All Activity

- Past hour

- Today

-

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

Thphantum replied to Bistro's topic in Upcoming OS Events

Can they leave the lights on at the track though. Just in case. -

I ran the standard 210 secondary jet and the AFR was pretty good. 210 seems like a really big jet but the secondary venturi on a weber 34 is much larger than the primary so you may not get a large pressure drop in the venturi. I think that's why Ford used such a large jet to get the fuelling correct. I'd give it a go with the standard jet, and you can always play around with it later if you need to.

-

Many years ago I had one made by Drive Inn in New Lynn. I'll probably have my new one made there too.

- Yesterday

-

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

Truenotch replied to Bistro's topic in Upcoming OS Events

I can organise parking inside the gates at Manfeild if that works for you. It won't be accessible after about 6pm at night though. -

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

arswenson replied to Bistro's topic in Upcoming OS Events

More than welcome to par it in my shed however I'm about 15 mins out of town so probably not ideal. -

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

sheepers replied to Bistro's topic in Upcoming OS Events

Feilding people, im planning on taking my fancy datsun to this event, we are staying at he fielding hotel which isnt the most secure of parking places. could i impose on someone to park my car in a secure location where it wont get stolen by the many and various fielding crackheads? thanks team. -

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

AllTorque replied to Bistro's topic in Upcoming OS Events

-

Also, a bit of advise when dealing with Russel... Although he is a good sort, his default will be the most expensive and overkill drivesahft rebuild. It will be $2500 and be good for 3000hp so instead of letting him decide what needs to be done, you have to tell him what you want and set limits.

-

Yeh hes moved the operation out to his home shed. Rent was getting too expensive in E.T.

-

they do have a lovely selection of pies there good work sheepers, i am impressed at your complete lack of ; lollygagging mucking around lazing about thumb twiddling hesitation dilly dallying goofing off dawdling

-

A pack of arseholes

-

What did you get from the Hunua general store?

-

FUCK GO MARK SKAIFE WOOO YEAH KING OF THE MOUNTAIN!

-

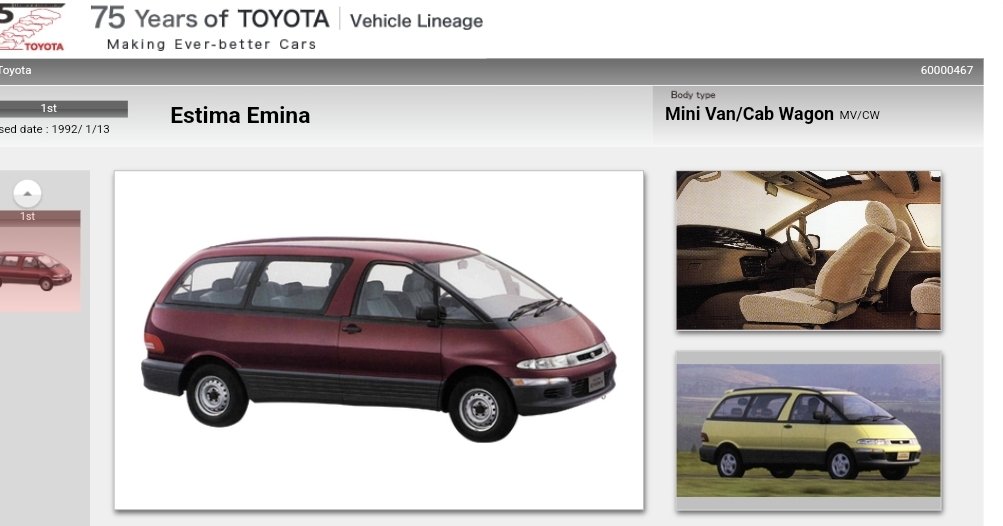

Pleasr use an estima. My 3.5v6 halls ass. 4wd too

-

Tumeke started following 2026 McKenzie Moped melee. 27/2-2/3 2026.

-

Bloody good work Dave! Stoked

-

Does it skid the wheel? Awesome effort!!

-

He's moved to ramarama.

-

no painted floors or violated spiders

-

Good work Koro Sheep You dont fuck round thats for sure

-

+10cm swing arm New rims Hubs and brakes Loom Check

-

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

vivaspeed replied to Bistro's topic in Upcoming OS Events

That agenda looks sweet, so much structure. Although I don't feel it has really captured the essence of the Swap Meet weekend which includes fair amounts of standing around doing fuck all / why are we still here and not going somewhere / the hosts of the thing we just looked at are wondering why we are still loitering here and not fucking off already. And speaking of Essence, that's the name of the cafe for Day 3 activities... Day 3: Sunday, 3rd August 10:00 – 12:00 Farewell Breakfast at [Local Café Name]