the pattern for 30kg sections. Will do some sequence of removing walls and work along the pattern. Probably key the sand together as I go so hopefully it doesnt shift around. The base is an overly complicated 30mm spacer that the inner cores align to. Could have done it out of wood but when you have a big printer why not! Once Ive figured out if the pattern works I will be able to fill it at the foundry in one go without partitions.3 points

-

Time to chuck up a post about my latest project since iv just started pulling apart the donor car, starting with 1 VR commodore wagon the old 3.8s rod came knocking and put a window in the block. Iv stripped the interior of that, to make way for a 6 point sfi cage and rear tubs to the rails to accommodate wider rubber and a parallel 4 link 9", to be commenced early/mid 2021, Now the fun part the bf falcon some of you may know from such shenanigans as palmy/fielding 2020 swapmeet is giving up its engine for the repower to be backed up by a th400, now let's see what the stocker na can do with an FG xr6 gt3576 strapped to the side of it. Already got some goodies a powertune digi dash to run off the factory ford pcm and eventually the link g4 when it goes full send, also picked up an e boost2 to keep the boost pixies under control. Plan is to make it fully street legal and be able to swap wheels and tyres and go full send on the drag strip/power cruise and chrome.2 points

-

Get us one of these please love - this ones fucked. Previous owner has indeed filled the seal lubrication hole with silicone. Everything has also been reassembled less the electrical insulation stuff so the front bearing was pretty loose in the outer housing - had not been loctited into place as they recommend. Might need to get someone talented on a lathe to spin up a new spacer. This ones got a pretty decent groove in it from the oil seal and the front edge is also chooched so i cant just turn it round. I really hope its not part of the shaft! I guess I'll find out soon enough once I get a suitable sized puller to go in there.2 points

-

^ I remember how amazing yet horrible that was. said dumb shit, complete with youtube clickbait. if tldw. it almost gained 1kw. so success ? just need one of these2 points

-

GPS plotted a path of some of our journey yesterday. Stupid tide running away from us though, there only seems to be a couple hour window where you have useable water depth. boat journey 2-1-21 by John Bell, on Flickr2 points

-

Yip, thats how I was feeling as I figured out that a lot the wires are spliced and share common power/earths etc. But by testing the resistance (ohms) through each circuit using a multimeter, i got there in the end. Pretty common shit I guess...but for an electrically retarded person like myself, self teaching as I go along, its a lot of condensed learning to fit into my already closed mind. That said, I'm there now. Each wire labeled and each corresponding circuit tested and working via its switch. so I'm now ready to buy expensive tools to strip and crimp the wires and then try installing OEM style connectors, yet another thing I've never done...but will soon have to figure out quick smart If I want it to work.2 points

-

2 points

-

2 points

-

2 points

-

Got the body in primer about 6 weeks ago It then took me all that time to get it up to a reasonable state so that it could then be painted. So then a couple days a go we loaded it up on the trailer (only just fit!) and dragged it into the spray booth at work. Sprayed the base and clearcoat on, it turned out pretty good! A few runs around in places, but nothing that can't be fixed. Pretty stocked really! Could of easily gone wrong haha. Gonna leave it in the booth for a few more days to harden, then take it home and get some underseal on the underside. In the meantime get the rest of the panels ready for some paint too.2 points

-

Burn off the other night went well. Got it to 500f and it held there for atleast 3 hours without adding any extra fuel. Left it going when I went to bed. Had a look in the morning and it looked like this... Emptied out the ash and gave it a good clean to prep it for seasoning and paint. Just used olive oil on the inside as that's all I had and Mangawhai shops are shit to go to this time of the year cause of all the jafas and northern bass homies.2 points

