Leaderboard

Popular Content

Showing content with the highest reputation on 06/03/24 in all areas

-

I ground a chunk of steel to hammer into the nut to free it up Then had to cut all of the rubber off the old hanger and press the bearing off. The new one should have gone straight on and I blindly slapped it on with the F facing the front. However, the F is supposed to face the back and the price was jammed on. It took a hour to get it off without fucking it. Fortunately the new bearing came with a new nut as that was fucked too. Haha. Reinstalled the driveshaft and also a trigger wheel to get driveshaft speed for the ecu and 4wd controller I am going to run.19 points

-

Long time no post - I still have this, though I have put it up on the market to sell as I need to downsize and this was the easiest to put on the chopping block. I did end up fitting the spring, strut rods etc along with new outer UJ's as they were worn and weren't helping out with keeping the rear geometry in check. I then had an X pipe added to the exhaust and replaced the yunk down-turn tips with quad chrome tips. I also converted rear lamps to LED halos, converted reverse lamp into dual purpose reverse and orange turn signal and fitted a high stop lamp in the parcel shelf. Some better pics I took of it over last few days:14 points

-

13 points

-

9 points

-

9 points

-

So much dust, everywhere, all the time, upto the point it rained on the last day. muddy visor smears. Random grader. drowned Subaru. giggling behind Bart going full send with all limbs flailing in every direction. never lift. fire ban in the campground, barbecue was driven across the road to cook meats for the hungry. broken clutch cables. flat tyres. ( not myself) Myself crashing in a small creek crossing (on the same leg/cracked rib side) good food, delicious ice cold dobros. amazing group of people, some who were new, had never met the Sharn master. Lots of smiles, (fuck that last bit was a bit squillery/steep/dusty/dodgy as fuck.) so good. Did 1400ks over 4 days. when’s the next one? keen.8 points

-

Oh and @Nominal will love this one, ran over a screw (likely my own considering it only drives in and out of the garage) and put a hole in one of the new tyres. So sat on a spare for a few months before I did anything about it. Got a proper vulcanised repair thingy done to it. So progress, but ended up exactly where I started. Classic.8 points

-

8 points

-

I've been chipping away a fair bit lately. I managed to find some radiator suport panels. This was my first time doing any sort of panel work, after a fair bit of tweeking I managed to get them good enough to where I was happy. I also filled in the 2 big holes in the engine bay. Years ago I hacked off the washer bottle mount to make room, luckily I kept the remains of it. I made new ends for it to replace the bits I hacked away. Replaced the battery tray. I did a test fit of the engine to sort a few things out. The main things were the gearbox cross member and where to fit a clutch master cylinder and sorting the exhaust. Not a hell of a lot of room, but it worked out OK. The wee fella helped modify a toyota gearbox cross member. I've just finished painting the engine bay today. It's not going to win any awards, but I'm happy enough with it. I'll start the final reassembly now. I sorted out the flywheel/clutch issue too. The guys who did the engine work (Kennally Cams) did some magic to the fly wheel and machined it to accept shouldered bolts to locate the pressure plate as it's being torqued down. Hopefully this week I'll get the engine in for the last time.8 points

-

Mostly finished up the tail light wiring tonight, brake lights and everything work, yay! Also I pulled the gearbox to inspect the clutch, it still looks brand new apart from surface rust. I will take it to the clutch man tomorrow to see if it cant be tweaked for a bit more clamping force. If anyone has a suggestion to improve this then let me know5 points

-

5 points

-

Orthia update. Done a few hundred km since the tune. Turns out more midrange torque/power means better economy. Best since the vtec conversion. The 7.8 L/100 was when it was stock auto non vtec The local ac shop redid the suction hose for me, was a bit more than I expected to pay but it's hopefully done right. I'll get a conversion fitting for the service port and let's hope that's it.5 points

-

Spent the last few nights in the shed on the premise of getting a datsun ready to go to nats, but got a bit sidetracked on this. Speedo fixed Then I removed the driveshaft to swap for the less 2nd hand one I have in stock. While I was in there I noticed the rear diff cover had been leaking and was covered in shit and thought I better do something about it now rather than later when it runs out of oil. I whipped the back cover off and spent hours with a Stanley blade shaving the original paper gasket that had set like rock. The drain plug magnet was broken into a few bits so that got replaced with a donor from a smashed gearbox. Then I needed to replace the centre bearing on the driveshaft. It's a cnut of a job.5 points