-

So yeah, as seen above, took it back to the water yesterday and it does run a lot better when its not breathing its own fart cloud. Picture of failed engine mount and V band that needed toightening. IMG_20201228_170634 by John Bell, on Flickr I'm not completely happy with its performance though now its making full more power, it doesn't 'bite' the water like I would expect, if you feed it more power than it can shift water, it nangs out and feels slower than if you were to nurse it up to speed. You can see/hear this in one of the vids. It handles a quite loosely, but I don't have much reference to compare it to, aside from the donor ski which carved corners like a water-skiing cut cat, comparatively. If you do manoeuvres that are too aggressive or any spins it comes off the plane pretty easily and doesn't pop out of the water like the motor seems capable. So next step is to look at the spare jetunit, if its any better pop it on for testing, and I feel I'll probably wind up giving one of the pumps a birthday. Cute IMG_20201228_182945 by John Bell, on Flickr2 points

-

Cut up some thicccc expanded mesh(this shit is about 10x6mm thick and expensive as shit. We use it for guarding heavy machinery, luckily we had some left over for the coal rack and also for the grille. And here's the upper vent mocked up. These are called butterfly vents and are used for marine purposes. Took me bloody ages to find something like this2 points

-

Bushes replaced and the Valiant drives nicely again. One of my boys finished year 8 schooling, they have a formal and parents etc are invited to drop their kids off at in front of the school hall pre formal. The valiant beached quite loudly as I was turning onto the field which my son thought was fantastic. Good boy! He was very keen on some school field paddock work. I exercised the utmost restraint and no circles were done. Here's a pic of some previous grass silliness. I put the Superlites on for the school run. Then decided I didn't like them and took them off the next day. I'd quite like a set of these modernized Cheviot Quattro's but the budget won't stretch that far at the moment. anyway that's enough sharnes. I have done some productive stuff too. I got my big fuel tank re tested, blasted and painted. It's slightly larger in diameter and considerably longer than the old one. My calculations suggest it will hold about 20 Liters more fuel than previous which equates to about %30 more. Luckily I managed to fit it into the old tank straps which was a bonus and saved much fucking about. Old. New. I Need to sort out some new ducting as the tank has is designed for 60mm as opposed to 2 inch as before and I'll be ready to run. This tank has a little magnetic gauge sender unit that is miles different resistances to what the factory sender had. It looks fairly simple and I'd like to see about getting it changed so I can use my factory gauge. Has any one in ChCh delt with E Parrot and Sons since it has changed hands? Are Robinson instruments still around? Suggestions please.2 points

-

2 points

-

I'm pleased to announce this boat has successfully completed stringent reliability and performance trials including but not limited to... Shallow water performance Low speed maneuverability Higher speed spins and dicking around2 points

-

Finished up the bumper mounting brackets. 5x large plug welds down through the floor skins into them. Outer edge also has a strap on each side, which it is also plug welded through. Also filled the last of the holes in the sills. Have now painted a chassis black primer underneath, anywhere underseal did not exist. Seam sealer tomorrow. Then spray on underseal.2 points

-

Have all the interior door handles back on. Modified the rods and clips from the Lexus doors. To join the Chevy Handle mechanisms to the Dakota Digital Bear Claw Latches. I had to modify/weld the lever on the Dakota Digital bear claw, so it would pull forward/Back, instead of Up/down. And had to cut the existing holes in the door a little bigger. They work beautiful and reliably so far. Latch smoothly. And have a good amount of movement in the handle, before they release the doors. Next up was the brackets for the rear bumper. Folded up a couple of 50x5mm steel brackets to bolt onto existing m12 holes. Couple more to make for the front of the bumper irons. Then all will be spot welded through the double skin beam in the floor, that the factory tow bar and hooks is mounted to.2 points

-

Ok so I'm going camping with some mates in a few days and had been planning on making a small smoker for a while so decided, fuck it lets get this done! I have a very short timeline to build this as I've been up north at Mangawhai for Xmas then back home for a day to build this then back up north for new years before heading to hot water beach. So basically I had 1 day to get the bulk of it sorted. I started off with sourcing a cooking chamber. I managed to procure a truck air tank for free about a month ago so that was sorted. First things first, remove all the unnecessary fittings.1 point

-

1 point

-

Doing the practical thing and hiding my wiring, so if there's a problem its impossible to get to it...oh, fuck...yeah...ummm...why do we do this again??? I googled and googled and the general consensus was that upto 1/2" (12.5mm) hole is fine, people have been doing that for years without any issues. I decided that 3/8" (10mm) was enough to get the job done and would leave a little bit more meat on the bone, so thats what I did. Offset slot to the left. Everything is going to run down the clutch cable once done. I spent ages sanding everything down so there's no sharp edges to cut the wires. Now I've just gotta heat wrap this mess and shove it down the inside of the bars. Oh and the other side has double this amount!! Ummm... for want of a better phrase this was my "first pull". Hey, sounds better than "tug"?? Boom, both side done. New loom pops out right by clutch cable, I'll cable tie it together and run it down to my new wiring under the transmission. So that's a good start on something I've been very much procrastinating. Winner, winner...chicken dinner!!1 point

-

My Mrs gave me a hand with the prep and paint. Cleaned with soapy water then a few wipe downs with acetone. After that we brushed on a few coats of pot belly black, decided to go with the stuff from the tin as previous spray can efforts turned to shit and flake off easy. 3 coats later and it looks like this. Disregard the handle, it is just makeshift for now so we can take the lid off easy and it's fitted with tekscrews. I'll make another later.1 point

-

1 point

-

Spent way too long cutting and buffing the entire outside but it was worth it. Super smooth and straight now, just needs a polish. Since then I've been working on fitting the rear seat. Van's never came factory with rear seats but it was very common to cut out the front section of the rear floor and have a rear seat made and fitted. Most seats fitted were home made out of ply wood and were very roughly mounted in, this one was no except. Escort estates had seats were fitted from factory and had a metal floor backing so when folded down and not in use, it looked like it was just an extension of the floor. I have been looking for one of these for years and was hoping to have one before I painted it, as I would have to weld in mounting points. Didnt end up happening and found this one afterwards. Untwisted it and it will need full upholstery at a later date but it fits (Temporarily fixed). Started making mountings for this, the first being the towers at the front of the lower half of the seat. Have made these so I could use the original alloy hinges. Have welded a plate into the bottom and tapped some 8mm threads. Started working on the rear upright half of the seat. The starting point of mounting the seat is based around making the back part completely level when folded down. Some temporary brackets were made to find its final position. After the front towers were made and welded in, I started making the mountings where the upright section would swivel down flat. I made these cups, which will be welded in to close the gaps between the wheel tub and seat frame, using the correct fine threaded seat belt bolts and fixings. Once these are welded in there final spot, I can start working on the last mounting points which sit on top of th wheel tub and hold the upright section in place when in the correct seating position. Again, from factory these were pretty poorly thought about. I have a few ideas of how to improve this with an automatic locking mechanism.1 point

-

i love me a good christmas car painting. i was looking at some of my other build threads and christmas is definitely the time i paint cars. dunno why? anywho, ive nearly finished the passengers side but i needed to get some paint on the drivers side so its got a couple of days to harden before i start sanding it. so today i applied some primer. also i figured out the blocking problem i've been having with my primer gun. turns out the pot vent was blocked. what a dick. 2020-12-24_05-22-20 by sheepers, on Flickr 2020-12-24_05-22-30 by sheepers, on Flickr1 point