-

Also @Truenotch, The idea was floated buy some of the OG Moped Melee crew that perhaps a change of username for @Hungry was in order? Surely Captain Porika is a username far more befitting such a seasoned and battle hardened mopest Melee participant?4 points

-

4 points

-

4 points

-

Did a chunk of the back end wiring today, not much to see as I have tried to keep things tidy so it pretty much blends in. I tried to fit a new power plant, amazing that for the size this unit only makes one pogpower.4 points

-

3 points

-

3 points

-

3 points

-

3 points

-

3 points

-

3 points

-

I glooped the two halves together, bolted them up, bolted the tailhousing on and let it set. Following morning it was bolted onto the engine, unsurprisingly a bit heftier with all the gubbins placed back within the box. Its about 9kg heavier than the standard imp box. I then started to fit the first part of the gearshift linkage. The first of those snazzy universal joints, handily available in a diameter to suit the shifter shaft on the Subaru box. I just needed to add a small locating hole for the grub screw... Universal in place.. Engine and box were then bolted back into the car. This bit is so quick and easy when using the 'engine stand 2000'. It takes about 10 mins and I'm getting quicker. It'll be slower when there's shift linkage to undo and driveshafts to slip out of the way. But at least the main heavy awkward part is actually easy. That lot in place I took some pics. Its neat to be able to look out from the one of the lounge room windows down onto the workshop floor and see this... With that lot in place I was able to suss out the angles I could get away with, as shallow as possible and allowing for the handbrake mechanism. I had this old imp gearstick assembly that @dmulally kindly posted over to me. Some previous owner of the car he got it from liked painting things. Everything. Multiple times... I scraped all the layers off, took it apart and cleaned off the dirty old grease. Discovered it had been cobbled together from two old shifter bases. It was originally a very early Imp unit when the very first cars had an automatic choke, which often proved problematic. Hillman then changed the cars over to a manual choke with a nifty little lever in front of the shifter. This mount had been added to the early base. Which means they must have chopped up a later baseplate to get the choke mount. Why they didn't just fit the entire newer base plate I don't know. But what I had in front of me was a frankenstein of base plates with barry spec welding and fixes, but also including a not too badly made bronze bush on the lever where there is normally a (wornout) plastic bush. I had a couple of shift rods to choose from. I chose the least worn. Moving back to the gearbox end I machined up some shaft ends from stainless bar to suit the universal joints. I had some stainless tube and welded the ends in place on the first shaft that runs from the gearbox universal down to the tunnel. Now I needed a sturdy, slippery support to mount in place of the second universal joint. This will not only take back and forth movement on the shaft but also a bit of thrust loading created by the angle on the connecting shaft. I had already bought a lump of slippery hard engineering plastic with this application in mind when I had ordered the plastic for the flywheel thrust bearing a while back. It was bright yellow. Luckily not seen under the car as it would clash with the blue paint. I put a hole in it and machined the outside down. Which also created a pile of pretty swarf.. Then reamed it out to 1" Still a bit tight so out with the adjustable reamers.. until it was just right... Then made a stainless cradle .. The cradle got some wings welded in place and I dug the rivnut tool out.. Mount now bolted in place in the tunnel I had to chop the last tube to the right length, weld on the end and bolt the universal in place.. The front end below the shifter was was standard imp stuff and this is where problems popped up to throw a medium sized spanner in my workings. The side to side gearstick movement across the gate was minimal. Ridiculously so. Like about 1". Or 25mm in new money. Yet the fore and aft movement was about right. But quite stiff. I was contemplating why this was so and what I could do to remedy this when I also noted that 1st gear was where 3rd was and 3rd was where 1st was. Poos. Four years ago when I had compared the Subaru gearshift pattern at the box to the imp unit I thought they were exactly the same. But I had not accounted for the reverse rotation taking place under the imp gearstick. Also I never really thought much about how little of rotation the Subaru box needed on its shifter shaft to shift the internal selector across the 3 rods. Its a tiny amount, like 3 degrees say. Whereas the Imp box has a shorter internal selector and requires more rotation at the shaft. Hence the Imps gearstick knob only moves a teeny bit when coupled to the Subaru box. But the Subaru box has a standard/similar amount of rod movement within (ie 1-2 and 3-4th) which was going to make things trickier to fix. Simple linkage/leverage multiplications that is easier to see than explain. Sorry if your brain hurts. I had to hurt my brain a little bit to suss out a solution but there was only a little bit of smoke. The reason the scooby box is different becomes obvious when you see the scooby shifter setup. Which luckily I can show you because last week thanks to @Leone I was put onto a local fella to me who happens to have many old Leones and Brats kicking about his property and he had a spare leone front wheel drive box that I wanted (always handy just in case...) His property is amazing!!! Long 4wd only driveway up to a ridgetop house with stunning views out over Tasman Bay. Old leones just kicking about... Luckily we have our trusty old 4wd Hiace and that became the days gearbox transporter... Box on bench. Look at that shifter mechanism... The shifter rod attached to the gearstick only rotates a tiny amount when the stick is moved sideways across the gate. But the rod moves 10mm in each direction when shifting for and aft. Simple. Robust. Very Subaru. I can't copy it though because I have turned my box 180 degrees. No matter where I put my pivot point (below or above) I'll have one of the planes working backwards. So I decided to build a new shifter base setup. The most important thing was to reverse the rotation so the gearstick pattern is correct. The imp pivot point needed raising to allow the offset shaft end to be rotated to above rather than below the centre line, so reversing the across gate movement. I would add the ability to adjust both rotation and lineal movement. Started with a new pivot cup because I was not happy with the worn and Barried pressed steel item.. I dug out a large lump of steel bar... Chopped out a square and cleaned it up in the mill.. Big drill = big hole.. Rough machined out a cup shape. Cut a form in cardboard to suit the brass ball and used a die grinder bit to finish the shape... Grinding paste time... Slots for pivot pin.. Lightened the lump down.. Built the shaft up with weld and machined it down so I could add a lower pivot point. Milled some steel like so.. Welded a boss on.. New socket for shift lever ball end... Cut out Barrys previous workmanship... Machined up some spacers and a base plate.. Welded up a little tower (my stainless and steel tig welding is definitely improving, helped muchly by realising that not being able to see what I'm doing does not help much and finally admitting to my age and buying some reading glasses....) Welded tower to base.. Now all together please... Bolted together. You can spot the adjustable rotation, which the spacers allow for, along with adjustable pivot point. In place... Yay- it works! The shift pattern is correct and the action is much smoother. The spring loaded indents on the internal gearbox shift rods are quite stiff, which I noted was the same on the other box with its stock shifter. Its a bit baulky to push past the synchro baulk rings into gear but I think will feel better when the gears are actually rotating. There's certainly no slop in the system and it feels very mechanical - not rubbery. I now note how much flex there is around the shifter base in the imps tunnel (granted a very rusty shell..) Its something I might just try to stiffen up on my blue Imp when fitting this lot in. Phew. That was a little mini engineering mission I was not expecting but that's this project in general3 points

-

3 points

-

3 points

-

2 points

-

Thanks for the pic dump Sean! They were awesome! Its just like being there again. Man duffers saddle/the nevis was amazing. Such a fast road.2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

Boring update: I finally changed the rear subframe mounts. Here's the one I had been most concerned about. I had expected to find it in worse shape once it was off the car. Hardly worth worrying about really. This rubber-to-metal bond is the only thing that seems to keep the IRS assembly attached to the car. There is a radius arm connected near each rear hub which twists the whole IRS assembly in its mounts as the car leans in the corners, creating a passive rear wheel steering drunken snake effect. Wikipedia says this "...may result in significantly improved handling". May? Anyway, the mounts can fail from age or too many burnouts, and then you definitely won't have significantly improved handling. In this shot, the two subframe mounts have been removed: You can see the IRS cage thing, the tricky double shocks and springs, the light reflecting off the inboard rear brake disc, the skinny anti-roll bar terminating at the base of the RH spring (not present on all XJSs).... You can also see that I managed to change the mounts without disconnecting anything such as the exhaust, brake lines, roll bar, driveshaft, radius arm etc. I did one side of the car at a time, using a jack and an axle stand. New mounts fitted (this is on the opposite side of the car, to mess with your head): Now that these mounts are done, I'm not gonna be THAT guy:2 points