-

So there's some time before the other half is in town again and we try and start things up so I kept myself busy on other stuff. I figured I should check out my benefactor's dizzy while I wait for the penetrating lube to take effect on my fuel pump, make sure it doesn't fall over when kicked. The rotor had really spotty continuity so I gave it a quick buff with some fine sandpaper. The cap had little or no continuity from inside to out. The ignition coil lead was very loose in it and the contacts are quite worn. Some fine grit sandpaper sorted out the continuity but when I assembled it all I wasn't able to get any continuity from the ignition coil contact to the spark lead contacts. This means either the rotor isn't contacting the output contacts, or the carbon input contact. To check I set up a professional continuity testing rig. There's no continuity from the input carbon contact to the rotor. Some thin foil bridges the gap and restores continuity. I got concerned that even with the foil bridge, I'm unable to get continuity from the spark lead plugs to the ignition plug when turning the dizzy. Fortunately some quick research later tells me that the output contacts should not actually touch the rotor so I think that's ok. Phew! Some quick googling tells me that the carbon is spring loaded. So like any good DIYer I poked it to see what would happen. It went all the way in and won't come back out ... :D. I must have pressed it in just enough to prevent contact with the rotor when I scuffed it with the sandpaper. Of course now I have to get it back down somehow, or just buy a new cap (which makes sense if the spring is toast). Pliers just scuffed the metal surrounding the carbon. Taking ideas on how to get it out... (mate says compressed air should work - getting one soon, but bought a new cap anyway) --- While I was noodling around the area I checked out the ignition coil lead and it is absolutely spanked. Zero continuity no matter how it's bent on any part of the contacts. The dizzy side also had basically zero grip until I flared the contact out a bit - not that it matters if it can't carry a current. So I'll get a new one. I might as well get new spark leads while I'm shopping. (Future Tom note: this is normal, spark cables have super high resistance!) --- I also make sure to take on easy goals to keep morale up, such as tidying up my rusted battery tray using vinegar, wire wheels and spray paint. Can't eff that up It's no custom machined wheel horn button but still satisfying to get something from fucked to passable. I think that's the motivation for this whole project in a nutshell for me.1 point