-

2 points

-

2 points

-

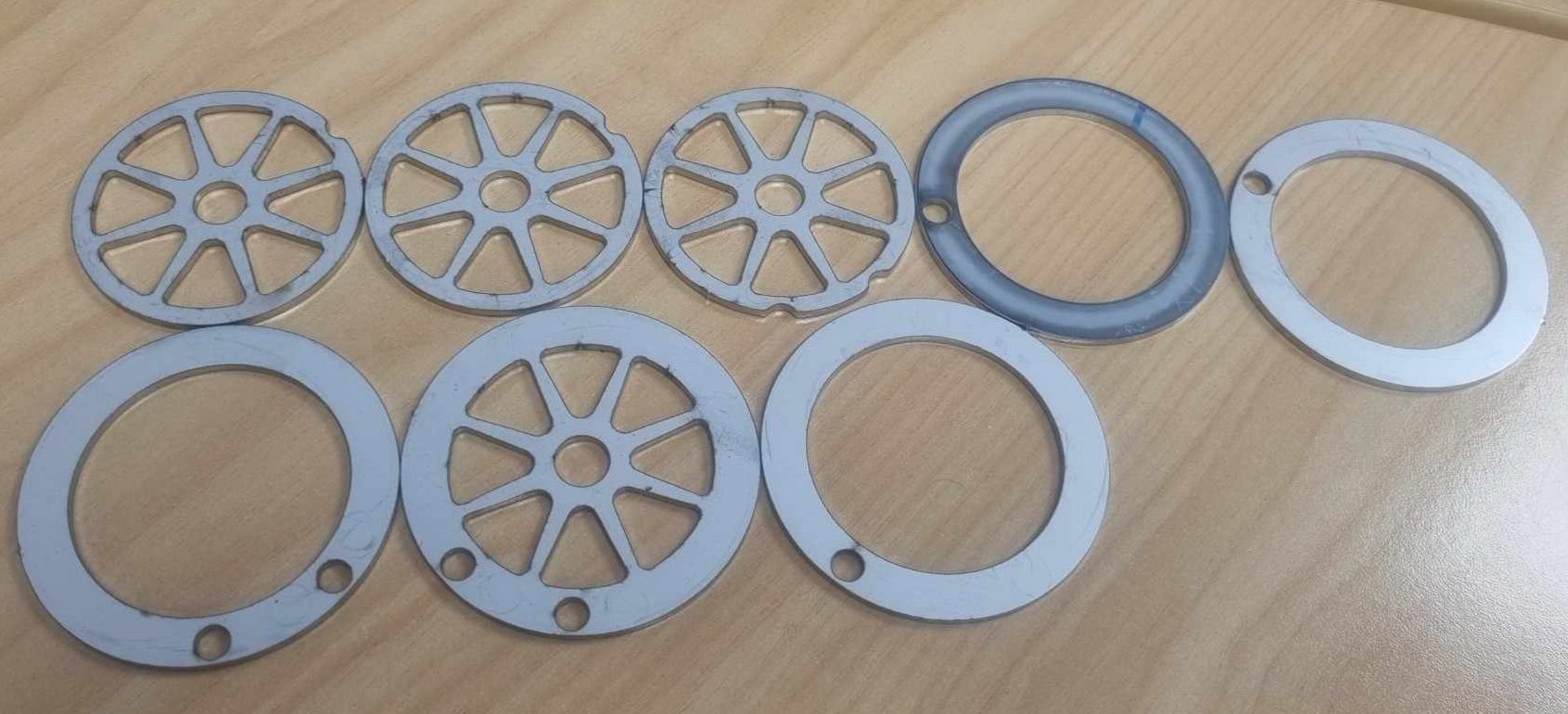

Alright so as of yesterday I'm finally out of mortgage prison! I finished moving house with heaps of time to spare, I definitely wasnt biffing trailer loads of stuff onto the lawn the night before settlement. I got some throttle pulleys cut from stainless. I'll put a radius on the inside of the pulley edges and deburr a few spots, but on the whole they came out really nicely. Quite heavy though, probably could have made some parts thinner. (Everything 2mm stainless) It's looking like it'll be fiddlier than expected to balance the cable length and pulley positions to get the banks even. One thing that I didnt take into account is that there is no tolerance for having a cable that is "overlength" as you physically cant slide the protruding end of the cable into the pulley. However I could probably chop out the relevant section of the pulley to allow this without any issues, as these are still significantly beefier than they need to be. I need to make some end stops of some sort to stop the throttle rails moving forward or backwards so everything stays aligned correctly. You may notice that in this photo I've got the linking cable on the wrong way up. It looks dumb having these on the front of the motor, but down the back is getting very crowded and I've got ants in my pants to get this damn thing fired up. I got the throttle rails drilled, took about 3 hours to drill 6 holes! We had to grind flats onto the rod to get through the hardening. Otherwise carbide bits didnt even make a dent. Next jobs are to print a final iteration of the manifold from Nylon, get fuel lines connected up, and keep working on the exhaust. Then I'm preeeeety close to firing it up!2 points

-

Yea so this got the backburner big time as the next day from that ^ I wound up in hospital and spent 8 days there. This is a tedious story where my partially removed gall bladder decided to spontaneously weld itself back together, make gallstones that happily blocked my bile duct, which basically meant my liver was pumping bile into the wrong bit of my insides. I turned very yellow until they flew me to chch on the flying doctor plane (this was actually pretty awesome) and reamed me out. I still have a drain in and hopefully will be getting surgery mid Feb to sort the rest of it. This is all very very boring, I would not recommend in any way. -43/10 So many wasted shed hours. But in the meantime I have been slowly picking away at things, nothing too serious tho. Splashed out on some new hoops, Goodride something's at $80 a corner fitted. They may not stay but will be an improvement on the tyres that were there, these were the same ones it had when I sold it. Then I installed the heater and dash, this hurt me and I probably shouldn't have done it. @HumberSS has found a heater mech out of an NA MX5 for me so I should be able to hack that in there. There is a wrecker in chch who quoted $260 plus shipping for an original heater mech, which is more than a 1/3rd the cost of the entire car so they can get fucked. I had to draw up and print a vent that was missing, some previous owner decided to bin all the heater gubbins and had weirdly blocked off the screen vents which wasnt particularly solid thinking. I also spent a bit of time rerouting and extending the control cables as the heater is out of an earlier car. I bought a cheap AFR off AliX a while ago so I mounted this while I was at it. The seatbelts were pretty toast and of different makes. I had bought some cheap seatbelts off FB, but when I picked them up the tags were unconvincing; So when I got flown to Christchurch to talk to the surgeon last Wednesday I (again probably stupidly given my state of health) grabbed a lime scooter over lunch and made my way to NZ Seatbelts and picked up some proper ones. These got fitted up; Now I just have to look wistfully at this and hope that in a month or so I will be fit enough be able to drop it so I can finally sort the wiring;2 points

-

As per previous photos, fixed the seat courtesy of @64valiant shit it looks good. My backside appreciates it as well. Also a small today up on the back using left over v50 bits (got rid of the big square plate mount and the oversized tail light bracket. Is now road legal and period correct plate style and stickers etc to round it off.2 points

-

2 points

-

1 point

-

1 point

-

1 point

-

Headlining: The Toy Shop here in Auckland created their own fibreglass mould specially for XJS headlinings, and their price is....... $1,800.00 plus GST. It's slightly cheaper to ship a new headlining from the other side of the world. Auto: I went to see an automatic transmission place, and regrettably I've booked the Jag in with them to give its ZF 4HP22 auto a birthday. The auto has always been a bit noisy and a bit rough during my ownership, and I guess I tempted fate by having the fluid changed and occasionally driving like I just borrowed some oil paintings. It kinda sucks to be spending money on an automatic transmission, but manual parts cars don't exist, and manual conversion kits only exist for the V12. Tell me I should spend more money on a Chevy LS swap and end up missing Nats here. I did manage to improve the drivers window operation by flipping the rubber guide seal around, and I lubricated the passenger side central locking so much that it might actually work reliably for once. For the radio, I wasn't lucky enough for the problem to have been caused by speaker wiring. It was caused by water leaks. This quote from the XJ-S Barry Bible will explain: Can you believe the official fix for various disastrous design decisions in the A/C system is to fit a condensation deflector shield? Guess whose car is prior to VIN 163790 but isn't fitted with one. As part of diagnosing this, I dug out an older head unit which I originally bought for my Alfa ~15 years ago, and as an extra bonus I discovered my missing Iron Maiden greatest hits CD was still in it. I strategically taped over some of this head unit's vent holes to keep any water from getting in, and I figured I'd run it in the Jag for a while. Then I took apart the faulty head unit and cleaned the corrosion.... I reassembled it and set it up on a test bench running off an AC adaptor... It makes noise again! Jolly good show. Now I must build a condensation deflector shield.1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)