-

1 point

-

1 point

-

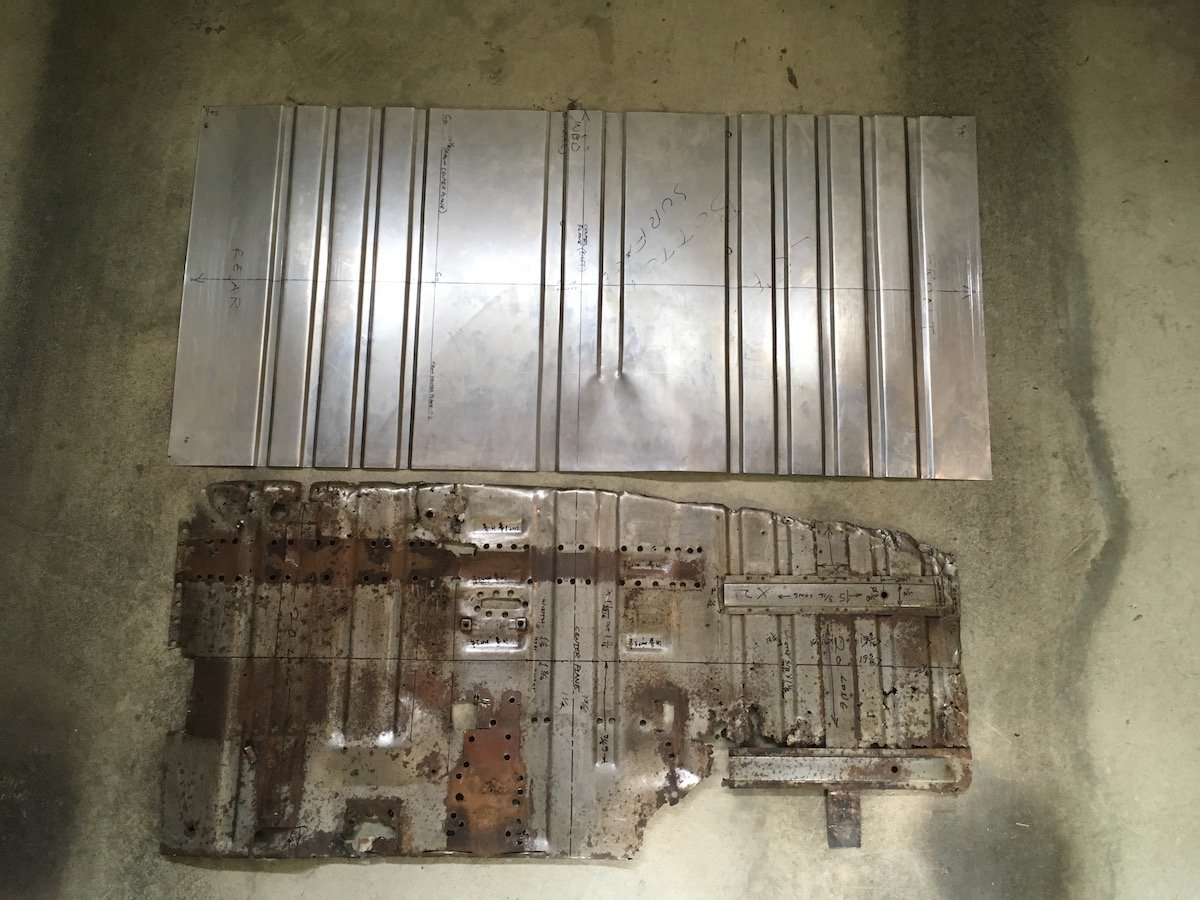

Back to work on reproducing the '61 310 Bluebird left side floor pan. First, I drilled out the spot welds to all the bits I wanted off the original floor. Top side Bottom side My collection of saved and de-rusted parts; including the seat bracket, longitudinal stiffener structure, hand brake reveal, B-pillar body mount bracket, and a couple of other brackets that are too far gone but get in the way. Bought some more steel sheet. Four foot by eight. I cut out a 26 by 56 inch blank and made some corrugated steel with a bead roller Scraped most of the under seal off the old floor pan bottom surface, did some measurements and began duplicating what was left. The bottom surface was more useful for measuring since it was much less rusty than topside. I'm leaving an extra inch or more all around to accommodate fit and trim later. Side-by-side compare Now I have to figure out a way to form some of the 3D shapes around the where the B-pillar body mount goes and the shallow depression under the hand brake lever. Hammer form over a wooden buck? Or form separate parts, cut the floor and weld in? Still have lots of work to do. Discussion: https://oldschool.co.nz/index.php?/topic/60267-marts-pl310-61-datsun-bluebird-sedan/1 point

-

A tale of two Bluebird transmissions. Had to take the trans out to continue and detail the tunnel weld work. I suppose I couldn't wait months to post something else. The all synchro side loader coming out. It was wedged against the firewall and momentarily stuck until I tilted the engine some more. The all synchro 312, 311 Bluebird side loader trans. It's a beast. Longer, wider and heavier than original 310 top loader trans. Side-by-side trans compare. 310 Bluebird top loader on left and 312 & 311 Bluebird side loader on right. The 310 trans uses a carbon hockey puck release bearing whereas the 312, 311 trans uses a rolling element bearing type. Sure wish I could find a verified source for otherwise unobtainable replacement parts for these two trans. Top loader needs a new 2-3 shift fork (completely worn out), input shaft for 2-3 (sheared off) and external lever arm for 2-3 (lost). Otherwise, as a last resort, I could get them made with expensive machine shop fabrication. I believe the side loader is is going to need a 2-3 shift fork soon as well since it does not always stay fully engaged in 3rd (high) gear on rare occasions. I actually prefer to use the top loader with its non synchro first gear as it is the much slicker shifting and shorter lever throw trans. Without repair parts though, it's not going back in anytime soon. As the situation stands, I'll reinstall the side loader after completing the tunnel underside details including epoxy primer. Discussion: https://oldschool.co.nz/index.php?/topic/60267-marts-pl310-61-datsun-bluebird-sedan/1 point

This leaderboard is set to Auckland/GMT+12:00

.jpeg.f51a899fbb62ee27267b4ca377d73c80.jpeg)

.jpeg.7db9077b86fe69e11960d3ceae544c3e.jpeg)

.thumb.jpeg.910c6632f6e66e8cba89476e83b41634.jpeg)